Fixed-Time Sliding Mode Control for Robotic Manipulators Based on Disturbance Observer

Abstract

A novel controller using fixed-time sliding mode (FTSM) and fixed-time disturbance observer (FTDO) is proposed to achieve trajectory tracking control of robotic manipulators. First, the mathematical model is established for robots with dynamic model uncertainties and external disturbances. An FTSM control strategy is presented where the integral terms of position errors are introduced into the existing sliding mode surface (SMS) to reduce the steady-state error of the system. The exponential form in the integral terms can provide an appropriate control force for tracking systems when the position errors are far from the sliding surface for a long time. Then, an FTDO is designed to obtain a precise estimation of lumped disturbances which can be used to weaken the impact of disturbances on the control accuracy. Finally, the fixed-time convergence properties of the tracking control system are demonstrated using Lyapunov stability theory. Simulation research is carried out to illustrate that the proposed control strategy has strong robustness and fast-tracking speed.

1. Introduction

With the expansion of the application range of robotics technology, the performance requirements for robotic manipulators are constantly improving. Consequently, the trajectory tracking accuracy of robots has important research significance [1–3]. In this regard, researchers have put forth an array of control algorithms, including fuzzy control [4], proportional integral differential (PID) control [5], sliding mode control (SMC) [6, 7], robust control [8], and backstepping control [9].

A learning algorithm controller based on the SMC theory was designed in [10], which achieves good tracking performance without considering the dynamic model of aerial manipulators. A variable universe fuzzy controller whose universe can be adjusted by contraction-expansion factor in real-time was presented to optimize the trajectory tracking effect of the system [11]. The dynamic model of mobile manipulators was adjusted, and the control laws of two subsystems were obtained based on the decentralized control method [12]. It is worth noting that these studies of tracking control for robotic manipulators did not adequately consider model parameter perturbations. However, SMC has a switching term, and its sliding mode dynamics can be designed, which has strong robustness to model uncertainties and external disturbances, so it is widely used in robot control. A terminal SMC is devised for flexible joint robots to eliminate the effects of lumped disturbances and estimation errors while ensuring system convergence within a finite time [13], and it is possible to suppress lumped disturbances and enhance the system’s robustness by modifying the control parameters. To enhance the flexibility of human-robot interaction, a finite time control method combined with super-twisted terminal SMC was employed to eliminate the problem of chatter in the system [14]. A continuous terminal SMC algorithm was proposed for servo systems in [15], which avoids the problem of replacing switch functions based on boundary layer methods and overcomes the disadvantage of high-order derivative discontinuity in high-order SMC. In [16], a nonsingular terminal SMC was proposed for the cable-driven manipulator, and the designed control scheme is model-free, which can avoid the uncertainty of the system model. In these three studies, the finite time control methods were introduced, and Lyapunov’s stability theorem was used to prove closed-loop stability and finite time convergence characteristics. A composite controller combining model tracking control strategy and robust adaptive terminal SMC was constructed in [7], which enables the robot to achieve high-precision tracking control of both directed curved-trajectory and undirected polyline-trajectory. In [17–19], variable structure control was proposed for tracking control of a six-degree-of-freedom robotic arm. Control laws were formulated based on their kinematic and dynamic equations, and experiments were conducted on a pseudoindustrial autonomous articulated robot to verify the feasibility of the proposed method. To improve the accuracy of the task, [18] also discussed the coupling effect between the joints of the robotic manipulator. An embedded controller for robot platforms is introduced in [19], which can analyze its transient performance and achieve stable state signal feedback in trajectory tracking control tasks.

The above control method can only ensure the asymptotic or finite time convergence of the robot system. The disadvantage is that the stability time depends on the initial conditions of the system and cannot be obtained in advance. On this basis, a SMC strategy combining fixed time control was considered. In contrast to typical finite-time control, regardless of whether the original condition of the system is near or far from the balance point, fixed-time control can ensure that the tracking error quickly approaches zero within a fixed time [20]. Non-singular fixed-time sliding mode (FTSM) control strategies for robotic manipulators were studied in [21, 22], and adaptive control was cited to estimate and compensate for disturbances, The closed-loop system’s error signals all converge in a fixed time, and the convergence time does not require any prior knowledge about the initial state. This scheme does not require coupling of uncertain boundary information and can avoid singular points, effectively reducing the phenomenon of chatter in the system. A FTSM control was proposed for robots with dynamic uncertainties and external disturbances in [23], which can completely eliminate singularity. The benefits of the planned control strategy’s quick convergence time and excellent tracking accuracy are confirmed by the simulation results. A control scheme combining inverse trigonometric function, adaptive control algorithm, and FTSM was proposed for manipulator systems with uncertain disturbances [24], and the designed controller can achieve faster convergence speed and higher accuracy.

The trajectory-tracking effect of the robotic manipulator is susceptible to interference from the external environment and unmodeled dynamics within the system. Therefore, the disturbance observer technology is introduced into the control law to form composite control, which estimates and compensates for the lumped disturbance. It can effectively improve tracking accuracy and ensure system stability. The fixed-time tracking design and the use of observers for interference estimates were studied in [25], and numerical simulations were used to confirm the effectiveness of the proposed method. An FTDO-based control scheme combining fixed-time control and an adaptive neural network was designed to address the dynamics and internal disturbance uncertainties of aerial robots [26]. A new form of composite controller combining fixed time disturbance observer and SMC was developed in [7], which can solve the problem of chattering and is suitable for nonlinear systems, such as robot systems and surface unmanned ship control systems. A disturbance observer was presented in [27] to estimate and compensate for joint position errors generated in robot milling. In [28, 29], An FTSM control method combining FTDO has been proposed, which can accurately estimate the lumped disturbance. In this research, a disturbance observer was constructed based on fixed-time theory to estimate uncertainties in the system. The designed FTDO ensures that the observation error converges within a fixed time, which does not require prior knowledge of the initial observation errors.

- 1.

In contrast to the method developed in [30], the integral terms with respect to the position error are introduced into the FTSM, which can reduce the steady-state error of the system. The integral terms of the sign function are added into the sliding mode surface (SMS) instead of directly using the sign function, which eliminates the problem of chattering in the error tracking. Further combining the fixed-time theory ensures that all tracking errors in the system converge to zero within a fixed time.

- 2.

The FTDO proposed in this paper can accurately estimate and compensate for lumped disturbances, effectively improving the tracking performance of the system. Meanwhile, the sig(⋅) function is introduced to avoid the problem of observation chattering.

The remaining work tasks are arranged as follows: Section 2 introduces the preliminaries and problem description. Section 3 presents the controller design without lumped disturbances and conducts stability analysis. The design of control algorithms and system stability analysis under bounded lumped disturbances are introduced in Section 4. Section 5 presents the numerical simulation results on a robotic arm with two degrees of freedom. Finally, the conclusion of the article is given in Section 6.

2. Preliminaries and Problem Description

2.1. Preliminaries

Notation 1. (⋅)T is the transpose matrix, |⋅| represents the absolute value, and ‖⋅‖ means the Euclidean norm. siga(x) = |x|asign(x), a > 0, x ∈ R, and sign(x) denotes the standard sign function shown as

Lemma 1 (see [31].)Consider continuous radial unbounded functions V : Rn⟶R+ ∪ {0}, and meet the following conditions:

- 1.

If any x(t) satisfies the inequality:

- 2.

If any x(t) satisfies the inequality:

2.2. Problem Description

Assumption 1. The nonlinear term f(t) is supposed to be constrained and bounded. The constrained force ϖi is bounded and satisfies , where is a positive constant.

Remark 1. In practical work, the forces that interact between the robot and its surroundings are mostly responsible for the external disturbance of the model. It has no effect on the system’s overall convergence; rather, it solely influences the estimated value or tracking error of the lumped interference during the operating time. In addition, the force f(t) is time-varying and bounded because of the constraints imposed by the robot’s physical structure. Then, we are aware that the robot’s joint position and joint velocity are related to the lumped disturbance ϖi = −M−1[JT(x)f(t) + τe]. We reasonably assume that the model error and disturbance are bounded because the system’s joint angles and velocities are bounded. Therefore, the above Assumption 1 is reasonable.

3. Controller Design Without Lumped Disturbances

Remark 2. The SMS used in [30] is . However, the SMS is altered in this article where the integration term is introduced into (11), which avoids oscillation caused by the direct use of the sign function on the sliding surface. Moreover, the integral terms are used to provide the necessary control force to enable the tracking system to rapidly approach when the position error is distant from the sliding surface for a long time; conversely, when the position error is close to the sliding surface, it slows down to reduce chattering.

Theorem 1. The designed tracking control law (13) enables the system to accurately track the desired trajectory xd within a fixed time T1.

Proof 1. Choosing the Lyapunov function V1as

Differentiating V1 leads to

From Lemma 1, the fixed time controller (13) can drive the tracking control subsystem to accurately track the desired trajectory and calculate the maximum convergence time T1.

Within the maximum set time T1, the sliding surface S can reach, i.e., S(t) = 0, . Furthermore, the tracking errors e1 and e2 will converge to zero along the SMS within a finite time. Based on the above analysis, the controller (13) can ensure that the robotic manipulator accurately tracks the given desired trajectory, namely, x = xd and . The proof is completed.

4. Control Design With Lumped Disturbances

4.1. Disturbance Observer Design

The actual robot system ((6)) has external disturbances and system uncertainties, which can affect tracking accuracy and reduce system control performance. Therefore, in this section, a disturbance observer is introduced to estimate the lumped disturbance and compare it with the actual disturbance. The system corrects the disturbance estimation value to achieve the goal of disturbance error approaching zero. The detailed design steps are provided below.

Step 1. To facilitate the design of the observer, we can design an auxiliary variable ξ ∈ Rn as follows:

Step 2. Define the observation error as , we can obtain

According to (22), it is evident that if ξ converges, then also converges.

In the case of Assumption 1, to prove that the designed FTDO is fixed-time stable, we select the following Lyapunov function

The derivative of time for V2 is

4.2. Controller Design

Theorem 2. In the presence of lumped unknown disturbances, the system error can be guaranteed to converge to zero within a fixed time T by the designed observer (21), SMS (26), and control law (28).

Proof 2. We consider the following Lyapunov function V3as

Differentiating V3 yields

Next, we conduct stability analysis on the closed-loop system and construct the following Lyapunov function V:

Taking the derivative of V yields

Remark 3. After the sliding stage, , combining (27), it can be concluded that . Within the maximum set time, the designed control strategy can ensure that the system can quickly track the desired trajectory within a fixed time during both the arrival and sliding stages. According to the above operation, we know that within the convergence time, the system can observe lumped disturbances. Within a fixed time T, the system can reach the FTSM surface S, and the tracking errors e1 and e2 will eventually approach zero. Therefore, the convergence time for the control system to reach stability from the initial state satisfies

5. Simulations

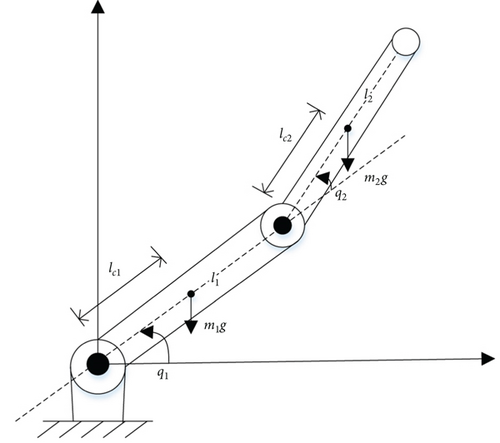

To demonstrate the effectiveness of the proposed control, simulation experiments were conducted on a robotic manipulator with two rotating joints in the vertical plane, as shown in Figure 1 [32]. mi and li are the weight and length of the link i, and lci is the distance from link i − 1 to the center of mass of joint i, i = 1, 2.

The parameter selection for the robot is m1 = 2.00 kg, m2 = 0.85 kg, l1 = 0.35 m, l2 = 0.31 m, I1 = 6.1 × 10−4 kgm2, and I2 = 2.0 × 10−4 kgm2.

The selection of the desired trajectory is the same as [32], xd1 = 0.14sin(0.5t), xd2 = 0.14cos(0.5t). We choose f(t) = [0.3sin(t); 0.3cos(t)] and τe = [0.1sin(t); 0.1cos(t)]. The simulation time is set to 40 s. The parameter values of the disturbance observer, SMC surface, and controller are shown in Table 1.

| Variable | Value |

|---|---|

| μ1 | 30 |

| μ3 | 5 |

| α1 | 7 |

| β1 | 5 |

| k1 | 100 |

| k3 | 2 |

| α3 | 5/3 |

| n | 5 |

| b | 9 |

| λ2 | 0.8 |

| μ2 | 4 |

| μ4 | 7 |

| α2 | 3 |

| β2 | 7 |

| k2 | 16 |

| k4 | 10 |

| m | 9 |

| a | 7 |

| λ1 | 1.2 |

| λ3 | 5 |

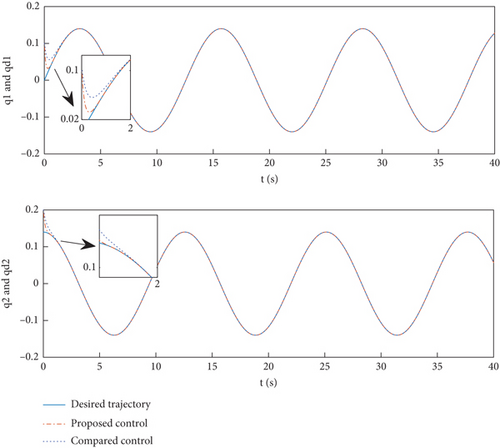

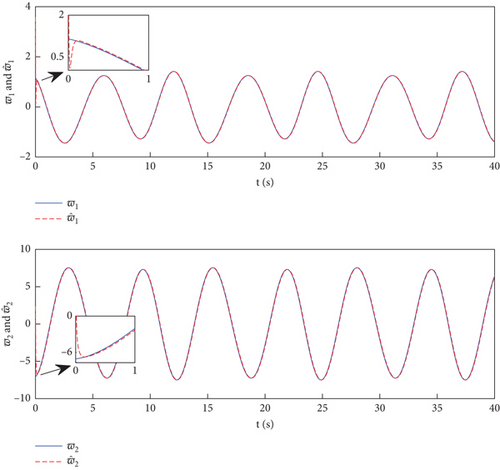

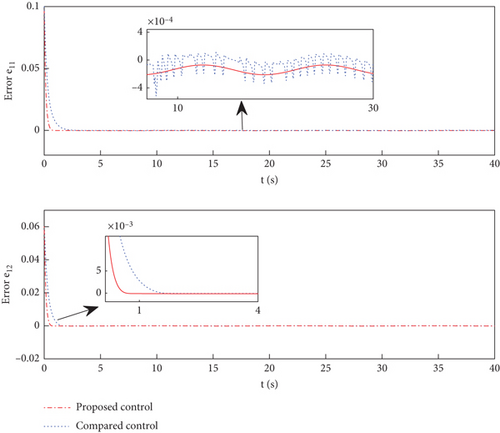

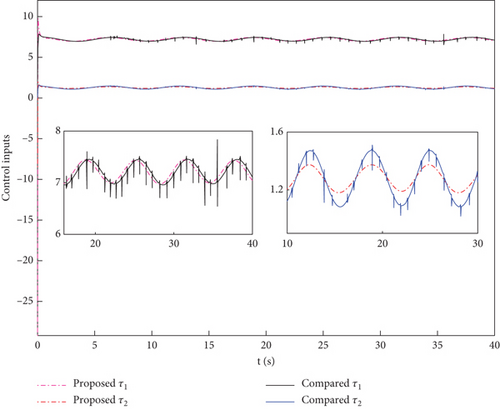

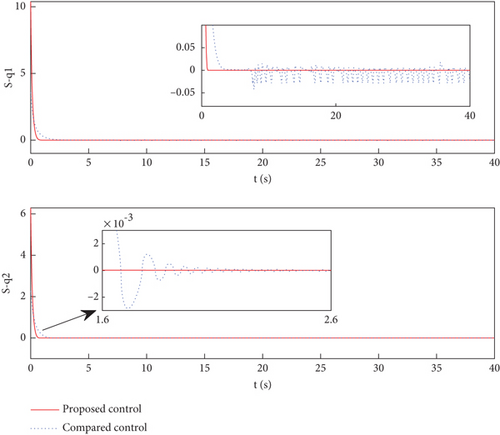

The results of the simulation are shown in Figures 2 and 3. Figures 2 and 4 illustrate the trajectory tracking and errors for two joints. From these two figures, we can see that both control design methods can effectively track the set desired trajectory. In Figure 4, it is evident that the tracking errors of e1 and e2 caused by the designed controller have higher accuracy than the control presented in [30], which proves that the added integral terms significantly reduce the steady-state errors of the system. The tracking errors can converge to zero within approximately 0.7 s with the proposed method, which is 58.8% faster than the comparative control. Additionally, the tracking error can be as small as 10−4 rad. The control inputs are shown in Figure 5. The proposed control input is smoother and without chatter, and this is because the integral terms of position errors are introduced into the sliding surface, which is a part of the control input. Figure 6 shows the response of variables S to the control scheme. The FTSM method was compared with the method developed in [30]. This reveals that the SMS in this article is smoother, and this is due to the SMS using the integral terms of the sign function, rather than directly using the sign function, which avoids system chattering. The disturbance true value ϖi and the observation value under the action of the observer are given in Figure 3, which demonstrates that the designed FTDO can achieve an accurate estimation of lumped disturbances.

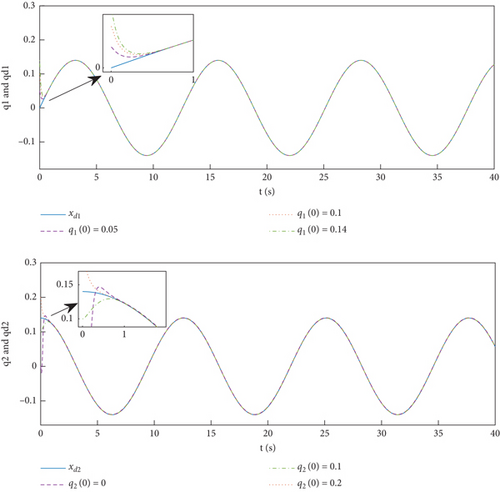

To prove that the time for the system to reach a stable state is independent of the initial state, we set the initial state as [q1(0); q2(0)] = [0.05; 0.1], [q1(0); q2(0)] = [0.1; 0.2], and [q1(0); q2(0)] = [0.14; 0]. The numerical simulation results are shown in Figure 7. It can be seen that under different initial conditions, the developed control algorithm can ensure the tracking of the desired trajectory within a fixed time, and the effectiveness of the designed control law is verified.

6. Conclusions

An FTSM control method based on FTDO was designed for trajectory tracking control of robot manipulators while considering the nonlinearity and uncertainty of the system. The stability of the designed controller and the fixed-time convergence of the observer were proven using the Lyapunov stability theorem. The comparison of simulation studies illustrates that the proposed strategy has a faster convergence speed and higher control accuracy. Then, the integral terms of the position error are applied to reduce steady-state errors, which benefit from providing an appropriate control force when the tracking error deviates or approaches the SMS. Moreover, the phenomena of chattering are lessened by adding the integral terms of the sign function to the sliding surface as opposed to employing the sign function directly. The designed FTSO can accurately estimate the lumped disturbance in the system and provide real-time compensation for the controller, effectively improving the robustness of the system. One of our future researches is to use optimization algorithms to adjust control parameters to improve control performance. Another task is to study the trajectory tracking control of dual-arm or multiarm robots and extend the proposed scheme to the aforementioned projects.

Conflicts of Interest

The authors declare no conflicts of interest.

Funding

This research was funded by the University Synergy Innovation Program of Anhui Province under Grant No. GXXT-2021-026, the Startup Fund for Distinguished Scholars of West Anhui University under Grant No. WGKQ2022050, the Smart Agriculture and Forestry and Smart Equipment Scientific Research and Innovation Team (Anhui Undergrowth Crop Intelligent Equipment Engineering Research Center) under Grant No. 2022AH010091.

Acknowledgments

This research was funded by the University Synergy Innovation Program of Anhui Province under Grant No. GXXT-2021-026, the Startup Fund for Distinguished Scholars of West Anhui University under Grant No. WGKQ2022050, the Smart Agriculture and Forestry and Smart Equipment Scientific Research and Innovation Team (Anhui Undergrowth Crop Intelligent Equipment Engineering Research Center) under Grant No. 2022AH010091.

Open Research

Data Availability Statement

All data utilized to support the findings of this paper are contained in the paper.