The Preparation and Preservation of Soybean Protein Isolate Were Studied Based on the Internet of Things

Abstract

With the gradual deepening of people’s understanding of the concept of environmental protection, this situation has brought new challenges to the preservation and packaging of food. Pure green, natural, and harmless edible film has become a hot topic. Edible protein membranes include animal protein membrane, plant protein membrane, and composite protein membrane. They are mainly used in the field of food production and food safety. The traditional food film has a poor water barrier in a humid environment, which cannot effectively avoid the anaerobic respiration of fruits. At the same time, it will also cause environmental pollution. In order to solve these problems, this paper studies the preparation and preservation of soybean protein isolate based on the Internet of things. Firstly, polyphenols were fused with soybean protein isolate by ultrasonic technology to form an edible fresh-keeping film. The edible membrane of the soybean protein isolate was tested, and the optimum conditions for the formation of the edible membrane were determined by the orthogonal test. The effects of soybean protein isolate, glycerol, reducing agent, and other additives on the film-forming properties were analyzed. Finally, the changes in properties and preservation indexes after film formation were analyzed. The results showed that the film-forming temperature of polyphenol soybean protein isolate edible film was positively correlated with the film properties. The prepared food preservative film can be used for the preservation of vegetables and other foods and has a good retention effect on food nutrients.

1. Introduction

Edible food film is a substance that can cover the surface of food and is used to preserve food and prevent microbial bacteria [1]. At present, most food preservative films and edible packaging films use synthetic plastics as raw materials, such as ethylene and other chemical materials. However, synthetic plastic films are difficult to degrade in the natural environment and cannot effectively deal with residual components, which brings great harm to the environment [2]. Phthalates and other chemicals in the synthetic plastic film are easy to bring hazards and hidden dangers to human health when they are covered in food. As more and more countries pay attention to the research on green environmental protection and food preservative film, they gradually adopt the prohibition of disposable plastic appliances [3]. This form of prohibition makes the research of food preservative film and covering film particularly urgent and important. In food edible film, macromolecular natural substances such as soybean protein, starch, and plant fiber have become a hot research topic in recent years, especially the edible food preservative film based on the soybean protein isolate [4]. An edible food film can effectively preserve and protect unused or used food, blocking the oxidation, erosion, and corrosion of food caused by air and micromolecular moist steam in the air [5]. The difference between edible membrane and edible protein membrane is that the protein membrane is environmentally friendly and renewable due to the common edible membrane [6]. The edible membrane of soybean protein isolate belongs to the plant protein membrane. In addition to animal protein, soybean separation of the plant protein edible membrane is loved by researchers at home and abroad. Soybean separation takes soybean protein isolate as the main material, adding plasticizer and auxiliary materials to press it into a film state. The price of soybean separation itself is low, it can be extracted from a variety of substances, and it is also stronger than other substances in the comparison of film-forming properties. It can block air, oxygen, oil, and other functions, but the extension property of the soybean protein isolate membrane is poor and cannot effectively block water molecules. We need to further optimize the soybean protein isolate membrane to improve the elongation, toughness, and antibacterial properties after film formation [7]. In recent years, it is found that many researchers at home and abroad often add nanoparticles to the improvement of the soybean protein isolate membrane. The membrane modification was studied by combining nanomaterials with edible protein membranes. After adding nanoparticles, the strength, toughness, and water barrier of the soybean protein isolate membrane were improved. Based on the above situation, starting from the fresh-keeping application of the soybean protein isolate film, we explore the improvement of the soybean protein isolate film by polyphenols in antioxidants. Finally, the process of film-forming and preparation and parameter changes are analyzed in real time combined with the Internet of things technology [8].

The preparation and preservation of soybean protein isolate were studied based on the Internet of things. Innovation contributions include the following: (1) Using ultrasonic technology, polyphenols were fused with soybean protein isolate to form an edible fresh-keeping film. The problem of environmental pollution caused by waste of bags is solved. (2) The optimum conditions for the formation of edible film were determined by the orthogonal test. The effects of soybean protein isolate, glycerol, reducing agent, and other additives on the film-forming properties were analyzed. (3) The changes in properties and fresh-keeping indexes after film formation were analyzed. The results showed that the film-forming temperature of the polyphenol soybean protein isolate edible film was positively correlated with the film properties. The prepared food preservative film can be used for the preservation of vegetables and other foods. Compared with the traditional food film, it solves the problem of poor water barriers in humid environments and cannot effectively avoid the anaerobic respiration of fruits.

This paper is mainly divided into three parts. The first part briefly describes the differences between the edible membrane of soybean protein isolate and the edible membrane of polyphenol soybean protein isolate and explores the current situation of edible membrane research at home and abroad. The second part first puts forward the research content of this paper from the defects of the edible membrane in the soybean protein isolate environment. The edible film was studied from the aspects of film-forming mode, nutrition, extensibility, water permeability, and oil barrier. The formation mechanism of the polyphenol soy protein isolate membrane was tested by ultrasonic. The orthogonal test was used to explore the preparation conditions of edible film. Finally, taking the polyphenol soybean protein isolate as the main research object, the fresh-keeping performance of the film and the factors affecting the performance indexes were analyzed. The third part is the analysis of the research results on the preparation method and fresh-keeping function of polyphenol soybean protein isolate edible film.

2. Related Work

Food packaging film can protect food from direct exposure to oxidizing air and can play a good role in isolating harmful substances and bacteria in the air, protecting food from corrosion and oxidation by external microorganisms to a certain extent [9]. With the concept of green environment becoming the research content of modern development, traditional synthetic plastic packaging materials cannot be degraded by the natural environment and are prone to a large number of white pollution. At present, edible biofilm has attracted more and more research and attention. The natural film formed by modified soy protein isolate can minimize the environmental harm on the basis of ensuring the food preservation period [10]. With the rapid development of modern technology, sensor technology such as the Internet of things and ultrasonic technology have become more and more developed and have been gradually applied in automobile manufacturing, biological manufacturing, material technology, and other fields [11]. We added polyphenols to the edible membrane of soybean protein isolate to optimize the film-forming property. The preparation process of film was analyzed by the Internet of things ultrasonic technology. The traditional soy protein isolate membrane has the properties of blocking oxygen, air, and oil and can be used in vegetable packaging, fruit packaging, and other foods [12]. The edible film composed of soy protein isolate can prolong the fresh-keeping period of poultry, eggs, fruits, and vegetables. The maximum limit can be extended by two weeks. As bioglycerols can change the properties of edible films, many researchers have found that soy protein isolate edible films can keep fresh and antibacterial in fruit packaging [13]. However, the traditional soy protein isolate membrane cannot effectively block water and steam. In order to optimize the traditional protein membrane, researchers at home and abroad proposed to add polyphenols in the preparation process. Polyphenols and other substances can have anticancer, antioxidation, antibacterial, and other properties and supplement the defects in soy protein isolate through stable fusion of molecular structure.

Japanese researchers mainly analyze the macromolecular structure of amino acids in the study of edible films. Edible gelatin protein film was obtained by chemical fusion degradation of animal fur and bone. This material can have high heat insulation and sealing performance and plays a good role in blocking air and grease [14] and can achieve biodegradation and compatibility. However, the disadvantage of gelatin film is the same as that of traditional soybean protein isolate film, which cannot be in direct contact with water molecules. It is easily soluble in water and has a poor barrier effect on water and steam. British researchers pay attention to the application of whey protein film in food preservation. Whey protein film can take plasticizers such as glycerol and beeswax as the basis of film-forming and fuse whey protein isolate to prepare fresh-keeping film. The film has low oxygen permeability and can be used as food nutrition and fresh-keeping material. Compared with the soybean protein isolate membrane, it has good extensibility. It can also block fragrance substances and oils in a humid environment [15]. However, the content of amino acids in the whey protein membrane is high, and its antibacterial effect is poor. Based on the above situation, we propose to use polyphenol soy protein isolate as the research content in food preservation and edible film preparation.

3. Methodology

3.1. Preparation and Properties of Edible Membrane of Polyphenol Soybean Protein Isolate Based on Internet of Things

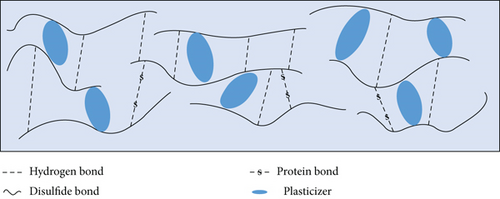

Polyphenol soy protein isolate is a mixed product of common protein globule structure and polyphenols. The main raw materials are soybean globulin, subunit globulin, and other substances. It contains different kinds of subunits, and each globulin is composed of acidic and basic subunits. The preparation process of soybean protein isolate without polyphenols is purified and refined from protein, which has high requirements for protein content. Common soy protein isolate can be easily obtained and refined, with emulsification and rapid film-forming. The edible film can be biodegradable and edible, and the preparation price is close to the people. However, the traditional soy protein isolate film has certain antioxidant properties and high water permeability. It cannot effectively block the invasion of water vapor and has weak ductility. With the change of the surrounding environment, the mechanical properties of the film are easy to be affected. To improve the ability of protein to resist external interference, a large number of disulfide bonds need to be added to the film. We first analyzed the molecular chain interaction in the edible protein membrane, as shown in Figure 1.

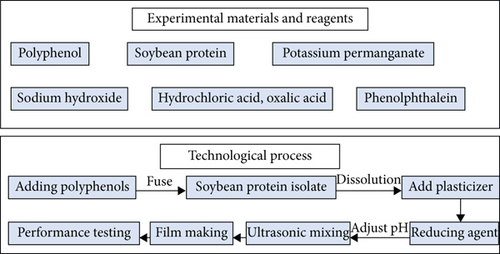

It can be seen from Figure 1 that the stability between molecules is maintained through the interaction of disulfide bond and hydrogen bond, and the polymerization degree of protein molecules presents a network structure, which can affect the performance of the final film. In this paper, natural tea polyphenols were added to the soy protein isolate membrane to improve the ductility and waterproofing of the membrane. The experimental materials and process flow are shown in Figure 2.

In the formula, ΔW represents the change of sample mass during weighing time, S represents the effective area of film-forming measurement, and ΔP represents the difference from water vapor pressure on both sides. Finally, we found that the mechanical properties of the edible membrane were affected by different contents of protein in soybean protein isolate after adding polyphenols. With the increase of protein and polyphenols, the extensibility of the soybean protein isolate membrane fluctuated up and down.

3.2. Application of Polyphenol Soy Protein Isolate Edible Film in Fresh Keeping Based on Internet of Things

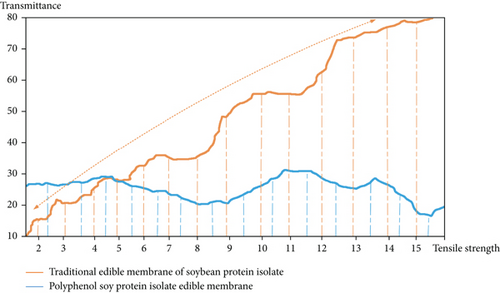

In the formula, X is the vitamin content, T is the number of samples consumed, and V4 is the total volume of samples to be tested. From the previous work, the polyphenol agent was added, and the tensile strength and light transmittance of traditional soybean protein isolate edible film and polyphenol soybean protein isolate edible film were compared by using Internet of things ultrasonic power, as shown in Figure 3.

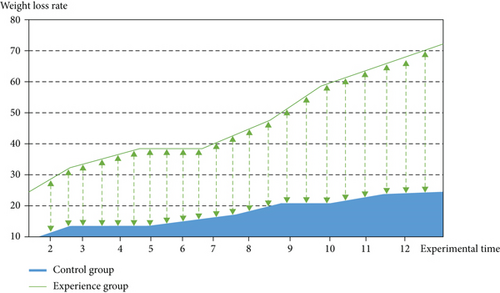

It can be seen from Figure 3 that in the orthogonal experiment, in the edible membrane parameters of polyphenol soybean protein isolate, the light transmittance increases with the increase of tensile strength. We found from the experiment that the effect of edible film on the preservation function is the weight loss coefficient. The effect of film-forming on the weight loss rate of fruits and vegetables was obvious. The control group and experimental group were set up. Put the fruits and vegetables with different treatment methods at the same room temperature, as shown in Figure 4.

It can be seen from Figure 4 that the weight loss rate of fruits and vegetables added with edible film in the experimental group was higher, and the water evaporation effect of fruits and vegetables was higher. With the increase of experimental time, fruits and vegetables without edible film treatment had obvious weight loss.

4. Result Analysis and Discussion

4.1. Preparation and Properties of Edible Polyphenol Soy Protein Isolate Membrane Based on Internet of Things

After modification, the functions of protein such as emulsification and film-forming have been significantly improved, and the molecular structure is relatively stable. It can make up for the defect of ordinary protein film. The ultrasonic function of the Internet of things is used to destroy the interaction of protein molecules and promote the transformation of substances into liquids. The edible film of soybean protein isolate added with polyphenols showed a good optimization effect from the barrier analysis. The film thickness is related to transparency. Transparency and thickness are the key contents in every edible film product parameter. The thickness of the film depends on the quality of insoluble substances in dairy materials, especially the content of precipitates. Too much sediment added to the membrane structure will cause matrix damage. Therefore, the thickness of the composite film is generally greater than that of the ordinary protein film. The thickness of the edible film of soybean protein isolate after adding polyphenols also increases, but the transparency is still within the standard range. In the experiment, the water barrier of the film can be tested to analyze the content of water molecules in the effective area of the film at constant temperature and humidity. Water vapor transmittance is the key factor for testing water isolation performance. The lower the permeability coefficient, it means that the edible film can effectively prevent water erosion. The process of packaging food is relatively stable and can prolong the shelf life. The internal structure density of the film will also be affected by the transmittance of water vapor. Most irregular areas are easy to cause voids, so that water vapor can pass through the gaps. However, after adding polyphenols, the internal structure of the edible membrane changed and filled irregular voids greatly.

From the analysis of nutritional characteristics, the nutritional index of soybean protein isolate added with polyphenols is high, which mainly comes from the mixture of soybean protein and polyphenols. Soybean protein contains the amino acid energy needed by the human body. After appropriate proportion and blending, the digestion efficiency can also reach 90%. This nutrient is easily recycled and absorbed by the human body, and soybean protein also has the effect of promoting the development of the human brain, which often appears in health products. The traditional edible membrane of soy protein isolate cannot effectively isolate water molecules in a humid environment, and the water vapor transmittance is high. It is greatly limited in barrier grease. The soybean protein isolate membrane added with polyphenols can improve the barrier performance of oil and reduce the diffusion of water and oil, ensuring the quality stability of food in transportation. The molecular weight of polyphenols combined with proteins can form molecular groups with high density, in which the disulfide bond and hydrogen bond are relatively stable in the mixed structure, which can compress the irregular gap and make the edible membrane have a certain tightness.

4.2. Application of Polyphenol Soy Protein Isolate Edible Film in Fresh Keeping Based on Internet of Things

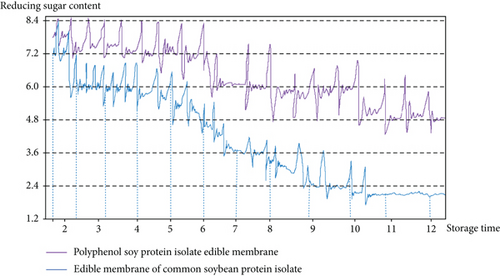

In the field of food preservation, edible films have been loved and concerned by major enterprises for their efficacy, safety, and environmental protection. There are more and more studies on the fresh-keeping effect of edible film at home and abroad. Fruit and vegetable preservation and food freezing processing are the means to protect food quality and improve food shelf life. China started late in the research of edible protective film, but the research efficacy of various types of edible film has been realized by adding various plasticizers and biomolecules on the basis of soybean protein isolate film. Among them, the materials that are cheap and easy to collect mainly include soybean protein isolate and starch. Soy protein isolate has high nutritional value, is easy to be absorbed and digested by the human body, and has plasticity and film-forming property. An ordinary soybean protein isolate membrane has good performance in isolating oxygen, oil, and bacteria, but there are still some defects. The protein molecular bond rigidity of the soybean protein isolate membrane is strong, it is easy to break in practical use, and its ductility and elongation are also low. In order to improve and overcome the defects of the soybean protein isolate membrane, we added polyphenols, sugars, glycerol, and other substances on the original basis. In this paper, the fresh-keeping effect of soybean protein isolate edible film added with polyphenols was analyzed and studied. The water permeability of the polyphenol protein membrane decreased with the increase of polyphenols. It shows that the water separation performance has been improved to a certain extent. When the ratio of polyphenols reaches 3 : 1, the water barrier performance is the best. This phenomenon is positively correlated with the extensibility of the edible membrane. The tightness of the film-forming structure is the main factor related to the two properties. In the above study, we have effectively evaluated the preservation performance of film-forming treatment and continue to explore the impact of film-forming treatment on reducing sugar and acid-base based on the original sample data. The comparison of reducing sugar influencing factors between polyphenol soybean protein isolate edible membrane and ordinary soybean protein isolate edible membrane is shown in Figure 5.

It can be seen from Figure 5 that the reducing sugar in the determination results can represent the changes of nutrients during the storage of fresh food. With the increase of storage time, the sugar content of food covered with polyphenol soy protein isolate edible membrane decreased slowly. With the increase of time, the sugar content in food as a respiratory consumption substance decreases rapidly. The optimized preservative film can greatly preserve the original food. In the acid-base effect, the food acidity of edible film of polyphenol soybean protein isolate decreases slowly, which can inhibit the nutrient loss caused by the erosion of nutrients in the air. With the increase of storage time, acid-base is consumed as oxide, and the optimized edible film can better maintain the acid-base content in food. Finally, we analyze the changes of vitamin content in fruit and vegetable food. With the increase of preservation time, the vitamin content in fruit and vegetable food gradually decreases. The use of optimized edible fresh-keeping film can delay the decline rate to a certain extent, reducing the water loss and vitamin nutrient loss of food in oxygen.

5. Conclusion

Different kinds of edible films have different characteristics. The application of various edible films in the food field is distributed according to the properties of the films. As the natural green edible protein membrane can realize the functions of biodegradation, reduction, and utilization and reduce environmental pollution, many researchers began to pay attention to the properties and preparation process of these substances. The traditional edible membrane of soy protein isolate can effectively isolate oxygen and bacteria and has certain nutritional value, but there are still some defects. Based on the above situation, this paper proposes to study the preparation and fresh-keeping application of polyphenol soybean protein isolate edible film in the environment of the Internet of things. Firstly, the functional defects and modification of traditional soybean protein isolate membrane were analyzed, and the properties of the protein membrane added with various substances were compared. Polyphenols were added to soybean protein isolate for fusion to improve film-forming efficiency, water barrier, and ductility. Aiming at the problem of high water vapor transmittance of ordinary protein membranes, the orthogonal experiment was carried out by ultrasonic to explore the best proportion of edible membranes. Finally, the edible film added with polyphenols was analyzed from the fresh-keeping performance to explore the effects of weight loss rate, reducing sugar content, and vitamin content on the fresh-keeping effect. The results show that the edible membrane of polyphenol soybean protein isolate can improve the defect of poor water barrier and improve the integrity of food protection in a humid environment. It can effectively avoid anaerobic respiration of fruits and vegetables and reduce physiological activity and weight loss rate. It provides an excellent basis for food preservation and has great commercial value. Although many properties of modified protein membranes have been studied in this paper, there are still some deficiencies. The soybean protein isolate membrane has certain antioxidant performance and high water permeability. Therefore, further modifications are needed in future research.

Conflicts of Interest

The authors declare no conflicts of interest.

Acknowledgments

The study was funded by the Key Discipline Project of Jilin Institute of Agricultural Science and Technology, Research on the Heavy Metal Adsorption Law of Pitaya Peel Extract (2019.10-2022.12), and Jinong Institute (2019) (No. X Y 005).

Open Research

Data Availability

The data used to support the findings of this study are available from the corresponding author upon request.