A Study on the Effects of Plastic Waste Strips and Lime on Strength Characteristics of Expansive Soil

Abstract

Expansive soils are known for their volume changes due to fluctuation in the moisture content of the natural ground. This volume change causes huge destruction to many infrastructures. To avoid such damages, expansive soils should be well treated so that they become safe against bearing capacity failure and excessive settlement. In addition, everywhere plastic environmental pollution is a critical issue, which needs a proper way of utilization. This study primarily aimed at utilizing waste plastic materials with lime as subgrade pavement materials, which is cost-effective and environmentally friendly. Plastic water bottles are used as reinforcement with lime to improve the plasticity and strength properties of the expansive soils. Various laboratory tests are conducted using plastic waste strips with 0.25%, 0.5%, 0.75%, and 1% proportions as soil reinforcement and constant 5% of lime. Finally, significant improvements in CBR, unconfined compressive strength, and free swell are observed at 5% lime and 0.75% plastic waste strips. This study found that stabilizing expansive soil using plastic waste strips and lime has a great influence on the plasticity and strength parameters of the soil. This technique helps to reduce plastic pollution and minimize the cost of stabilizers used to stabilize the subgrade soil.

1. Introduction

Expansive soils have a unique behavior of shrinking and swelling due to the seasonal fluctuations of soil moisture during wetting and drying seasons. These occur due to the presence of swelling clay minerals [1]. The semiarid and arid regions are highly exposed to infrastructure damages from expansive soils. Most parts of east Africa including Sudan, Kenya, Ethiopia, and Uganda are covered with expansive soils. With economic growth, increasing construction of infrastructures, urbanization, and construction of development projects are susceptible to these damages. It caused huge damages to buildings, roads, irrigation systems, water supply lines, and other infrastructures. These significant damages lead to an economic crisis and lack of basic infrastructures, which highly affect the day-to-day life of the society [2]. The complex behavior of expansive soils is not suitable for engineering works directly implemented on them. To make expansive soils appropriate for engineering works, many attempts through utilizing different materials and techniques have been made [3–6].

Expansive clay soils need to be treated before they can be used as subgrade pavement foundations, the foundation of buildings, or airfield constructions. Recently, many methods have been proposed to control the volume change due to fluctuation in moisture content of the ground [7]. The most widely used techniques to improve the erratic behavior of expansive soils are chemical and mechanical stabilizations. Mechanical stabilization includes dynamic compaction, reinforcement, prewetting, wetting-drying cycles, and solid wastes. On the contrary, chemical stabilization includes using traditional agents and nontraditional agents to stabilize the soil through altering the chemical composition of the soil [8–10].

Compaction by expelling out the air voids, prewetting by overwhelming and adjusting the soil in a moisture-rich environment, wetting-drying cycles inundating with water, and allowing drying until the soil returns to its initial water content and reinforcing expansive soil with fibers materials can improve the geotechnical properties of the soil [11–13]. Chemical agents such as lime, fly ash, cement, and other byproducts are used in chemical stabilization. The chemical reactions that occur between these additives and soil resulted in resistance to volume change, improvement in shear strength, and reduction in swelling potential. Some of the mechanisms of these additives are pozzolanic reaction, cation exchange, carbonate cementation, and flocculation [9, 14].

The production of plastic for daily use increases with time. On the contrary, plastic wastes are the most dangerous environmental polluting wastes since they take a long time to decompose. Many techniques have been implemented to reduce plastic environmental pollution. The most popular technique is recycling plastic wastes. However, toxic gases are released into the environment during melting the plastic to recycle. The other technique is landfill, which is exposing the landfilled ground to landsliding due to weak plastic shear property [15].

Lime stabilization enhances the construction activities by reducing the liquid limit and increasing the plastic limit, which resulted in a decrease in the plasticity index of the soil. This change in plasticity index enhances the workability of the stabilized soil as compressibility and volume change of the soil reduce with a reduction in the plasticity index [16–18]. Recently, reinforcing the soil is becoming the most popular mechanism of mechanical stabilization. The study conducted on weak clay soil investigated the appropriateness of reinforcing soil with sisal fiber and polypropylene fibers to increase shear strength parameters, which shows the potential of this reinforcement in reducing adverse effects on roads, buildings, retaining structures, and water supply lines [19–22]. Experimental study on expansive soil reinforced with polypropylene fiber shows that maximum dry density, swell characteristics, and shrinkage limit decrease with the addition of polypropylene fiber and increase in unconfined compressive strength, CBR, and tensile strength was observed. But it has little impact on the plastic properties of the soil [23, 24].

This study aimed to examine the effects of plastic waste strips and lime on the strength properties of expansive clay soil through experimental investigation. The investigation was carried out by laboratory tests on soil samples considering 0.25%, 0.5%, 0.75%, and 1% plastic waste strips while taking a constant 5% lime. The results obtained from CBR, compaction, unconfined compressive strength, and swelling tests are showing the relevance of using plastic strips and lime to stabilize an expansive soil.

2. Experimental Study

2.1. Materials

2.1.1. Soil

The soil used in this study has been collected from a selected site in Jimma town. Some of the geotechnical properties of the soil are shown in Table 1. Different laboratory tests were conducted to characterize the soil. Depending on the geotechnical properties of the soil shown in Table 1, the soil is categorized as highly plastic clay soil. The free swell shows that the soil is highly expansive.

| Soil property | Value | Standard specification |

|---|---|---|

| Coarse percentage | 4.6% | ASTM D2487 |

| Fine percentage | 95.4% | ASTM D2487 |

| Liquid limit (LL) | 72% | ASTM D4318 |

| Plastic limits (PI) | 36% | |

| Free swell | 103% | ASTM D 4546 |

| Maximum dry density (MDD) | 1.486 g/cm3 | ASTM D 698 |

| Optimum moisture content (OMC) | 27% | |

| USCS classification | CH | ASTM D2487 |

| Classification based on LL | Clay, high plasticity |

2.1.2. Plastic Waste

In this study, the widely available plastic waste (high-density polypropylene water bottle) is used. This plastic waste has been considered due to its availability, low cost, and chemically unreactive nature, and also because it does not absorb water and has no reaction with soil. The plastic water bottles are collected by daily laborers and manually cut into strips of chosen size as fibers as shown in Figure 1. The detailed description of the plastic waste strips used in this study is shown in Table 2.

| Descriptions | Values |

|---|---|

| Compressive strength | Low |

| Water absorption (%) | 0.015 |

| Unit weight, g/cm3 | 0.90 |

| Ultimate tensile strength, MPa | 54 |

| Melting point (ᵒc) | 200 |

| Resistance to acid and alkali | Good |

| Elasticity modulus E, MPa | 110–450 |

2.1.3. Lime

In this study, commercially available hydrated lime at the Senkele lime factory in Ethiopia is used. The chemical composition of this hydrated lime is shown in Table 3 with an ignition loss of 17.04% [4].

| Contents | SiO2 | CaO | Na2O | MgO | Fe2O3 | Al2O3 | K2O | Others |

|---|---|---|---|---|---|---|---|---|

| Percentage of composition | 6.21 | 59.47 | 0.61 | 3.91 | 3.57 | 2.18 | 0.79 | 1.394 |

2.2. Sample Preparation

Initially, the required amount of air-dried soil sample is prepared. The amount of lime and plastic strips added to the soil has been calculated in the percentage of the dry weight of the soil. For compaction, CBR, and UCS, the specimens were compacted to attain maximum dry density at optimum moisture content obtained from the compaction test. The process by which the soil, lime, and plastic strips are mixed follows systematic procedures. First, the lime is mixed with the soil thoroughly at optimum moisture content. Then, the plastic strips were manually added and mixed with soil. During the mixing process of the stabilizers with the soil, uniform distribution of plastic strips is visually observed. Therefore, the study examined the effects of lime with constant proportion (5%) and plastic strips with 0%, 0.25%, 0.5%, 0.75%, and 1% variation on the plasticity and strength properties of expansive soils.

3. Results and Discussion

Various laboratory tests are carried out to determine the optimum percentages of plastic waste strips and lime required to stabilize an expansive clay soil. Accordingly, strength parameters, CBR, and free swell tests are conducted. Table 4 shows the summary of the laboratory test results of soil stabilized with lime and plastic waste strips.

| Addition proportion | Free swell (%) | Atterberg limits | Compaction characteristics | UCS (kPa) | CBR (%) | ||

|---|---|---|---|---|---|---|---|

| LL | PL | MDD (g/cc) | OMC (%) | ||||

| Soil alone | 103 | 72 | 36 | 1.486 | 27 | 75 | 1.96 |

| 5% L + 0% PS | 86 | 63 | 30 | 1.563 | 28.4 | 102 | 2.34 |

| 5% L + 0.25% PS | 77 | 58 | 29 | 1.541 | 26.9 | 132 | 3.08 |

| 5% L + 0.5% PS | 65 | 49 | 27 | 1.519 | 25.2 | 189 | 4.32 |

| 5% L + 0.75% PS | 51 | 46 | 26 | 1.502 | 23.9 | 249 | 5.62 |

| 5% L + 1% PS | 41 | 44 | 25 | 1.483 | 22.3 | 227 | 6.64 |

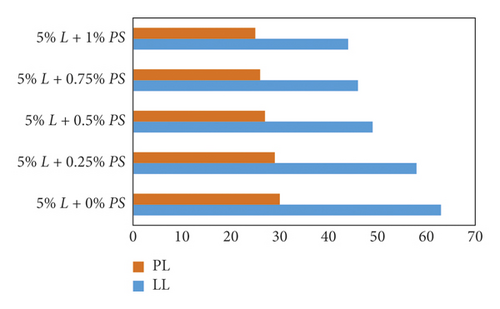

3.1. Atterberg Limits

The Atterberg limit of the treated soil is investigated according to ASTM. During the test, the required percentages of lime are mixed with soil. Plastic waste strips are added after lime and soil are thoroughly mixed. Liquid limit and plastic limit are carried out following the ASTM standards by Casagrande method and on glass plates, respectively.

With the addition of lime and plastic waste strips, the liquid limit and plastic limits slightly decrease, which results in decreases in the plasticity index. A decrease in the plasticity index leads to a reduction in the plasticity property of the soil, which increases the strength of the soil. The addition of lime initiates the pozzolanic reaction, which increases the cementation between soil particles. The cementation between soil particles provides strength. At a constant percentage of lime, an increasing percentage of plastic strips resulted in a decrease in liquid limit and plastic limit as shown in Figure 2. The decrease in liquid limit and plastic limit has a direct relationship with the plasticity and strength properties of the soil.

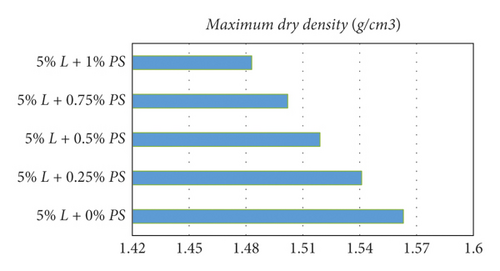

3.2. Compaction Characteristics

The summary of the standard proctor compaction test is shown in Figure 3. The test procedure follows the addition of plastic strips and lime with different water contents and compacting the mixture in standard molds in three-layer 25 blows for each layer.

A standard proctor compaction test has been carried out on soil mixed with different plastic strip contents of 0.25%, 0.5%, 0.75%, and 1% at constant 5% lime. As shown in Figure 3, the addition of lime leads to an increase in maximum dry density of 1.563 g/cm3 from 1.486 g/cm3 for the untreated soil. However, with the addition of plastic waste strips, the maximum dry density starts decreasing. This decrease in maximum dry density as plastic strips increase is due to the lightweight of the plastic compared with the weight of the soil.

The addition of lime alone to the soil results in an increase in optimum moisture content from 27% to 28.4%. This increment in optimum moisture content is due to the high water absorption property of the lime as water highly facilitates the chemical reaction between soil and lime. On the contrary, as the proportion of plastic waste strips increases, the optimum moisture content starts decreasing as shown in Figure 4. This decrease in optimum moisture content shows that the plastic waste strips have low water absorption capacity.

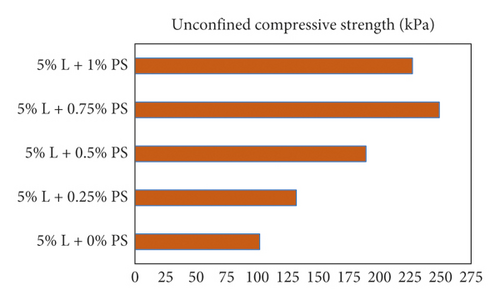

3.3. Unconfined Compressive Strength Test

A strain-controlled unconfined compressive strength test is conducted according to ASTM D2166-06 to determine the undrained shear strength of the plastic strip reinforced lime stabilized soil. The test is carried out for each trial at different proportions of plastic strips at constant lime proportion accordingly. The results show that the addition of lime to the soil helps the particles of the soil to cement together which increases the strength of the treated soil. For a constant lime proportion, as the proportion of plastic strips increases, the unconfined compressive strength increases up to 0.75%, and after that, it starts decreasing as shown in Figure 5. This indicated that the addition of plastic waste strips above 0.75% causes the formation of weak shear planes that initiate the failure of the soil under the load.

The combination of 5% lime and 0.75% waste plastic strips gives a 187 kPa difference compared with that of the untreated soil. This change in unconfined compressive strength shows a significant improvement in the undrained shear strength of the stabilized soil.

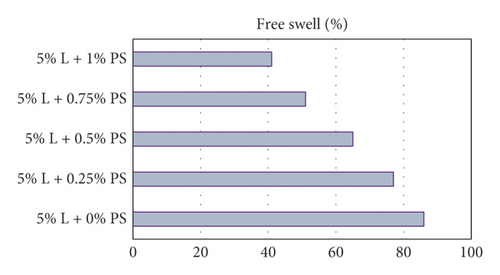

3.4. Free Swell Test

A one-dimensional swell test was carried out to determine the swelling property of the treated and untreated soils. The untreated soil has a free swell percentage of 103%, which shows that the soil is highly expansive. The addition of lime reduced the swelling property of the soil from 103% to 86%.

During the one-dimensional swell test, the soil mixed with stabilizers allowed 24-hour placement. Finally, as the proportion of plastic strips increases, the swelling property of the treated soil decreases. Figure 6 reveals the addition of plastic waste strips improves the swelling properties from 86% to 42% which can be considered a significant improvement.

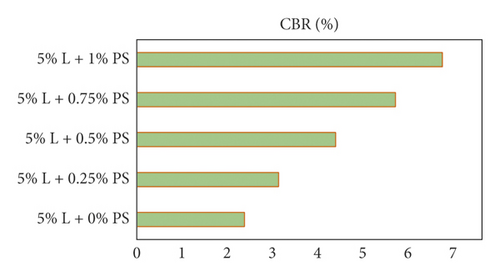

3.5. CBR

CBR test is carried out to determine the subgrade soil strength according to ASTM procedures. It is the ratio in the percentage of force per unit area required to penetrate a soil mass compacted at maximum dry density and optimum moisture content of the soil. The study carried out a soaked CBR test for considering the worst condition of the soil mass. The addition of lime alone increases the CBR value as a cementation of soil particles occurs due to the chemical reaction between the soil and the lime. In addition, the addition of plastic waste strips helps the soil mass compacted in CBR mold by enhancing the resistance to the load from the plunger.

The result indicated that a significant improvement is observed with an increase in the proportion of plastic waste strips. Finally, the CBR value of the soil is improved from 1.78% for the untreated soil to 6.64% at 1% addition of plastic waste strips as shown in Figure 7. With this CBR value, the stabilized soil has the strength to be used as subgrade soil for road pavements. This indicated that the result of this study is crucial for both improving the strength and plasticity of the expansive subgrade soil and disposing of plastic environmental pollution in an environmentally friendly way.

4. Conclusion

- (i)

The addition of plastic waste strips and lime improves the plastic properties of the stabilized soil where significant changes in liquid limit and plasticity index are observed.

- (ii)

The strength parameters increase, showing that these stabilizers are effective to improve the strength of expansive soil. The UCS increases from 62 kPa to 249 kPa while CBR increases from 1.78% to 6.64% with the addition of 5% lime and different proportions of plastic waste strips.

- (iii)

The experimental investigation concluded that the required strength and plasticity properties are obtained at 5% of lime and 0.75% of plastic waste strips.

- (iv)

Generally, the improvement in strength and plasticity properties of the soil with addition of plastic waste strips and lime revealed that the stabilized soil can be used as subgrade materials in flexible pavement construction.

- (v)

The study introduces an effective way of disposing of plastic wastes instead of recycling, landfilling, and dumping plastic wastes in an open environment.

Conflicts of Interest

The authors have no conflicts of interest.

Open Research

Data Availability

The data used to support the findings of this study are included within the article.