Research on the Determination Technology of Key Position of Sealing Holes for Gas Extraction Drilling in Zhangcun Coal Mine

Abstract

In view of the problem of how to determine the position of the sealing hole and increase the concentration of gas extraction, this article proposes the use of a high-pressure gas attenuation method to test the key sealing position and the comparison test of the sealing method using the new sealing position and the traditional sealing position, proposes a method to determine the range of the coal seam roadway loosening belt by measuring the pressure attenuation, and develops a set of devices for rapid determination of the range of the loose belt. Through the field test in Zhangcun Coal Mine, it is shown that when the sealing range is 7.5 m∼18 m, the best effect can be achieved, and when the sealing length is greater than the loose belt, the extraction concentration is higher, and the concentration attenuation and long drilling life are long.

1. Introduction

In China’s primary energy consumption structure, coal accounts for about 70%, and under the goal of a low-carbon economy, it can still account for about 66% of primary energy consumption by 2020. Therefore, for a long time to come, coal will remain the dominant energy source in our country [1–5]. In coal mining, sealing holes also occupy an important position, and the sealing method and sealing depth of sealing holes determine the sealing quality and extraction effect [6, 7]. Before sealing the hole, in order to clarify the root cause of the air leakage in the drilling rupture area, the damage to coal rock and the gas seepage are issues that we must consider [8]. In hydraulic fracturing, the height growth of fractures is mainly affected by ground stress, and the fracture toughness of rocks inhibits the growth of fracture height to a certain extent [9]. Liu et al. proposed a coupled model of a thermal-water-mechanical system that considers fractal fracture deformation [10]. Xue et al. established a coupled model of gas pumping and groundwater loss and found that the permeability of coal seams increased with the distance from the borehole [11]. Brittleness is an important feature of rocks, and highly brittle coal has a good production capacity and final recovery after fracturing. Based on statistical damage theory and the energy evolution law of coal, Li et al. established a mathematical model of coal brittleness and proposed a brittleness evaluation method for coal [12].

In terms of sealing holes, there are continuous studies on sealing technology [13–19], sealing process [20, 21], sealing method [22, 23], and sealing materials [24] in order to achieve better sealing quality and sealing effect. At present, many people at home and abroad have studied the aspect of sealing holes, and Hao et al. have established an elastoplastic model that considers the plastic softening and expansion characteristics of coal bodies and believed that the main factors controlling the shortest sealing hole depth are the initial ground stress, the strength of the coal body, the supporting stress of the roadway, and the roadway size [25]. Yang analyzed the microstructure of gas-containing coal bodies and the law of gas transport inside the coal body, elaborated the reasons for the attenuation of gas concentration in the extraction drill hole, and proposed that the sealing depth of the extraction drill hole should exceed the surrounding rock loose circle of the roadway and the sealing hole length should be greater than the limit extraction radius of the gas extraction drilling hole [26]. Li et al. proposed a reasonable hole sealing depth test method for pumping and drilling, which borrowed the principle of the bundle method [27]. Wang et al. used the self-made multifield coupled coalbed methane mining physical simulation test system to study the influence of drilling position on gas flow characteristics during the extraction process and found that the stress concentration area will have a certain barrier effect on the gas flow in the coal seam, and when using a single drilling pressure relief area for extraction, the gas pressure drop gradient is large and the extraction effect is better [28]. Jia believed that the sealing length of the pumped gas drill must exceed the width of the crevice of the surrounding rock of the roadway, so as to avoid the underground air entering the extraction drill hole and increase the gas extraction concentration of the drilled hole [29]. Liang et al. optimized the sealing parameters for different coal mines and increased the gas extraction concentration [30, 31].

When many mines in China arrange the sealing parameters of gas extraction drilling holes underground, they usually rely only on daily experience to determine, but due to the complex geological conditions of the coal seam itself and the increase in the depth of mine mining, the sealing parameters of gas extraction drilling determined by experience cannot always be reasonable, and there are still many related problems that need to be solved urgently. Therefore, the study of reasonable sealing parameters for downstream gas extraction is of great practical significance to ensuring the sealing quality of gas extraction drilling, effectively improving the efficiency of coalbed methane extraction, and guiding the prevention and control of coal mine coal and gas prominence.

2. Project Profile

The site of this test is Lane 2802 of the No. 3 Coal Seam of Zhangcun Coal Mine, located in the south of the 28 mining area. The section of the main lane of the 2802 roadway is a 5.4 × 3.5 m (width × height) rectangle, the row spacing is 1 m, and the area of the boring section is 18.9 m2. The construction length of the 2802 roadway comprehensive excavation is 2050 m (28 belt lanes − digging and cutting eyes), and the construction depth of the drilling yard is 4 m.

The overall east of the 2802 roadway is high in the west, and the height difference is about 76 m. The middle and eastern parts of the 2802 roadway tunnel boring area basically show a single oblique structure, with a slope of 2°∼15° westward inclination; 2802 laneway west develops a one-way oblique structure and a dorsal oblique structure, which is inclined to the northwest, and the two wings’ inclination angle is 2°∼6°; the 2802 roadway reveals that its axial position is about 1192 m east of 28 belt lane; the western anticline tilt is 330°, the two wings’ inclination angle is 4°∼8°; the 2802 roadway reveals that its axial position is about 1650 m east of 28 belt lane.

The gas content of the 2802 roadway is predicted to be 8.71∼10.32 m3/t, the gas outflow during the tunneling period is 0.7∼2.2 m3/min, and the gas outflow during the 2802 roadway is predicted to be 1.8∼5.1 m3/min. 3# coal dust is explosive, the flame length is 20 mm; 3# coal seam is a nonspontaneous combustion coal seam; the ground temperature is 15°C∼17°C. During the excavation process, the mining depth was increasing, and the CH4 content of the 3# coal seam showed an increasing trend.

3. Field Testing by High-Pressure Gas Attenuation Method

3.1. High-Pressure Gas Attenuation Method Test Principle

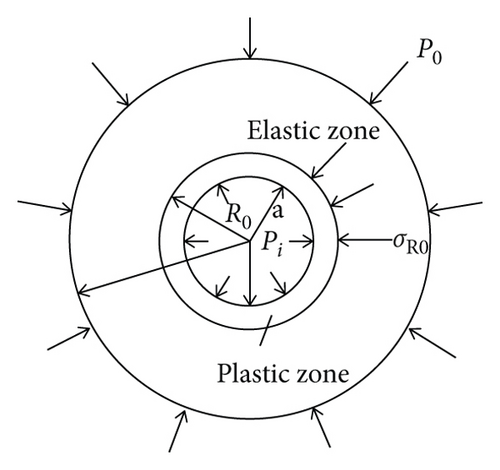

The surrounding rock loosening zone refers to the excavation of the roadway, the surrounding rock stress changes from three-way to approximately two-way, when the compressive strength of the surrounding rock decreases to less than the redistributive stress, the surrounding rock ruptures, gradually forming a loose zone, and because the surrounding rock mass in this area has yielded, it is also called the plastic loose belt, referred to as the loose belt. The internal stress and strength of the loosening belt have decreased significantly, the crack expansion has increased, the volume has increased, and there has been a significant plastic slip. After the excavation of the roadway in the rock formation, the stress distribution around the roadway is the loosening zone (plastic zone), the stress concentration zone (elastic zone), and the original stress zone (elastic zone), the plastic zone, and the elastic zone around the circular roadway are shown in Figure 1, where P0 is the thick rock stress, P1 is the support reaction force, a is the radius of the roadway, R0 is the radius of the plastic zone, and δR0 is the internal pressure.

PC is when the injected gas volume and gas temperature are constant to the drill hole closed air chamber after the injection of gas will reach an equilibrium, so that PCVC = PPVP, because PCVC is a fixed value, and as the gas in the air chamber continues to diffuse into the crack around the borehole to achieve a new equilibrium, so that the balanced volume VP = VC + VL, according to the stable equilibrium pressure PP measured after reaching the equilibrium, you can get VL = PCVC/PP − VC. By moving the sealing position and changing the sealing length for multiple tests, the maximum equilibrium pressure Pmax can be obtained, and the smallest crack volume at this time can be calculated, which is Vmin = PCVC/Pmax − VC. It can be seen from the theory that the volume of the fracture in the loose zone is more unstable than in other positions, and the fluctuation of this position is large, and the volume of the fracture in other positions is basically unchanged. Therefore, the range of the loosening belt can be determined by analyzing VL, the area with smaller cracks can be found, and the position of the sealing section and the length of the sealing segment can be determined.

PC is the initial gas pressure, unit Pa; VC is the initial gas volume, unit m3; PP is the equilibrium gas pressure, unit Pa; VP is the equilibrium gas volume, unit m3; VL is the fracture volume, unit m3; Pmax is the maximum equilibrium pressure, unit Pa; Vmin is the minimum fracture volume, unit m3.

According to the above research results, it can be seen that after the excavation of the roadway in the coal seam, the surrounding rock stress around the coal seam roadway will be redistributed from the roadway to the deep part of the surrounding rock, in turn, the loosening zone (plastic zone), the stress concentration zone (elastic zone), the original stress zone (elastic zone), the surrounding rock stress of the coal body in the pressure relief zone is reduced, in the stress concentration zone, the surrounding rock stress of the coal body increases, and the stress on the coal body in the original stress zone is the original stress before excavation. So for the coal body in the plastic zone, the fracture development is greater than that of the coal body in the elastic zone, so the equilibrium pressure in the plastic zone is less than the equilibrium pressure in the elastic zone so as to determine the position of the sealing section and the length of the sealing section.

3.2. High-Pressure Gas Attenuation Method Test Scheme

3.2.1. Drilling Parameters

In the designated working surface construction of the smooth layer drilling, according to the following drilling parameters for construction: (1) drilling hole height of 1.5 m, drilling hole diameter of 113 mm, and drill hole depth of 30 m; (2) drilling hole perpendicular to the roadway, parallel to the opening downward, in the experimental drilling spacing of 10 m shall not be constructed, in order to avoid interference.

3.2.2. Experimental Apparatus

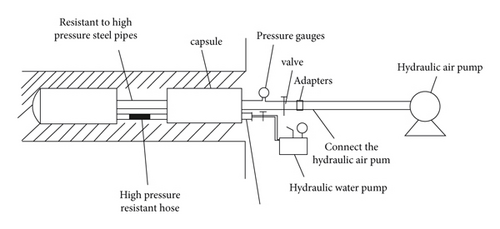

According to its test principle, combined with the experience of the underground site and the actual situation, the project team developed a coal mine underground loosening belt measurement device and applied for a national patent in the name of Zhangcun Mine, and the experimental device was divided into two parts: sealing components and pressure testing devices.

The sealing component includes two capsules set side by side before and after, and the middle of the two sealing capsules is provided with an integrated trachea and a trachea, which is used to realize the water injection inside the two capsules and the injection between the two capsules; when the water is injected into the capsule through the water injection pipe, the expansion of the two sealing capsules is in close contact with the hole wall, and a closed air chamber is formed in the middle of the two sealing capsules, and the water injection pipe is connected to the hydraulic water pump; in the laboratory, we measured the capsule expansion without space restrictions.

When the pressure inside the capsule without space restrictions reaches 1.7 MPa, the outer diameter of the capsule reaches 125 mm, which is much larger than the drilling diameter of 113 mm, so we chose the water injection pressure of 3 MPa in the field test, and the capsule should be able to contact the borehole wall very closely and play a good sealing effect.

Pressure test device: the pressure test device is connected to the gas injection pipe, connected by a three-way pipe to measure the internal pressure of the gas injection pipe, and the initial measurement pressure is provided by the pressure air under the mine, 0.7 MPa. In the borehole, due to the existence of a certain crack around the closed air chamber between the two capsules, the gas volume of the sealing section increases, thereby reducing its gas pressure. Therefore, we can observe the relationship between the magnitude of the pressure reduction and the position and length of different drilling holes and judge the optimal sealing position and sealing section through this.

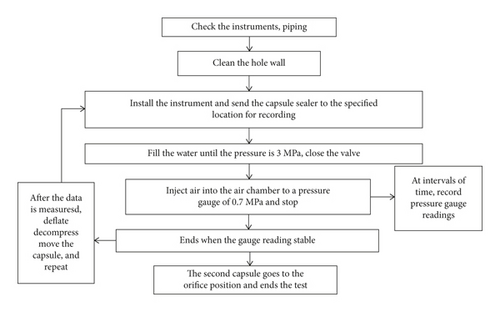

3.2.3. Test Steps

The test steps of the high-pressure gas attenuation method are as follows: (1) first, the capsule sealer is leak detection and inspection test on the ground, check whether the pipelines are unobstructed, and prevent accidents in the test process to meet the requirements of the downhole test. (2) Before sending the capsule into the borehole, use the pressure air to blow out the crushed coal in the hole, clean the hole wall, and do not leave the cinder to prevent the gangue or cinder from cutting the surface of the capsule and causing water leakage. (3) After reaching the designated working surface, the capsule is installed; first with a steel pipe with an outlet in the middle, the two capsules are connected to form a 1.5 m gas chamber. Then we use a special high-pressure-resistant tube and connect the water inlet between the two capsules, and there is a three-way joint on the outer capsule, which is equipped with a pressure gauge, connected to the valve switch, and the hydraulic air pump is connected to the valve through the adapter. The capsule sealer is sent to the predetermined position in the coal hole, and the position of the formed gas chamber is recorded, the pipelines are connected, and the hydraulic water pump begins to fill the capsule with water, and when the pressure rises to 3 MPa, stop the pressure and close the pressure control valve of the water pump. (4) Connect the gas chamber injection pipeline, open the hydraulic air pump, and open the valve to inject gas into the gas chamber; when the pressure gauge reading reaches 0.7 MPa, stop the gas injection (in order to prevent the pressure from falling, immediately close the switch), set this reading as the initial reading, at this time, record the initial value of the pressure gauge and the time of the initial gas injection, and then after a certain interval of time, record the reading and interval time of the pressure gauge, and after the pressure gauge reading is basically stable, the measurement of the gas chamber can be ended. (5) After completing the data measurement of an air chamber, first release the air in the gas chamber, open the gas valve, and open the pump pressure relief valve after the gas is completely released. After the capsule is completely decompressed, move the capsule outward so that the formed gas is moved outside, repeat steps (3) and (4) until the second capsule is located at the position of the orifice, and the test is concluded.

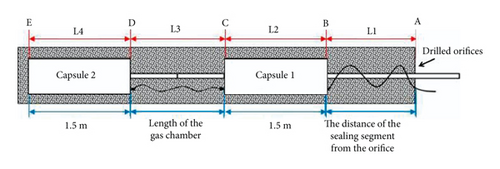

According to the above requirements, the equipment uses a capsule sealer to seal the holes to form a measurement space, the capsule sealer expands under the action of adding water to the outside world and forms a closed space between the two capsules, and each sealing has no impact on the drilling hole, will not affect the drilling next test, and can be used many times. The specific connection method is shown in Figure 2, the sealing position length calculation schematic is shown in Figure 3, and the seal hole position length calculation schematic diagram is shown in Figure 4.

3.3. Method for Determining the Key Position of the Sealing Hole

According to the test operation steps of the first drill hole, the stable pressure of different air chamber lengths (note: the length of the air chamber includes the length of two capsules and the pressure-resistant steel pipe connected in the middle) is tested sequentially, the gas stabilization pressure at each different depth is recorded, and then the curve of the gas stability pressure at different positions in the drill hole is made with the change of the drilling position. Through the analysis, (1) the drilling depth with small stable pressure and large attenuation in the figure indicates that the range is located in the loosening zone, the fracture is more developed, and the area is not suitable for sealing and extraction; (2) the stable pressure has increased, but the degree of increase is relatively low in the drilling depth, indicating that the drilling in this range is affected by stress and the fracture development changes greatly, with the deepening of the drilling, the fracture decreases sharply, which can be determined as the transition zone of stress concentration to the loosening belt, although the fracture development decreases with the depth increase, but because the gas flow in this area is still unstable, the extraction drilling hole requires a long time to be effective, so the range is not suitable for the sealing of the hole extraction and injection gas flow; (3) the gas injection pressure in the figure is basically stable, and the position of the least decay and the fracture development tend to be stable within this range; according to the theory, the gas injection pressure attenuation in this area should be 0, but the actual use of capsule sealing determination can not completely close the small cracks around the borehole, so there is a certain attenuation in the actual measurement, but from the trend, it should be seen that the fracture development in these areas is the most stable, and the sealing hole can be extracted, so as to determine the key position of the sealing hole.

4. Analysis of Key Positions and Lengths of Sealing Holes

In order to determine the sealing effect of different sealing hole positions, using the sealing hole experiment, analysis, and the field test selected Zhangcun Coal Mine No. 3 coal seam, the test site is 2802 transportation lane, the height difference of the alley is about 76 meters, corresponding to the ground elevation of +950 m∼+1020 m, the working surface burial depth is between 476∼608 mm, the thickness of the coal seam is 5.53 m∼6.69 m, the average thickness is 6.03 meters, the coal seam inclination angle is 2°∼15°, and during the test process, 6 test holes were built in the Zhangcun Coal Mine roadway. Each drilled hole has a length of 60 m and an inclination angle of 2°.

4.1. Key Position of the Sealing Hole

According to the test data, a graph of the stable pressure of the gas at different positions in the borehole changes with the change of the drilling position is created. According to Figure 2, at this time, the starting position of the sealing hole we represent is from orifice A to the inward L1 length B, the end position of the sealing hole is the length L1+ capsule 1 from the orifice L2+ the length of the chamber L3+ the length of the capsule 2 L4, to section E; that is, the sealing section is the section B to the section E.

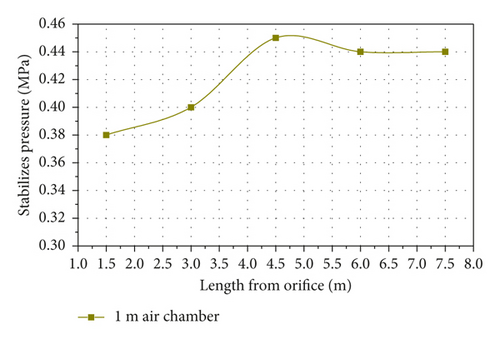

As can be seen from Figure 5, the first test of hole 1 is that the opening position of the sealing hole starts at 1.5 m from the orifice. At this time, the air pressure in the air chamber is reduced from 0.7 MPa in the initial state to 0.38 MPa, the pressure drop is 0.32 MPa, and the pressure drop percentage is 45.7%, indicating that the sealing position of this section is located in the loose belt and cannot seal the air leakage well.

In order to further test the key sealing position, the project team conducted the 2nd∼5th test of the No. 1 hole, and the starting position of the sealing hole changed from 1.5 m from the orifice to 3 m, 4.5 m, 6 m, and 7.5 m, and the end position of the sealing hole was 3 m (4.5 m, 6 m, and 7.5 m) from the orifice + the length of capsule 1.5 m + the length of the gas chamber length 1 m + the length of capsule 2 1.5 m = 7 m (8.5 m, 10 m, 11.5 m); that is to say, the sealing section was 3 m∼7 m, 4.5 m∼8.5 m, 6m∼10 m, and 7.5 m∼11.5 m, respectively. At this time, the air pressure in the air chamber was reduced from 0.7 MPa in the initial state to 0.4 MPa, 0.45 MPa, 0.44 MPa, and 0.44 MPa, and the pressure drop was 0.3 MPa, 0.25 MPa, 0.26 MPa, and 0.26 MPa, respectively, and the pressure drop percentage was 42.8%, 35.7%, 37.1%, and 37.1%, respectively. In order to more intuitively see the influence of the sealing position on the sealing effect, we analyzed the increase of the stable pressure, and the increase was 0.02 MPa, 0.07 MPa, 0.06 MPa, and 0.06 MPa, and the increase percentage was 5.26%, 18.42%, 15.79%, and 15.79%, respectively, indicating that the sealing effect of these positions was improved compared with the first sealing effect. However, at 3∼4.5 m, it still can not seal the air leakage well, indicating that the drilling in this range is affected by stress and the fracture development changes greatly; with the deepening of the drilling, it can be determined that it is still in the loose zone, so the range is not suitable for sealing and extraction.

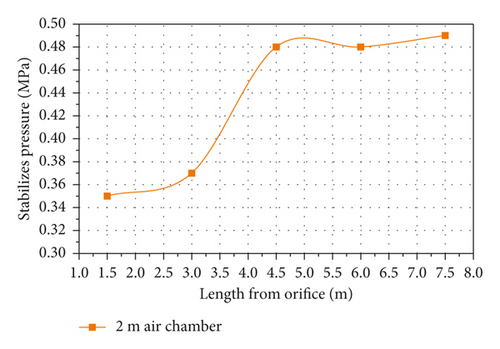

From Figure 6, it can be analyzed that the first test of hole 2 is that the length from the orifice is 1.5 m, the air pressure in the air chamber is reduced from 0.7 MPa in the initial state to 0.35 MPa, the pressure drop is 0.35 MPa, and the pressure drop percentage is 50%, indicating that this sealing hole cannot seal the air leakage well. In order to further test the key sealing position, the project team conducted the 2nd∼5th test of hole 2, the air pressure in the air chamber was reduced from 0.7 MPa in the initial state to 0.37 MPa, 0.48 MPa, 0.48 MPa, and 0.49 MPa, respectively, and the pressure drop was 0.33 MPa, 0.22 MPa, 0.22 MPa, and 0.21 MPa, respectively, and the pressure drop percentage was 47.1%, 31.4%, 31.4%, and 30%, respectively, and the length of the orifice of the No. 2 hole was 3 m, 4.5 m, 6 m, and 7.5 m. The increases in the maximum stable pressure were 5.71%, 37.1%, 37.1%, and 40%, respectively. When the length from the orifice is 3 m, although the stable pressure is improved, the increase is not large, indicating that the range is located in the loosening zone in 4.5∼7 m. In the range of 5 m, the stable pressure increased rapidly, and the increase was 37.1%∼40%, indicating that the drilling in this range was affected by stress, and the fracture development changed greatly, and with the deepening of the drilling, the fracture decreased sharply, which can be designated as the transition zone of stress concentration to the loosening belt.

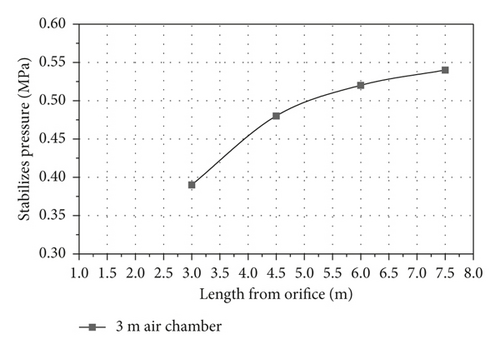

From Figure 7, the first test of hole 3 was that the length of the sealing hole from the orifice was 3 m, and the air pressure in the air chamber was reduced from 0.7 MPa in the initial state to 0.39 MPa, and the pressure drop was 0.31 MPa, with a pressure drop percentage of 44%. In order to further test the key sealing position, the project team conducted the 2nd∼4th test of hole 3, and the air chamber range became 4.5 m∼10.5 m, 6 m∼12 m, and 7.5 m∼13.5 m, and the air pressure in the air chamber was reduced from 0.7 MPa in the initial state to 0.48 MPa, 0.52 MPa, and 0.54 MPa, and the pressure drop was 0.22 MPa, 0.18 MPa, and 0.16 MPa, and the pressure drop percentage was 31.4%, 25.7%, and 22.9% respectively. When the length of the orifice of hole No. 3 was 4.5 m, 6 m, and 7.5 m, the increase of the maximum stable pressure was 17.9%, 33.3%, and 38.5%, respectively, and the increase was 4.5∼6 m. In the range of 5 m, the stable pressure increases, indicating that the drilling hole in this range is affected by stress, the fracture development changes greatly, and with the deepening of the drilling, the fracture decreases sharply, which can be determined as the transition zone of stress concentration to the loosening belt.

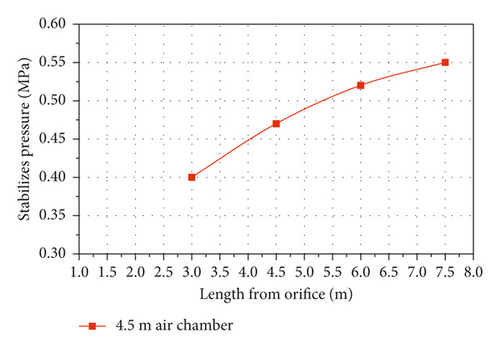

From Figure 8, the first test of hole 4 is that the length from the orifice is 3 m, and the air pressure in the air chamber is reduced from 0.7 MPa in the initial state to 0.4 MPa, the pressure drop is 0.3 MPa, and the pressure drop percentage is 42.9%. In order to further test the key sealing position, the project team conducted the 2nd∼4th test of hole 4, and the air chamber range became 4.5 m∼12 m, 6 m∼13.5 m, and 7.5 m∼15 m, and the air pressure in the air chamber was reduced from 0.7 MPa in the initial state to 0.47 MPa, 0.52 MPa, and 0.55 MPa, and the pressure drop was 0.23 MPa, 0.18 MPa, and 0.15 MPa, and the pressure drop percentage was 32.9%, 25.7%, and 21.4%, respectively. When the length of the hole of the No. 4 drilling hole is 6∼7.5 m, the stable pressure increases rapidly, and the increase is 37.50%, indicating that the drilling hole in this range is affected by stress, and the fracture development changes greatly, and with the deepening of the drilling, the fracture decreases sharply, which can be designated as the transition zone from stress concentration to the loosening belt.

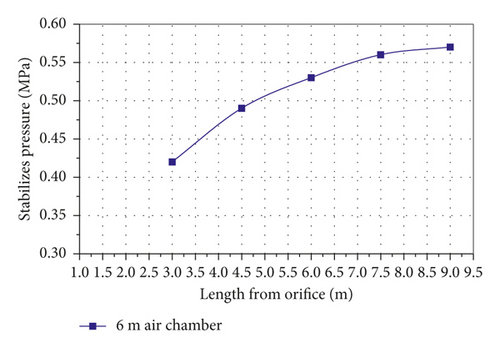

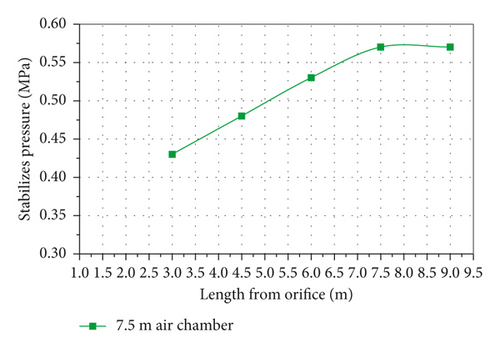

From Figure 9, the first test of hole 5 is that the length from the orifice is 3 m, and the air pressure in the air chamber is reduced from 0.7 MPa in the initial state to 0.42 MPa, and the pressure drop is 0.28 MPa, and the pressure drop percentage is 40%. In order to further test the key sealing position, the project team conducted the 2nd∼5th test of hole 5, and the air chamber range became 4.5 m∼13.5 m, 6m∼15 m, and 7.5 m∼17.5 m, and the air pressure in the air chamber was reduced from 0.7 MPa in the initial state to 0.49 MPa, 0.53 MPa, 0.56 MPa, and 0.57 MPa, and the pressure drop was 0.21 MPa, 0.17 MPa, 0.14 MPa, and 0.13 MPa, respectively. The percentage of pressure drop was 30%, 24.3%, 20%, and 18.6%, When the length of the No. 5 borehole is 7.5 m from the orifice, the pressure after the injection is basically stable, and the pressure increase is small, and the stable pressure can reach 80% of the injection pressure, and within this range, the fracture development tends to be stable and reaches the minimum value.

From Figure 10, it can be analyzed that the stable pressure of the No. 6 borehole from the orifice is 3 to 7.5 m when the stable pressure increases rapidly, and the increase is 32.56%, indicating that the drilling hole in this range is affected by stress, the fracture development changes greatly, with the deepening of the drilling hole, the crack is sharply reduced, which can be determined as the transition zone of stress concentration to the loosening zone, but because the gas flow in this area is not stable, the extraction drilling hole requires a long time to be effective, so the range is not suitable for sealing and extraction. At 7.5 m, the pressure after gas injection is basically stable, and the pressure increase is small, and the stable pressure can reach 81.43% of the injection pressure; within this range, the fracture development tends to be stable, reaching the minimum value, suitable for sealing and extraction.

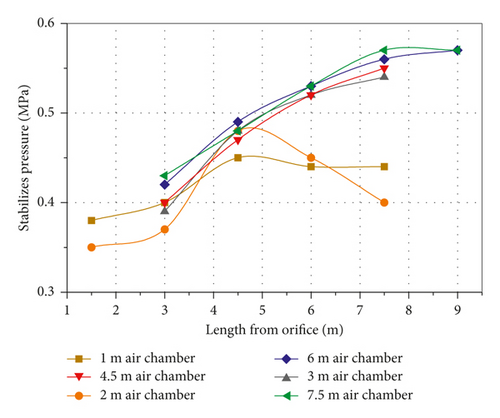

As can be seen from Figure 11, with the depth of the sealing position, the gas injection stabilization pressure shows a gradual increase trend; until a certain sealing depth, the gas pressure tends to be stable. Drilling holes in different positions, at a distance of 7.5 meters from the orifice, the gas stabilization pressure can reach the maximum value, so the initial position of the sealing hole starts from 7.5 meters.

4.2. Determination of the Length of the Sealing Hole

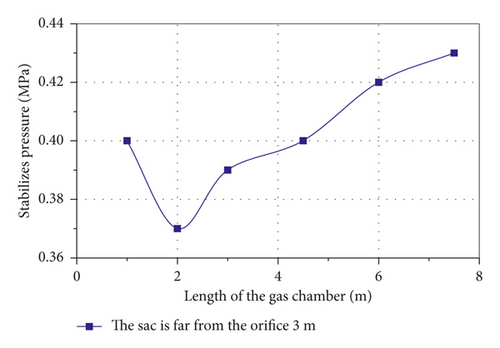

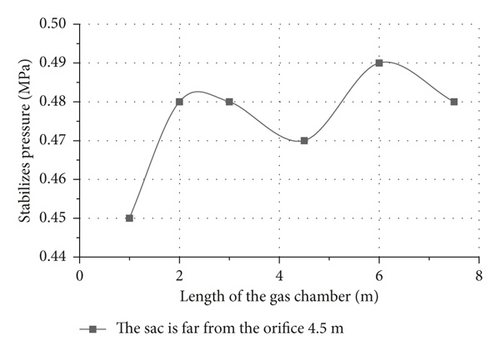

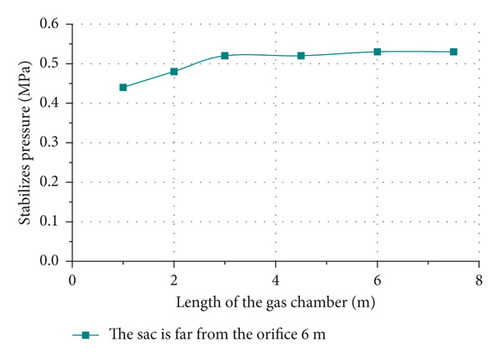

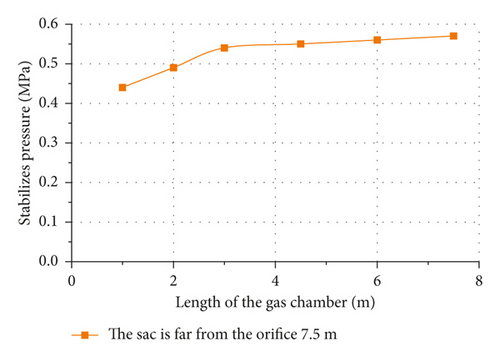

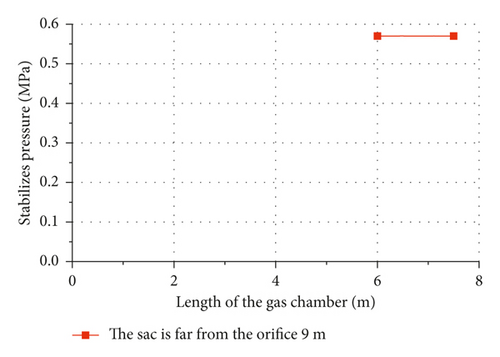

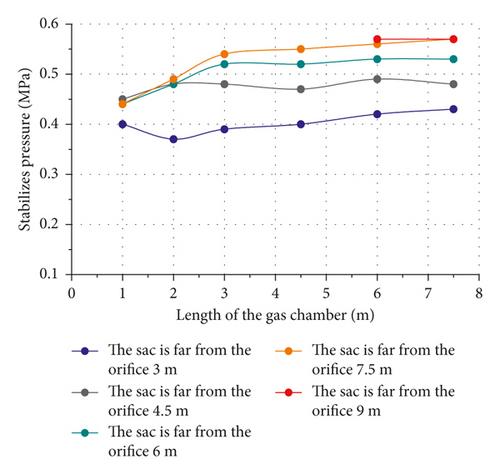

In order to find out the optimal sealing length, according to the test data, a curve of the change in the stable pressure of the gas when different sealing lengths in the drill hole are in the same initial position of the sealing hole is made.

As we can see from Figures 12-17, at the same initial position of the sealing segment, basically, when the length of the gas chamber is 7.5 m, the stability pressure of the sealing section is the largest, but in the test process, there may be some errors. Theoretically speaking, the stable pressure of the 1 m gas chamber should be the lowest, so in the analysis, we should pay attention to avoiding the data with errors; therefore, we finally determined that the optimal distance of the sealing hole is 7.5 m. In the previous article, we have discussed that 0∼7.5 m is not suitable for sealing, so the initial position of the sealing section should be 7.5 m, plus the length of the capsule 3 m, and the optimal sealing length of 7.5 m, the sealing hole final hole position is 18 m; in summary, our sealing hole is the best range of 7.5 m∼18 m.

5. Conclusion

- (1)

On the basis of theoretical analysis, the high-pressure gas attenuation method is proposed, a set of devices for rapid determination of the range of the loosening belt is designed, and a method for determining the range of the loose belt of the coal seam roadway is proposed by measuring the pressure attenuation, which has strong practical significance for guiding the drilling and sealing distance of the downward layer extraction and is simple and easy to promote.

- (2)

The use of the design of high-pressure gas attenuation method to determine the coal seam roadway loosening belt device and equipment is applied to the site; after field tests, the device can determine the coal seam roadway loosening belt; Zhangcun Coal Mine 2802 transport lane sealing range is determined to be 7.5 m∼18 m when the best effect is achieved.

- (3)

When the sealing length is greater than the loose belt, the extraction concentration is higher, and the concentration decay and the drilling life are long, so the sealing distance of the pumping drilling hole should be determined according to the range of the loosening belt on the basis of meeting the national standards.

Conflicts of Interest

The authors declare no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Acknowledgments

The project was supported by the Open Research Grant of the Joint National-Local Engineering Research Center for Safe and Precise Coal Mining (Grant no. EC2021012); project entrusted by China Coal Energy Research Institute Co., Ltd., Contract No. ZMYHT∗AJ-W-WSZNCC-02-21-090. This research was financially supported by the National Natural Science Foundation of China (nos. 51934007 and 51904013) and Shandong Key S&T Innovation Engineering Project (2019JZZY020504).

Open Research

Data Availability

Data can be obtained from the corresponding author.