Synthesis and Food Applications of Resistant Starch-Based Nanoparticles

Abstract

Starch is recognized biopolymer because it is abundant in nature. Dietary starches are major energy source for various human civilizations, and it is obvious that they may also contribute to health in very particular ways. Resistant starch has got a lot of interest because of its possible health advantages (similar to soluble fibre) as well as its functional qualities. Resistant starch improves blood cholesterol levels, microbial flora, gastrointestinal tract function, the glycemic index, and helps with diabetes management. Aside from the significant health advantages of starch, there is an additional benefit that it has a smaller effect on food sensory characteristics than usual sources of fibre, such as grains, bran, or fruits. Moreover, when boiled, many starches form weak-bodied and unpleasant gels, which are influenced negatively by temperature, humidity, and storage duration. The present review article highlights resistant starch as a functional food, starch extraction method, preparation of starch nanoparticles, and nano- and microencapsulation of probiotics in detail.

1. Introduction

Starch is a well biopolymer that is prevalent in environment. It has piqued the curiosity of experts all around the world since it is biodegradable, renewable, and environmentally benign, and it has been extensively researched for usage in the pharmacological, food, and cosmetics sectors [1]. Starch is a chemical found in plants that is used to store glucose. It is made up of two different polymers: amylopectin, a branching molecule, and amylose, a linear molecule. Starch is a primary storage of carbohydrate and, after cellulose, the 2nd most prevalent polymer. In tubers (sweet potato and potato), immature fruits (mango and banana), unripe seeds of legume plants or cereal, and various other storage organs of plants, starch can be found in the type of granules. Starchy foods have long been utilized by humans and their predecessors. Over 50% of daily energy consumption for people in agricultural societies and about 25% of people in westernized civilization comes from starch, which is a key component of the majority of plant-derived meals and feeds as well as many industrial raw materials [2]. Up to 25% of the calories in a typical human diet come from starch, which may be converted to glucose by a group of enzymes called amylases and amylos glucosidases. Although starch is widely utilized in the food industry, it is insoluble in water at ambient temperature. In addition, a lot of starches when boiled form weak-bodied and unfavourable gels due to the adverse effects of temperature, relative humidity, and storage duration (retrogradation mechanism) [3]. Since native starches lack the qualities necessary to ensure the quality of finished food items, the food sector has been for a long period to enhance the physicochemical characteristics of starches. Because starch is broken down quickly in the human intestine, blood glucose rises quickly as well. This can cause chronic disorders such inflammation, oxidative stress, and impaired insulin sensitivity [5]. New technology and ingredients are being used more often as a result of growing customer demand for high-quality food items. Health issues (such as cholesterol, obesity, and cancer), variations in demographic characteristics, the desire for convenience, modifications to distribution networks, and pricing are some of the variables that have an impact on changes in consumer demand. These developments have led to a sharp rise in demand in new items, notably those that are convenience-oriented and produced utilizing cutting-edge technology, with high pressures [6].

2. Resistant Starch

A portion of starch known as resistant starch (RS) avoids breakdown of food with in intestine and moves intact through to the large intestine. After that, bacteria in the gastrointestinal tract ferment RS to create short-chain fatty acids (SCFAs). It was Englyst who first used the phrase “resistant starch” in 1982 [7]. The absence of leftover starch constituents seen in human wastes has led to the assumption that starch is totally absorbed by the human’s body. However, scientists have shown via in vitro tests that amylase does not hydrolyze all components of starch. Additionally, parts that are not digested are known as resistant starch (RS), which is a particular component of the starch molecule that resists enzymatic degradation, reaches the intestine, and almost completely enters the colon. In recent times, undigested parts have become a popular delicacy all around the world [8]. The potential health advantages and practical qualities of resistant starch have drawn a lot of interest. As a portion of starch that is robust to pancreatic-amylase breakdown, resistant starch travels from the intestine to the large intestine wherever it serves as a prebiotic for the gastrointestinal bacteria [9]. Both normal and abnormal patients have benefited from resistant starch’s positive benefits on fatty acid (FA) digestion, inflammation mitigation, and glycemic management [10]. SCFAs which are produced by the digestion process of resistant starch in the colon can control glucose homeostasis, protect colorectal cancer by red meat, promote postprandial lipid oxidation, and boost feelings of satiety [11]. Scientists have categorized resistant starch into four groups based on its structural traits, chemical modifications, the effects of cooking, or associations with lipids (RS1, RS2, RS3, and RS4). Each kind must be taken into account separately because to the variety in content, structure, and effects caused by different processing procedures. When RS enters the colon, it is fermented by bacteria in the gastrointestinal, mostly making the SCFAs acetate, propionate, and butyrate [12]. Although butyrate has been specifically recognized for improving health and is the short-chain fatty acids that is most elevated by RS ingestion, propionate and acetate can also have effects on wellbeing. Butyrate has a significant impact on gut health in humans, minimizing risk factors for colorectal cancer, decreasing inflammation, and enhancing gastrointestinal barrier activity [13]. Table 1 shows the physiological benefits of resistant starch.

| Physiological consequences | Preventive function |

|---|---|

| Micronutrient absorption has improved | Increased calcium uptake, osteoporosis |

| Regulation of glycemic as well as insulinemic actions | Diabetes |

| Enhanced satiety and decreased energy intake | Obesity |

| Better bowel role | Inflammatory bowel disease, colorectal cancer, ulcerative colitis, constipation, and diverticulitis, are all possibilities |

| Protagonist of prebiotics and culture | Healthy colon |

2.1. Resistant Starch as a Functional Food

Starch is categorized into four kinds based on the pace and degree of in vitro digestion (see Table 2). The first 2 categories are highly digestible starch (HDS, or the quantity of starch that is quickly digested and assimilated by enzymes in less than 20 minutes in vitro method) and slowly digestible starch (SDS, which could be entirely metabolized yet not as quickly from 20 minutes to 120 minutes) [18]. People are becoming more interested in functional food as their living conditions rise. Dietary fibre, as an incredibly significant raw dietary ingredient, has piqued the interest of nutrition and medical experts. Every country in the world has specific guidelines for daily fibre consumption. As a novel form of food additives, RS has the physiological role of dietary fibre as well as other benefits that dietary fibre does not have. Its fundamental properties are comparable to normal starch, and when added to food, it affects the flavour, texture, and sensory assessment. RS’s structure, production process, deuterium action mechanism, and health qualities have all been widely explored to date. Furthermore, a large amount of RS is employed as a dietary component in the food sector [19]. Many RS products are also on the market. Given the specific functional features and physiological advantages of RS, manufacturing and managing RS are simple, especially given the RS’s low water retention capacity [20]. RS functions similarly to dietary fibre. Colloidal RS4 nanoparticles derived from acid hydrolysis and cross-linking are appropriate for developing a fibre-rich beverage [21]. To guarantee that RS meets the functional needs of the beverage sector, the natural sources, mixed flavour, white colour, good viscosity ability and rheological qualities, and weak water-retaining capacity were identified [22]. RS is used as a texture modifier in a variety of baked goods, providing bread crumbs a desirable brittleness and softness [23]. According to Jain and Anal, the produced stability employing protein hydrolysates was improved with the inclusion of RS [24]. RS significantly increases emulsion emulsifying ability and slows oxidation process of lipid in food items. This deduction is supported by the published study [25]. Because of its enhanced viscosity, tiny particle size, high sticking temperature, and weak water-retaining capabilities, RS may also be employed as a thickening ingredient in soups and dairy products. Additionally, RS utilized as feed additives is a substitute to in-feed antibiotic, which can boost protein and energy utilization to raise animal development rate [26]. Owing to the physical boundaries generated by protein matrices and cell walls, RS1 is unavailable to enzymes for digestion. When contrasted to other varieties, it is less resistant to digestion. (1) RS2 is starches that are resistant to digestion owing to their crystalline form. (ii) RS3 is a retrograded starch generated after cooking and cooling starchy meals (e.g., pasta and potatoes). Amylopectin’s long, branching chains create double helices that gastrointestinal enzymes cannot catalyze the hydrolysis. (iii) RS4 is cross-linked, etherized, or esterified starch. Because of its tiny particle size, pale colour, excellent extrusion, mixed flavour, film-developing capabilities, high gelatinization temperature, low calorific significance (1.6-2.8 kilo calories per grams), and low water interaction ability, RS has great prospective as a functional component [27, 28]). Because of these qualities, RS has been effectively included into a wide range of foods, including baked goods, pasta, and dairy products, [29, 30]. RS has also been used to microencapsulate probiotics in dairy products [31] in an endeavour to boost viability, as well as fish oil to minimize oxidation as well as odour [32].

| Sources of food | Description | Lowered resistance by | Starch types | Small intestine digestion |

|---|---|---|---|---|

| Seeds and grains, whole or partially milled, pasta, and legumes | It is physically entrapped in a nondigestible matrix, making it unavailable for digestion in small intestine digestion | Chewing, grinding | RS1 |

|

| High amylose starches, raw potatoes, certain legumes, and green bananas | Type-B crystalline resistant granules that have not been gelatinized, slowly breakdown by alpha amylase | Cooking and food processing | RS2 | Small degree; very slower rate freshly prepared food is completely digested |

| Bread, cooked, and chilled potatoes, corn flakes, and foodstuffs that have been subjected to a lengthy and/or repeated wet heat treatment | When starch-comprising foodstuffs are cooked and chilled, retrograded starch is produced | Conditions of processing | RS3 | Slowly; to a limited extent digestion that can be reversed: reheating increases digestibility |

| Drinks and foodstuffs containing modified starches are high in fibre (certain cakes and breads) | A few chemically altered resistant starches and dietary components that have undergone industrial processing | In vitro digestibility is less susceptible | RS4 | Can withstand hydrolysis as a consequence of a chemical change |

3. Starch Nanoparticles

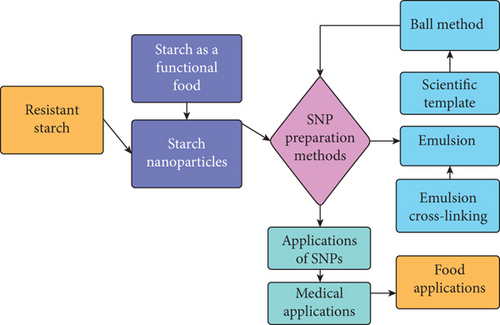

Because of its significant specific surface area and quantum size impact, nanoparticles have been one of the effective and interesting in recent times. Due to their biodegradability, biodegradable nanoparticles are extensively employed in biotechnology, medicine, food, and other sectors [35]. SNPs have several features that make them appropriate for use as bioactive components in meals, including better water dispersibility, high specific surface area, small size, low toxicity, low immunogenicity, and high biocompatibility [4]. Furthermore, resistant starch nanoparticles have the benefit of being resistant to breakdown by digestible enzymes in the upper gastrointestinal tract (like amylase). As a consequence, RS nanoparticles have the ability to be used as prebiotics, colon-specific delivery methods, and bioactive elements [36]. Because of their mechanical qualities and renewable form, these starch nanoparticles have been extensively employed in food packaging [37, 38], plastic fillers, treatment and diagnosis of heart diseases, and medication administration [39, 40]. Figure 1 shows the preparation methods of starch nanoparticles and their applications.

3.1. SNP Preparation Method

Starch nanoparticles are resistant to enzymatic hydrolysis owing to their compact shapes and significant level of crystallinity. As a result, they are a novel type of RS that may be used as a functional component in meals and other goods. RS nanoparticles offer certain significant benefits as functional components in meals as compared to regular resistant starch, including their tiny size, high surface-to-volume ratio, strong adsorption characteristics, and superior water dispersibility [41]. RS nanoparticles might be used as amylase inhibitors and medication delivery vehicles, in addition to their intrinsic prebiotic properties comparable to soluble dietary fibres. As a result, the creation of RS microparticles has gained increasing interest.

3.2. Emulsion

Through the interaction of two phases—an aqueous phase comprising the soluble polymers and an organic solvent which is completely or partially miscible in water—an emulsion is created. The two stages are then vigorously stirred together using an ultrasonic homogenization, such as microfluidization or mechanical homogenizer, to create an emulsion. To sustain the emulsion, a surfactant must be present. The agitation-induced droplets serve as nanoreactors to cause the regulated crystallization of starch within the shape of nanoparticles [42]. Emulsifiers reduce the surface pressures between the two nonmiscible fluids, minimizing the repulsive force between the two fluids and so reducing the adhesion between constituents of the same fluid, which is the concept on which the process of emulsion is developed [43].

3.3. Emulsion Cross-Linking

It has been claimed that SNPs were created using an emulsion cross-linking process. In this method, an aqueous layer containing cross-linking reagents is combined with another liquid containing dissolved starch. The combination is then introduced into an organic or oily phase, while emulsifiers are still present. Small nanoparticles are produced by a cross-linking process within the liquid droplets of this W/O emulsion. The particles produced by this emulsion cross-linking method are, however, rather big and on the microscopic scale [44].

3.4. Scientific Template

This technique is particularly useful for manufacturing porous or hollow particles. Until recently, hollow nanoparticles (HNPs) were created by producing a void space within a solid precursor using a range of physical and chemical approaches like nozzle reactor techniques, phase separation, emulsion polymerization, and sacrificial template method [37, 45]. The hard templating approach is one of the simplest and most widely used methods [46]. This method usually entails covering a substance that will serve as a prototype with a composite matrix, in this example starch, and then gradually removing the template component unless a hollow particle are formed [47].

3.5. Ball Method

Ball milling is one of the most dependable methods for producing nanomaterials without the use of additives or the need for a subsequent step of dehydration to retrieve the nanoparticles. The ball milling method has been studied over time for the nanoreduction of various polymeric substances, especially starch [4], cellulose [26], and protein-based polymers [48] for Appl. Sci. 2021, 11, 4547 9 of 26 different applications. This procedure can be carried out either wet (with solvents) or dry (without solvents). Milling happens as a result of mechanical action between the crushing medium, like balls of varying sizes, and the powdered material. Typically, the grinding balls and the container are constructed of the same exceptionally hard substance (corundum, stainless steel, and zirconia). The rotational movement of the bowl, as in a planetary ball mill, provides mechanical energy to the system. Wet ball milling is also regarded a green chemical technique because it does not need high temperatures (conserving energy) and uses little solvents [49]. Acid hydrolysis is a mechanism that may be classified into three stages depending on the activity rates involved: slow, rapid, and extremely slow. SNPs are commonly produced by a sequence of stages utilizing the acid enzymatic hydrolysis: (i) the starch is blended by the acid; (ii) this solution is heated for a fixed period of time while being persistently stirred; (iii) the consequential suspension is rinsed with distilled water with consecutive centrifugation until neutralisation is attained; and (iv) the suspension is kept in the fridge for a set duration of time [50].

4. Applications of SNPs

4.1. Medical Applications

Cancer treatment is one of the key medicinal uses for SNPs that are possible. In a recent research, Alp et al. [51] showed the benefits of encapsulating anticancer drugs in polymeric nanomaterials for increasing the drug’s solubilization, delaying the onset of cytotoxicity, and guarding against fast systemic metabolism. The researchers tested the encapsulated medication on MCF-7 breast carcinoma cells to gauge its efficacy. The evidence showed that encapsulating CG-1521 in SNPs increased anti-MCF-7 cell functional effectiveness and recommended that additional hormone-dependent malignancies could benefit from this encapsulation method [51]. Additionally, Yang et al. [52] conducted in vitro studies using synthetic, antibiotic-loaded SNPs. They used MTT tests to compare normal hepatic cells (AML12) versus liver hepatocellular lines (HepG2), and the results showed that SNPs had remarkable bioactivity for both types of cells. Moreover, due to direct engagement with carcinoma cells, the free-drug showed stronger antitumor behaviour than nanoparticles attached to Hepg2, even while loaded SNPs demonstrated a slower drug discharge. But at the other side, researchers also showed that for the various antibiotic doses investigated, AML12 cells had a greater vitality than Hepg2 [52]. SNPs have been shown to be effective as medication delivery methods by Wang et al. [53]. Rats were used in the investigations, and serum specimens were taken for examination. The drug or drug-loaded SNPs, in addition to the drug topically on the resistant starch, were administered orally. The average values discovered for the particle residence time did not differ considerably from those of the unprocessed paclitaxel. It was determined that the method used to prepare SNPs had a significant impact on the bioactivity of paclitaxel and that using SNPs had a greater impact than loading the medication directly onto starch. As a result, creating SNPs is a successful way to boost paclitaxel’s bioactivity [53]. Some investigators also conducted studies to assess the performance of SNPs packed with pharmaceuticals to confirm their usefulness as carriers of drugs within a very broad clinical application range. A histopathological research on the skin of rat was carried out by El-Naggar et al. [54] to determine if the manufacturing was accepted without producing irritant symptoms. Rodents’ skin was covered with a gel containing the medication diclofenac sodium that was incorporated with cross-linked SNPs, and the outcomes were matched to a control group in which the rodents’ skin was not coated. Last but not least, the study showed that the drug-loaded SNPs had no negative effects on the rodents’ skin, making them an excellent treatment option for rheumatoid illnesses and also other chronic inflammation conditions [54].

4.2. Food Applications

Ahmaad et al. [1] have investigated the discharge of catechin from SNPs for food uses in order to maintain the qualities of the beneficial chemical during simulating intestinal and stomach environments. The SNPs aided maintain catechin’s bioactive characteristics during in vitro digestion pathway by shielding it from the harsh stomach environment [1]. Ahmad et al. [55] also conducted in vitro tests on the probiotic loaded SNPs’ survival. Utilizing both simulating gastric juice and synthetic intestine liquid, the investigation was conducted under simulated gastrointestinal as well as processing circumstances. Although it was demonstrated that the nanoparticles were quite tiny to incorporate the probiotics within them, they were nonetheless directly discharged into the simulated gastrointestinal solutions, which led to cell damage owing to the severe climates of such environments, leading to the conclusion that SNPs are not excellent probiotic delivery systems [56]. Various food simulators, a few of which were designed to imitate high hydrophilic meals and many others and highly lipophilic meals, were utilized to examine curcumin outflow patterns in a current research by Nieto-Suaza et al. [57]. The investigators came to the conclusion that lowering the polarity of the SNPs might limit the emitted curcumin, which was preferred in lipophilic compounds [57]. The in vitro emission of SNPs coated with polyphenol in simulating intestinal and stomach fluids was also studied by Liu et al. [52]. This research demonstrated continuous polyphenol release patterns from SNPs and demonstrated that SNPs might be intriguing and effective nanocarriers for protecting bioactive substances from harsh conditions and controlling their release [58].

4.2.1. Water Chestnut Starch

Nontraditional food sources have received a great deal of notice in recent years since they are employed as bioactive components in innovative food creation and food formulations. Water chestnut (Trapa natans L.), a member of the Trapaceae family, is an aquatic warm-season crop that floats on the surface of lakes and ponds. It is an aqueous angiospermic plant that thrives in fresh water wet areas, lakes, ponds, swamps, and slow portions of rivers and freshwater or brackish estuaries. According to Hummel and Kiviat [59], water chestnut harvesting area worldwide is 603,076 hectares, with a total production of 2327495 tonnes [60]. Water chestnut is frequently referred to as “Singhara” in Pakistan. The water chestnut kernel contains vital minerals, proteins, and carbs. Dried water chestnut weighs about 100 g protein (10.8 percent), moisture (7.3 percent), fibre (6.4 percent), fat (1.85 percent), iron (3.8 mg), ash (8.5 percent), calcium (102.8 mg), and phosphorus (325 mg) are the other macronutrients [55]. In terms of dry weight, the water chestnut’s starch content ranged from 85 to 97.4% [62].

5. Probiotic

The word “probiotic” is Greek in origin and translates to “for life.” For “life,” we mean any element or creature that helps the host maintain good health. Probiotics were defined by the WHO and FAO as “live microorganisms that, when provided in suitable proportions, impart a health benefit on the host” in 2002. Probiotic bacteria have been shown to have a number of positive effects, including (a) improving food products’ nutritional value, (b) regulating and lowering serum cholesterol, (c) strengthening the immunological system, (d) trying to prevent gut infectious diseases as well as reducing antibiotic-associated diarrhoea, (e) lowering symptoms of lactose intolerance, (f) lowering the risk of colorectal cancer, and (g) enhancing the breakdown of gliadin versus celiac in gluten-containing foods that are dependent [63]. Individuals are interested in ingesting goods that include probiotics because of these capabilities. Products containing probiotics standout among the goods with health claims that have been created and promoted in the media in recent years [64]. Due to these delivery systems’ negative health implications, marketing campaigns attempting to produce innovative functional food items have been launched. Probiotics can be found in a variety of commercially available delivery modalities, including food items (such as dairy, processed meat, vegetables, juices, and cereal-based products), dietary supplements (tablet, liquid, pill, and in powder form), and medications. Over time, the meaning of the term “probiotic” has evolved and become more inclusive. Although most researchers agree with the definition given by FAO and WHO, additional definitions have recently been introduced to the probiotic vocabulary, including “paraprobiotics” (probiotic inactivated cells) and “postbiotics” (probiotics’ beneficial metabolites). Therefore, research has demonstrated that Lactobacillus species are common in the atmosphere and found in a variety of surfaces, like water, soil, and plants, as well as decayed cells (either intact or cell extracts/ruptured cells). Additionally, Lactobacillus spp. are naturally occurring commensal occupants of the female vaginal tract, GIT, and oral cavity [65]. Lactobacillus rhamnosus GG (LGG) (ATCC 53103) is a probiotic now being utilized in methodological approaches for cancer treatment [66]. The name of the species is derived from LGG’s biochemical property of rhamnose metabolism and fermentation, which is used to distinguish this species of Lactobacillus. A variety of techniques, PFGE characterization of L. rhamnosus GG, comprising species-specific PCR, phage type, proteome characterization with the utilization of 2D-DIGE, and culture techniques (by means of MRS growth agar medium), are used to identify Lactobacillus spp. Some L. rhamnosus strains have positive impacts on the body that called them as probiotics. In particular, LGG can successfully adhere to the gastrointestinal mucosa and survive stomach acidity and bile salts. The power of the bacteria to create antistress proteins, which increase its capacity for survival in intestinal movement after oral ingestion, results in its ability to tolerate acidity of stomach and bile salts [66]. Exopolysaccharides with high galactose residue content and particular sticky pili on the bacterial wall both promote adhesion to the intestinal membrane. The activation and production of various cytokines, including IL-12, IFN-, IL-10, IL-6, TNF-, and IL-1, as well as a specific protein, p40, secreted by L. rhamnosus GG cells that can lessen the inflammatory process and programmed cell death of intestinal epithelium, account for the impact on the immune response. In a later section of the paper, it will be discussed how other apoptosis inhibition pathways are connected to the control of cyclooxygenase-2 (COX-2). As a result, LGG is well understood and is renowned for a variety of anti-inflammation actions. Therefore, therapy with LGG may lower the incidence of colon cancer in animal models by regulating the gastrointestinal microbiota and downregulating proinflammation chemicals. First discovered in a healthy adult’s faecal sample in the late 1980s, LGG has now had its whole genome sequence thoroughly described and registered. In specific, a study recognized LGG-specific islands comprising genes that code for 3 secreted LPXTG-like pilins (spaCBA) but a pilin-specific sortase infamously involved in the pathways of adhesion to the intestine-epithelium through contrast of the genomic sequences of Lactobacillus species include LGG. It satisfies the probiotic selection criteria, which include strong in vitro adhesion, survival through the GIT (bile and gastric acid), and propensity to make colonies with excellent intestinal persistence. Additionally, the cellular metabolites may have a substantial negative influence on human health [67].

6. Encapsulation of Probiotic

Encapsulation may be thought of as a technique for putting components into capsules before putting them into a system. Probiotics can be packaged as powder formulations to protect living microorganisms, increase their stability, and provide advantages for targeted distribution [68]. Encapsulated materials can be created by packing bioactive compounds such as enzymes, antioxidants, polyphenols, and micronutrients into wall substances. Encapsulation technique is referred to as microencapsulation (from 3 to 800 m) or nanoencapsulation depending on the particle size (from 10 to 1000 nm). By protecting bioactive chemicals from harmful surroundings and delivering them directly to the target location, nano-/microencapsulation can increase their bioavailability [69]. Encapsulation is frequently utilized in a number of food and nutritional purposes to deliver food components just where they are needed [41]. Functional ingredients are shielded from harsh process parameters during food security by being encapsulated, which also improves food safety by better hindering microbial growth and increase sensory quality by covering up unpleasant flavours (such as the bitterness of polyphenols) [12]). The bioavailability of bioactive compounds during human digestion can be increased by encapsulating bioactive substances. The encapsulation increases the bioactive ingredients’ water solubility, safeguards them from adverse circumstances in a specific area of the digestive tract (such as the stomach), and emits them in a targeted area (such as the intestine) for improved human absorption [70, 71]. For instance, amylose inclusion structures enhanced the in vivo efficacy of genistein (a type of isoflavones) in a rat model [70].

7. Microencapsulation

The technique of microencapsulation involves packing tiny amounts of solid, liquid, or gas (active core) into a secondary substance (encapsulant) to create a capsule (microcapsules have a size range between 1 and 1000 nm, while nanocapsules are in the submicron range). The encapsulation of essential oils, colorings, flavours, sweeteners, and microbes is just a few examples of the many uses for microencapsulation in the pharmacological, agricultural, medical, and food sectors. In the food sector, microencapsulated substances may shield essential molecules from the impacts of the environment (heat, oxygen, moisture, and light). The creation of probiotic encapsulates uses a variety of microencapsulation processes.

7.1. Emulsion Technique

A liquid is dispersed into another immiscible liquid to create an emulsion. Probiotic cells are encapsulated when they are added to the dispersion liquid [13]. The connection and association between the phases of discontinuity and continuity are the foundation of this approach. To be more precise, the procedure entails dispersing the cells in a little amount of a suspension of a polymer based on water (dispersed stage). It is then added to a sizable amount of oil and organic stage (continuous phase) and mechanically homogenized with the help of a surfactant, and a water-in-oil emulsion is created as a result. Gel beads inside the oil phase are produced as the water-soluble biopolymer becomes insolubilized and are collected by centrifugal or filtration. According to the properties of the supporting material being employed, the insolubilization method differs [72]. It can be started by chilling the emulsion or adding a cross-linking substance to it [73].

7.2. Extrusion Technique

Probiotic cells are injected into hydrocolloid components like carrageenan and alginate resulting in their physical encapsulation [74]. It is a common and well-known method that entails pushing a solution having the cells through nozzles or other small holes while using the proper droplet-generating equipment [13]. A biopolymer solution is initially combined with the bacterial culture to make a suspension [75, 76]. The finished liquid is extruded under high pressure through a nozzle, and the resulting droplets are collected in a bath of gelling liquid (most frequently a CaCl2 solution). The cells are confined in a grid in three dimensions created by because of the polymer’s ionic cross-linking, and gel beads are generated as a result [75]. The size of the generated microspheres is influenced by a number of variables, including the viscous and fluid velocity of the polymer solutions, its concentration and temperature, the orifice’s diameter, and its drop altitude or distances from the cross-linking solution.

7.3. Spray Drying (SD)

One of the most common methods of microencapsulation is spray drying (SD). The mixture of heat and mass transfer from the air to the atomized droplets and back is its fundamental idea [37]. Probiotics are emulsified or dispersed in an aqueous solution of a carrier components in the process. The liquid combination is then atomized through a nozzle or spinning wheel and evaporated by making contact with hot air or gas [75–77]. The carrier acts as a defensive agent against abrasive elements during storage and transit through the digestive tract while encasing the cells (Huang et al. 2016). Using a cyclone or bag filter, the dry particles are removed from humid air and gathered [76, 77]. Probiotic properties (growth phase and probiotic strain), dryer qualities (drying time and temperature type of atomization), feed character traits (carrier material and its intensity and particular conditions applied: oxidative, mechanical, or osmotic), operational conditions (feed rate and drying temperature), and storage conditions are the main variables that can impact the method’s efficiency [76].

7.4. Freeze Drying (FD)

For heat-sensitive constituents, such bacterial cells, freeze drying (FD), also described as lyophilization or cryodesiccation, is the most common drying technique. It depends on water freezing and then sublimating under vacuum from the solid/frozen state into the gas state [76, 77]. Probiotics are negatively impacted by FD because it alters the structure of sensitive cell proteins and the condition of cell membrane lipids [78]. To solve this issue, it has been suggested using probiotics combined with cryoprotectants like as polymers, sugars (trehalose, lactose, maltodextrin mannose, and fructose), honey, milk, polyols (sorbitol), and amino acids (monosodium glutamate) [79]. Different cultures have varying degrees of cryoprotection [80]. Additionally, according to reports, some probiotic strains have great viability after freeze drying because of specific variations in the strains’ properties, such as surface area, cell wall, and membrane composition [80]. The immobilized cell technique is also a potential solution for viability problems [81].

8. Conclusion and Future Perspectives

Starch-based nanoparticles have generated a lot of attention recently because of their tiny size, excellent biocompatibility, environmental friendliness, and prospective uses in meals, drug delivery systems, and biodegradable edible films. RS can be used as an enzyme-responsive carrier because it can be enzymatically degraded into glucose in vivo, unlike nonstarch polysaccharides. Higher adsorption properties, water dispersibility, small size, and high surface-to-volume ratio are only a few of the major benefits that RS nanoparticles offer as functional food components and can be prepared by using extrusion, cross-linking, ball milling method, and scientific template methods. The solubility of the nanosized starch particles, as well as their bioaccessibility and bioavailability in vitro or in vivo, is significantly increased by their ultrafine structure and large surface area. The use of derivatives of starch nanoparticles as drug delivery platforms is gaining popularity recently because of their biocompatibility, enhanced mechanical and absorption characteristics, and flexibility in functional qualities. Similar pharmacological and physiological functions are also carried out by resistant starches, such as endorsing the development of a healthy gut flora, improving mineral absorption, lowering the risk of colon cancer, and reducing the levels of blood sugars etc. However, further research is still required to determine efficient ways to increase the RS content in various types of starchy foods and to clarify the effects of increasing RS levels on food quality (such as appearance, texture, and mouthfeel). Furthermore, research is also needed to determine the gastrointestinal destiny of various RS nanoparticle types in the human body.

Conflicts of Interest

All authors have affirmed zero conflict of interest.

Acknowledgments

The authors are thankful to the Government College University, Faisalabad, and Kampala International University, Kampala, for the provision of the facilities used for this study.

Open Research

Data Availability

Any additional data is available on request, although all the relevant data has been provided here.