Research on Health Monitoring of Flying-Swallow-Typed Tied Arch Bridge Based on PSO-GRNN Algorithm

Abstract

In the health monitoring work of long-span concrete-filled steel tube tied arch bridges, finite element models have been commonly employed to indicate the practical stress state, and providing accurate data in real time and efficiently has been confirmed as the weakness of the finite element model. The prediction model is built in accordance with the general regression neural network (GRNN), and the parameters of the GRNN model are optimized using particle swarm optimization (PSO) to build the PSO-GRNN prediction model, with the aim of modifying the finite element model. A finite element analysis model is built using the Qiuhuli flying-swallow-typed tied arch bridge to verify the effect of the PSO-GRNN prediction model. The model test data are acquired using the horizontal thrust of arch foot, the bulk weight of main beam, and the tension of tied rod as the input variables and using the stress of main arch rib steel pipe, the stress of main arch concrete, and the displacement of mid span as the output variables. As revealed by the results, the average prediction accuracy of the PSO-GRNN model constructed in this article is 96.706%, 98.531%, and 99.634%, respectively, which are 1.980%, 1.706%, and 0.40% higher than the back propagation (BP) neural network model and 2.262%, 1.632%, and 0.387% higher than the GRNN model. The mean absolute percent error (MAPE), root mean square error (RMSE), coefficient of determination (R2), and Nash-Sutcliffe efficiency (NSE) coefficient were used to evaluate the prediction performance of the model. The PSO-GRNN model has the highest fitting accuracy, indicating that the established PSO-GRNN prediction model can more effectively predict the relevant parameters of concrete-filled steel tube tied arch bridges and has high accuracy.

1. Introduction

The finite element model modification technology has been extensively investigated and employed over the past two decades. Using the existing finite element model parameter modification method that has been widely applied for, the model structural response can be consistent with the practical structural response through the selection and modification of model parameters, such that a finite element model that can indicate and predict the practical structural behavior is built [1]. In the field of civil engineering, the finite element model is built for the structure based on certain assumptions, and the practical structure is affected by external load and environment in construction and operation. On that basis, errors are generated between the finite element model and the practical structure, and the model usually cannot indicate the practical working state of the structure [2]. Accordingly, parameters should be modified to ensure that the calculation results of the finite element model can express the practical structural conditions [3, 4].

In recent years, the health monitoring and safety status assessment of long-span bridge structures have become a hot research field worldwide [5–8], and finite element model modification technology is capable of developing a reliable and effective model for this purpose, which can be adopted to invert the working and health status of bridge structures and even identify the location and degree of structural damage. The general regression neural network (GRNN) model exhibits several advantages (e.g., nonlinear approximation ability, generalization ability, strong robustness, and fewer training parameters) [9–11].

Particle swarm optimization (PSO) is a population-based algorithm that uses the behavior of biological populations to solve optimization problems. The algorithm generates random candidate solutions and evaluates them using a fitness function. In each iteration, the particles are updated based on their known position and the known position of the population. The PSO algorithm has simple rules, requires relatively few parameters, and is easy to apply, making it a good choice for optimization problems [12]. Samanataray and Sahoo [13] used the PSO algorithm to optimize the ANFIS (adaptive-network-based fuzzy inference system) model, which improved the convergence speed, prediction accuracy, and reliability compared with the independent ANFIS model. Chaudhury et al. [14] used the PSO algorithm to optimize the simple rainfall prediction of ANFIS model, and the results indicate that the PSO algorithm has a significant improvement in model performance. Samantaray et al. [15] used the PSO algorithm to optimize the SVM model, and the results showed that coefficient of determination (R2), Nash-Sutcliffe efficiency (NSE) coefficient, and mean absolute error (MAE) were significantly improved. The above research shows that PSO algorithm can improve different models to varying degrees.

The flying-swallow-typed tied arch bridge has been reported as a special type of arch bridge [16, 17]. Its major characteristics are presented as follows. First, the arrangement of tie rods and arches on both sides is capable of effectively balancing the horizontal thrust generated by the main arch foot and increasing the arch span. Second, combined with the use of concrete-filled steel tube as arch rib, its construction difficulty will be significantly reduced, such that it exhibits more significant economic advantages than cable-stayed bridges of the same span. Third, using prefabricated concrete slabs in the bridge deck can significantly shorten the construction period. In the construction control of long-span concrete-filled steel tube tied arch bridge, a calculation model was built using finite element analysis software to analyze the influences of the changes in horizontal thrust of arch foot, the bulk weight of main beam, and the tension of tied rod on the stress of main arch rib steel pipe, the stress of main arch concrete, and the cumulative displacement.

In order to further reduce the error between the finite element model and the actual structure, this paper proposes to use particle swarm optimization generalized regression neural network (PSO-GRNN) [18] to establish a prediction model to predict the main parameters such as steel pipe stress in the main arch rib, concrete stress in the main arch, and cumulative displacement. The PSO-GRNN model used in this article has successfully overcome the disadvantage of slow convergence speed in traditional neural network training, greatly improving the uncertainty caused by the empirical determination of model parameters. Compared with the local linear estimation model and linear regression model, the prediction accuracy and convergence speed of the PSO-GRNN model are significantly improved, and the PSO-GRNN model has strong adaptive ability. For this algorithm, which is prone to getting stuck in local optimal solutions and has certain limitations, this article will use Z-score to solve this problem. Z-score is the standard score, which represents the standard deviation of the score above or below the average result score. Through normalization, it can be compared across different variables. This method solves the problem of model parameters getting stuck in local optima and improves the prediction accuracy of the PSO-GRNN model [19].

2. Prediction Model Based on PSO-GRNN Algorithm

2.1. General Regression Neural Network (GRNN)

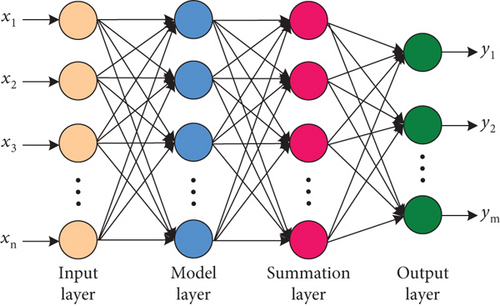

GRNN is a nonlinear regression model based on neural networks. The model maps input data to high-dimensional space through radial basis functions and then convert the output of the hidden layer into the final prediction result through linear combination. The GRNN model has good nonlinear approximation ability and generalization ability and is commonly used in fields such as regression analysis and time series prediction. Its structure is illustrated in Figure 1.

2.1.1. Input Layer

The main function of the input layer refers to receiving input data, and the number of input neurons should be identical to the dimension of the input data.

2.1.2. Model Layer

2.1.3. Summation Layer

2.1.4. Output Layer

2.2. PSO Algorithm

Particle swarm optimization (PSO) refers to an optimization algorithm based on swarm intelligence, which simulates the behavior of biological groups (e.g., birds or fish) and searches for the optimal solution through continuous iteration [22–24]. The basic idea of PSO algorithm refers to transforming the optimization problem into a search problem in multidimensional space and treating the respective solution as a particle. By continuously updating the position and velocity of particles, it moves towards the direction of the global optimal solution. PSO algorithm has the advantages of strong global search ability, fast convergence speed, and easy implementation, making it suitable for various optimization problems.

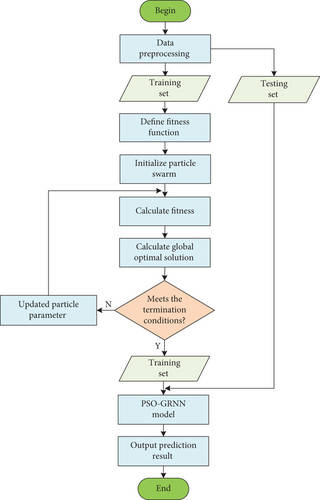

2.3. PSO-GRNN Model

- (1)

Define fitness function: the fitness function is used to evaluate the fitness of each particle, that is, the prediction accuracy of the model. In GRNN model, the fitness function can be defined as the reciprocal of training error ε (1/ε). The larger fitness function indicates the higher prediction accuracy of the model

- (2)

Initialize particle swarm: initialize the position and velocity of the particle swarm, where position represents the center point and width parameters of the radial basis function and velocity denotes the movement direction and velocity of each particle in the search space

- (3)

Calculate fitness: calculate the fitness of each particle according to the current position, i.e., the value of the objective function

- (4)

Update the global optimal solution: update the global optimal solution in accordance with the current fitness to determine the optimal center point and width parameters of the radial basis function

- (5)

Update particle velocity and position: update the particle velocity and position according to the current position and the global optimal solution, causing particles to move towards the direction of the global optimal solution

- (6)

Train GRNN model: employ the searched optimal center point and width parameters, with the aim of training the GRNN model and building the final prediction model

2.4. Model Evaluation

3. Case Analysis

3.1. Project Overview

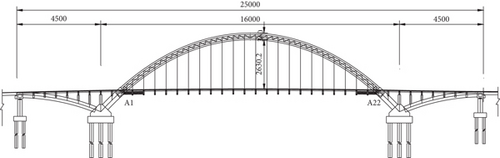

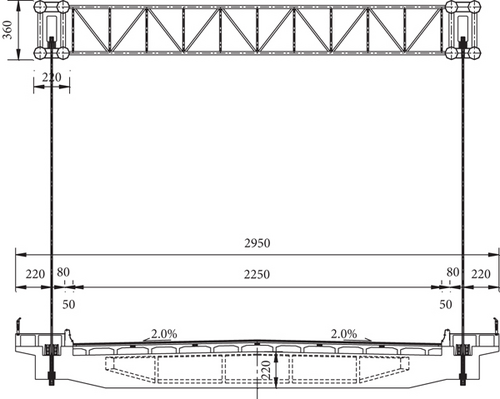

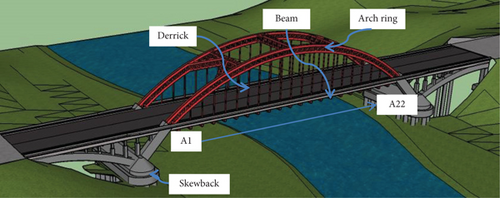

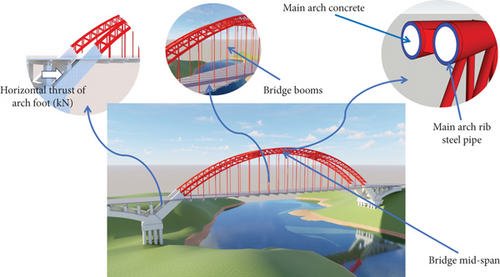

The Qiuhuli Bridge is located in Jiujiang City, Jiangxi Province, China. Its upper structure adopts flying-swallow-typed tied arch structure, with a span arrangement of 45 + 160 + 45 m. The overall layout is presented in Figure 3. A combination of rigid arch and flexible tie rods, with four arch rings Φ 800 mm steel pipes, forms a spatial truss structure, with each steel pipe connected with a transverse steel truss, and the steel pipes are filled with concrete. The height of the arch rib of the main span is 3.6 m, the width of the arch rib reaches 2.2 m, the rise span ratio is set to 1/4, the design alignment of the main arch axis is catenary, and the arch axis coefficient is 1.5. The rise span ratio of the eastern side arch is set to 1/10, the arch axis is catenary, and the arch axis coefficient reaches 1.5. The rise span ratio of the western side arch is 1/9.544, the arch axis is catenary, and the arch axis coefficient is 1.5. The total width of the main bridge reaches 29.5 m, and the bridge deck system adopts π-shaped reinforced concrete prefabricated beams with plate-type rubber bearings. Figure 4 presents the standard cross section of the main bridge.

There are a total of 22 pairs of suspenders in the whole bridge, numbered from left to right as A1 to A22. The suspenders are made of factory produced whole bundle extruded steel strands, with models 15-37. The steel strands are coated with anticorrosion grease, protected by a single HDPE sheath. Moreover, the whole bundle is wrapped with high-strength polyester and then wrapped with HDPE sheath to prevent corrosion of the suspenders. The tied rod pertains to the type of 15-55, which is fully corrosion-resistant, interchangeable, and adjustable. It is anchored at the two ends of the arch ribs on both sides at the arch foot. The respective arch foot comprises six groups of tie rods, each with 55 steel strands. The tie rods are arranged longitudinally in a curved shape. The bridge deck adopts prefabricated trough-shaped plates. The substructure adopts bored pile foundation and rectangular abutment.

Based on Midas/Civil 2020 finite element software, this study establishes a spatial finite element model for the structure analysis of Qiuhuli tied arch bridge. According to the stress characteristics of different components in tied arch bridge, two types of elements are mainly used to achieve, beam element and truss element, in which the suspenders and tie rods are simulated by truss element, and the main arch and its transverse connection, cross tie beam, and substructure are simulated by beam element. The spatial finite element model of the Qiuhuli tied arch bridge consists of 1558 nodes and 2114 elements, including 1400 beam elements and 714 truss elements, which is shown in Figure 5.

3.2. Predictive Analysis Using Horizontal Thrust of Arch Foot and Bulk Weight of Main Beam as Input Variables

During the construction process of filling core concrete to the arch ribs of concrete-filled steel tube arch bridge, there may be differences between the configured concrete and the design values. Secondly, there may be insufficient filling, gaps in the steel pipes, and other reasons. The above-mentioned factors can cause changes in the bulk weight of main arch ring, which can affect the arch rib line shape and stress, as well as the stress of tie beam and the horizontal thrust of arch foot. The design bulk weight of core concrete of the Qiuhuli Bridge is 25 kN/m3. To verify the feasibility and reliability of the improved PSO-GRNN model prediction, this study plans to use the horizontal thrust of arch foot and the bulk weight of main beam as the input variables, to predict the stress values of the upper and lower edges of core concrete and steel pipes at arch foot and mid span arch rib, as well as the displacement of mid span values, which is shown in Figure 6.

The change model of the horizontal thrust of arch foot and the bulk weight of main beam is built using Midas/Civil 2020 finite element software. The stress of main arch rib steel pipe, the stress of main arch concrete, and the displacement of mid span are determined, and the sample data corresponding to the parameter variations in the horizontal thrust of arch foot and the bulk weight of main beam are obtained (Table 1). To be specific, the sample data numbered 1 to 14 pertain to training data, and the sample data numbered 15 to 17 belong to testing data.

| Sample number | Horizontal thrust of arch foot (kN) | Bulk weight of main beam (kN/m3) | Stress of main arch rib steel pipe (MPa) | Stress of main arch concrete (MPa) | Displacement of mid span (mm) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| F | γ | σ1s | σ1x | σ2s | σ2x | σ1s | σ1x | σ2s | σ2x | Δ | |

| Training sample | |||||||||||

| 1 | 5070 | 25 | 0.934 | 0.766 | 0.025 | 0.039 | 0.891 | 0.808 | 0.000 | 0.010 | 46.292 |

| 2 | 5016 | 25.25 | 0.938 | 0.769 | 0.027 | 0.041 | 0.895 | 0.810 | 0.001 | 0.012 | 46.441 |

| 3 | 4971 | 25.50 | 0.942 | 0.773 | 0.029 | 0.043 | 0.899 | 0.814 | 0.002 | 0.014 | 46.613 |

| 4 | 4917 | 25.75 | 0.946 | 0.777 | 0.029 | 0.043 | 0.903 | 0.818 | 0.002 | 0.014 | 46.688 |

| 5 | 4862 | 26.00 | 0.950 | 0.781 | 0.031 | 0.045 | 0.907 | 0.822 | 0.004 | 0.016 | 46.921 |

| 6 | 4808 | 26.25 | 0.953 | 0.785 | 0.033 | 0.047 | 0.911 | 0.826 | 0.006 | 0.017 | 47.082 |

| 7 | 4754 | 26.50 | 0.959 | 0.789 | 0.033 | 0.048 | 0.915 | 0.829 | 0.006 | 0.017 | 47.357 |

| 8 | 4700 | 26.75 | 0.963 | 0.793 | 0.035 | 0.048 | 0.919 | 0.833 | 0.008 | 0.019 | 47.594 |

| 9 | 4645 | 27.00 | 0.967 | 0.797 | 0.037 | 0.050 | 0.922 | 0.837 | 0.008 | 0.021 | 47.675 |

| 10 | 4592 | 27.25 | 0.971 | 0.798 | 0.027 | 0.056 | 0.926 | 0.841 | 0.010 | 0.021 | 47.912 |

| 11 | 4554 | 27.50 | 0.975 | 0.802 | 0.039 | 0.054 | 0.930 | 0.845 | 0.012 | 0.023 | 48.047 |

| 12 | 4501 | 27.75 | 0.979 | 0.806 | 0.041 | 0.054 | 0.934 | 0.849 | 0.012 | 0.025 | 48.206 |

| 13 | 4446 | 28.00 | 0.983 | 0.810 | 0.041 | 0.056 | 0.938 | 0.853 | 0.014 | 0.027 | 48.365 |

| 14 | 4393 | 28.25 | 0.986 | 0.814 | 0.043 | 0.058 | 0.942 | 0.857 | 0.014 | 0.027 | 48.524 |

| Testing sample | |||||||||||

| 15 | 4339 | 28.50 | 0.990 | 0.818 | 0.045 | 0.060 | 0.946 | 0.860 | 0.016 | 0.029 | 48.683 |

| 16 | 4285 | 28.75 | 0.994 | 0.822 | 0.045 | 0.060 | 0.950 | 0.864 | 0.017 | 0.031 | 48.842 |

| 17 | 4232 | 29.00 | 1.000 | 0.826 | 0.047 | 0.062 | 0.955 | 0.868 | 0.017 | 0.031 | 49.001 |

In Table 1, σ1s expresses the stress at the upper edge of arch foot, σ1x denotes the stress at the lower edge of arch foot, σ2s is the stress at the upper edge of mid span arch rib, and σ2x represents the stress at the lower edge of mid span arch rib.

3.2.1. Data Preprocessing

3.2.2. Model Training and Prediction

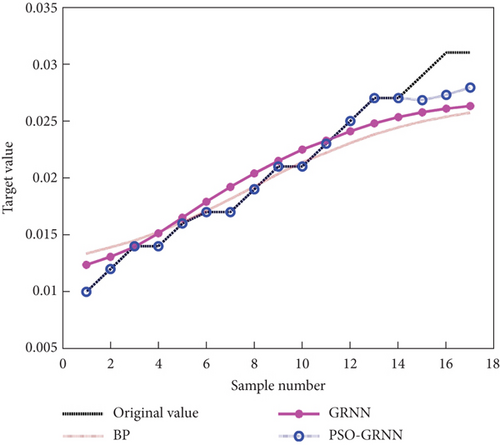

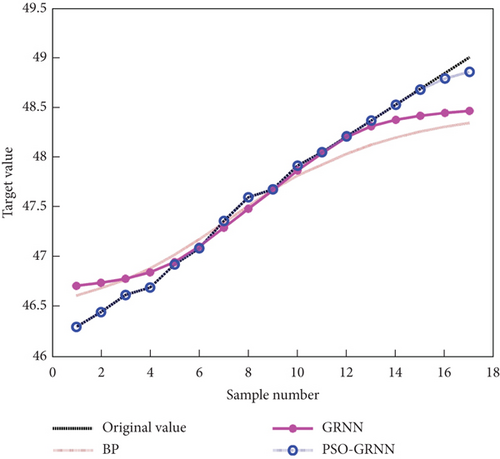

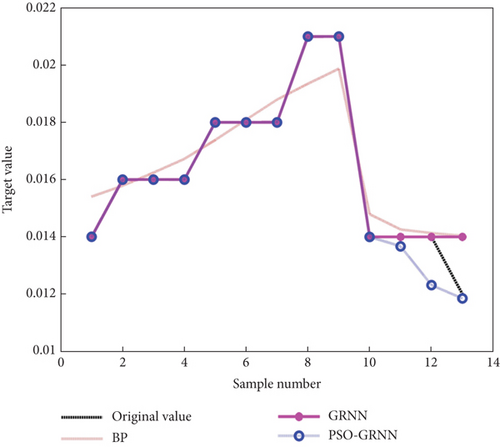

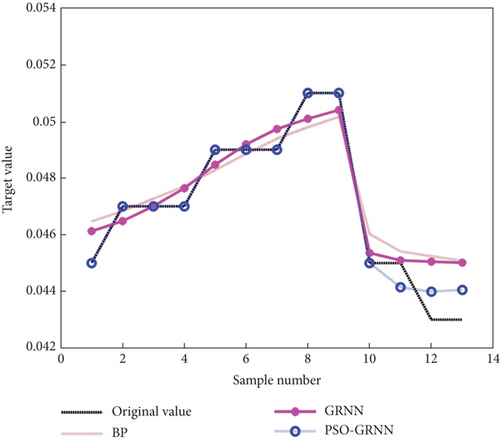

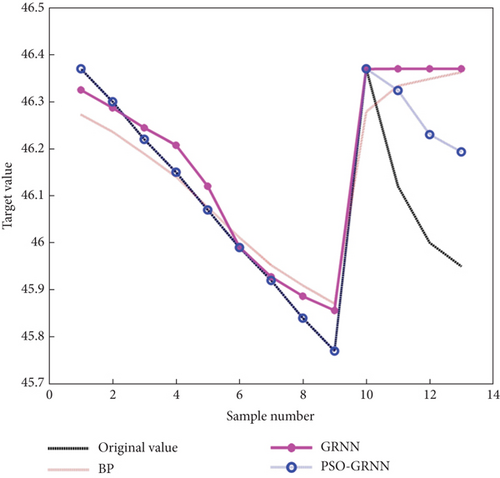

As depicted in Table 1, when the horizontal thrust of arch foot and the bulk weight of main beam vary, the stress of main arch rib steel pipe, the stress of main arch concrete, and the displacement of mid span vary notably. After the training sample data are normalized and the sample data are tested, a prediction model is built using MATLAB. The normalized training sample data is adopted to complete the prediction model training, and then, the testing sample data is substituted into the prediction model. The output data of the testing sample serves as the prediction result and compared with the real value. The BP neural network, the GRNN neural network, and the PSO-GRNN method are employed, respectively, to further compare the prediction performance of the PSO-GRNN model. The horizontal thrust of arch foot and the bulk weight of main beam serve as the input variables, and the stress at the lower edge of main arch concrete span, the stress at the lower edge of main arch rib steel pipe span, and the displacement of mid span serve as the output variables to establish the model for prediction. The prediction results are presented in Figures 7, 8, and 9.

As depicted in Figures 7, 8, and 9, compared with the BP model and the GRNN model, the PSO-GRNN model is capable of well predicting all three variables, such that prediction errors can be significantly reduced. Table 2 lists the prediction errors and average accuracy of the stress at the lower edge of main arch concrete span, the stress at the lower edge of main arch rib steel pipe span, and the displacement of mid span obtained from three prediction models. As revealed by the above-mentioned result, the average prediction accuracy of the PSO-GRNN model reaches 94.949%, 97.274%, and 99.914%, respectively; 10.607%, 5.500%, and 0.976% higher than that of the BP model; and 6.410%, 2.200%, and 0.623% higher than that of the GRNN model. On that basis, the PSO-GRNN model exhibits higher prediction accuracy.

| Category | Stress at the lower edge of main arch concrete span | Stress at the lower edge of main arch rib steel pipe span | Displacement of mid span | ||||||

|---|---|---|---|---|---|---|---|---|---|

| BP | GRNN | PSO-GRNN | BP | GRNN | PSO-GRNN | BP | GRNN | PSO-GRNN | |

| Error of 15 | 0.0038 | 0.0023 | 0.0014 | 0.0047 | 0.0026 | 0.0012 | 0.4033 | 0.2091 | -0.0170 |

| Error of 16 | 0.0054 | 0.0041 | 0.0020 | 0.0043 | 0.0023 | 0.0009 | 0.5154 | 0.3421 | 0.0068 |

| Error of 17 | 0.0051 | 0.0041 | 0.0012 | 0.0060 | 0.0041 | 0.0029 | 0.6377 | 0.4886 | 0.1015 |

| Average accuracy | 84.342% | 88.539% | 94.949% | 91.774% | 95.074% | 97.274% | 98.938% | 99.291% | 99.914% |

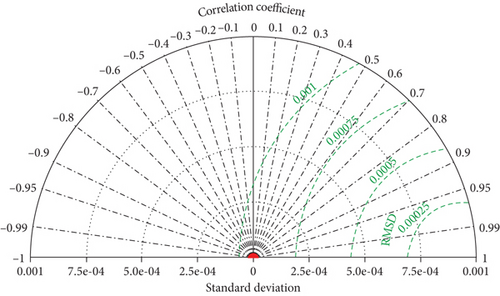

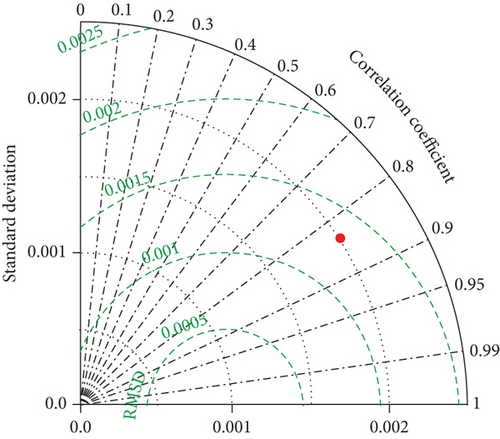

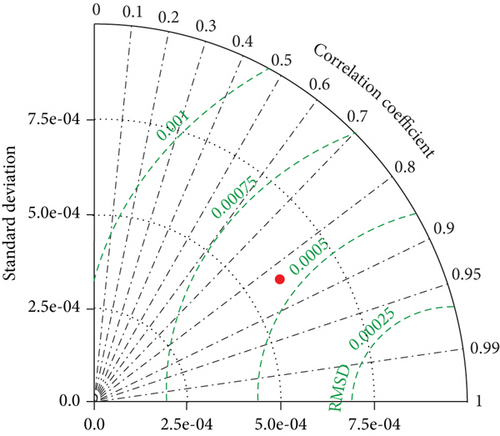

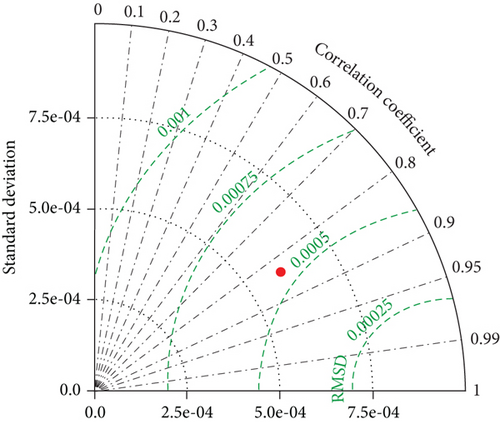

In order to further compare the prediction performance of the BP model, GRNN model, and PSO-GRNN model, four error indicators, MAPE, RMSE, R2, and NSE, were used to evaluate the prediction performance of the model. The results are shown in Table 3, and the Taylor diagram of the PSO-GRNN model predicted results is shown in Figure 10 [26, 27]. From the results, it can be seen that the PSO-GRNN model has the highest fitting accuracy, with R2 and NSE values close to 1, and MAPE and RMSE values are very small. Thus, the performance of the PSO-GRNN model is better than that of the BP model and GRNN model.

| Category | Stress at the lower edge of main arch concrete span | Stress at the lower edge of main arch rib steel pipe span | Displacement of mid span | ||||||

|---|---|---|---|---|---|---|---|---|---|

| BP | GRNN | PSO-GRNN | BP | GRNN | PSO-GRNN | BP | GRNN | PSO-GRNN | |

| MAPE | 0.264 | 0.183 | 0.125 | 0.168 | 0.138 | 0.113 | 0.154 | 0.068 | 0.035 |

| RMSE | 2.025 | 1.023 | 0.017 | 3.023 | 2.121 | 1.018 | 4.135 | 3.097 | 0.038 |

| R2 | 0.505 | 0.627 | 0.915 | 0.495 | 0.541 | 0.843 | 0.454 | 0.716 | 0.938 |

| NSE | 0.871 | 0.889 | 0.989 | 0.871 | 0.889 | 0.918 | 0.823 | 0.908 | 0.985 |

3.3. Predictive Analysis Using Horizontal Thrust of Arch Foot and Tension of Tied Rod as Input Variables

The existing application of prestressed structures turns out to be progressively widespread, and the damage and destruction arising from the relaxation of prestressed steel bars are increasing. The tie rods of the Qiuhuli Bridge are anchored at the arch foot at both ends of the side arch ribs. The respective arch foot comprises six groups of tie rods, each with 55 steel strands. The tie rods are arranged longitudinally in a curved shape. The tension of the tie rod can be reduced due to the loss of prestress and anchor deformation. In this section, the horizontal thrust of arch foot and the tension of tie rod serve as the input variables, and the stress of main arch rib steel pipe, the stress of main arch concrete, and the displacement of mid span serve as the output variables. Analysis and calculation are conducted using Midas/Civil 2020 finite element software, and the sample data are acquired (Table 4). The sample data numbered 1 to 10 refer to training data, and the sample data numbered 11 to 13 pertain to testing data.

| Sample number | Horizontal thrust of arch foot (kN) | Tension of tied rod (kN) | Stress of main arch rib steel pipe (MPa) | Stress of main arch concrete (MPa) | Displacement of mid span (mm) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| F | F | σ1s | σ1x | σ2s | σ2x | σ1s | σ1x | σ2s | σ2x | Δ | |

| Training sample | |||||||||||

| 1 | 5294.8 | 300 | 0.996 | 0.819 | 0.031 | 0.045 | 0.951 | 0.862 | 0.002 | 0.014 | 46.37 |

| 2 | 5575.6 | 297 | 0.998 | 0.819 | 0.033 | 0.047 | 0.951 | 0.862 | 0.004 | 0.016 | 46.30 |

| 3 | 5846.3 | 294 | 0.998 | 0.819 | 0.033 | 0.047 | 0.953 | 0.862 | 0.004 | 0.016 | 46.22 |

| 4 | 6127.14 | 292 | 0.998 | 0.819 | 0.033 | 0.047 | 0.953 | 0.862 | 0.004 | 0.016 | 46.15 |

| 5 | 6407.9 | 289 | 0.998 | 0.819 | 0.033 | 0.049 | 0.953 | 0.862 | 0.004 | 0.018 | 46.07 |

| 6 | 6678.6 | 286 | 0.998 | 0.819 | 0.035 | 0.049 | 0.953 | 0.864 | 0.006 | 0.018 | 45.99 |

| 7 | 6949.6 | 283 | 1.000 | 0.821 | 0.035 | 0.049 | 0.953 | 0.864 | 0.006 | 0.018 | 45.92 |

| 8 | 7230.1 | 281 | 1.000 | 0.821 | 0.035 | 0.051 | 0.955 | 0.864 | 0.006 | 0.021 | 45.84 |

| 9 | 7510.9 | 278 | 1.000 | 0.821 | 0.035 | 0.051 | 0.955 | 0.864 | 0.006 | 0.021 | 45.77 |

| 10 | 5294.8 | 275 | 0.996 | 0.819 | 0.031 | 0.045 | 0.951 | 0.862 | 0.002 | 0.014 | 46.37 |

| Testing sample | |||||||||||

| 11 | 5010.3 | 272 | 0.996 | 0.819 | 0.031 | 0.045 | 0.949 | 0.862 | 0.002 | 0.014 | 46.12 |

| 12 | 4963.3 | 269 | 0.994 | 0.799 | 0.029 | 0.043 | 0.949 | 0.862 | 0.002 | 0.014 | 46.00 |

| 13 | 4756.3 | 265 | 0.994 | 0.799 | 0.029 | 0.043 | 0.947 | 0.860 | 0.001 | 0.012 | 45.95 |

In Table 4, σ1s expresses the stress at the upper edge of arch foot, σ1x denotes the stress at the lower edge of arch foot, σ2s is the stress at the upper edge of mid span arch rib, and σ2x represents the stress at the lower edge of mid span arch rib.

3.3.1. Data Preprocessing

To facilitate neural network identification, it is necessary to normalize the input data. The processing of data normalization in this part is identical to that in Section 3.2.1, so it will not be repeated here.

3.3.2. Model Training and Prediction

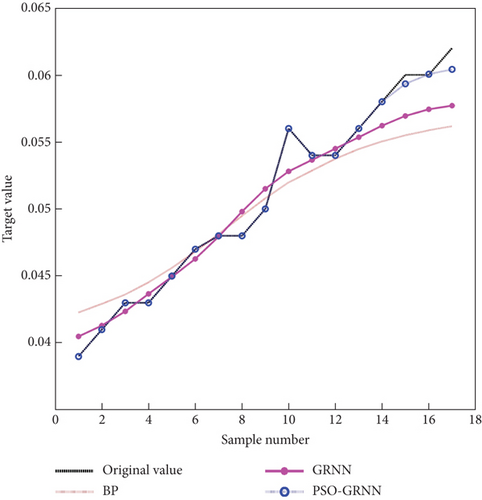

According to Table 4, when the horizontal thrust of arch foot and the tension of tied rod change, the stress of main arch rib steel pipe, the stress of main arch concrete, and the displacement of mid span change significantly. After normalizing the training sample data and testing sample data, a prediction model is built using MATLAB. The normalized training sample data is used to complete the prediction model training, and then, the testing sample data is substituted into the prediction model. The output data of the testing sample serves as the prediction result and is compared with the real value. To further compare the prediction performance of the PSO-GRNN model, three methods are used: the BP model, the GRNN model, and the PSO-GRNN model. The horizontal thrust of arch foot and the tension of tied rod serve as the input variables, and the stress at the lower edge of main arch concrete span, the stress at the lower edge of main arch rib steel pipe span, and the displacement of mid span serve as the output variables to establish the model for prediction. The prediction results are shown in Figures 11, 12, and 13.

As depicted in Figures 10, 11, and 12, after using the horizontal thrust of arch foot and the tension of tie rod as input variables, compared with the BP model and GRNN model, the PSO-GRNN model can still make a good prediction of the three variables, greatly reducing the prediction error. Table 5 presents the prediction errors and average accuracy of the stress at the lower edge of main arch concrete span, the stress at the lower edge of main arch rib steel pipe span, and the displacement of mid span of the three prediction models. It can be seen that the average prediction accuracy of the PSO-GRNN model is 96.706%, 98.531%, and 99.634%, respectively, which is 1.980%, 1.706%, and 0.340% higher than that of the BP model. Compared with the average accuracy of the GRNN model, it is improved by 2.262%, 1.632%, and 0.387%, suggesting that PSO-GRNN model has higher prediction accuracy.

| Category | Stress at the lower edge of main arch concrete span | Stress at the lower edge of main arch rib steel pipe span | Displacement of mid span | ||||||

|---|---|---|---|---|---|---|---|---|---|

| BP | GRNN | PSO-GRNN | BP | GRNN | PSO-GRNN | BP | GRNN | PSO-GRNN | |

| Error of 11 | -0.0001 | 0.0000 | 0.0002 | -0.0001 | 0.0000 | 0.0001 | -0.2135 | -0.2500 | -0.1732 |

| Error of 12 | -0.0001 | 0.0000 | 0.0006 | -0.0020 | -0.0020 | -0.0014 | -0.3483 | -0.3700 | -0.1628 |

| Error of 13 | -0.0020 | -0.0020 | -0.0005 | -0.0020 | -0.0020 | -0.0004 | -0.4125 | -0.4200 | -0.1696 |

| Average accuracy | 94.726% | 94.444% | 96.706% | 96.825% | 96.899% | 98.531% | 99.294% | 99.247% | 99.634% |

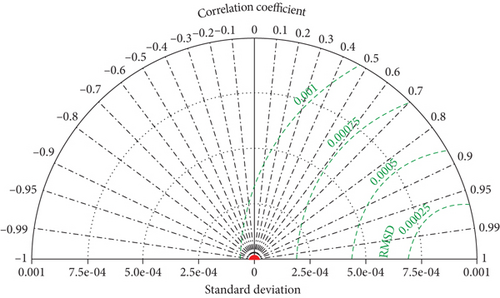

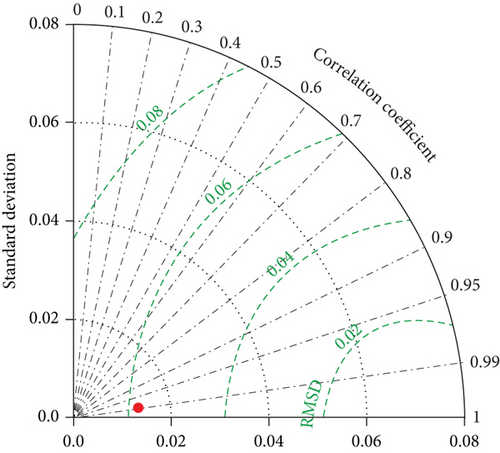

Similarly, the prediction performance of the three models was evaluated using four error indicators: MAPE, RMSE, R2, and NSE. The results are shown in Table 6, and the Taylor diagram of the PSO-GRNN model predicted results is shown in Figure 14. From the results, it can be seen that the PSO-GRNN model has the highest fitting accuracy, with R2 and NSE values close to 1, and MAPE and RMSE values are very small. Thus, the performance of the PSO-GRNN model is better than that of the BP model and GRNN model.

| Category | Stress at the lower edge of main arch concrete span | Stress at the lower edge of main arch rib steel pipe span | Displacement of mid span | ||||||

|---|---|---|---|---|---|---|---|---|---|

| BP | GRNN | PSO-GRNN | BP | GRNN | PSO-GRNN | BP | GRNN | PSO-GRNN | |

| MAPE | 0.236 | 0.167 | 0.128 | 0.184 | 0.152 | 0.118 | 0.216 | 0.173 | 0.077 |

| RMSE | 6.088 | 4.028 | 1.013 | 3.874 | 1.548 | 0.427 | 3.151 | 2.143 | 1.031 |

| R2 | 0.519 | 0.674 | 0.924 | 0.581 | 0.657 | 0.927 | 0.528 | 0.712 | 0.882 |

| NSE | 0.848 | 0.886 | 0.977 | 0.871 | 0.912 | 0.975 | 0.659 | 0.731 | 0.901 |

4. Conclusion

- (1)

In the construction control of large-span concrete-filled steel tube tied arch bridge, finite element analysis software is used to establish a calculation model, which can analyze the stress situation of the bridge. This article uses Midas/Civil 2020 software for finite element modeling of bridges and constructs a prediction model based on PSO-GRNN algorithm to predict the partial stress situation of bridges, simplifying the number of finite element analysis models and having high practical value

- (2)

By using the PSO algorithm to optimize the GRNN model, a PSO-GRNN prediction model is proposed. Z-score normalization is used to standardize the data, solving the problem of parameters falling into local optima in conventional GRNN models and improving the prediction accuracy of the PSO-GRNN model

- (3)

The average prediction accuracy of the PSO-GRNN model is higher than that of the BP model and GRNN model, and the prediction effect is better. By comparing MAPE, RMSE, R2, and NSE, it is shown that the PSO-GRNN model has the highest fitting accuracy. This indicates that the PSO-GRNN model proposed in this study is effective. The result of this study is consistent with the accuracy of Wang et al. [28] in predicting the health status of lithium-ion batteries using the PSO-GRNN algorithm, which further indicates that PSO-GRNN algorithm has excellent prediction ability

- (4)

The PSO-GRNN prediction model constructed in this article has a high fitting accuracy, but due to the small amount of training and testing samples, the number of training and testing samples will be further increased in the future to further improve the application of the PSO-GRNN prediction model. At the same time, we will continue to research and explore more optimization algorithms to improve the performance of prediction models

Conflicts of Interest

The authors declare no conflicts of interest regarding this article.

Authors’ Contributions

All the authors have accepted responsibility for the entire content of this submitted manuscript as an approved submission.

Acknowledgments

This research was funded by Key Problems in Science and Technology of Henan Provincial (222102320040).

Open Research

Data Availability

The data used to support the findings of this study are included within the article.