Effect of Process Parameters and Material Selection on the Quality of 3D Printed Products by Fused Deposition Modeling (FDM): A Review

Abstract

This work presents an investigation on the quality of parts manufactured using fused deposition modeling (FDM), which is influenced by a large number of different elements. Some of which are based on the materials used in the production of the part, though others are rather pertinent to the process parameters. The manufacturing process and filament formulation has also a significant impact on the cost of the final product, as well as its physical, mechanical, and thermal properties. As the result, judicious combination of parameters can effectively act toward fine-tuning FDM toward three-dimensional printing (3DP) of pieces with quality fit-for-application. In this sense, the use of design of experiments (DOEs) is often needed for the purpose. Printing process parameters, including layer height, wall thickness, temperature, printing velocity, and tool path, have been discussed, in the understanding that 3DP time increases with decreasing layer thickness, and in turn increases production time and overall cost. A specific account is given on recent developments increasingly and more thoroughly focused on recognizing the impact of the process parameters and raw materials on the final product.

1. Introduction

Additive manufacturing (AM), also referred to as “three-dimensional printing (3DP),” is a process for the fabrication of a 3D structure of any complex geometry through the layer-upon-layer deposition of softened material. Digital data of objects are processed through computerized aided design (CAD) or 3D scanner to prepare 3D CAD model [1]. The technical and geometrical versatility of AM, recently coupled also with possible outcomes brought forward by artificial intelligence, suggests its increasingly diffused application, though issues remain in the selection of adapted materials for the purpose [2]. AM is, therefore, commonly used so far throughout the prototype’s primary and conceptual design phases, which is leading to cost-effective manufacturing for high productivity and time to market. 3DP technology accelerates any shift in fabrication modalities and opens up a new era of personalized manufacturing. Various factors influence the time it takes to 3D print a part, including size, height, complexity, and printing technology employed in the project. As a result, timeframes for fabrication can range from a few minutes to several weeks. Production is followed by postprocessing, which is normally required, despite the fact that usually demolding of the 3D produced part is quite easy, yet not always offering outstanding dimensional and functional accuracy. Precision can be enhanced though by adjusting a large set of parameters, which often necessitates the intervention of an optimization process, which supplements what is obtainable with deterministic algorithms [3].

Some AM techniques are reasonably simple as for physical principle, such as in particular fused deposition mode, especially when the low-cost manufacturing of very complex parts is required: they are therefore widely adopted in specific situations. For example, one of these cases is carbon fiber composites intended for automotive applications [4].

More precisely, AM procedure obtained through controlled and uniform squeezing of a continuous thread of partially fluidized thermoplastic polymer through a nozzle moving over a deposition table in defined as fused filament fabrication (FFF) [5]. Some quality parameters, on which more details will be offered, are related to the filament material properties, deposited strand geometry, infill rate pattern design type and orientation, part orientation, welding parameters (material flow, nozzle temperature, bed temperature, printing feed, and environmental conditions) [6]. Most FFF machines use the concept patented by Stratasys, which is defined as fused deposition mode, on which this review concentrates. Fused deposition modeling (FDM) has a significant industrial importance due to low processing costs, absence of expensive tooling, and possible introduction of a wealth of alternative materials and blends for operation [7]. In particular, the drive toward the application of bio-based and recycled filaments appears very strong in some contexts, where reducing the dependance over petrochemical raw materials for the purpose appears of paramount importance [8].

Many different types of printers use FDM printing technology: the different categories adopted are Cartesian, delta (with three transactional degrees of freedom), Core XY or H-Bot for horizontal motion, polar (rotating around a fixed axis), Selective Compliance Assembly Robot Arm (SCARA) (with one translational and two rotational joints), and belt [9, 10].

However, once again, the respective significance of various factors involved in the development of the pieces needs to be highlighted, and their effect compared to the maximum possible extent, especially on composites. In particular, orientation refers to the inclination of the part, assumed as built on a X–Y platform of part and developed along the Z axis. Depending on the nozzle, a layer of a defined thickness is deposed. A number of characteristics are then related to the raster, which can take a direction with respect to X axis, then the width necessary to fill the interior regions of curved parts, while obviously between two adjacent rasters on the same layers, an air gap is present.

This has been applied, for example, in a study on carbon fiber and glass fiber composites using a poly (ether ether ketone) (PEEK) matrix, where a number of factors were tailored toward their effect on product characteristics [11]. These included the temperature of nozzle and platform, the printing speed, and the layer thickness. For the production of composites, the coextrusion process of the carbon fibers with a polymer filament was attempted, for example, with a glycol-modified polyethylene terephthalate (PETG), where both for unreinforced and reinforced polymer the highest mechanical properties were obtained using a raster orientation of 0° [12]. More recently, the potential embedded by the application of natural fibers included in FDM processing of the filament has also been explored, namely concerning jute and flax [13].

It is also possible that other steps would need to be performed beyond the demolding process. These would include secondary curing, normally performed by ultraviolet (UV) rays, where again different process parameters can be applied, such as different temperatures and curing times, for example, 15, 30, 45, and 60 min, and 190 and 200°C on poly (lactic acid) (PLA) [14].

The quality of the piece obtained might be variable though: especially, one of the surfaces is normally more refined and smoother than the other. This requires further operations, such as surface coating [15]. This is most commonly achieved by materials addition, in which case four methods are more typically applied, in particular, by chemical coating: gap filling, coating spray, plating, and water transfer printing [16].

To have reasonable guarantees about the strength and durability, it is essential to perform tensile characterization on the samples of the materials to be used, possibly even leading to modeling their properties, and repeat these tests also after performing durability-enhancing treatments on their surface. An even more accurate assessment of the properties would be obtained through fatigue testing of 3D polymer blends and composites. Apart from tensile performance, properties that are essential to provide a good 3DP and need therefore to be known before printing process starts are the deflection (softening onset) temperature, Charpy/Izod impact performance, and the ability to provide the required print resolution with sufficient accuracy.

It is particularly significant to have the ability to characterize the base materials for FDM use, in order to measure the effect of printing orientation and other parameters, and to assess the results from the modification of the filament, which is a common practice in recent years. Some characterization studies focused on the 3D use of polymers were focused on PLA [17], acrylonitrile–butadiene–styrene (ABS) [18], and polycaprolactone (PCL) [19]. When other considerations arise, such as biocompatibility, FDM is able to effectively reproduce complexities, which are inherent to biologically hierarchized materials. This is the reason for this method enjoying considerable success, for example, in the production of biomedical scaffolds, though only a limited number of bioactive and biocompatible materials are available: these include hydroxyapatite, normally blended with thermoplastic polymers, such as PLA and PCL [20], and polyethylene glycol (PEG), again blended with PLA [21].

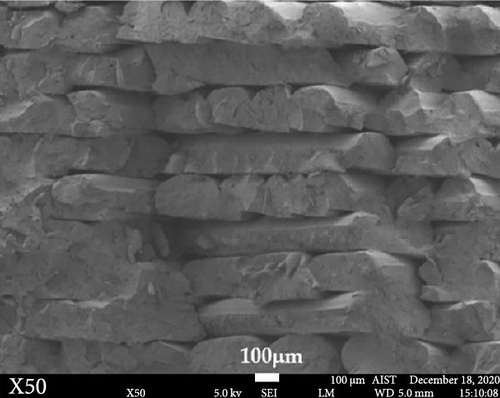

On PLA, reviews have investigated the possibilities obtained by the inclusion of different fillers, ranging from lignocellulosic materials, such as hemp hurds, flax, and bamboo fibers, so mineral basalt fibers and glassy fillers, such as diatomaceous earth, a mixture of amorphous silica and single-celled algae quartz remains [22]. Being considered a kind of standard material, also the application of recycled polylactide as the raw material for PLA filament has been considered, which is subjected to the assessment of an adapted value for melt flow index (MFI) [23]. In contrast, ABS was proved to be particularly effective when considering its tensile capabilities, and, therefore, its resistance to the extrusion process [24]. Studies on ABS extrusion have also been performed in the case of addition of fillers, such as multiwalled carbon nanotubes (MWCNTs) up to 2 wt.%, which increased the mechanical properties, whilst on the other side did affect the MFI [25]. The layered complex structure of the filament after tensile testing is reported in Figure 1. It can be indicated by this that the fabrication of composites FDM filaments might even complicate further the assessment of parameters for its quality.

One of the main questions that concerns the optimization of 3D processes on different materials and structures is the combined effect of the different parameters, which are often tailored by stochastic variation techniques applied to design of experiments (DOEs), in particular Taguchi orthogonal array and general linear analysis of variance (ANOVA) [26], then down to more accurate and complex multiparameter prediction methods. This will be the object of further considerations in Section 2.

To summarize, the growing range of applications of FDM is due to its unique characteristics, which include managing complexities regarding geometry, material, and hierarchical design, together with rapid processing. These capabilities provide new avenues for customization, improved product performance, and multifunctionality, resulting in reduced scraps and decreased small-batch manufacturing costs. This technique enables obtaining components with accurate dimensionality and a long lifespan, using a relatively short processing time. FDM is in competition with a number of other techniques, in view of rapid prototyping, yet also of the production of industrial pieces at different rates of production [27]. The contending techniques do not always involve an extrusion process, which are briefly exposed in Table 1.

| Method | Characteristics |

|---|---|

| DIW | Originally defined as RoboCasting [28], this expands the selection of materials possibly used in 3D printing, provided that the ink generated has adapted rheological behavior [29]. In practice, this needs to control ink flowing through the syringe barrel and printing nozzle, being ejected then from the nozzle, and finally deposed onto the already printed layers. This allowed obtaining materials aimed at energy storage useful for ink functionality [30] and was also successfully used with porous geopolymers with tailored silica/alumina ratio [31]. In general, the versatility of DIW in terms of materials is absolute, which is particularly useful in the case of biomaterials. The layer-by-layer limitation is likely to be solved by ad adapted combination of nozzle geometry, print parameters, and ink rheology [32] |

| DMLS | Based on the principle of lased powder bed fusion, comprehensively reviewed in [33], it is particularly useful for biomedical alloys, such as Ti-6Al-4V [34]. This technique does also allow to control the roughness and improve the densification of the sintered pieces [35]. In some cases, it also allows performing thermal treatment on some alloys, such as AlSi10Mg [36]. Another possibility is the introduction of typical hardeners and flow controllers, such as graphene [37] |

| SLM/SLS | SLM is again based on powder sintering, does enable to selectively fuse materials, especially metals, within and between layers [38], or specific alloys, such as AlSi10Mg [39]. The main difference between the two techniques is given by the prevalence of one or other binding processes. Namely, a number of these have been recognized, solid-state sintering, liquid-phase sintering—partial melting, chemically induced binding, and full melting [40]. Near-net shape and good surface quality are the two principal advantages of these processes [41]. Difficulties for operating them are to be referred to high-temperature gradient, resulting in significant thermal stress, and ultimately warping deformation, which suggest a careful design of the scanning process [42] |

| MJF | Recently developed (2016) to enhance build rate, precision, and mechanical performance through an inkjet array for deposition [43]. This enables once again to widen the variety of materials for potential use, for example, to various polymers, such as polyamide 12, and elastomers, such as TPU [44]. In other cases, also conductive elastomers with the introduction of carbon nanotubes were developed [45]. Very recent developments concerned the possibility to prepare plastic inserts for molds [46] |

| PJ | Allows the use of various materials together (multimaterial) with the creation of functionally graded structures, using photoresponsive polymers, therefore that solidifies when exposed to UV light. This was first the principle of stereolithography (SLA) back in the 1970s [47], hence also of Vat photopolymerization, which extended the range of applicable materials, even to metamaterials [48]. In polyjet, it is possible to act on a number of factors, which include in particular on the photocuring effect, for required build orientation, layer thickness, and print angles [49]. Postprocessing is also frequent, in particular chemical smoothness [50]. In practice, a number of no less than four inkjet heads and UV lamps, transversing the workspace, deposits tiny droplets of photopolymers: in [51], polyjet effectiveness has been compared with that of FDM, resulting more precise, yet sometimes increasingly expensive |

- Abbreviations: DIW, direct ink writing; DMLS, direct metal laser sintering; MJF, multijet fusion; PJ, polyjet; SLM, selective laser melting; SLS, selective laser sintering; TPU, thermoplastic polyurethane.

It is also possible to combine different techniques with FDM, such as it is the case for direct ink printing, which is also the reason why the previous table was presented. In this case, also defined as multidirectional robot printing, the extent of applications to be considered notably widens, extending to the fabrication of electronic components, obtaining tailored and different production sequences for PLA and silver paste [52]. Moreover, another possibility that is widely used is the combination of PLA with other more flexible materials, such as it is the case with the flexible filament Filaflex to simulate bone structure in anatomical models [53]. In this sense, and also as concerns a circular economy approach, the introduction of recyclates from end-of-life processes has been attempted, such as it has been the case for waste from wind turbines decommissioning [54]. Another type of approach is also possible, such as obtaining bio-based and biodegradable polymers from marine resources, for example, bioactive compounds from fish by-products [55]. It can also be possible to attribute other functionalities to the introduction of extraneous materials into the filament, such as demonstrated the use of diatomite as porogen material for a hierarchical structure [56]. In practice, a biogenic composite filament made of PLA and up to 5% of diatomite in two different fractions (<40 µm) and 40–63 µm has been proposed, indicating improved thermal stability and a greater degree of hydrophobicity with larger water contact angle with water treatment [57].

Filling and toughening with various additives also appear as also a wide subject for investigation. Always centering on PLA, two possibilities have been subjected to a broad amount of research, the introduction of carbon-based nanomaterials (graphene, carbon nanotubes), or blending with other bio-based polymers, such as poly (butyl succinate) (PBS), poly (hydroxyalkanoates) (PHA), and PCL [58]. Under a strict control of their suitability and variability as far as the rheological properties are concerned, PLA for use in FDM has also been often filled with various amounts of natural, that is, lignocellulosic, fibers [59]. More specifically, attempts have been performed to blend PLA with pineapple leaf fibers (PALFs) to obtain 3D printed composites, where the principal limitation did appear the reduced elongation to break of the final material [60]. A large number of parameters is involved in the introduction of biomass-based materials, such as natural fibers, in the 3D filament: recent successful examples also include henequen [61], but the trend does appear general, and the number of biobased fillers added is countless. This led, in addition to the parameters connected with printing, to other observations linked to the presence of the fillers, in particular lowering interstrand cohesion [62]. In this sense, it is worth noting that Taguchi method can also be of some use in assessing the relevant weight of the different factors, as it has been studied, for example, on ABS reinforced with oil palm fibers [63].

In general terms, while FDM is a popular technique for creating plastic parts because of its low cost, low waste, and ease of changing materials, being a complicated process, it can suffer an influence by many variables. In recent years, their effect has been particularly elucidated [64, 65]. These factors can be divided into four categories: part depositing parameters, machine settings, filament properties, and environmental factors. Examples of part depositing parameters are infill pattern and velocity, raster angle and width, layer thickness, air gap, and contour width. The print bed temperature, nozzle temperature, and nozzle diameter can all be adjusted on an FDM machine. Principal filament properties are its density and its color, due to the introduction of fillers: for the latter parameter, the pigmentation was proved to modify the dimensional variability of the final piece [66]. Temperature and humidity are also important environmental factors, especially on PLA where hygroscopicity of the polymer may affect its strength and stiffness [67].

Even the tiniest change in these process parameters can disrupt the finished product. FDM process parameters and material behaviors have only been the subject of a few studies, which is the main reason why this review can come as a timely work. Evaluations of their effect of some material’s properties is nonetheless an urgent topic. Some indications have been previously offered, for example, the air gaps and raster width, that is, the inclination of the part on the three axes with the Z line, were proven to affect the material’s porous structure and mechanical strength [68]. It is also noteworthy that in many cases the combined effect of various parameters can hardly be elucidated, as it occurs on tensile, flexural, and impact strength of a 3D printed part made of ABS material, as from examining air gap, layer orientation and thickness, raster angle, and width [69]. Another study indicated that cross-ply directions (45°/−45°) were superior to angle-ply (0°/90°) raster orientations in ABS [70], a result that was subsequently reversed, suggesting instead that environmental conditions, such as moisture content, of the material pre- and post-processing would also play some role [71]. According to previous research, PLA is often able to offer better mechanical properties than ABS in 3DP because of the higher layer heights, denser infill, and layer orientations [72]. In the case of PLA, Letcher and Waytashek [73] found that the 45° raster positioning provided slightly improved material properties. A gradual upsurge in raster angle, from 0° to 90°, did not reveal any change in material behavior, though after 3DP, the part undergoes microstructural changes due to the varying raster angles, yet PLA appears to be able to compensate. In contrast, a strong dependance over the raster angle is indicated nonetheless by ABS [74].

The aforementioned considerations on the influence of various production factors on the 3D product quality do particularly apply whenever some fillers are added to them, in the understanding that properties would be exalted by this addition. In particular, some properties other than fundamental mechanical and thermal ones targeted for filler additions are, for example, wear resistance [75], dielectric permittivity [76], and limited distortion [77]. In general, the use of composite materials with powders or fibers of various aspect ratios (length/diameter) is increasingly diffuse in FDM. In practice, obtaining a sufficiently strong interface between the polymer and the fillers is not always obvious. To overcome this problem, for example, with the application of natural fibers as fillers, the latter needs to be chemically treated, as more generally suggested in [78] and explicated then practically in the specific case of a typical natural fiber used as polymer filler in FDM, such as coir [79]. In this sense, when using this coconut by-product, the improvement of tensile properties of the hybrid filament proved particularly impressive, such as 24% and 175% increase in tensile strength and Izod impact strength, respectively, compared to pure PLA at 60° raster angles [80].

To try to further summarize general parameters that have an influence on quality, some are related to the composition of the 3D material, including grain size, viscosity, and reactivity while others are connected to the process. The latter include the exposure time of the individual layers, the velocity of application, especially as regards transition between the base layer and the following layer, and the processing temperature. Even with all the advancements in 3DP made possible by FDM and the considerable range of materials that can be used for production, some drawbacks exist. These concern the range of materials that can be reproduced, the difficulty of 3DP items with subtle details, and issues with finished product quality are three of these significant limitations. In this context, studying the effect of the different parameters on the quality of the final piece is of paramount importance.

2. Process Parameters Selection

2.1. General Considerations

An additive’s efficiency, precision, and properties heavily depend on its manufacturing process parameters. The FDM method has been considerably studied to make functionally reliable fundamental studies into different process parameters. Several variables affect the FDM printing process, which are discussed in the following points of this section. Some indications on studies are reported together with the parameters, whilst a more detailed analysis of the properties affected will be reported when dealing with the latter.

2.2. Parameters

2.2.1. Nozzle Size

There are many different types of 3D printers, and each has its own unique design. The diameter of the nozzle ranges from 10 to 100 mm. Typically, the nozzle size is 0.4 mm due to the good balance of print speed and precision. A smaller nozzle means longer printing time, while a larger one is at risk of having excess material: in case a sufficient control is achieved, which depends also on the polymer’s rheology, it is suggested that a higher strength of the part can be obtained [81]. On the other hand, an obvious effect of the nozzle size is, for example, on the dimensions of the pores of the obtained final product: the larger the nozzles, the bigger the pores, whilst the amount of porosity is not substantially affected [82].

2.2.2. Filament Size

Fusion deposition materials can be created with the use of 3D filament, a thermoplastic feedstock. There are a variety of filaments to choose from, each with a different printing temperature requirement. 1.75 and 2.85 mm, both standard diameters of filaments, are available. It is not uncommon to hear people refer to 2.85 mm filament as a “3 mm” filament. When introducing different materials in the production process, such as it can be the case for natural fibers, the tolerance issue in the fabrication of the filament needs to be considered, as a too-marked variability of diameter can lead to gripping problems in the printer [83]. This required an accurate control of the granulometric dimensions of the filler introduced, such as, for example, on PLA/wood teak flour composite, where two sizes of powder were inspected for composite fabrication, that is, 74 and 125 µm [84]. Beyond the filament size, other effects were indicated by its resting time, such as in the case of PCL, where after a few days the stiffness did increase up to a plateau value [85].

2.2.3. Bed Temperature

For 3DP, heated beds are a necessity to avoid too fast and abrupt cooling down of the material, therefore leading to uneven stress distribution in the product. Printers that require a specific temperature setting do not come standard with all models. A good range between 55 and 70°C does normally reduce the risk for uncontrolled shrinkage [86] and fracture resistance [87]. In turn, bed temperatures do have influence on other factors, including in particular warpage and shrinkage, especially in stiffer polymer blends, such as ABS [88].

2.2.4. Printing Speed

The speed of 3DP determines the technology’s level of performance. The X- and Y-axis control electric motors and the extruder motor. It can add the material to the 3DP process with each subsequent addition. A 3D printer’s Z-axis vertical resolution, or layer height, is an essential technical feature. When using additives in the design process, there are three dimensions to consider: X, Y, and Z. Specific indications on additives are offered in [89], which include a number of aspects, most of which are considered already for the production of traditional composites yet are adapted to the specific challenges required to be met in 3DP. These include, beyond aesthetic improvements, obtained with colors, pigments, and dyes, the more critical introduction of reinforcements, thermal stabilizers, antioxidants, and flame retardants. Moreover, entering some fields, such as biomedical applications, does also need blending with bioactive or bioinert materials, while electronic applications do require electrically dissipative or thermally conductive materials. Tailoring the performance has particularly become of paramount importance in view of passing to 4D printing, therefore ensuring the suitability of the characteristics to stimulus-driven activation. This is particularly true when ensuring the penetration in fields such as tissue engineering, when tailored processing appears imperative [90]. An obvious effect of printing speed is on the possibility of deformation recovery, since it impinges on the viscoelastic behavior of the polymer, therefore possibly affecting the shape memory effect [91].

2.2.5. Infill Geometry

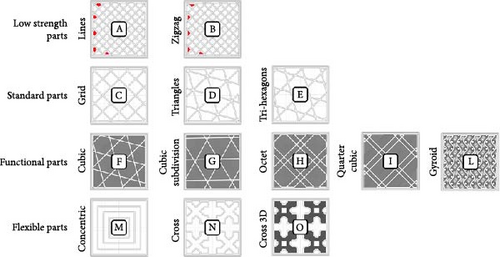

Infill pattern or geometry does refer to the way in which the structure is printed, not using a 100% material density, being even as low as 20%, which constitutes the infill density. Different infill patterns can be depicted for various shapes and sizes using slice tools. Triangular and rectangular infill patterns are the most common: wiggle and hexagonal or honeycomb shape, the relation these and the expected characteristics of the objects are exposed in Figure 2 [92]. The type of infill is obviously related to the printed object’s internal geometry. Inner fill can come in various shapes, including linear, hexagonal, and diamond [93], and those that serve a more aesthetic purpose (Moroccan star, catfill, sharkfill, etc.) [94]. In Figure 2, the filling by “lines” (discontinuous) and “zigzag” (continuous) leads to different grids, which are highlighted for better clarity.

Printing speed and time, object strength, weight, and mechanical properties can all be affected by infill patterns, as reported in [95].

2.2.6. Infill Density

The aforementioned infill patterns are strongly linked with the function and also with the technical importance being recognized to the piece in the structure. To further minimize waste, it is also essential to tailor as much as possible the amount of material used to fill the inner area of each layer: this is defined as “infill density” [95]. The major effect obtained by increasing infill density is obtained on flexural performance: in addition, a judicious arrangement of it is beneficial to minimize anisotropy [96]. The desired strength can be obtained through progressive topological optimizations, that is, allowing the strength to be distributed in the most correct mode, for example, by controlling fiber orientations [97]. A predictable trend in this sense, to acquire a total control over performance, is the combination of various infill patterns and densities in the realization of the same piece [98].

Some further properties are then connected to the raster physical characteristics. These have already been hinted, yet need to be defined more into detail.

2.2.7. Raster Angle

The angle between the printer’s nozzle direction and the control board X-axis, measured in degrees. The raster angle has an impact on the sample’s shape precision as well as mechanical efficiency. It is suggested that only when the raster is parallel to the predicted loading direction of the piece, it actively contribute to tensile performance [99]. Physically, a lower raster angle (down to 0°) provides a higher jet spreading together by requiring a lower supply pressure [100].

2.2.8. Air (Raster) Gap

The distance between two adjacent filaments is deposited at the same time to form the same layer. The number of contours corresponds to the number of filaments at the outer edge. For the most part, academic research has focused on layer height (slice height, thickness), which refers to the thickness of an individual layer deposited by one of the nozzle tips on a printing surface. Side surface “resolution” is determined by this factor. If the layer height is kept as low as possible, it is possible to achieve a finer side surface [101]. The so-called “staircase effect” will become more apparent if the layer height increases, resulting in rougher side surfaces, a critical issue, especially when composites with high-performance matrices, such as PEEK are employed [102].

2.2.8.1. Raster Width

Extruder temperature is commonly regulated to control filament width in the “XY” direction. Increasing the raster width results in a more durable interior, but the production requires longer times, since the outline refers to the tool path in its movement around the curves of the component [103]. A raster width reduces the build time, in doing which it has a combined effect with orientation [96].

2.2.8.2. Contour Width

“Shelled” refers to the layer’s outermost contour, or “shell,” surrounding the component. It would be important for the contour to be well defined, if not glossy, avoiding both underfilling and overfilling: adaptive methods to minimize this issue have been proposed [104]. A typical combination of parameters including contour width is with air gap, raster angle, contour number, and raster width [105].

2.2.8.3. Build Orientation

An “X,” “Y,” and “Z” axis angle is defined by this parameter, which orients the construction of the piece. Also, this parameter has been subjected to optimization studies, based on evolutionary algorithms [106]. Shape optimization that follows the careful selection of the most suitable build orientation can be further linked to mechanical performance following the principal stress lines (PSLs) across the section and the orientation of the applied loads [107].

2.2.8.4. Number of Contours

The number of filaments deposited in the outer walls of the printed object is the subject of this parameter. The object’s wall thickness can be modified by adjusting this parameter’s value, which also contributes to reducing the imperfections with respect to section circularity [108, 109] and reducing the amount of warping [110].

2.2.8.5. Nozzle Temperature

Temperature control of semimolten material utilizing the heating element (nozzle). A correct balance needs to be found between increase in the nozzle temperature, which results in a development of the rasters’ accuracy and a more effective layers bonding and the need to not increase too much the thermal stresses and possible damage in the polymer [111]. It has been recently noticed that the emission of ultrafine particles does increase by an exceedingly high nozzle temperature: this suggests the presence of a possible further environmental impact from it [112]. A number of studies on the influence of this factor on performance are available, which will be discussed later on.

2.2.8.6. Nozzle Tip Diameter

2.2.8.7. Envelope Temperature (Environment or Build Platform Temperature)

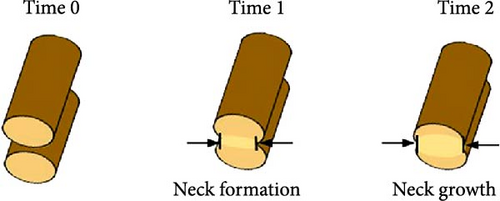

This factor measures the air temperature around the printer. It is not obvious to control it, therefore devices were applied in some cases, such as building a chamber around the printing setting [111]. The control of envelope temperature has a particular influence on the formation of necks in the polymer during printing (Figure 3).

Having discussed the parameters affecting in different measures the characteristics of FDM printing, the following section passes to the evaluation of the influence of material selection.

2.3. Materials Used in 3DP

The materials possibly used in fused deposition mode can be divided into three categories: thermoplastics, among which the main representatives are PLA or ABS, liquid metals, or edible materials [116].

In the case of PLA, the characteristics of easier biodegradability and bio-based nature (polymerized from sucrose) of this polymer do suggest its reinforcement in the filament with other bio-mass derived materials [117], lignocellulosic fibers [118], or specifically wood materials [119]. A large number of ABS grades are also employed in FDM printing, in particular the general purpose P400 [120]. Other more technically challenging polymers are also used. These include first and foremost polyamide (PA), normally referred to as nylon in its fibrous form, which can form filaments for specific high-tensile strength applications, also in combination with ceramic hardening additives [121]. Other polymers have a sufficient thermal resistance to be able to be treated to improve their performance, which is the case for polyetherimide (PEI) [122]. Also, the previously mentioned PEEK can be joined to its considerable thermal stability a slightly conductive behavior and a different application potential, linked to biocompatibility [123]. Polycarbonate (PC) in the fused deposition form proved particularly suitable for the manufacture of aluminum-faced laminates [124]. Also, the use of poly (ethylene terephthalate) glycol (PET-G) has been recently considered, which can provide sufficient resistance, though at the expense of a high temperature (230–250°C) processing [125].

As far as liquid metals are concerned, which can remain liquid at ambient temperature, their coextrusion in polymer filaments using FDM, for example, in the case of gallium and its eutectic alloys with indium, was proposed for the fabrication of stretchable electric circuits [126]. With these procedures, miniaturized and reconfigurable antennae have also been obtained, where 3DP did allow also to produce the insulated part of the feed network integrated with it [127].

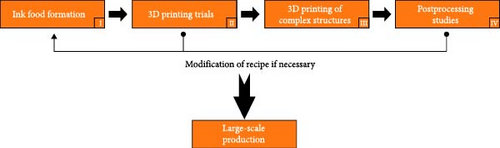

A further field of application for FDM is the production of edible inks for different sectors, going from biomedical to food engineering [128]. In more general terms, FDM may allow obtaining customized foods for specific nutritional needs, tailoring to complexity shapes and structures, carrying out this process with high levels of efficiency [129]. A conceptual scheme to obtain 3D-printed food is reported in Figure 4.

2.4. Filament Color With Extrusion Temperature

Measurement of the filament’s color during the FDM printing process can, among other things, also indicate the severity of its thermal degradation. Accelerated aging has been applied on FDM filaments then translating its effect into colorimetric data, which proved a reliable indicator of relevant performance [130]. As an example, a WFRPC (wood fiber reinforced PLA composite) filament extruded from the nozzle at various temperatures between 200 and 230°C is shown in Figure 5 [131]. Increasing the extrusion temperature affected the printed samples’ characteristics as for color, which became gradually darker. Color parameters of FDM-printed WFRPC components were examined in Table 2, as regards the L∗ (white/black axis) value, which gradually increases with extrusion temperature, as well as the (red/green axis) value, while the (yellow/blue axis) value remained fairly stable. As the result of the combination of these values, the global color parameter color increased up to 3.9 for extrusion at 230°C, taking extrusion at 200°C as equal to zero. This result indicated that the extrusion temperature affected the WFRPC component’s wood fiber color. The effect of extrusion temperature is reported in Table 3. Polysaccharide changes have previously been linked to thermally treated wood’s color variation [132], and also the presence and degradation of hemicellulose may be responsible for the findings of Kačíková et al. [133], in which E∗ and L∗ decrease while degradation increases. When wood is exposed to heat, it darkens due to extractive changes and the formation of hemicellulose decomposition products and oxidation product changes, which was noticed in using wood polysaccharide waste for filament production [134].

| Code | ∆E∗ | a∗ | b∗ | L∗ |

|---|---|---|---|---|

| WFRPC230 | 3.9 ± 0.1a | 14.4 ± 0.1a | 22.4 ± 0.1a | 52.9 ± 0.2c |

| WFRPC220 | 2.7 ± 0.9a | 14.2 ± 0.2a,b | 22.4 ± 0.3a | 54 ± 0.8b,c |

| WFRPC210 | 1.1 ± 0.4b | 14 ± 0.2b,c | 22.7 ± 0.2a | 56.1 ± 1.0a,b |

| WFRPC200 | — | 13.7 ± 0.1c | 22.5 ± 0.1a | 57.3 ± 0.6a |

- Note: Values represent the average ± SD (n = 3). Different letters (a, b, and c) indicate a significance difference at p < 0.05.

- Abbreviations: SD, standard deviation; WFRPC, wood fiber reinforced PLA composite.

| Code | W (g) | V (cm3) | Ra (μm) | Density (kg/m3) | MC (%) |

|---|---|---|---|---|---|

| WFRPC230 | 2.91 ± 0.1a | 2.73 ± 0.01a | 6.3 ± 0.5a | 1065 ± 6a | 1.9 ± 0.2a |

| WFRPC220 | 2.81 ± 0.07b | 2.70 ± 0.02a | 6.0 ± 0.7a | 1041 ± 7b | 1.8 ± 0.2a |

| WFRPC210 | 2.83 ± 0.04a,b | 2.70 ± 0.01a | 6.2 ± 0.6a | 1048 ± 12a,b | 1.9 ± 0.2a |

| WFRPC200 | 2.79 ± 0.08b | 2.71 ± 0.04a | 6.0 ± 0.6a | 1032 ± 17b | 2.1 ± 0.3a |

- Note: Values represent the average ± SD (n = 6). Different letters (a and b) indicate a significance difference at p < 0.05.

- Abbreviations: SD, standard deviation; WFRPC, wood fiber reinforced PLA composite.

As from more recent studies, it needs to be considered that extrusion rate can also be modified to provide more patient-adapted characteristics for applications to bone tissue replacement, as defined by surgical phantoms that are able to mimic the bone-specific geometrical features, always preserving the use of PLA [135]. However, PLA filament of various colors is also present commercially, which quite unexpectedly may lead to different levels of accuracy in 3DP fabrication, the highest one being obtained with black color, and bearing some relation also with tensile strength, whilst having a much more limited effect on layer height [136].

2.5. Technological Properties

2.5.1. Strength

It is expected that FDM parts would have a lower resistance than injection molded ones. In particular, a study evidenced that the tensile strength of overlap (negative air gap) parts was 65%–72% of that of the injection molded part [137]. The study also found the compressive strength of FDM parts of the ABS polymer to be between 80% and 90% of that of an injection molded ABS part. Therefore, researchers have developed guidelines for building an FDM part to maximize its structural integrity. Bellini and Güçeri [138] used experimental and analytical methods to investigate the effects of raster angle and part orientation on tensile strength and flexural strength. Using the Tsai–Wu failure criterion and classical lamination theory, Tajik, Khan, and Parezanović [100] developed an analytical model for predicting tensile strength of FDM parts.

According to Lee, Abdullah, and Khan [139], the application of optimal process parameters maximizes elastic achievement (throwing distance of catapult). Similarly, Ang et al. [68] studied porosity, compressive strength, and compressive modulus in ABS-engineered scaffolds, using FDM factors. It was found that small porosity frameworks offered the most outstanding mechanical properties, and that process parameter optimization improved the tensile strength by 90.45% [140]. Another option concerning porosity, always in a FDM context, is trying to induce a multiscale, hence hierarchical porosity, spanning over different orders of magnitude, from the micron to the millimeter: for the purpose, foaming agents such as supercritical carbon dioxide were employed [141].

One of the most critical process parameters is deposition orientation. PLA polymer parts produced were studied to determine the optimal thickness for the enhancement of impact properties [142]. In general, optimization does appear still an open issue, for the coupling of a number of parameters with mechanical performance. Back in 2009, the bacterial foraging technique, based on how bacteria can manage their feeding over the nutrients they dispose of [143, 144], was used to improve specimens’ tensile, flexural, and impact strength with respect to five parameters, namely layer thickness, orientation, raster angle, raster width, and air gap [145]. The study suggested against the application of small raster angles which, by the consequent adoption of long rasters, would increase the stress concentration over the piece. It was elucidated that a reduction in distortion is necessary for good strength. However, the optimal factor settings for impact strength varied from those for tensile and flexural strength, which required a simultaneously optimized response [146]. It is nonetheless recognized that tensile strength is required first and foremost to scale-up the dimension of pieces developed using FDM [147]. In terms of flexural strength, using PLA, when flow rate is taken at its highest value, some flexibility is possible with two competing couple of intervals offering the same flexural strength for nozzle temperature and printing speed, in particular, 210−220°C when printing at 50–52 mm/s, or 227−230°C with 55–65 mm/s printing [148]. Other significant yet poorly investigated property so far is compression strength: in recent years, ironing parameters were related to these characteristics, suggesting that a lower layer thickness and a higher nozzle temperature would be beneficial for compression strength [149]. More recent studies also identified the importance of adhesion among PLA layers and the presence of intermediate defects as an essential factor to tailor the mechanical properties of the product, which can be achieved by opportunely varying the infill percentages [150].

Overtime, the importance of DOEs has become increasingly significant to assess the mechanical properties of FDM pieces. A recent study, focusing on tensile strength, selecting a square lattice structure and using PLA for production, concentrated on three different values of layer height (0.1, 0.2, and 0.3 mm), printing temperature (190, 200, and 210°C), and printing speed (50, 75, and 100 mm/s), respectively. With the use of signal-to-noise (S/N) ration and ANOVA, the smaller layer height of 0.1 mm, a printing temperature of 190°C, and a relevant speed of 100 mm/s, finally resulting in a possible improvement of 25.4% of tensile strength, with layer height playing by far the largest role (87%) [151].

Response surface methodology (RSM), whose historical evolution is reported in [152], was also applied to determine an association between process parameters in FDM and response in final properties, when also coupled with other DOE methods, namely particle swarm optimization (PSO), symbiotic organism search (SOS) or the application of genetic algorithms, to offer predictive indications on the roughness of the final product [153]. The latter methods improved the results obtained using RSM. This has been also proven applicable to nonconventional materials for 3DP, such as it is the case for chicken meat in [154], where together with parameters associated with filament and nozzle, also the optimal amount of sodium chloride (NaCl) has been investigated, finally being set at 2.5%.

Another method applied very recently on FDM is PSO [155]. This multistep technique demonstrated a particular effectiveness, outperforming RSM, for the prediction of tensile strength for PLA 3D printed samples [156].

2.5.2. Creep

Temperature and strain rate affect polymer behavior, evidence that is defined as “creep.” Creep properties must be studied because polymer family feedstock typically makes up the raw materials for FDM production. The complexity of the relation among creep behavior and the large number of operational parameters that can be modified into 3D manufacturing suggests the adoption of DOE methods, also alternative ones, such as definitive screening design (DSD), which proved having a substantial effectiveness in this problem [157].

In particular, in short-time creep distortion of PC/ABS components, the major influence being shown by layer thickness, number of contours, raster angle and build orientation, while minor effects were revealed by road width and air gap [158]. It is possible to reduce creep deformation by finding the ideal combination of parameter values. Pinholes and cavities can form in the component if the layer height is too low. Salazar-Martín et al. [159] looked at how parameter changes affected creep behavior for FDM-PC parts. It was found that placing filaments in a similar direction to that in which the sample was pulled had a significant impact on part build orientation. Overall, YZ positioning, zero air gap, and the number of contours provided the best possible process parameters. According to the literature review, creep performance is most strongly influenced by layer height, raster angle, part orientation, and the number of outline paths; road width and air gap have a more negligible effect.

Attempts to increase the resistance to creep and other-time based phenomena, such as creep, have also been developed based on the addition of fillers, namely graphene, on PLA [160]. Despite the decrease of crystallinity and the higher porosity of the filament with added graphene, it was found out a 20.5% enhancement in creep resistance at the microscale with an applied load equal to 90 mN. These studies do appear particularly timely in view of the fabrication of recycled 3D filaments, where properties would possibly be enhanced and brought to an acceptable industrial level by the addition of conductive fillers, normally metal-based ones, or hardening ceramic ones, as reported in [161].

2.6. Thermal Properties

Countless investigators have analyzed the thermal characteristics of FDM parts, starting from the metal/polymers investigations reported in [162]. More recently, the emphasis on conductivity of 3D produced parts produced a novel flow of interest in this theme: in particular, it opened possibilities for the production of “thermal sinks,” in situations where the common manufacturing methods, such as injection molding, are not available, and even the application of a mold is not available, such as in typical Do-It-Yourself (DIY) situations, which encountered a renewed interest recently, as a powerful design tool [163]. Based on thermal insulation potential in FDM production, a wealth of polymers is available as filaments, in particular, other than PLA and ABS, also acrylonitrile styrene acrylate (ASA), PC, polyphenylene sulfide (PPS), and PEEK. To these, thermally conductive fillers can be added, which can be particularly managed in suitable way by a coextrusion process of the filament, as reported in Figure 6 [164].

New metallic and nonmetallic (nylon/iron) materials were examined as case studies, concluding that they were suitable for rapid tooling on injection molded parts. Using differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA), Boparai, Singh, and Singh [165] evaluated a nylon 6-based nanomass composite and phase change to determine its thermal classification. Tensile properties were harmed during embedding, as demonstrated in [166]. The paused layer can be reheated during the FDM process to address these issues. Layer height, heating time, and pressure were all studied to determine how warming affects FDM objects’ mechanical properties [167]. Prajapati et al. [168] demonstrated an experimental method for measuring anisotropic thermal conductivity and interlayer thermal contact resistance in FDM parts made of ABS and ULTEM by varying the air gap. Thermal conductivity values for air gaps were also predicted using an analytical model. Samples’ thermal conductivity was measured along the raster of the filament and in the build direction and did this by varying the air gap. Building direction has a high thermal contact resistance, which causes part anisotropy, hence it should be adequately taken into consideration. According to research, the build direction, layer thickness, and air gap all significantly impact the thermal properties of FDM components. Yang and Zhang [169] used the “birth–death element technique” to develop a numerical model of the FDM process’s temperature and stress fields. Thermal-structural transient coupled analysis was presented. As a result of the dismissal of heat during the transition from liquid to solid, the FDM process combined structural and thermal analysis.

2.7. Wear Properties

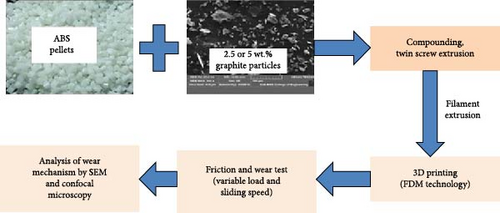

More recently, the prospected introduction of other materials, especially as fillers, for FDM filament also requires some investigations on their wear and friction properties, based on the initial parameters of the FDM process, suggesting that a low layer height, part orientation, and a large raster angle all contribute to wear decrease [170]. For example, graphite can be considered as a “solid lubricant” [171]. In its addition in an amount of 5 wt.% to ABS, as per the procedure shown in Figure 7, a decrease of friction coefficient from 0.65 to 0.22 was observed, whereas the wear rate dropped from 115 to 62, when the sliding velocity was 0.262 m/s and the applied contact load was 5 N, respectively. A similar study under rapid tooling and in wet conditions was also conducted considering ABS and graphene in wet conditions [172].

It is well-assessed that to improve the tribological properties of some polymers that are particularly suited for high wear resistance applications, such as Nylon 6, the addition of harder fillers, metallic, such as iron [173, 174], or ceramic, such as titanium dioxide [175], is particularly of interest. However, this procedure also shows some merit by proposing polymers alternative to PA for applications into, for example, junction elements, such as it is the case for PLA by using iron particles [176].

In [177], PLA was added instead with aluminum powder, which more than halved the wear rate. Similar attempts were carried out also considering a blend between PA6 and titanium dioxide and comparing it with PLA with a reduction of wear rate around 30% [178]. Other propositions to improve PLA wear properties in FDM concerned the use of nanoclay filling [179] or passing to agrowaste by the introduction of almond skins [180]. Attempts to optimize the wear properties of Nylon6-SiC-Al2O3 based feedstock filament of FDM have also been carried out, obtaining pins with high resistance to wear [181]. Examples of pins manufactured by FDM are reported in Figure 8.

2.8. Roughness

Another aspect that needs to be considered is the roughness of the filament obtained and consequently the one of the objects. Roughness, in its relationship with accuracy, is dependent over a large number of parameters, as such it has been modeled in [182] according to the thermal analysis of bonding formation between the different filaments. In this way, correlations among a large number of parameters of 3DP have been established, including nozzle temperature, printing speed, layer thickness, deposition road width, and temperature of printing platform, demonstrating that the optimal layer thickness for 3DP of PEEK was equal to 0.15 mm using a printing speed of 20 mm/s. A similar outcome, as for layer thickness, suggested to be in the same order of magnitude, for optimized roughness, was obtained in [183], aiming at the production of dental implants, with controlled parameters being infill rate, platform temperature, and printing temperature. This has also been revealed by a more comprehensive study including 13 different parameters in a Taguchi DOE study, which highlighted that using PLA surface roughness was mostly influenced by the layer height, geometrical considerations on the top layers, and finally the fill print velocity [184]. The effect of raster angle on roughness was also evaluated indicating that applying a perpendicular instead of parallel raster angle increased the roughness from 1 to 7 µm, due to the fracture of interlayer bonds [185].

2.9. Considerations on the Influence of Parameters on the Various Properties

Some final considerations can be drawn, which involve the gradually increasing number of parameters on which the properties of FDM-manufactured products depend. Despite the abundance of studies that suggest trends for the single characteristics of the filament, of the nozzle, or on the laying down process, in terms of temperature, orientation, etc., the necessity for statistical studies based on the DOEs appears evident to shed some light on the matter. Even investigations concentrated on one set of parameters, such as infill patterns, on mechanical properties, that is, extension, stress, elongation, energy, and stiffness, applying a single material, namely PLA, highlighted the large influence of the patterns, yet on the other hand it is not very likely these conclusions can be generalized in any way [186]. For example, in the case of fatigue properties, again on infill patterns and using PLA, the application of a line modifiers led also to distinct benefits to extend over service life the tensile performance [187]. Also, statistical analysis based on DOE would be referred to as of major importance whenever a different material than PLA or ABS, such as PA 6-6 (Nylon), less investigated in FDM production [188], or a blend of two polymers, such as thermoplastic polyurethane (TPU) and ABS, is applied [189].

3. Conclusions

The quality of prototypes and potentially products for use obtained using FDM represents a concern for users of this 3DP method, though in general terms more flexible than the competitors. This review discussed the influence of the different parameters for deposition, and also the prospected change of materials for the filament with respect to the different properties to be studied. These include physical (reflected by the change in color of the filament), mechanical and creep ones, thermal degradation, and ultimately the wear and friction characteristics of the obtained prototypes. The manufacturing process and filament formulation significantly affect the cost of the final product, as well as its physical, mechanical, and thermal properties. 3DP time increases with decreasing printing layer thickness, which prolongs the production time and raises overall cost. If industrial companies or individual users producing with 3D printers would know the effects of process parameters and raw materials on the final product, they will be able to decide on parameter and filament selection according to their expected performance.

- 1.

The maximization of efficiency in evaluating the effect of the different fabrication parameters, which can be achieved via the application of complex DOEs techniques and possibly also by the introduction of artificial intelligence methods for data treatment. It is suggested that with progress of studies and the significant increase of the number of factors involved in final performance, the use of DOE will become inevitable.

- 2.

The availability and the assessment of suitability for a larger number of materials, which again requires to reset the various parameters for production. This will also include the potential of using some of these materials and combinations with adapted fillers in terms of some specific needs (e.g., biocompatibility for fabrication of biomedical devices).

- 3.

In terms of circular economy, FDM can definitely contribute to the judicious introduction of waste and by-product from other systems, such as it is the case for lignocellulosic materials, used as fillers for the various filaments.

Nomenclature

-

- ABS:

-

- Acrylonytrile–butadiene–styrene

-

- AM:

-

- Additive manufacturing

-

- ANOVA:

-

- Analysis of variance

-

- CAD:

-

- Computerized aided design

-

- DDM:

-

- Direct digital manufacture

-

- DOE:

-

- Design of experiments

-

- FDM:

-

- Fused deposition modeling

-

- FFF:

-

- Filament fused fabrication

-

- MWCNT:

-

- Multiwalled carbon nanotubes

-

- PBF:

-

- Powder bed fusion

-

- PLA:

-

- Poly (lactic acid)

-

- PSO:

-

- Particle swarm optimization

-

- RP:

-

- Rapid prototyping

-

- SLA:

-

- Stereolithography

-

- SLS:

-

- Selective laser sintering

-

- WFRPC:

-

- Wood fiber reinforced polylactic acid composite.

Conflicts of Interest

The authors declare no conflicts of interest.

Author Contributions

Ganesan Karuppiah, Sivasubramanian Palanisamy, Praveen Kumar, Shanmugam Dharmalingam, Suhail Mubarak, Nadir Ayrilmis, Srikanth Karumuri, and Carlo Santulli: conceptualization. Ganesan Karuppiah, Praveen Kumar, and Shanmugam Dharmalingam: formal Analysis. Suhail Mubarak, Sivasubramanian Palanisamy, Nadir Ayrilmis, and Carlo Santulli: investigation. Suhail Mubarak, Sivasubramanian Palanisamy, Shanmugam Dharmalingam, and Srikanth Karumuri: resources.Srikanth Karumuri, Nadir Ayrilmis, and Carlo Santulli: supervision. Ganesan Karuppiah, Sivasubramanian Palanisamy, Praveen Kumar, Shanmugam Dharmalingam, and Srikanth Karumuri: writing–original draft. Sivasubramanian Palanisamy, Nadir Ayrilmis, Suhail Mubarak, Carlo Santulli, and Srikanth Karumuri: writing–review and editing.

Funding

This research received no external funding.

Open Research

Data Availability Statement

All data that support the findings of this study are included within the article.