A Framework of Selecting Building Flooring Finishing Materials by Using Building Information Modeling (BIM)

Abstract

Building materials selection is a critical process affected by many complicated factors. Due to the specific function of elements, alternatives to materials must be appropriately chosen as they differ in quality, performance, and cost. Implementing a Value Engineering (VE) process is challenging as it requires effort and several workshops. Thus, this study proposes a framework to automate the VE process of selecting building flooring material. The framework identified selected agreed criteria of flooring finishing materials measured based on agreed standard tests. The developed framework is distinguished from other current research using a combination of Analytic Hierarchy Process (AHP), Pairwise, and Function Analysis System Technique (FAST) methods to define the criteria ranking weight and include the building function. Furthermore, the framework is integrated with Building Information Modeling (BIM) that has been widely used in the Architecture, Engineering, and Construction industry (AEC). Finally, a case study of a residential house in Saudi Arabia was used to demonstrate the framework. The proposed framework was verified by using two questioners and expert consultations.

1. Introduction

Regarding cost, the criterion is quite clear since it has a measurable unit to compare numbers, while the quality evaluation is complex to measure since quality is affected by several criteria measurement units. Therefore, these criteria should be identified, weighted, and linked with material function. Othman [22], Fan and Shen [23], Marzouk [24], Wei and Chen [19] utilized function analysis in their studies. Many materials are available in the market with different specifications. These materials’ variety makes the selection task relatively complicated. Besides that, the current construction trends require an implication of a more widespread scope of evaluation criteria, which increases the complexity of the material selection process [25].

Floor finishing materials are one of the critical items in any construction project. They are defined as the material used to cover the floor, as these materials provide the required quality and at a moderate cost [26]. AL-Oqla and Sapuan [27] stated that the material selection process is one of the tasks that engineering design requires. Based on the VE concept, a wide variety of flooring finishing materials is chosen. This selection method will help the decision-makers to select the most valuable materials.

There is a demand for a systematic approach to automate these selection methods due to comparing a wide different variety of flooring finishing materials. Many international standards measure the building material quality using a standard test and assign a minimum value of accepted quality measurement unit. Some countries have their material standards, such as Saudi Standards, Metrology, and Quality Organization (SASO) [28], adopted from the international standard. These material standards can be used as a base to create and measure criteria for building material to be more objective and be able to be automated. The cost and quantities of the material building are other factors that need to be controlled to simplify the VE concept selection process.

The fifth dimension of Building Information Modeling (BIM) deals with material cost and quantity [29]. Hence, BIM can be adapted to facilitate and automate the process. BIM is described correctly as a model designed on a technological basis, connected with a project information database that is readily accessible and retrievable for detailed estimation of construction, proposed project schedules, and project management. This helpful design technique can assure higher productivity, enhance quality, and secure the project delivery schedule at a minimum cost [30]. Furthermore, BIM tools provide an efficient platform for implementing other constructive model features [31]. For example, Li et al. [32] demonstrated the significance of integrating BIM and VE using the proposed framework and applying it to Chines high-rise buildings to control construction cost and optimization.

The VE right now depends mainly on shared experts’ information and data, making it a more abstract method. This impediment makes VE implementation more avoidable, as mentioned in previous papers [9]. A solution to respond to this challenge is to automate the VE process. This study introduced a framework model to attempt automated the material selection process for building floor finishing materials utilizing the concept of VE. The study also defines the selection criteria based on international standards, research, and expert knowledge. Measuring selection criteria (including material quality) varies from one country to another. However, it can be customized to a specific country, such as Saudi Arabia. These criteria can be measured based on a standard test or agreed on weight to be programmed and easy to use by the practitioners.

Moreover, the novelty in the developed framework is identified general eleven selection criteria of finishing selection material. These selection criteria were measured and ranked based on standard test and weighting values using a methodology that integrates the Analytic Hierarchy Process (AHP), Pairwise, and Function Analysis System Technique (FAST) methods that are not done before. In addition, the framework is integrated and automated within BIM. The BIM framework model allows users to use the relative weight of ranking the selection criteria according to the building’s material function. If building material is automated in such a manner, VE can be utilized efficiently during the design process as a guideline to achieve the optimal VE for the entire building design and encourage the practitioners to implement VE.

2. Literature Review

This section presents a range of literature reviews dealing with the methods and stages of the material evaluation and former studies related to Multi-Criteria Decision-Making (MCDM) and flooring materials.

2.1. Material Evaluation Process and Methods

Due to the vast number of available materials, managing and verifying the material selection process is a challenging task. The current construction trends require a broader scope of evaluation criteria [26]. The material selection has been broadly covered in writing through numerous methodologies [33]. MCDM has been used as a research tool since the year 2000 up now [34]. MCDM simplifies complex problems to the natural form to become a prevalent method for solving decision-making problems in many areas. One of the MCDM applications is a material selection [35]. Table 1 summarizes some of the papers.

| References | Purpose | Techniques |

|---|---|---|

| Yazdani [36] | Material selection | AHP, FARE ∗ and WASPAS ∗ |

| Shahinur et al. [37] | Material selection | DSS and fuzzy analysis |

| Jadid [38] | Material selection | DSS |

| Venkata and Davim [39] | Material selection | AHP and TOPSIS ∗ |

| Sefair et. al. [26] | Material selection | OSM |

| Usman et al. [20] | Material selection | AHP and BIM |

| Alhammad and Zanklo [40] | Material selection | AHP, VE, and BIM |

| Alrahhal Alorabi et al. [41] | Material selection | AHP, VE, and BIM |

| Yang [42] | Material selection | AHP and DSS |

| Abdallah, et al. [43] | Green building measures selection | DSS |

| Jalaei et al. [44] | Building components selection | DSS and BIM |

- ∗Refer to Abbreviation table.

2.2. Value Engineering (VE)

VE is organized to provide the required facility with the lowest total costs, consistent performance, reliability, and maintainability [24]. The current construction practices require an inordinate effort to balance money, time, and quality. The Society of American Value Engineers defines VE as the systematic application that identifies and provides the necessary function reliably at the lowest overall cost. VE improves service value by modifying and enhancing functions. The fundamental objective of VE is value improvement. Value, as defined, is the ratio of integrating function and quality to the cost [45].

2.3. Analytical Hierarchy Process (AHP)

Saaty [46] had put forward the AHP to address the hierarchical problems by downsizing complex decisions. Hence, the AHP contributes to pinpointing a decision’s subjective and objective dimensions. Furthermore, the AHP involves an efficacious technique and reduces any possible bias in the decision-making process. The AHP has become a flexible and efficient tool to obtain final ranking by evaluating the criteria and user options relatively using the pairwise method [47].

2.4. Material Evaluation Criteria

Several solutions are usually considered to select the best building design alternative. These solutions should be optimally evaluated [48]. Some researchers restrict themselves to evaluating the material alternatives according to the cost and environmental criteria [26, 49], and [50]. Other studies evaluated energy criteria versus cost criteria in comparing alternatives [51]. On the contrary, some researchers evaluate material alternatives, including quality, performance, durability, and cost [48, 52].

2.4.1. Water Absorption

Water absorption is defined as “percentage of water impregnating the body of a tile, measured under ISO 10545-3” determination of water absorption, apparent porosity, apparent relative density, and bulk density. The fundamental property of floor finishing materials determines water’s effect on the flooring surface. Water absorption can be classified based on low, medium, and high. Low water absorption enhances durability, especially when tiles may be subjected to heavy loads and high foot traffic levels [53].

2.4.2. Breaking Strength

It is an important criterion that affects the durability of the flooring. The higher breaking strength shows the higher quality of the tiles [54]. According to ISO 10545/4, breaking load is necessary to break the specimen. Also, the ISO specs defined the breaking strength as the force obtained by multiplying the breaking load by the ratio (span between support rods)/(width of the test specimen) [55].

2.4.3. Modulus of Rupture

The mechanical property of floor finishing materials is the rupture modulus, defined as dividing the breaking strength by the square of the minimum thickness along the fractured edge. A higher tear coefficient indicates higher tile quality [55].

2.4.4. Abrasion Resistance

Tile surface resistance to abrasion is determined by rotating the abrasive load on the surface and visually evaluating the abrasion results (ASTM C1027-19, 2019). Abrasion is, therefore, a crucial aging factor for natural stones. The abrasion causes a decrease in the mechanical properties and variations in the aesthetical characteristics, such as color and brightness [56].

2.4.5. Surface Hardness

It indicates the ability of the tile surface to resist abrasion and scratches. It also represents surface durability and aesthetic properties. It is measured using the Mohs scale [57].

2.4.6. Coefficient of Friction

This standard affects building design, as industrial and recreational buildings. It is essential for easy cleaning, draining, and similar work [58].

2.4.7. Thermal Conductivity

Low-water absorption floors have high thermal conductivity. Therefore, low thermal conductivity floors are unsuitable for radiant floor heating applications. Al2O3 particles play an important role in increasing the thermal conductivity to 50% when adding 20% to the ceramic paste [59].

2.4.8. Stain Resistance

Many materials cause stains on the surface of the tiles. Therefore, stain resistance is considered the most sophisticated quality standard that must be achieved due to the possibility of interactions between these materials and the tiles’ surface [60].

2.4.9. Frost Resistance

Frost Resistance is directly related to the tiles’ water absorption property. Exposure of tiles to temperatures below 0°C causes the absorbed water to freeze, causing the tiles to expand and break. Thus, the tiles are frost-resistant or nonresistant [61].

2.4.10. Chemical Resistance

Chemical resistance refers to the ceramic surface’s behavior when exposed to chemicals that corrode it to permanently penetrate it or alter its aesthetic appearance due to its composition and properties. The deterioration of the surface of ceramic tiles caused by chemicals generally includes two different effects of the mechanisms, chemical, and physical action. Chemical action is the ceramic surface change due to a reaction between the chemical and some surface components. Physical action is due to the adsorption of chemicals that penetrate the surface to settle permanently, making it difficult to remove [62].

2.4.11. Thermal Shock Resistance

Thermal shock refers to sudden and unexpected changes in the temperature of floor or wall tiles due to contact with hot or cold objects (such as boiling water or cleaning steam). Due to thermal shock resistance, a tile can withstand such events without damage [63].

2.4.12. Crazing Resistance

Crazing is a typical and occasional effect consisting of subtle, irregular-shaped cracks in a tile’s glaze. Generally, in a Ceramic tile, crazing is considered a defect. However, in particular cases, it can be a deliberate effect, intentionally created during production to give the surface an “antiqued” look. The causes of crazing are due to an incorrect dilatometric ratio between glaze and support. Construction or environmental conditions cause fine cracks in the glaze, termed as crazing [64].

2.4.13. Maintainability

Maintainability measures the easiness of retaining or restoring an item to a particular condition within a given time during the maintenance performance [65]. Usually, the maintainability factor dramatically affects the selection of material that needs heavy maintenance. This criterion has a direct impact on calculating material LCC.

2.4.14. Durability

Durability refers to a product’s ability to fulfill its essential function for an extended period under normal usage conditions without requiring significant maintenance or repair [66]. The durability factor becomes critical building materials selection criteria for heavy usage such as Heating, Ventilation, and Air Conditioning (HVAC), flooring, and similar material types.

2.4.15. Buildability

The amount to which a structure’s design allows ease of construction, subject to the overall necessities for completing a building, is known as buildability [67]. Usually, this factor requires the contractor’s experience with construction methods for installing building materials. Ferguson [68] defines buildability as “the ability to construct a building efficiently, economically and to agreed quality levels from its constituent materials, components, and subassemblies.” Buildability factors can include labor skill, supervision, complexity, working duration, types of material used, site layout, availability of power tools, the proportion of work done by a subcontractor, etc. [69].

2.4.16. Aesthetic

Aestheticism is an essential criterion for floor finishing materials. The visual impression of the flooring types, color, and surface finishing quality forms the aesthetic characteristics of the floor of finishing material [70]. In contrast, this criterion may significantly increase the cost of these materials.

2.4.17. Sustainability

Sustainability is the fulfillment of the requirements of people and society by employing technology and practice optimally throughout the building’s life cycle [71]. These parameters and their weights differ from one system to another due to environmental, regional, and cultural conditions [72].

3. Research Methodology

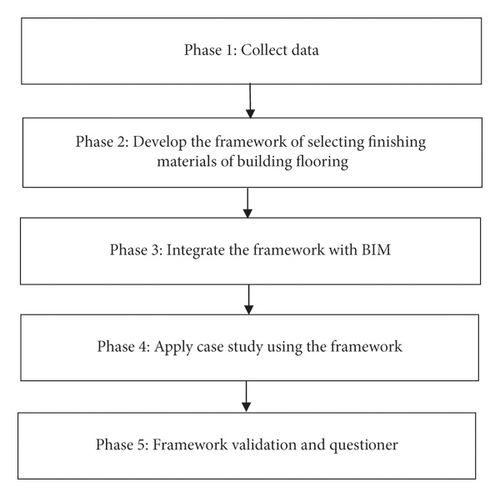

This section defines the research methodology that followed to achieve the study objective, which develop a framework of selecting finishing materials of building flooring utilized VE concept. Figure 1 shows the flowchart of the research process phases. The study’s first phase collects many formal studies and standards to understand the framework’s requirements. The next phase is to develop the framework using four research methods: VE, AHP, FAST, and Pairwise. The following section is a full explanation of developing this framework. The following phase task is to program the framework within the BIM platform. Then, applying the developed automated framework to a case study for validation. The final phase is to discuss the case study result and validate the framework by consulting three experts and questioners, which will be explained later.

3.1. Phase 1: Collecting Data

This phase has a comprehensive search on published papers, reports, catalogs, and standard manuals. In addition, several meetings with material suppliers during the exhibition events or visiting the flooring stores. This task aims to understand the needs and missing gaps in selecting the floor materials. The outcome of this task is to develop a plan and methodology for implementing the introduced framework.

3.2. Phase 2: Develop the Framework of Selecting Finishing Materials of Building Flooring

This study’s framework depends on predominant criteria based on previous literature reviews, international quality standards, and expert questionnaires. Several international quality standards are used to determine the material’s required quality (ISO, SASO, ASTM, and EN). SASO [29] adopted many of these standards in Saudi Arabia. This research studied a long list of SASO criteria with different floor materials (Ceramic, Marble, and Porcelain) to identify the most common criteria from this long list. Experts and quality engineers have been consulted to perform this task.

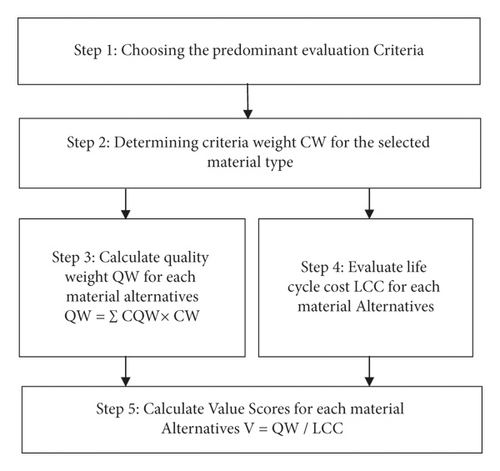

The framework is designed to achieve the research objective. Figure 2 shows the framework of the material selection process that consists of six steps. These steps include five variables which are Criteria Weight (CW), Criteria Quality Weight (CQW), Quality Weight (QW), and Life Cycle Cost (LCC). These five parameters are used to calculate only one final variable, the Material Value Ratio (V). To simplify and better understand the relationship between these variables according to the AHP method arrangement, Table 2 shows the relations between all these variables in tabulated form for an example of three materials alternatives and three material criteria.

| Criteria weight | Material 1 | Material 2 | Material 3 | |

|---|---|---|---|---|

| Criterion 1 | CW1 | CQW11 | CQW12 | CQW13 |

| Criterion 2 | CW2 | CQW21 | CQW22 | CQW23 |

| Criterion 3 | CW3 | CQW31 | CQW32 | CQW33 |

| QW | QW1 | QW2 | QW3 | |

| LCC | LCC1 | LCC2 | LCC3 | |

| V | V1 | V2 | V3 | |

The below steps sections represent the evaluating materials process applied to materials to be evaluated. It is then linked with the BIM Model to facilitate data input and automate the output accordingly. A case of a residential building was then studied and validated based on the proposed framework.

3.2.1. Step 1: Choosing the Predominant Criteria

This step establishes the essential evaluation criteria for the selected material by following several methods. One method is searching the literature review and grouping all these criteria into appropriate items. Another method is studying the international material standard. The goal of these standards is safety and health protection, measurement, analysis, quality control, and environmental protection [73].

The criteria upon which the evaluation is based include five main criteria categories: (1) material quality and standards, (2) aesthetic standards, (3) maintainability, (4) buildability, and (5) sustainability. The process of determining the predominant criteria was carried out in five tasks.

Task 1: Gather technical specifications for floors: By gathering and studying a range of flooring specs and standards, these standards have been classified and grouped based on the type of flooring. Table 3 shows the preliminary results obtained at this stage, showing the floor type with the standard and its reference in SASO [29].

| Flooring type | Test method | Standard |

|---|---|---|

| Ceramic | Definitions, classification, characteristics, and marking | SASO-ISO-13006 |

| Determination of frost resistance | SASO-ISO-10545-12 | |

| Determination of moisture expansion | SASO-ISO-10545-10 | |

| Sampling and basis for acceptance | SASO-ISO-10545-1 | |

| Determination of linear thermal expansion | SASO-ISO-10545-8 | |

| Determination of resistance to stains | SASO-ISO-10545-14 | |

| Determination of chemical resistance | SASO-ISO-10545-13 | |

| Determination of resistance to surface abrasion for glazed tiles | SASO-ISO-10545-7 | |

| Determination of crazing resistance for glazed tiles | SASO-ISO-10545-11 | |

| Determination of lead and cadmium gave off by glazed tiles | SASO-ISO-10545-15 | |

| Determination of slight color differences | SASO-ISO-10545-16 | |

| Determination of modulus of rupture and breaking strength | SASO-ISO-10545-4 | |

| Determination of resistance to thermal shock | SASO-ISO-10545-9 | |

| Determination of resistance to deep abrasion for unglazed tiles | SASO-ISO-10545-6 | |

| Determination of impact resistance by measurement of coefficient of restitution | SASO-ISO-10545-5 | |

| Determination of water absorption, apparent porosity, apparent relative density, and bulk density | SASO-ISO-10545-3 | |

| Natural Marble Tiles | Methods of test for the natural marble tiles | SASO-1026 |

| Standard Specification for Marble Dimension Stone | SASO-ASTM-C503 | |

| Interlocking concrete paving blocks | This standard is concerned with interlocking concrete paving blocks. | SASO-1246 |

| Methods of test for interlocking concrete paving blocks | SASO-1247 | |

| Cement tiles | Specification for Cement tiles | SASO-1029 |

| Methods of test for cement tiles | SASO-1028 | |

| Vinyl | Sound insulation | SASO-ISO-717-2 |

| Colourfastness | SASO-ISO-105-B02 | |

| Effect of chair castors | SASO-ISO-4918 | |

| Reaction to fire | SASO-ISO-9239-1 | |

| Thermal conductivity | SASO-ISO-10456 | |

| Parquet | Acoustical-Impact noise reduction | SASO-ISO-717-2 |

| Bond strength/Cross-cutting test | SASO-ISO-2409 | |

| Broadleaved wood raw parquet blocks—General characteristics | SASO-ISO-3397 | |

| Reaction to fire | SASO-ISO-9239-1 | |

| Carpet | Light fastness | SASO-ISO-105-B02 |

| Burning behavior | SASO-ISO-6925 | |

Task 2: Reduce the repeated and unnecessary flooring criteria: The unrelated criteria required to be eliminated to simplify the evaluation process.

Task 3: Determined the used standards in this study: By visiting SASO [29] and discussing the quality standards affecting the types of floors with specialists in the field, a list of agreed standards has been developed to be used in the research.

Task 4: Define the final criteria to be used in this study: A list of twenty-one criteria was presented to experts in an official questionnaire to determine the most common and influential criteria in selecting floor finishing materials (refer to questionnaire and validation section). The results of previous steps showed that the following eleven criteria are the most common, as shown in Table 4.

| No. | Criteria | The optimum reference value | Unit | International standard | |

|---|---|---|---|---|---|

| 1 | Material Quality and Standards | Modulus of Rupture | 50 | N/mm2 | ASTM C 629 |

| 2 | Breaking Strength | 8000 | N | ISO 10545-4 | |

| 3 | Surface Hardness | 8 | Mohs | EN 101 | |

| 4 | Abrasion Resistance | 75 | mm3 | ISO 10545-6 | |

| 5 | Water Absorption | 0.01 | % | ASTM C 615 | |

| 6 | Coefficient of Friction | 0.25 | μ | ASTM C1028 | |

| 7 | Thermal Conductivity | 0.08 | W/m·k | [74] | |

| 8 | Aesthetic | 5 | Subjective | NA | |

| 9 | Durability | 5 | Subjective | NA | |

| 10 | Maintainability | 5 | Subjective | NA | |

| 11 | Buildability | 5 | Subjective | NA | |

Tasks 5: Determine the optimal reference values of each measurement criteria test: After setting the eleven criteria, there is a need to define the flooring material quality level for each of these criteria. For this purpose, the optimal reference values for each material criterion have been determined through experts’ verbal and validated using a questionnaire (refer to questionnaire and validation section). Table 4 shows these optimal values, called in this paper “optimal CQW,” as will be discussed later in Step 3.

3.2.2. Step 2: Determine the Framework CW

VE concept uses function analysis as a factor for selecting material. FAST is a popular method to assess material function [21]. This final output technique determines the logical relationships between functions of material. However, the method does not calculate the weight for each function item and does not include functional analysis in the procedure [75, 76].

Lin and Yang [77], Liu and Hai [78], and Hamdan and Cheaitou [79] use the hierarchy analysis chart in their analysis without functional analysis. This study differs from other methods in integrating FAST and AHP methods for defining the CW for all material criteria selection. CW’s purpose in the AHP method is to determine the priority relation between criteria (criteria priority) [80]. The FAST analysis defines the CW to meet the project goal in this study. Zardari et al. [76] emphasized that many researchers overlook the difficulties in estimating CW. In this framework, CW can be calculated by the following these five phases:

(1) Phase 1. Determination of Project Goal and Function Analysis. The chosen materials must accomplish the project’s key objective. Goals are essential to know the “what” and the “why” design. Also, function analysis plays a significant role in the VE process. If the function analysis is not appropriately determined, the material criteria would be weighted less accurately.

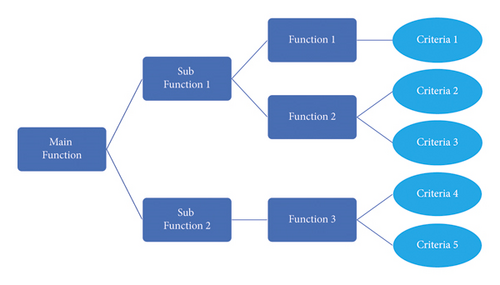

(2) Phase 2. Link the Criteria with Its Function/Subfunction/Criteria. This phase applies integration between the FAST and AHP/Pairwise method. Each criterion should be relevant to its function to accomplish this integration. Figure 3 shows an example of such integration. The rectangular shape in this figure represents the function analysis from the FAST method. On the other side of the figure, the oval shape represents the material criteria resultant from Step 1.

(3) Phase 3. Assigning Weights for All Function/Subfunction/Criteria on FAST Diagram. As shown in Figure 3, some functions may be linked to more than one criterion. Therefore, according to the following two methods, all criteria must be evaluated with assigned weights. According to Zardari et al. [76], the point allocation method is adopted when compared criteria in one level are less or equal to three. When greater than three, the pairwise comparison method is adopted. The latter method considers the expert judgment to evaluate the relative importance between each of the criteria against each other by using scale factors from 1 to 9. If the two criteria have equal importance, each has a value of one. Suppose one criterion is more important than the other; a scale of 2 to 9 is assigned as a factor of the importance degree. The method then developed a matrix and used equations to reach each criterion’s weight described by Bhushan and Rai [75]. By the end of this phase, all functions/subfunctions/criteria are assigned a weight.

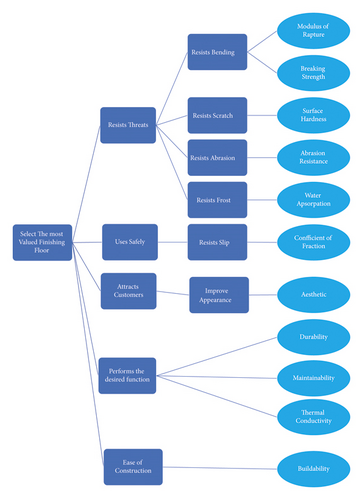

Figure 4 shows the integration of the FAST diagram with the assigned criteria, where each criterion is attached to its relevant function. After this integration, weights are given at each level of the diagram. As the selection of method is noted previously, therefore, the pairwise comparison has been employed when comparing the subfunctions (Resists Threats, Uses Safely, Attract Customers, Performs the desired function, Ease of Construction) as per the matrix shown in Table 5, and for functions comparison, as shown in Table 6.

| Resists bending | Resists scratch | Resists abrasion | Resists frost | W vector | |

|---|---|---|---|---|---|

| Resists Bending | 1 | 4 | 2 | 5 | 0.51 |

| Resists Scratch | 0.25 | 1 | 0.5 | 2 | 0.14 |

| Resists Abrasion | 0.5 | 2 | 1 | 3 | 0.26 |

| Resists Frost | 0.2 | 0.5 | 0.33 | 1 | 0.09 |

| ∑ W | 1 |

| Resists threats | Uses safely | Attracts customers | Performs the desired function | Ease of construction | W vector | |

|---|---|---|---|---|---|---|

| Resists Threats | 1 | 2 | 0.5 | 0.33 | 0.5 | 0.13 |

| Uses Safely | 0.5 | 1 | 0.25 | 0.25 | 1 | 0.09 |

| Attracts Customers | 2 | 4 | 1 | 1 | 2 | 0.3 |

| Performs the desired function | 3 | 4 | 1 | 1 | 2 | 0.33 |

| Ease of Construction | 2 | 1 | 0.5 | 0.5 | 1 | 0.16 |

| ∑ W | 1 |

Table 7 shows the 11 criteria linked with its function and subfunction. Also, the table represents the calculation of equation (2).

| 1-function | 2-subfunction | 3-criteria | W1 | W2 | W3 | DCW = W1 ∗ W2 ∗ W3 | CW |

|---|---|---|---|---|---|---|---|

| Resists threats | Resists bending | Modulus of Rupture | 0.13 | 0.51 | 0.4 | 0.03 | 0.03 |

| Resists threats | Resists bending | Breaking Strength | 0.13 | 0.51 | 0.6 | 0.04 | 0.04 |

| Resists threats | Resists Scratch | Surface Hardness | 0.13 | 0.14 | 1 | 0.02 | 0.02 |

| Resists threats | Resists Abrasion | Abrasion Resistance | 0.13 | 0.26 | 1 | 0.03 | 0.03 |

| Resists threats | Resists Frost | Water Absorption | 0.13 | 0.09 | 1 | 0.01 | 0.01 |

| Uses safely | Resists Slip | Coefficient of Friction | 0.09 | 1 | 1 | 0.09 | 0.09 |

| Attracts customers | Improves Appearance | Aesthetic | 0.3 | 1 | 1 | 0.3 | 0.3 |

| Performs the desired function | Durability | 0.33 | 1 | 0.3 | 0.1 | 0.1 | |

| Performs the desired function | Maintainability | 0.33 | 1 | 0.4 | 0.13 | 0.13 | |

| Performs the desired function | Thermal Conductivity | 0.33 | 1 | 0.3 | 0.1 | 0.1 | |

| Ease of Construction | Buildability | 0.16 | 1 | 1 | 0.16 | 0.16 | |

| ∑ CW | 1 | ||||||

However, none of the criteria are linked with more than one function/subfunction on this framework. Thus, DCW becomes equal to CW for all floor criteria, as shown in Table 7. For validation purposes, all the overall material CW should be equal to 1 (equivalent to 100%), represented at the bottom of Table 7.

3.2.3. Step 3: Calculating QW for Each Material Alternative

Now, the material QW calculation is done through three phases.

(1) Phase 1. Define the CQW for Each Criterion. As mentioned in the first step of framework methodology, each criterion quality needs to be measured according to international tests or other sources such as the manufacturer’s information, manuals, material catalogs, information available from contractors, specialized consultants, and other literature [82].

The next task, these measured agreed tests, needs to be applied to different materials, ranging from low quality to high one, for defining the material quality classification. In case the criterion is not measured, the CQW needs to be weighted subjectively based on the experience of design professionals. 1-5 scale is used where the value ranges from 5 is excellent to 1 as inferior.

Equation (4) for beneficial values.

Equation (5) for nonbeneficial values.

Whereas: Rij: Normalized value of material i for criterion j. Xij: Criterion value of the evaluated material. Ximax: Maximum criterion value. Ximin: Minimum criterion value.

(3) Phase 3. Calculate the QW for Each Material Alternative. Before proceeding to the next step, each material’s final quality value (i.e., QW) needs to be calculated from CQW determined previously. This new QW factor can be calculated by multiplying corresponding CW and CQW together for each of the material criteria, as shown in Table 2 and according to the following equation:

3.2.4. Step 4: Evaluate the LCC for Each Material Alternative

To use the selected material’s value ratio, LCC has to be evaluated for each material alternative. LCC includes initial cost, operating and maintenance cost, and may consider the material’s salvage value at the end of the building’s estimated life cycle period. The LCC can be affected by many variable factors that are difficult to solve in the exact equation. By the end of this step, it requires normalizing the LCC for the next step and comparison purpose, as explained previously using equation (4).

3.2.5. Step 5: Calculate the V and Select the Best Options

By applying this equation for all material alternatives, each material alternative gets its value ratio (V). The VE concept’s preferred material alternative is the highest V.

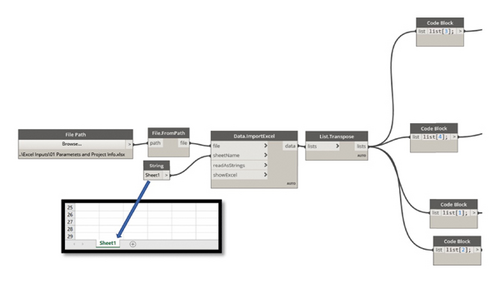

3.3. Phase 3: Integrated the Framework with the BIM

The primary objective of linking the proposed model with BIM is to help decision-makers select the optimal materials based on function, quality, and cost factors. For modeling the proposed approach using BIM, all data relating to the types of materials, their CW, QW, and V were included. The above evaluation process is linked to the BIM model through the “Application Programming Interface” (API). Furthermore, Dynamo programming is used in this research. It is an open-source visual programming tool that provides access to the Revit API in a more accessible manner. It gives users the ability to create programs visually by manipulating graphic elements called “nodes.” Also, it gives the ability to access BIM data, write, edit, and automate repeated tasks. A python coding programming is a powerful tool that can extend the capabilities of Dynamo.

- (1)

Modeling the floor finishing materials: All the materials alternatives were modeled. Materials specifications were specified.

- (2)

Entering the materials data: All quality criteria values are assigned. Besides, cost data were added. It could be entered manually or linked with an external database.

- (3)

Entering the project information criteria: All data relating to the project was defined, including the criteria’ weights as per the project function analysis.

- (4)

Run the calculation program: After entering all inputs, the calculation process ran, selecting the materials with the best value was displayed. All alternatives were ranked, and output was displayed.

| Parameters group | Parameters names | Assigned category | Parameter name prefix | Parameter type |

|---|---|---|---|---|

| Criteria Parameters |

|

Flooring | CR. XX. | Number |

| Benefit |

|

Project Information | BC. XX. | Yes/No |

| Weights Parameters |

|

Project Information | WP. XX. | Number |

| Cost Parameters | LCC Cost | Flooring | N/A | Number |

| Value Output Parameters |

|

Flooring | N/A | Number |

Figure 6 displays the integration process between Excel sheet and BIM using Dynamo.

3.4. Phase 4: Apply Case Study Using the Introduced Framework

A case study of a residential building has been used in this research to understand the evaluation process better and validate it. The results and output are outlined to help the decision-maker select the material type that secures the best value. General information of the case study is shown in Table 9:

| Building name: | Duplex villa |

|---|---|

| Building Type: | Residential |

| Project Area (m2): | 373 m2 |

|

|

| Project life span | 30 years |

The building is a residential duplex villa. The building consists of a ground floor (Area = 208 m2), first floor (Area = 213 m2), and roof floor (Area = 210 m2). Figure 7 shows a 3-dimensional model for the case study. The villa is under design, and the engineering office needs to coordinate with the owner to select the more valuable materials. One of the important decisions is selecting the flooring type available on the Saudi market. As a result, this case study uses the proposed framework to select the most valued material between the three most alternative floors in the Saudi residential villa (refer to the questionnaire section): Marble, Ceramic, and Porcelain. The following substeps are used in the case study.

3.4.1. Calculating Normalized QW and LCC

-

QW (Ceramic) = (0.44 × 0.03) + (0.13 × 0.04) + … + (0.8 × 0.16) = 0.64.

-

QW (Porcelain) = (0.7 × 0.03) + (0.16 × 0.04) + … + (0.8 × 0.8) = 0.67.

-

QW (Italian Marble) = (0.14 × 0.03) + (0.23 × 0.04) + … + (0.8 × 0.7) = 0.66.

| Criteria | Normalized (N) or value (V) | Modulus of rupture | Breaking strength | Surface hardness | Abrasion resistance | Water absorption | Coefficient of friction | Aesthetic | Durability | Maintainability | Thermal Conductivity | Buildability |

| Unit | N/mm2 | N | Mohs | mm3 | % | μ | Subjective | Subjective | Subjective | W/m·K | Subjective | |

| Alternatives | CQW according to international standards and experts | |||||||||||

| The optimal reference values | 50 | 8000 | 8 | 75 | 0.01 | 0.25 | 5 | 5 | 5 | 0.08 | 5 | |

| Ceramic (BIIa) | V | ≥22 | ≥1000 | ≥5 | 345 | ≤6.5% | 0.4 | 4 | 4 | 3.5 | 1.7 | 4 |

| N | 0.44 | 0.13 | 0.63 | 0.22 | 0.002 | 0.63 | 0.8 | 0.8 | 0.7 | 0.05 | 0.8 | |

| Porcelain (BIa) | V | ≥35 | ≥1300 | ≥5 | 175 | ≤0,5% | 0.4 | 4 | 4 | 4 | 1.3 | 4 |

| N | 0.7 | 0.16 | 0.63 | 0.43 | 0.02 | 0.63 | 0.8 | 0.8 | 0.8 | 0.06 | 0.8 | |

| Italian Marble | V | ≥6.9 | ≥1850 | ≥4 | 250 | ≤0.10% | 0.6 | 5 | 4.5 | 3 | 2.07 | 3.5 |

| N | 0.14 | 0.23 | 0.5 | 0.3 | 0.1 | 0.42 | 1 | 0.9 | 0.6 | 0.04 | 0.7 | |

The case study cost data are shown in Table 11. M&R annual costs are 3% of the application’s initial cost [84]. According to the conditions of the Saudi Market, 1% of the initial cost has been considered in this study. The prices mentioned above and costs were obtained from the local Saudi market. Table 11 represents the Normalized LCC based on equation (4).

| Cost | Initial Cost | M&R Annual Cost | LCC | Normalized LCC |

|---|---|---|---|---|

| Unit | S.R/m2 | S.R/m2 | S.R/m2 | Value |

| Porcelain | 80 | 0.8 | 232.24 | 1103.15/232.24 = 0.21 |

| Ceramic | 65 | 0.65 | 188.7 | 1103.15/188.7 = 0.17 |

| Marble | 380 | 3.8 | 1103.15 | 1 |

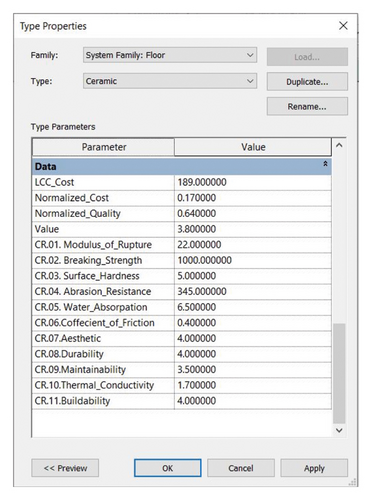

3.4.2. BIM Modeling and Calculate the Final Result

All the three selected floor finishes are modeled in the Revit model. Also, all CW and LCC values were entered (as calculated before using Tables 7, 10, and 11). They were entered promptly using Dynamo (as mentioned before) by importing them from the Excel sheet. Figure 5 shows one of the entry windows for the material. Subsequently, getting all QW and LCC values of three case study flooring materials, the V value for each of three material alternatives is calculated according to equation (7) as shown in Table 12 (column titled with “Value”) from the highest alternatives to the lowest value. It also shows all the other material criteria values. The first best option is Ceramic and then Porcelain, characterized by quality standards nearly close in value. However, the cost criterion for Ceramic is better than the cost criterion for Porcelain and Marble. At the same time, the Marble has a higher aesthetic, less water absorption, and higher breaking strength.

| 01 selection of floor finishes | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Type | Value | LLC_Cost | Normalized_Cost | Normalized_Quality | CR.01. Modulus_of_Rupture | CR.02. Breaking_Strength | CR.03. Surface_Hardness | CR.04. Abrasion_Resistance | CR.05. Water_Absorption | CR.06. Coefficient_of_Friction | CR.07. Aesthetic | CR.08. Durability | CR.09. Maintainability | CR.10. Thermal_Conductivity | CR.11. Buildability |

| Porcelain | 3.2 | 232 | 0.21 | 0.67 | 35 | 1300 | 5 | 175 | 0.5 | 0.4 | 4 | 4 | 4 | 1.3 | 4 |

| Ceramic | 3.8 | 189 | 0.17 | 0.64 | 22 | 1000 | 5 | 345 | 6.5 | 0.4 | 4 | 4 | 3.5 | 1.7 | 4 |

| Marble | 0.66 | 1103 | 1.00 | 0.66 | 6.9 | 1850 | 4 | 250 | 0.10 | 0.6 | 5 | 4.5 | 3 | 2.07 | 3.5 |

3.4.3. Case Study Discussion

The result of this case study of choosing the Ceramic based on the VE concept is compatible with a case study done by Labuan and Waty [85]. In their study of flooring material in a two-story housing project in Indonesia, the ceramic flooring materials received a score of 32.1% as the highest percentage among the other ten flooring materials used in this study. The study used the probabilities technique with AHP and FAST methods to apply Expert Choice. Lee [10] attempts to develop a cost-effective evaluation of composite building materials such as flooring and wall system in other country studies. The study used two types of flooring systems (including the building slab concrete and insulation) in a Korean apartment to be evaluated. In another study, Lee [86] proposed a model for indexing the function, cost, and value scores using the vector normalization method. This model is applied to a case study of the office floor building to select its finishing materials.

This study used a typical housing building function weight to calculate the CW’s. However, if the owner has a significate preference or needs regarding the type of flooring, the CW’s values can be changed accordingly. Thus, the introduced framework gives a general guideline to building designers and needs to be updated to generate all types of buildings such as office, hospitality, healthcare, and others. Another flooring condition is exposing the floor to external weather, not transmitting electricity, minimizing sports injury, minimizing slipping near wet areas, and so on. Accordingly, further study is needed to develop the CW that satisfies the building function and performance. This model assumed all the nominated, evaluated alternatives are approved by the minimum acceptance designs of flooring materials for specific requirements such as having outdoor flooring, owner preference, or meeting minimum country specification (such as ISO or SASO). Future studies could eliminate these materials within the BIM model to meet the minimum accepted specification.

3.5. Phase 5: Framework Validation and Questionnaires

In this study, two questionnaires were designed. The first questionnaire is the experts’ questionnaire; it is distributed to nine experts (three quality engineers, three consultants, and three designers), and the second one is the main questionnaire. Table 13 below includes a summary of details about the questionnaires.

| Questionnaire category | Respondents | Objective |

|---|---|---|

| Experts | 9 | Verify the common and most influential evaluation criteria (eleven predominant criteria) in selecting floor finishing materials. |

| Verify a list of the designer’s essential design considerations that aid experts in choosing the floor finishing materials to achieve the desired function of their design. | ||

| Validate the optimum CQW value (Satisfaction Percentage). | ||

| Validate the proposed framework (Satisfaction Percentage). | ||

| General | 80 | Verify the common flooring types used in residential buildings in Saudi Arabia to be used in the case study (Satisfaction Percentage). |

| Validate the predominant eleven criteria in choosing floor finishing materials (Satisfaction Percentage). |

3.5.1. Experts Questionnaire Results

Three specialized experts in the field were consulted, three professional and qualified architectural designers, and three expert consultants in stages for the research’s reliability and verification during this study. Table 14 represents the results of the first question experts were asked for the most effective criteria for selecting floor finishing materials. These criteria are related to the necessary design considerations that assist in selecting materials for floor finishing.

| Frequencies | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| No | The most common and influential evaluation criteria in the selection of buildings floor finishing materials | 1 strongly disagree | 2 disagree | 3 neither agree nor disagree | 4 agree | 5 strongly agree | Total | Total likert –points | Select score ≥ 4 |

| 1 | Fire Reaction | 1 | 2 | 5 | 1 | 33 | 3.6 | ||

| 2 | Coefficient of Friction | 3 | 6 | 42 | 4.6 | ✓ | |||

| 3 | Colour Fastness | 1 | 6 | 2 | 30 | 3.3 | |||

| 4 | Breaking Strength | 1 | 5 | 3 | 38 | 4.2 | ✓ | ||

| 5 | Surface Hardness | 1 | 3 | 5 | 40 | 4.4 | ✓ | ||

| 6 | Stain Resistance | 1 | 7 | 1 | 27 | 3 | |||

| 7 | Frost Resistance | 4 | 3 | 2 | 30 | 3.3 | |||

| 8 | Water Absorption | 1 | 1 | 7 | 41 | 4.5 | ✓ | ||

| 9 | Slip Resistance | 4 | 3 | 2 | 34 | 3.7 | |||

| 10 | Thermal Conductivity | 2 | 1 | 6 | 40 | 4.4 | ✓ | ||

| 11 | Compressive Strength | 2 | 1 | 3 | 3 | 34 | 3.7 | ||

| 12 | Chemical Resistance | 2 | 3 | 2 | 2 | 31 | 3.4 | ||

| 13 | Dimensional Stability | 7 | 2 | 29 | 3.2 | ||||

| 14 | Abrasion Resistance | 9 | 45 | 5 | ✓ | ||||

| 15 | Modulus of Rupture | 1 | 6 | 2 | 37 | 4.1 | ✓ | ||

| 16 | Thermal Shock Resistance | 5 | 3 | 1 | 32 | 3.5 | |||

| 17 | Crazing Resistance | 1 | 7 | 1 | 28 | 3.1 | |||

| 18 | Maintainability | 1 | 3 | 5 | 40 | 4.4 | ✓ | ||

| 19 | Durability | 1 | 8 | 44 | 4.8 | ✓ | |||

| 20 | Buildability | 5 | 4 | 40 | 4.4 | ✓ | |||

| 21 | Aesthetic | 2 | 7 | 43 | 4.7 | ✓ | |||

Table 15 represents the questionnaire results of asking experts about the most important considerations for the designer to respond to the owner’s needs and achieve its desired function. The results indicate that the most five considerations are Resists Threats, Uses Safely, Attracts Customers, Performs the desired function, and Eases the Construction.

| Frequencies | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| No | The most common and influential evaluation criteria in the selection of buildings floor finishing materials | 1 strongly disagree | 2 disagree | 3 neither agree nor disagree | 4 agree | 5 strongly agree | Total | Total likert –points | Select score ≥ 4 |

| 1 | Uses Safely | ✓ | |||||||

| 2 | Facilitate the operation | 1 | 4 | 5 | 34 | 3.8 | |||

| 3 | Performs the desired function | 1 | 5 | 3 | 38 | 4.2 | ✓ | ||

| 4 | Resists Threats | ✓ | |||||||

| 5 | Attracts Customers | 9 | 45 | 5 | ✓ | ||||

| 6 | Improve the Environment | 2 | 4 | 3 | 28 | 3.1 | |||

| 7 | Ease of Construction | 1 | 3 | 5 | 40 | 4.4 | ✓ | ||

In addition, the experts validate the optimum reference value recorded for CQW. Table 16 represents the satisfaction results for each criterion’s optimum reference value.

| Criteria | Unit | The optimum reference value | Satisfaction percentage (%) |

|---|---|---|---|

| Modulus of Rupture | N/mm2 | 50 | 93 |

| Breaking Strength | N | 8000 | 100 |

| Surface Hardness | Mohs | 8 | 100 |

| Abrasion Resistance | mm3 | 75 | 91 |

| Water Absorption | % | 0.01 | 98 |

| Coefficient of Friction | μ | 0.25 | 95 |

| Aesthetic | None | 5 | 100 |

| Durability | None | 5 | 100 |

| Maintainability | None | 5 | 100 |

| Buildability | None | 5 | 100 |

| Thermal conductivity | W/m·k | 0.08 | 97 |

3.5.2. General Questionnaire Results

The general questionnaire seeks professional personnel working in the field of construction in Saudi Arabia. This questionnaire has been achieved according to the following three parts:

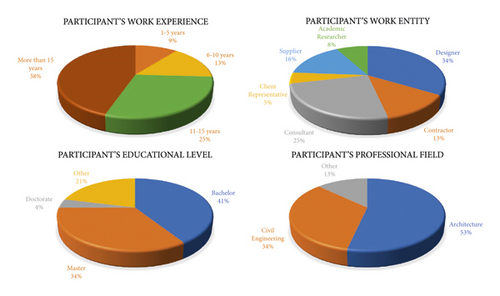

(1) Part One: Getting General Information about the Survey. This part was used to obtain information about the respondents. Seven hundred sixty-five persons received the questionnaire. The respondents’ education distribution was as follows: 80 persons (10.45% of the total receivers), 4% of the respondents were with a Ph.D. degree, 34% were with a master’s degree, 41% had a bachelor’s degree. The respondents’ backgrounds were mainly Architecture (53%) and Civil Engineering (34%). They have experience in various areas, Contractors (13%), Consultants (25%), Designers (34%), Client Representatives (5%), Academic Researchers (8%), and suppliers (16%). 38% of the participants have work experience of more than 15 years, 25% have experience ranging from 11 to 15 years, 13% have experience of 6–10 years, 9% have experience of 1–5 years. Figure 8 represents graphical distributional to questionnaire respondents.

(2) Part Two: Determine the Commonly Flooring Residential Types used in Saudi Buildings. The questionnaire participants were asked about the flooring types commonly used in residential buildings in Saudi Arabia. The questionnaire results in Table 17 showed that Marble, Ceramic, and Porcelain flooring are the most common types of flooring used in residential buildings in the Kingdom of Saudi Arabia. The results in this part were used in the previous case study.

| Frequencies | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| No | Flooring types are commonly used in residential buildings in Saudi Arabia | 1 strongly disagree | 2 disagree | 3 neither agree nor disagree | 4 agree | 5 strongly agree | Total | Total likert-points | Select Score ≥ 4 |

| 1 | Parquet | 27 | 19 | 21 | 9 | 4 | 184 | 2.3 | |

| 2 | Carpet | 14 | 23 | 25 | 10 | 8 | 215 | 2.7 | |

| 3 | Ceramic | 2 | 5 | 14 | 22 | 37 | 327 | 4.09 | ✓ |

| 4 | Granit | 27 | 36 | 5 | 9 | 3 | 165 | 2.06 | |

| 5 | Vinyl | 14 | 18 | 13 | 20 | 15 | 244 | 3.05 | |

| 6 | Marble | 7 | 10 | 29 | 34 | 330 | 4.13 | ✓ | |

| 7 | Porcelain | 4 | 7 | 39 | 30 | 335 | 4.2 | ✓ | |

(3) Part Three: Validate the Predetermined Eleven Criteria in Choosing Floor Finishing Materials (Satisfaction Percentage). The participants were asked about their satisfaction with the results of the experts’ questionnaire on the common criteria that most influenced the process of selecting floor finishing materials. The results are shown in Table 18. The results of this part are used to validate the framework criteria.

| The Most common criteria affecting the quality of finishing materials floors | Agree (%) | Disagree (%) |

|---|---|---|

| Modulus of Rupture | 89 | 11 |

| Breaking Strength | 81 | 19 |

| Surface Hardness | 86 | 18 |

| Abrasion Resistance | 80 | 20 |

| Water Absorption | 100 | 0 |

| Coefficient of Friction | 95 | 5 |

| Aesthetic | 99 | 1 |

| Durability | 93 | 7 |

| Maintainability | 94 | 6 |

| Thermal Conductivity | 91 | 9 |

| Buildability | 93 | 7 |

3.5.3. Validate the Proposed Framework

The case study results were presented to the same nine specialized experts consulted in the expert questionnaire to validate the research’s final results. They were asked to express their satisfaction degree on a Likert Scale about the quality values, cost values, the criteria weights, and the overall value results. Their response is summarized in Table 19.

| No | Data | Experts’ satisfaction (%) |

|---|---|---|

| 1 | Criteria Weights (CW) Values | 80 |

| 2 | Quality Weights (QW) Values | 87 |

| 3 | Life Cycle Cost (LCC) Values | 93 |

| 4 | Overall Value Results | 87 |

The expert’s opinions prove that the proposed framework gives reliable results that can be adopted for materials evaluation.

4. Conclusion

This study suggested an automated BIM framework for selecting floor finishing materials. Eleven criteria for selecting flooring finishing are identified by searching several references and material standards and catalogs. They are also validated by interviewing three strong backgrounds in flooring quality. Seven common and agreed standard tests are identified to measure the flooring quality criteria from these eleven criteria. Also, four subjective selection criteria have been evaluated within the framework. Table 1 represents these eleven criteria. These selection criteria are weighted by conducting interviews with three experts. The weighting methodology links these criteria with building function and integrates AHP, FAST, and pairwise methods. These weighted criteria become a basis for measuring any flooring finishing material. Moreover, the framework has been integrated with BIM using API Application and Dynamo.

A case study of a residential building is utilized to demonstrate the proposed automated framework. The case study shows the incorrect perception that not all materials with good quality are selected, but their cost has to be considered along with quality. Lastly, three experts’ opinions are conducted to validate the proposed framework. Expert engineers evaluated the value of cost and quality, overall value results, and criteria weight. The proposed framework was validated as 85% satisfaction by the experts.

Because of having various market options, selecting and evaluating the finishing flooring materials is considered a complicated process. Thus, VE is difficult to apply in such a task because of having variations in flooring material standard tests, selection criteria, LCC, and the building’s needs and function. As a result, the VE process becomes more dependent on the expert’s knowledge and does not follow a systematic approach that can be automated. In general, the proposed automated framework is a valuable tool to respond to such issues. It assists the designers/owners in selecting the most efficient finishing flooring materials. The residential case study result demonstrates a helpful general guideline tool to the designer/owner in reaching the right decision in a short time. Moreover, the framework simplifies the time-consuming process of comparing numerous flooring material specifications to judge the material quality and measure it. Nevertheless, the framework can be developed more comprehensively for all building functions and performance.

Abbreviations

-

- AEC:

-

- Architecture, Engineering, and Construction industry

-

- AHP:

-

- Analytic Hierarchy Process

-

- ASTM:

-

- American Society for Testing and Materials

-

- BIM:

-

- Building Information Modeling

-

- CQW:

-

- Criteria Quality Weight

-

- CW:

-

- Criteria Weight

-

- DSS:

-

- Decision Support Systems

-

- EN:

-

- European Standards

-

- FARE:

-

- Factor relationship

-

- FAST:

-

- Function Analysis System Technique

-

- HVAC:

-

- Heating, Ventilation, and Air Conditioning

-

- ISO:

-

- International Organization for Standardization

-

- LCC:

-

- Life cycle cost

-

- LSTMM:

-

- Linear Scale Transformation Max Method

-

- MCDM:

-

- Multi-Criteria Decision-Making

-

- OSM:

-

- Optimal Scoring Method

-

- QW:

-

- Quality Weight

-

- SASO:

-

- Saudi Standards, Metrology, and Quality Organization

-

- TOPSIS:

-

- Technique for Order Preference by Similarity to Ideal Solution

-

- V:

-

- Material Value Ratio

-

- VE:

-

- Value Engineering

-

- WASPAS:

-

- Weighted Aggregated Sum Product Assessment method.

Conflicts of Interest

No conflicts of interest exist.

Acknowledgments

The author would like to thank the Deanship of Scientific Research (DSR), the King Saud University (KSU), for supporting this research through the initiative of DSR Graduate Students Research Support (GSR). Also, the authors would like to thank the Saudi Standards Metrology and Quality Organization (SASO) for their support. Moreover, the authors would like to thank all participants for verifying and validating this study. The author would like to thank the Deanship of Scientific Research (DSR), King Saud University (KSU), for supporting and funding this research.

Open Research

Data Availability

Different research papers and journals were used to produce this paper using common academic databases and search engines. Therefore, raw data supporting the findings of this paper will be available by the corresponding author on request.