Digital Twin-Driven Machine Condition Monitoring: A Literature Review

Abstract

Digital twin (DT), aiming to characterise behaviors of physical entities by leveraging the virtual replica in real time, is an emerging technology and paradigm at the forefront of the Industry 4.0 revolution. The implementation of DT in predictive maintenance has facilitated its growth. As a major component of predictive maintenance, condition monitoring (CM) has great potential to combine with DT. To describe the state-of-the-art of DT-driven CM, this paper delivers a systematic review on the theoretical and practical development of DT in advancing CM. The evolution of concepts, main research areas, applied domains, and related key technologies are summarised. The driver of DT for CM is detailed in three aspects: data support, capability enhancement, and maintenance mode shift. The implementation process of DT-driven CM is introduced from the classification of DT modelling and the extension of monitoring algorithms. Finally, current challenges and opportunities for future research are discussed especially concerning the barriers and gaps in data management, high-fidelity modelling, behavior characterisation, framework standardisation, and uncertainty quantification.

1. Introduction

The fourth industrial revolution “Industry 4.0”demonstrates a new modernisation and digitisation trend of industrial machines driven by the advances of Internet of things (IoT), advanced computing, and artificial intelligence (AI) [1]. The industrial machines in this new trend are expected to be with higher efficiency, longer lifetime, and lower operating costs. Maintenance is crucial in achieving the requirements above. Therefore, a transformation from preventive maintenance to predictive maintenance is demanding in the era of Industry 4.0. Predictive maintenance can maximise machine in-service time by monitoring the condition and predicting the optimal schedule. Condition monitoring (CM) has played an increasingly significant role in supporting predictive maintenance by estimating the current and future condition of the monitored machine. Data-driven CM has achieved remarkable progress in the past decade with advances in sensors, information and communication technologies, and data mining. However, the pure data-driven approaches have faced fundamental challenges in providing interpretable, reliable, and practical solutions due to the limitation of data availability, black-box nature of machine learning, and diverse operational conditions.

With the development of smart sensors, digital modelling technology, and data science, a new concept and paradigm digital twin (DT) is developed, which mainly consists of physical space, virtual space, and the bidirectional connection. It corresponds one-to-one with a potential observation of a particular physical entity. The virtual mirror is the representation that implies capturing the real asset’s essential physical manifestation in a digital format, such as CAD or engineering models with the associated metadata. DT can respond rapidly to stimuli (forces, temperatures, etc.) and describe the operating context, such as wind or waves, in which the assets exist or operate within. There has been continuous research towards building digital twins. DT was originally developed for air force vehicles by NASA and the US air force to enable the safety and reliability of equipment [2]. Since then, DT has gotten much interest from academics and industry, and many efforts have been made. Though the DT-related research is still in the infant stage, a lot of definitions of DT have been proposed [3]. Current DT research mostly focuses on modelling methods and prototype frameworks depending on the usage scenario [1].

Due to the promising capabilities of DT, scientific research and practical applications of DT in CM have emerged in recent years. DT brings new solutions for CM in predictive maintenance, while the architecture, workflow, and related methods of DT-driven CM are not yet well defined and established. Besides, to the best of our knowledge, there are several papers [4–7] that reviewed the development of DT or predictive maintenance, but the advances of DT-driven CM have not been reported. A summary of the recent advances in CM facilitated by DT is needed. Therefore, this paper conducts a systematic review of the development on DT-driven CM.

This paper is organised as follows: Section 2 illustrates the background of CM and DT, providing the definitions, applications, and limitations; Section 3 describes the adopted methodology and materials for the literature review. Section 4 contains a descriptive and detailed analysis of the research results and a discussion of the faced challenges and opportunities. Finally, the conclusions of this study are provided in Section 5.

2. Background

This section aims to provide a brief overview of the principal concepts and applications of CM and DT.

2.1. Condition Monitoring

With the evolution from preventive maintenance to condition-based maintenance for machinery, the origins and concepts of condition monitoring have been defined as Table 1 shows. Conservatively, condition monitoring is a process of observing parameters that indicate the current status of the system [4]. It plays a significant role in the maintenance, management, and sustainable operations of various sectors, such as manufacturing industries [8], electronics [9], and transportation [10]. The execution of condition monitoring in these industries enables maintenance to be scheduled and actions to be taken to prevent consequential damages. It would bring many benefits, such as reducing machine downtime and costs and prolonging the machine’s life.

| Author | Definitions of condition monitoring |

|---|---|

| Álvarez et al. (2013) [11] | “Assessing the current state and estimating the future state of a system by means of measurements and calculations.” |

| Chaulya and Prasad (2016) [12] | A process of monitoring different parameters of condition in machinery in order to identify any significant change, which is indicative of a developing fault. |

| Correa and Guzman (2020) [13] | An evolution of predictive maintenance or proactive maintenance. |

| Ali and Abdelhadi (2022) [4] | A process of observing a set of parameters and/or variables that indicate the state of the system under investigation. |

The implementation of condition monitoring is spread in various applications, such as performance assessment [14], vibration modelling [15], thermal monitoring [16], and oil analysis [17]. Each implementation would include three basic steps: data acquisition, data processing, and decision-making process. Various sensors (e.g., electrical, electronic, and mechanical) have been installed in machinery to acquire kinds of data. These data then are processed to estimate the operating state of a machine by numerous techniques. Upon processing the data, the status information would be helpful for decision-making, such as in determining/predicting (i) health condition, (ii) remaining useful life, (iii) failure analysis, (iv) downtime reduction, and (v) performance improvement strategy.

The application of condition monitoring has increased the reliability of machinery, while there are still some limitations. Data unavailability or qualitative data makes it difficult to assess the equipment status. Failures and performance deterioration are not easy to trace and characterise without expertise and numerous samples.

2.2. Digital Twin

To have an overview of the digital twin concept, Table 2 provides some definitions in academic publications. The concepts are constantly being redefined, while most of them include three main elements: physical space, virtual space, and their connections of data and models. The features of DT can be drawn from these concepts as individualised, high-fidelity, real-time, and controllable [18]. By building an accurate one-to-one mapping and feedback link between real physical space and digital space, the digital twin can implement real-time data/information exchange, dynamic modelling, and update throughout its lifecycle.

| Author | Definition of digital twin |

|---|---|

| Glaessgen et al. (2012) [19] | An integrated multiphysics, multiscale, probabilistic simulation of a vehicle or system that uses the best available physical models, sensor updates, fleet history, etc., to mirror the life of its flying twin. |

| Chen (2017) [20] | A computerised model of a physical device or system that represents all functional features and links with the working elements. |

| Luo et al. (2019) [21] | A multidomain and ultrahigh fidelity digital model integrating different subjects such as mechanical, electrical, hydraulic, and control subjects. |

| Madni et al. (2019) [22] | A virtual instance of a physical system (twin) that is continually updated with the latter’s performance, maintenance, and health status data throughout the physical system’s life cycle. |

The implementation of digital twins is based on several key technologies: (i) data management, (ii) high-fidelity modelling, and (iii) model-based simulation [18]. As the basis of a digital twin, data goes through the steps of collecting, processing, mapping, and calculating to drive DT. Both physical modelling and data-driven methods are used and integrated to characterise complex behavior of a physical object and make predictions/reactions rapidly in DT. Simulations enable a virtual model to predict the behaviors of physical entities in real-time, provide measures to locate failure parts, predict remaining life, and quantify uncertainties.

The research and practice of digital twin technology are inseparable from targeted systems and application scenarios. Numerous industries have been exploring its applicability, such as unmanned aerial vehicles [23], gas turbines [24], wind turbines [25], and manufacturing systems [26]. However, the connotation of the digital twin concept and technical framework has not yet formed a unified consensus in the operation and maintenance phase of these machines. Some bottleneck technologies, such as merging multidomain physical modelling and data-driven approaches, accurate mapping, and dynamic evolution of digital twins, are being investigated for breaking through.

3. Research Methodology

3.1. Research Objectives/Questions

- (i)

Q1: why is digital twin technology suitable to facilitate machine condition monitoring?

- (ii)

Q2: how does digital twin technology drive machine condition monitoring?

Overall, the motivation of this paper is to research how condition monitoring is changing through digital twin technology, including reasons, measures, and gains. Meanwhile, critical challenges and future trends will be involved.

3.2. Research Sources and Methods

A systematic literature review (SLR) is used to analyse and evaluate the existing status of research derived from the given questions. This method is different from the traditional review with advantages of avoiding biased introduction and lack of critical analyses. Referring to Zonta et al. [7] and Silvestri et al. [27], the implementation of this method includes five stages: (1) formulation of the research question, (2) collection of relevant literature in universal databases through specific keywords, (3) extraction of eligible papers which meet qualified criteria, (4) design of a database to assess and sort the extracted papers, and (5) description of the results and findings.

- (i)

“Digital twin” AND (“real-time” OR “health” OR “condition”) AND “monitoring”

- (ii)

“Digital twin” AND (“performance” OR “state”) AND (“evaluation” OR “estimation”)

A high volume of papers that match the scope of keywords were collected. Then, we selected the eligible papers by setting exclusion criteria listed in Table 3. 2017 was chosen as the start date of the search filter because DT in academia and industries was still in infancy before 2017. Digital twin technologies are applied across many areas, such as healthcare, smart cities, and machinery, where the meanings of condition monitoring are different [3]. As shown in criteria 2, the implementation of both technologies in machines is the research object. Papers from professional conferences and journals are considered because of their concision and high quality.

| Section | Description |

|---|---|

| Criteria 1 | Set the published period from 2017 to now. |

| Criteria 2 | Limit research object as machinery or equipment. |

| Criteria 3 | Remove technical reports, dissertations, and theses. |

| Criteria 4 | Remove documents less than 6 pages long. |

We conducted a preliminary investigation on titles and abstracts to evaluate relevance. For better classification and analysis, the selected papers are categorised by article structure (concept, review, case study, etc.), research methods (data-driven, physical-based, hybrid, e.g.), research objects (gas turbines, wind turbines, manufacturing systems, etc.), and research purposes (health monitoring, structure damage assessment, performance evaluation, etc.). Meanwhile, the full text of selected articles was reviewed to extract features for research questions.

4. Results and Findings

Investigating results and findings based on research questions are presented in this section.

4.1. Descriptive Analysis of Research Results

We have collected 133 papers published from 2017 to 2022 in professional academic search databases. After removing duplicates, the final database contains 95 papers suitable for responding to the research objective. We chose one article to read the full text for papers that studied the same type of machines or used the same methods. Finally, 64 papers were explored fully, and others were read simply as shown in Table 4.

| Identified articles | Articles post removing duplicates | Articles post abstract review | Articles post full text review | |

|---|---|---|---|---|

| Total | 133 | 38 | 31 | 64 |

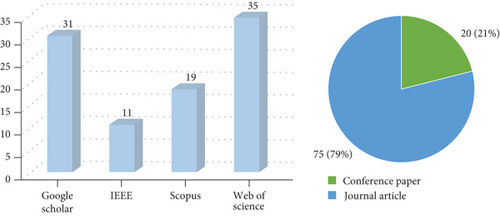

The article distribution by search databases and types is shown in Figure 1. Google Scholar and Web of Science are the main sources in this review. In the database, journal articles are obviously more than conference papers. According to statistics, the main journals and conferences that presented more than one occurrence were IEEE Access, International Journal of Advanced Manufacturing Technology, Robotics and Computer-Integrated Manufacturing, Journal of Manufacturing Systems, ASME Turbo Expo, and IEEE international conference.

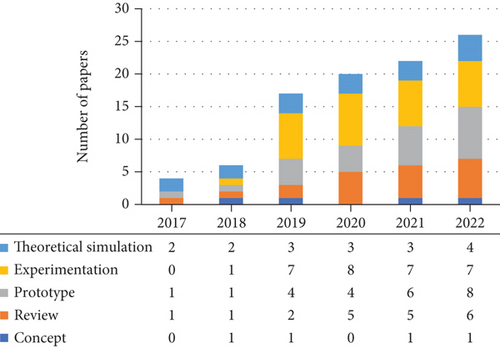

Since 2015, the number of publications has generally increased yearly, as shown in Figure 2. Most of the literature is dominated by case studies (74.7%), which were divided into three categories: (i) theoretical simulation (17.9%): theories were proposed and compared by simulation; (ii) experimentation (31.6%): methods and models were verified by virtual-real interaction under ideal experimental conditions; (iii) prototype (25.3%): methodology was proved with real monitoring data or applied in in-service machines. The rising trend of papers with experimentation and prototype means that the study of DT-driven CM is shifting from theories to implementation. Meanwhile, this shifting situation facilitated discussions about related technologies and challenges, which caused an increase in the review literature.

To demonstrate the applied area and cases of DT-driven CM, we present some representative papers listed by date in Table 5. Each paper’s research area, objects, and related parameters were extracted for analysis. Digital twins bring more connotations and extensions to condition monitoring, as shown in the column of specific areas, such as structural load monitoring, remote online cluster monitoring, and prediction of remaining useful life (RUL). The experiments and applications have been spread in numerous domains, including energy (steam turbines and wind turbines), transportation (vehicle braking systems and vessels), aeronautics (aircraft and aero-engines), astronautics (satellites), manufacturing (lathes and 3D printers), and electronic (converters and batteries). In these scenes, most monitoring variables are inaccessible, unpredictable, or changing obviously with operating conditions, which are unable or difficult to monitor and estimate only by traditional sensors and data processing technologies.

| Authors | Specific area | Case | Variable |

|---|---|---|---|

| Li et al. (2017) [28] | Structural health monitoring | Steam turbine | Stress, strain, fatigue crack length |

| Zakrajsek and Mall (2017) [29] | Structural health monitoring | Aircraft tire | Sink rate, tire profile, wear state |

| Magargle et al. (2017) [30] | Predictive maintenance | Automotive braking system | Speed, force, accumulated wear |

| Tao et al. (2018) [31] | DT-driven PHM | Gearbox of wind turbines | Vibration, stress |

| Zaccaria et al. (2018) [32] | Fleet monitoring | Aircraft engine | Component performance parameters |

| Gholami Mayani et al. (2018) [33] | Operating condition monitoring | Drilling | Temperature, pressure, etc. |

| Tygesen et al. (2018) [34] | Structural health monitoring | Offshore platform | Stress, fatigue damage |

| Johansen and Nejad (2019) [35] | RUL prediction | Drivetrains in marine | Displacements |

| Xie et al. (2019) [36] | State monitoring | Hydraulic support | Tilt angles, hydraulic-support height |

| Venkatesan et al. (2019) [37] | ML-based condition monitoring | Permanent magnet synchronous motor | Distance, operating time, RUL |

| Qamsane et al. (2019) [38] | Machine failure prediction | Numerical control lathe | Spindle current |

| Revetria et al. (2019) [39] | Load real-time monitoring | Metal shelving | Strain, stress |

| Balta et al. (2019) [40] | Performance monitoring | Off-the-shelf 3D printer | Heater input and output signal |

| Zheng et al. (2019) [41] | Remote, real-time, visual monitoring | Welding production line | Geometric, physical parameters |

| Peng et al. (2019) [42] | Condition monitoring | Dc-dc converter | Inductor current, output voltage |

| Moi et al. (2020) [43] | Structural load monitoring | Knuckle boom crane | Strain, stress |

| Yu et al. (2020) [44] | Online performance monitoring | Steam turbine | Mass flow, pressure, temperature |

| Shangguan et al. (2020) [45] | Health monitoring | Satellite power system | Current, voltage, health index |

| Ye et al. (2020) [46] | Structure health monitoring | Spaceship’s bearing beam | Vibration, stress, fatigue crack growth |

| Gonzalez et al. (2020) [47] | State/parameter estimation | Vertical transportation system | Speed, forces, guide alignment |

| Li et al. (2020) [48] | Health state estimation | Battery system | Current voltage, remaining capacity |

| Moutis and Alizadeh-Mousavi (2021) [49] | Real-time monitoring | Distribution power transformer | Voltage, current |

| Panov and Cruz-Manzo (2021) [50] | Performance evaluation | Industrial small gas turbine | Performance parameters |

| Wang et al. (2021) [51] | Real-time monitoring | Die-cutting machine | Speed, pressure, position of the cutting plate |

| Yu et al. (2021) [52] | Health monitoring | Electro-optical system | Transfer function of phase, modulation, optical |

| Zhuang et al. (2021) [53] | Tool Wear monitoring | Cutting tool | Temperature, vibration, lubricant |

| Wu and Li (2021) [54] | Health management | Aircraft engine | Performance parameters |

| Li et al. (2021) [55] | Pre-warning | Trailing suction hopper dredger | Torsional vibrations, residual warning value |

| Toothman et al. (2021) [56] | Health state estimation | Industrial pump system | Flow rate and pressure, health index |

| Moghadam and Nejad (2022) [57] | RUL prediction | Main shaft of wind turbines | Torque, stress, RUL |

| Abbate et al. (2022) [58] | Health monitoring | Electric motor | Signal and energy of vibration |

| Nguyen et al. (2022) [59] | Fault detection | Thermal–hydraulic system | Flowrate, temperature |

| VanDerHorn et al. (2022) [60] | Fatigue damage monitoring | Containership | Wave condition, fatigue damage |

| Bonilla et al. (2022) [61] | State estimation | Pump | Operating speed, pressure, flow rate |

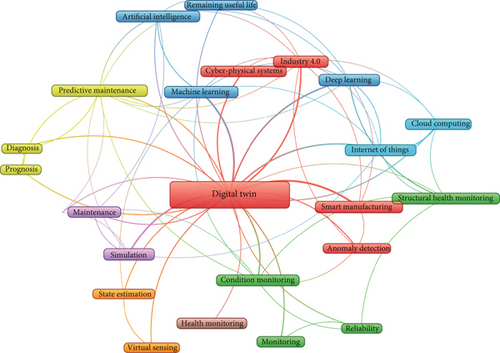

To find all terms directly related to the combination between condition monitoring and digital twins, we generated a relation map of keywords, occurrences of which are more than twice, from the literature database and categorised them into four groups, as presented in Figure 3 and Table 6. “Digital twin” is the most frequently occurring word, which builds the links among developing backgrounds and subjects, emerging technologies and approaches, as well as innovations in implementations. Modern technologies (digital twin, cyber-physical systems, Internet of things, etc.) enable traditional condition monitoring to be incorporated with various novel methods, i.e., artificial intelligence, cloud computing, and virtual sensing.

| Key terms | |

|---|---|

| Backgrounds | Industry 4.0, smart manufacturing, and predictive maintenance |

| Technologies | Digital twin, cyber-physical systems, and Internet of things |

| Methods | Artificial intelligence, machine/deep learning, cloud computing, virtual sensing, and simulation |

| Implementations | Condition monitoring, anomaly detection, structural health monitoring, state estimation, and RUL prediction |

According to keyword analysis, DT-driven CM is presently used mostly in two fields: manufacturing processes (represented by smart manufacturing [62]) and operation and maintenance processes (represented by predictive maintenance [63]). Some studies take a modelling-oriented approach, digital twin, based on technical engineering challenges, with the goal of characterising precise physical behaviors. Others take an information management-oriented approach, such as IoT, emphasising semantic relationships and seamless information flow. Both approaches are derived from artificial intelligence, cloud computing, and other methods, all of which are in the early stages of development. The above advances provide possibilities for the application of condition monitoring in multiple fields, such as RUL prediction components, rapid failure diagnosis of complex systems, and structural health monitoring.

4.2. Content Analysis of Digital Twin Driven Condition Monitoring

This section presented the results and discussions based on the previously elaborated questions.

4.2.1. Q1: Why Is DT Suitable to Facilitate Machine Condition Monitoring?

- (i)

Availability of a multilevel, multidomain database

DT belongs to an integrated database, which stores holistic and hierarchical data covering the whole life cycle. This database is built with design-manufacturing-operating-maintenance data and records from machine layer to part layer. The new monitorable variables (stress, strain, etc.) are available for condition monitoring and make it possible to assess RUL of new failure modes. Li et al. built a versatile probabilistic model to realise the digital twin vision and predict the aircraft wing fatigue crack growth [28]. Magargle et al. presented a digital twin-driven approach to support heat monitoring and accumulated wear prediction of an automotive braking system [30]. Xie et al. proposed an attitude monitoring method for hydraulic supports based on the digital twin theory [36].

Furthermore, a new concept, “virtual sensor,” has been proposed by Nguyen et al. as a novel analytical solution for a process variable that can be used in place of a sensor [59]. They used virtual sensors based on DT to construct performance prediction models for a feedwater heater. Virtual sensors driven by digital twin have also been applied in vertical transportation systems [47] and dredgers [53] to monitor guide alignment and defined residual warning values.

- (ii)

Enhanced ability of fault tracing and degradation prediction:

Condition monitoring based on data-driven methods with monitoring data as input can trigger early warnings accurately while identifying the root cause of faults is a challenge for such approaches due to lacking connections with failure mechanism and physical structure. Conversely, the virtual mirror of DT is an intergradation of multiphysics, multiscale, and multidomain models, which can characterise the dynamic behavior of the physical entity. Therefore, components or systems that cause failures are located directly by the output and inner interactions of the virtual mirror. Tao et al. proposed a DT-driven PHM method to identify and estimate gearbox failure, and the DT model had much better performance in detecting the fault cause (e.g., tooth wear, fatigue, and breakage) than the signal diagnostic method [31]. The DT-based method proposed in this paper covers physical entity, virtual equipment, service, data, and connection, which is suitable for improving the accuracy of prognosis. However, balancing the costs and benefits of the DT and processing a large amount of DT data would impact the application. Zaccaria et al. built a framework for monitoring, diagnostics, and health management of an aircraft engine fleet based on a digital twin [32]. By this framework, different degrees of coupling failures were identified and isolated accurately. However, this framework is far too simplistic to suit the needs of digital twins as it is based solely on an engine performance model and Monte Carlo simulations.

- (iii)

Requirements for maintenance mode revolution

Condition monitoring has already been applied in operation and maintenance of high-value assets. However, this measure driven by solely monitoring data can only provide reference information rather than final decisions for maintenance plans in most cases because the trained model is not reliable and interpretable enough to locate failure and predict serviceability. Thus, maintenance intervals are fixed for most machines, leading to high costs and low utilisation. Predictive maintenance is a method that produces updated information allowing the prediction of future behavior to maximise the part’s service life [13]. It aims to minimise maintenance costs while ensuring the safety and reliability of machines. Currently, the application of DT in predictive maintenance is the most related topic both in academic research and industry practice [18].

It is necessary to promote the combination between DT and monitoring methods to achieve predictive maintenance. Ding et al. proposed a predictive maintenance method for shearer key parts to predive the RUL and support decision-making based on high-fidelity modelling and hyperrealistic behavior simulations, both of which are the key technologies of digital twin modelling [66]. Moghadam and Nejad proposed an innovative drivetrain RUL monitoring approach based on digital twin modelling to perform predictive maintenance of the turbine main shaft [57]. Both papers only explore predictive maintenance in a narrow sense, and future research should include more failure models and decision considerations. Mi et al. proposed a cooperative awareness and decision-making framework integrated with data, knowledge, and DT to support fault diagnosis and maintenance planning and an actual engineering case, prediction maintenance decision-making for bearings in grinding rolls of the large vertical mill, is analysed to illustrate the accuracy and applicability of this framework [67]. In general, the framework is broad and advanced, taking into account all critical elements such as multilevel data, self-adaptive models, uncertainties, and operating conditions.

4.3. Q2: How Does Digital Twin Drive Condition Monitoring?

- (i)

DT modelling to characterise machine behaviors

Numerous modelling methods have been developed to make accurate and bidirectional mapping between the physical entity and the virtual model. They can be divided into physical-based, data-driven, and hybrid methods, as shown in Table 7. Physical-based methods are applied to keep virtual models with high fidelity, including principle-based modelling for mechanical systems, numerical simulation for structure, and equivalent modelling for electronic devices. Data-driven methods build the specific link between machine operating conditions and the variables of interest. Hybrid methods combined with physical-informed and data-driven methods are commonly employed to integrate physical or system principle knowledge. Rapid response scan be generated by reducing the model degree of freedom using hybrid methods. Models built by hybrid methods have required features for standard DT, such as high-fidelity, quick-update, and rapid-response abilities.

According to the literature investigation, most of the current prototype studies are aimed at simple systems or structures. The physical-based modelling is qualified to support digital twin modelling in this situation. Shangguan et al. presented a new physical-virtual convergence approach for a satellite system by Modelica-based modelling [45]. Moi et al. built a digital twin of a small-scale knuckle boom crane by finite element modelling and verified the results by strain gauges [43]. Some studies use data-driven approaches to build data links in digital twins. Li compared the accuracy of digital twin-driven virtual sensors built by different models, such as long-short term memory network, extreme gradient boosting, support vector regression, and deep belief network [55]. Stoumpos and Theotokatos employ a neural networks data-driven method into digital twin as virtual sensors of marine dual-fuel engines [70]. Booyse et al. proposed a new form of DT, deep digital twin [71]. It is constructed from deep generative models which learn the distribution of healthy data directly from operational data at the beginning of an asset’s life-cycle [71]. However, the parameter mapping performed by the black box model has yet to meet the requirements of DT-driven CM, due to a lack of interpretability and physical knowledge.

- (ii)

Development of model-based diagnosis and prediction

- (a)

Performance evaluation

- (b)

Anomaly detection

- (c)

Health monitoring

- (d)

RUL prediction

The amount of papers related to RUL prediction based on DT dominates the literature database. On the one hand, the remaining life of key components has a significant impact on the safety of the whole machine and the maintenance schedule. On the other hand, it can acquire real-time load of components and calculate the accumulative damage based on digital twin. Upon getting the load, the RUL can be obtained by using a damage estimation model of the specific failure mode, such as accumulated wear of a braking system [30], fatigue crack length of aircraft wings [46], thermal mechanic fatigue of turbine blisks [73], and creep damage of turbine blades [72]. These methods are based on reduced order modelling to build a quick mapping model from performance monitoring parameters to thermal or structural loads of key components. DT provides the potential for predicting the RUL of these critical parts, of which life is always affected by loads and temperatures. However, collection of data such as geometric, material, and historical failure data has made algorithm development and validation complex.

4.4. Challenges and Future Directions

Though effects have been made for improving condition monitoring through digital twin technologies, some barriers and restrictions still exist. Simultaneously, the application of digital twins on condition monitoring in this paper proves that there are many chances and new directions for further research in this field. Hence, the challenges and future directions were discussed in this section.

4.4.1. Current Challenges

(1) Data Collection and Management. Multisource, multimodal, multitemporal scale data (e.g., geometry, material, monitoring data, environments, usage, and maintenance records) will be involved in building a digital twin, which can accurately reflect the operating condition. They cover the whole life cycle of a machine, including designing, manufacturing, operation, and maintenance phases. Collecting the above data with high quality and completeness is an essential but difficult challenge. After data collection, managing these data into a complete and standard order, which supports condition monitoring, is one more critical issue.

The amount of data generated by a cluster of individual digital twins is far too large to be stored on standard storage devices. Meanwhile, these data should be easily accessible online to conduct remote real-time condition monitoring without delay. Wang et al. proposed the big data-driven control mechanism and IoT-cloud technologies to build CPS-Digital-twin for the multi-life-cycle remanufacturing process [74]. Although cyber-physical systems and the IoTs are fast evolving, implementing online storage and access will be costly and time-consuming.

(2) Modelling and Method Development. Digital twin modelling for machines needs a good trade-off between fidelity and efficiency, with the consideration of the requirements for rapid response and the available computational resources. Physical-based modelling is a time-consuming computing process. The data-driven methods are efficient but lack interpretability and transparency. Though the integration of both methods is a solution for DT-driven CM, the error and uncertainty that occurred in the model-coupling process is a derived problem that is being explored in academia.

DT-driven CM is currently in its early stages. How to develop new methods based on the new variables generated by the digital twin for monitoring new states still needs in-depth research and innovation.

(3) Validation of Accuracy of Behavior Characterisation. The operation condition of a large system is dynamically changing. Time and operational environments affect the performance degradation and part damage. Incorporating these changing characteristics of a physical entity into the updating process of the virtual model is a challenge. Then, the accuracy of the updated digital twin remains to be verified after each replacement. However, few digital twins can enable real-time updates based on input data. Hence, condition monitoring cannot rely entirely on this kind of digital twins.

4.4.2. Future Directions

(1) Multicomponent, Multilevel Model Development in DT-Driven CM. Most research objects of DT are single-component models in the reviewed papers. It may be a part of multicomponent, multilevel machinery in the industry. Single-component DT is hard to satisfy the needs of performance evaluation and fault isolation for the complex system. In addition, each system element might be simulated and modelled by different software due to adaptability. Coupling all elements into an integrated system is one concerning part that needs to be designed and organised effectively. The integrated system should ensure that existing submodels can be reused, replaced, or modified without corrupting the entire system simulation. Therefore, this is deemed a promising direction for DT-driven CM research.

(2) Framework Standardisation for DT-Driven CM. The concept and connotation of digital twins have been fully developed in the decade since DT was proposed. However, the implementation of DT-driven CM comes into many forms. No standardisation is slowing the progress of in-depth development and leading readers unable to find appropriate solutions for machines. An effective way is to propose the standard DT framework for condition monitoring, including system architecture, workflow, modelling methods, and evaluation indices.

(3) Uncertainty Quantification for DT-Driven CM. Numerous sources of uncertainty cause decision-makers to have reservations about the accuracy and reliability of monitoring performance. The three major sources include input data uncertainty, such as geometry, operating conditions, and the uncertainty of model forms, which are only an approximation to a real condition and are limited by computational budgets, as well as numerical uncertainty induced by iterative error,discretization error. To effectively manage uncertainties, uncertain quantification should be incorporated into DT-driven CM, containing uncertainty identification, propagation, analysis, and optimisation stages.

5. Conclusion

- (i)

Many new monitorable variables provided by DT extend the monitoring scope.

- (ii)

DT’s real-time response and behavior characterisation enhance the monitoring ability.

- (iii)

Predictive maintenance based on DT provides novel monitoring paradigms.

The details of the modelling methods of DT towards CM (e.g., physical-based, data-driven, and hybrid methods) and the novel monitoring paradigms (performance evaluation, anomaly detection, health monitoring, RUL prediction, etc.) were discussed to provide insights for building DT-driven CM. This work investigates more the support supplied by DT for CM and details less how CM is really applied based on DT, as influenced by the gathered literature. In the future, more emphasis should be placed on the superiority and usability of digital twin-driven condition monitoring over traditional condition monitoring.

Overall, various frameworks and methodologies for DT-driven CM have been presented, but only a few have gained industry consensus. The majority of present research focused on individual component modelling and one-way physical to digital communication, which has not yet proven to be a powerful driver of condition monitoring from a technical engineering view. Meanwhile, there is no unifying standard for DT-driven CM, making the research more dispersed and difficult to refer to by other scholars, which may cause repeated research. It is critical that researchers work together to create a systematic framework for DT and DT-driven CM further.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

This work was supported in part by Innovate UK (76940).