Thermal and Wet Comfort of Clothing in Different Environments Based on Multidimensional Sensor Data Fusion and Intelligent Detection

Abstract

With the improvement of quality of life, people pay more and more attention to the comfort performance of clothing, of which thermal and wet comfort is an important part of evaluating the comfort of clothing, referring to the performance of keeping the human body in a reasonable thermal and wet state. When the human body sweats a lot or is in a highly humid environment, the clothing fabric will be soaked to make people feel wet, which seriously affects the comfort performance of clothing wear, and with the rapid development of sensing technology, the comfort of human clothing can be comprehensively evaluated by a variety of sensing data (clothing pressure, temperature, humidity, and heart rate). Therefore, how to analyze and process these data and establish an objective and accurate evaluation criterion for clothing comfort is a difficult problem and has attracted the attention of many researchers. In this paper, an improved kernel function fuzzy kernel c-means clustering algorithm is used to analyze the pressure at specific points in human activities. Unsupervised clustering analysis was performed for five clustering metrics (mean, pressure range, temperature range, humidity range, and heart rate variability). The clustered samples were learned and discriminated by a support vector machine to determine the comfort level of the clothing. The method can be applied to multi-indicator and multiclassification problems, providing smart clothing researchers with an intelligent, objective, and accurate method for evaluating clothing comfort. Experiments show that the method designed in this paper has good performance experience in terms of mean value, pressure range, temperature range, humidity range, and heart rate variability.

1. Introduction

With the progress of the times, people’s living standards continue to improve, and people’s requirements for clothing are not only a gorgeous appearance, but also pay more attention to the comfort of wearing clothing feeling. And in a survey, questionnaire shows that 78.5% of consumers’ survey results on clothing comfort requirements are much higher than the style, workmanship, and price of clothing [1, 2]. And in this case, it requires clothing with good moisture wicking and other functions to ensure that clothing has good thermal and wet comfort performance, so that the human body is in a comfortable state.

At present, consumers pay more and more attention to the comfort of clothing. Especially, after decades of development, the comfort of clothing is subdivided into hot and humid comfort, contact comfort, fit (sport) comfort and visual comfort. The comfort of clothing mainly includes thermal and wet comfort, contact comfort, body (sports) comfort, and visual comfort [3, 4]. Research shows that in the heat and humidity comfort, contact comfort, and body (sports) comfort on the human dressing comfort contribution ratio of 61.5%, 11.5%, and 9%, respectively [5], it can be seen that the clothing heat and humidity comfort is a more important part of the clothing comfort [6].

As an important part of clothing comfort, it is the most widely researched field at home and abroad, which analyzes the heat and moisture exchange law between the integrated human body, clothing, and the environment from a deeper level and a broader perspective. Therefore, many scholars have done relevant research on it, for example, from the perspective of fibers on the composition, structure, and performance of fibers [7]; from the perspective of yarns on the performance of yarns, twist, hairiness, etc. [8]; and from the perspective of fabrics on the performance of fabrics and structure and other aspects [9]; there are also more and more scholars and experts on different types of clothing research and development [10, 11]. These studies have also improved the comfort of people wearing clothing to varying degrees, but there are still many issues that need to be studied and explored by subsequent scholars.

Smart clothing is an extension and expansion of clothing, but it is still a type of clothing, so the comfort of the human body when wearing it must be considered. The comfort of clothing means that with the development of clothing, people pay more and more attention to the comfortable feeling when wearing clothing to meet their physiological and psychological needs [12, 13]. Therefore, in the design and production process of clothing, it is necessary to consider the comfort feeling produced by the human body when wearing. Nowadays, many consumers take the comfort of clothing as the main reference standard for clothing selection [14]. And more researchers of clothing materials and clothing styles take clothing comfort as a key research topic. Smart clothing is also a combination of clothing and information technology, where miniaturized and flexible electronic components are implanted into advanced textile materials and textile technology to make it have information perception, computational analysis, communication, and other functions [15, 16]. It can provide intelligent analysis, decision support, and feedback to the user based on the changes in the surroundings of the person currently working in a particular environment.

In order to achieve the functions of smart clothing, it is necessary to combine key technologies such as textile, communication, computer, and microelectronics. Since smart garments need to be sufficiently portable, low energy consumption and durable in production and application, flexible sensors and functional textiles, flexible power generation and energy storage devices, flexible display devices, low-power chips and circuit boards, flexible stretchable wires, flexible device processing and packaging technologies, new testing instruments, and information security are essential key technologies in smart garments.

These studies have also improved the comfort of people wearing clothing to varying degrees, but there are still many problems that need to be studied and explored by subsequent scholars [17, 18]. The samples after clustering are learned and discriminated by support vector machine to determine the comfort of clothing. This method can be applied to multi-index multiclassification problems and provides an intelligent, objective, and accurate clothing comfort evaluation method for smart clothing researchers. Experiments show that the method designed in this paper has excellent performance experience in average value, pressure range, temperature range, humidity range, and heart rate variability.

2. Multifunctional Clothing Design System and Evaluation System

Currently, knitted garments are the most closely integrated textile category between smart wearable devices and garments, and its flexibility and weaveability are more in line with the current development trend [19]; therefore, knitted garments are mainly considered in the combination approach, and most smart wearable devices are sensor-based components [19]. With the development of sensor miniaturization and regionalization, the layout of wearable devices is no longer limited to parts but to the whole-body domain network of human garments. In addition to interacting and communicating with human body information, it can monitor, collect, and transmit interaction data from the surrounding environment.

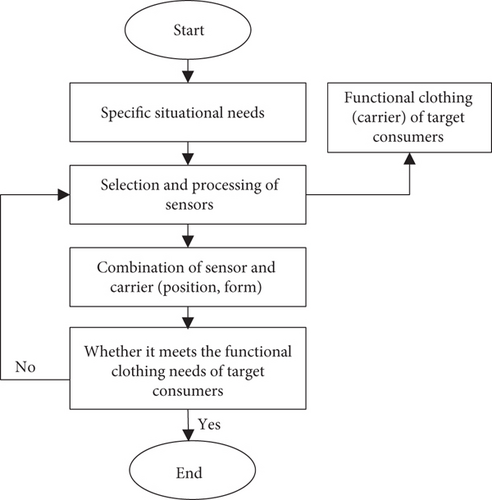

Therefore, this paper investigates the combination of smart wearable devices and target consumers’ clothing from several aspects to meet the needs of target consumers for functional clothing in specific environments (or specific safety situations) in terms of safety, comfort, and design aesthetics. Based on an in-depth understanding of the needs of target consumers, we select suitable smart wearable devices (matching the characteristics of the target information) and explore the form of combination with functional clothing to conclude a design process that can balance function and aesthetics. Figure 1 shows the basic process of the study of combining smart wearable devices with target consumers’ clothing.

With the popularity of mobile terminals such as smartphones and iPads, most wearable smart devices rely on mobile terminals to receive and analyze data. Currently, wearable devices and mobile terminals mainly transmit data through short-range wireless transmission, such as Bluetooth (Bluetooth), Zigbee, Wifi, and light fidelity (LiFi) technologies [20, 21]. The interaction between wearable devices and mobile terminals is mostly one-way, i.e., the interaction between wearable devices and terminals is relatively single, and the degree of data sharing is low, which affects the functional effect of the products. Therefore, in order to achieve high service efficiency of information processing between wearable devices and terminals, it is necessary to study the data information transmission and interaction between wearable devices and between wearable devices and mobile terminals, i.e., multi-interaction.

The multi-interaction framework of smart wearable device data transmission is shown in Figure 2.

For the multiple interaction methods between smart wearable devices and mobile terminals, this paper divides the information interaction methods into two categories: one is the information interaction triggered by human behavior, such as touch and click and behavior recognition; the other is the precise monitoring and interpretation of behavior language through wireless data transmission technology, which is still immature.

In this paper, we establish a single connection between smart wearable devices and mobile terminals through the current relatively mature near-field communication technology (e.g., FC technology), Bluetooth technology, and iBeacon technology [22, 23]. A diversified and full-coverage interaction mode between multiple smart wearable devices and mobile terminals is established, and a low-consumption and multifunctional optimized connection scheme is concluded.

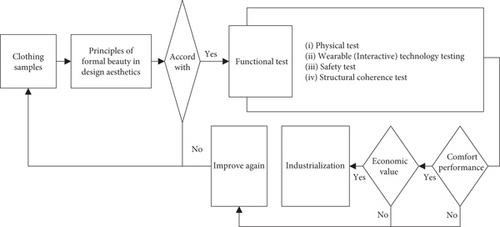

This paper proposes a multifunctional apparel evaluation system for the apparel production process based on the research methods of related literature. First, the design aesthetics of the garment, such as style, color, and fabric, are evaluated using the principle of formal beauty; then its functions are comprehensively tested, including physical testing, wearable (interactive) technology testing, considering comfort, safety, economy, and other factors, safety testing, and structural continuity testing, to make it industrially valuable. The multifunctional garment design evaluation system is shown in Figure 3.

3. Kernel-Based Fuzzy C-Means Clustering Algorithm

An improved fuzzy kernel clustering algorithm, called fuzzy ISODATA, is a clustering algorithm that uses affiliation to determine the degree to which each data point belongs to a particular cluster. In many complex practical applications, it is necessary to replace the kernel function in linear space with a more expressive high-dimensional space. The nonlinear problem is transformed into a linear problem by constructing new feature vectors and finally clustering in the high-dimensional feature space.

Among them ω is the weight coefficient.

Since each index has different degrees of importance to the judgment of clothing comfort, it is necessary to determine the weight corresponding to each index. Among them, the subjective weighting method is divided into layers and the Delphi method. This method is mature and easy to use. Therefore, this paper uses the Delphi method to determine the corresponding indicators weight value.

- (1)

Data preprocessing determine the number of clusters c, the fuzzy coefficient m, and the scale parameter to σ2 and the function, and initialize the membership matrix uik, and set the iteration precision

- (2)

Update membership matrix uik according to Equation (6)

- (3)

Calculate the kernel function

- (4)

If ‖Ui+1 − Ui‖ < ε, stop the iteration, get the cluster center vi, and the membership matrix uik; otherwise, return to step (2).

4. Principle of Data Classification Based on Support Vector Machine

The multi-index sample set establishes a corresponding model between clustering categories and clothing comfort levels through certain rules. In this process, the relationship between a single index and the wearing comfort of the subjects and its importance to the overall comfort can be considered at the same time. The construction of this model provides a quantitative criterion for the evaluation of clothing comfort, which makes the evaluation of clothing comfort more objective. This paper uses SVM to classify the clustered results.

Among them m is the weight vector; n is the bias vector.

Among them, ai ≥ 0 is the Lagrange multiplier; 。.

In this paper, the clustered samples are divided into two parts; one part is used for learning, and the discriminant rules of clothing comfort are established. The remaining samples are judged by the established discriminant rules, and their types are determined, so as to discriminate the comfort level of clothing.

5. Comfort Experiment and Analysis

In order to ensure the accuracy of the experimental results, 30 volunteers were selected to wear the same tight-fitting clothing and perform the same actions as the subjects in Chapter 3, and collect four quantitative indicators of pressure, temperature, humidity, and human heart rate between the human body and the clothing, and ask the subjects’ subjective feelings during the experiment; 1 represents discomfort, and 2 represents comfort. After simple processing of the data collected by the system, the clothing comfort analysis is carried out. In this paper, five parameters are selected as the clothing evaluation index. Among them, the pressure average and range at points C, E, I, J, and L are used as two pressure indicators; it is expressed by pressure, and the unit is pa: the temperature range value at point p is used as the temperature index, and the unit is °C; the humidity extreme difference value at point O is used as humidity, and the unit of degree index is %: the heart rate change rate during the human experiment is used as the heart rate discrimination index, and the unit is 4%.

The physical parameters of the selected 30 subjects and the subjective evaluation of clothing comfort during the experiment are shown in Table 1:

| Subjects | Height | Weight | Shoulder width | Bust | The waist | Hipline | Subjective evaluation |

|---|---|---|---|---|---|---|---|

| 1 | 177 | 72 | 44 | 92 | 83 | 102 | 1 |

| 2 | 178 | 71 | 45 | 93 | 82 | 102 | 1 |

| 3 | 178 | 72 | 45 | 96 | 85 | 99 | 1 |

| 4 | 176 | 71 | 43 | 95 | 82 | 96 | 1 |

| 5 | 177 | 72 | 44 | 96 | 84 | 97 | 1 |

| 6 | 183 | 75 | 43 | 93 | 97 | 88 | 1 |

| 7 | 182 | 74 | 42 | 96 | 99 | 89 | 1 |

| 8 | 181 | 72 | 45 | 95 | 98 | 87 | 1 |

| 9 | 179 | 73 | 42 | 94 | 102 | 85 | 1 |

| 10 | 177 | 72 | 41 | 92 | 104 | 84 | 1 |

| 11 | 178 | 71 | 42 | 93 | 102 | 79 | 1 |

| 12 | 172 | 68 | 43 | 92 | 89 | 97 | 1 |

| 13 | 174 | 72 | 45 | 95 | 85 | 94 | 1 |

| 14 | 173 | 72 | 43 | 95 | 87 | 96 | 1 |

| 15 | 175 | 71 | 42 | 91 | 78 | 98 | 1 |

| 16 | 181 | 75 | 44 | 99 | 78 | 96 | 1 |

| 17 | 167 | 61 | 42 | 85 | 71 | 95 | 2 |

| 18 | 169 | 59 | 42 | 85 | 72 | 89 | 2 |

| 19 | 179 | 68 | 42 | 92 | 81 | 97 | 1 |

| 20 | 178 | 63 | 42 | 93 | 74 | 94 | 2 |

| 21 | 164 | 55 | 42 | 95 | 84 | 97 | 1 |

| 22 | 178 | 56 | 43 | 78 | 77 | 84 | 2 |

| 23 | 174 | 55 | 42 | 78 | 74 | 85 | 2 |

| 24 | 176 | 64 | 41 | 86 | 82 | 94 | 2 |

| 25 | 164 | 55 | 41 | 88 | 82 | 97 | 2 |

| 26 | 172 | 71 | 43 | 95 | 82 | 98 | 2 |

| 27 | 177 | 61 | 42 | 85 | 77 | 94 | 2 |

| 28 | 175 | 57 | 40 | 75 | 74 | 85 | 2 |

| 29 | 168 | 55 | 41 | 87 | 74 | 87 | 2 |

| 30 | 170 | 52 | 41 | 75 | 74 | 83 | 2 |

After the experiment, the specific values of the five comfort evaluation indicators of the 30 subjects are shown in Table 2:

| Subjects | Pressure/pa | Temperature p/°C | Humidity 0/% | Heart rate/% | |

|---|---|---|---|---|---|

| Average value | Range | Range | Range | Rate of change | |

| 1 | 5754 | 4192 | 0.7 | 44 | 29 |

| 2 | 5887 | 2432 | 1.2 | 43.5 | 22 |

| 3 | 5193.7 | 5008 | 1.4 | 37.9 | 25 |

| 4 | 6245 | 7544 | 1.7 | 42.5 | 26 |

| 5 | 9333.8 | 6423 | 1.5 | 36.4 | 18 |

| 6 | 6113.27 | 4551 | 1.7 | 42.5 | 22 |

| 7 | 6641.7 | 4975 | 1.5 | 43.5 | 15 |

| 8 | 5888.6 | 2872 | 1.4 | 34.5 | 16 |

| 9 | 4933 | 6728 | 1.4 | 31.5 | 14 |

| 10 | 5076.2 | 7335 | 2.2 | 38 | 9 |

| 11 | 7196.55 | 7336 | 2.1 | 39 | 8 |

| 12 | 5855.35 | 3934 | 2.8 | 34.8 | 9 |

| 13 | 4905.75 | 4687 | 1.8 | 35.8 | 17 |

| 14 | 6591.75 | 6369 | 1.6 | 39.4 | 11 |

| 15 | 4923.25 | 3996 | 0.9 | 31.5 | 13 |

| 16 | 5415 | 5869 | 1.6 | 36.62 | 11 |

| 17 | 3089.25 | 4905 | 0.6 | 24.5 | 10 |

| 18 | 2826 | 5432 | 0.3 | 14.2 | 7 |

| 19 | 4748.75 | 5126 | 1.4 | 18.1 | 12 |

| 20 | 3599 | 4006 | 1.2 | 16.4 | 5 |

| 21 | 5527.25 | 5297 | 1 | 15.4 | 5 |

| 22 | 2882.25 | 3851 | 0.8 | 12.3 | 4 |

| 23 | 2587.25 | 3732 | 1.4 | 12.7 | 0 |

| 24 | 3113.75 | 3731 | 1.4 | 12.8 | 1 |

| 25 | 4233 | 2114 | 0.5 | 7.5 | 8 |

| 26 | 2425.25 | 2906 | 0.4 | 21.4 | 3 |

| 27 | 2588 | 4378 | 0.8 | 12.9 | 8 |

| 28 | 1859.5 | 1574 | 0.4 | 15.5 | 4 |

| 29 | 1598 | 5 | 1541 | 0.3 | 13.3 |

| 30 | 1241.25 | 2927 | 0.1 | 9.6 | 2 |

Based on the improved FKCM clustering based on the MATLAB platform. Determine the fuzzy coefficient m = 2, the scale parameter σ2 = 0.4, and the iteration accuracy 0.00001. Use the Del Pei method to determine the corresponding weight coefficient ω = (0.3, 0.3, 0.15, 0.15, 0.1) of the clothing comfort index set. The KF clustering effectiveness index of the improved FKCM clustering analysis results is used to determine the optimal number of classifications as shown in Table 3. It can be seen that the KF index value shows that the sample data set is divided into two categories, that is, the number of clustering categories c = 2.

| Preset classification number | 2 | 3 | 4 |

| Actual classification number | 2 | 3 | 3 |

| KF value | 31.0948 | 22.7665 | Nan |

Since the relationship between the indicators is nonlinear, the ordinary linear classification is no longer suitable for the evaluation of clothing comfort. In this paper, the LIBSVM software developed by Professor Chih-Jen Lin of National Taiwan University is used for multiclassification and discriminative model [24]. The SVM type is selected as C-SVC, the Gaussian kernel function is selected for nonlinear transformation, the loss function P is 01, and the termination criterion is 0.001. 15 groups of test samples are selected from two types of objects, including 8 samples in the first category and 7 samples in the second category. The identification results are shown in Table 4. It can be seen that the judgment model has accurately identified the classes of the samples.

| Judgment category | First kind | Class II |

|---|---|---|

| Sample number | 1, 2, 5, 7, 8, 9, 10, 12, 14, 19 | 15, 17, 24, 25, 28, 30 |

In this paper, the clustering algorithm based on the improved FKCM is applied, and after clustering the comfort index samples of 30 subjects for many times, two categories are determined as the optimal number of clusters. And use the support vector machine to learn some of the samples, establish a discriminant rule, and use this rule to discriminate the comfort of the remaining samples, so as to identify the accuracy of the discriminant rule. Experiments show that a clothing comfort evaluation method based on the combination of improved FKCM clustering and support vector machine proposed in this paper can intelligently classify and identify clothing comfort and avoid the judgment of subjects and subjective factors in the evaluation process impact on results. It provides a reference and evaluation method for comfort discrimination for the production researchers of smart clothing and also provides a research idea for the next multilevel comfort evaluation.

6. Fabrics under Different Moisture Content

In order to obtain the variation of thermal insulation properties of fabrics at different moisture contents, this section will start from the following two aspects.

6.1. Changes of Thermal Conductivity of Fabrics with Different Water Content

The sportswear fabrics provided by T Apparel were chosen as the experimental materials for testing, mainly 10 kinds of woven and knitted fabrics. These 10 fabrics were placed in a constant temperature and humidity chamber (ambient temperature: 20 ± 2°C; ambient humidity 65 ± 5%) for 12 hours, and the basic parameters of the fabrics were tested. The results are shown in Table 5.

| Fabric number | Fabric classification | Thickness mm | Square meter gram weight g/m2 | Volume weight g/cm3 | Thermal conductivity/w/m · °C | Heat preservation rate/% | Permeability | Moisture permeability/g/m2 × 24 h |

|---|---|---|---|---|---|---|---|---|

| Woven 1# | Woven | 0.112 | 72.58 | 0.661 | 0.05 | 19% | 6.88 | 1710.3 |

| Woven 2# | Woven | 0.105 | 72.59 | 0.689 | 0.03 | 22% | 4.69 | 1734.5 |

| Woven 3# | Woven | 0.117 | 71.85 | 0.605 | 0..04 | 25% | 7.40 | 1703.2 |

| Woven 4# | Woven | 0.118 | 79.16 | 0.672 | 0.04 | 25% | 3.54 | 1705.5 |

| Woven5# | Woven | 0.145 | 97.41 | 0.677 | 0.05 | 20% | 5.06 | 1732.8 |

| Woven 6# | Knitting | 1.021 | 250.74 | 0.245 | 0.07 | 32% | 211.93 | 1869.7 |

| Woven 7# | Knitting | 1.251 | 251.94 | 0.203 | 0.06 | 31% | 589.52 | 2016.5 |

| Woven 8# | Knitting | 2.420 | 357.44 | 0.149 | 0.04 | 42% | 544.22 | 2031.7 |

| Woven 9# | Knitting | 0.493 | 141.51 | 0.288 | 0.05 | 29% | 286.71 | 1773.9 |

| Woven 10# | Knitting | 1.243 | 308.64 | 0.245 | 0.06 | 27% | 192.73 | 1984.1 |

The above 10 kinds of fabrics were uniformly treated with moisture, and the prepared fabrics were placed in deionized water to make them completely wet, and then they were taken out and placed in a constant temperature and humidity room, until the fabric moisture content reached the moisture content to be measured. Test it after rate requirement. According to different fabric types, the moisture content of woven fabrics is set to 5%, 10%, 15%, and 18%, and the moisture content of knitted fabrics is set to 10%, 20%, 30%, 40%, 50%, and 60%.

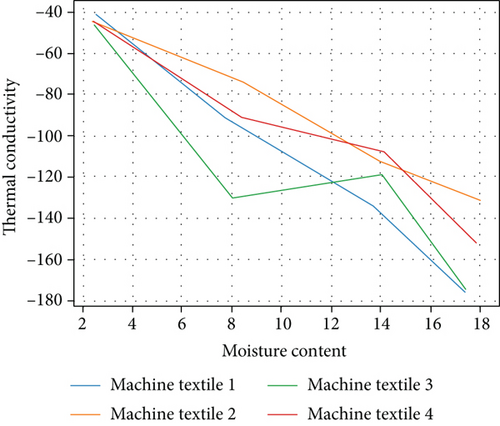

The whole process of the experiment was completed in a constant temperature and humidity room. The thermal conductivity of 10 kinds of fabrics and the heat preservation rate of the fabrics were tested by using the KESF-7 precise instantaneous thermal property tester. The test process was completed according to the requirements of the experimental instrument. This experiment was carried out to obtain the test results of the thermal conductivity and the thermal insulation rate of the fabric under different moisture contents and draw them into a line graph, and the change rule is as follows.

6.2. Influence of Different Moisture Contents on the Thermal Conductivity of Fabrics

Read the test results of thermal conductivity of fabrics with different moisture contents on the KESF-7 precision instantaneous thermal property tester C.

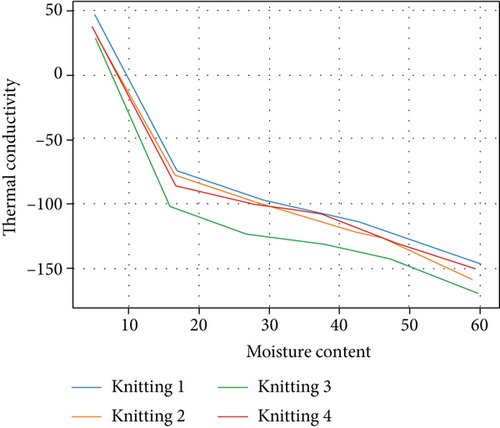

The following will take the average of the 5 test results of each fabric, import the data results into the origin software, and draw a line graph of the change of thermal conductivity with moisture content of woven fabrics and knitted fabrics, as shown in Figure 4, and the abscissa in the broken-line graph represents the moisture content of the woven fabric and the knitted fabric, the ordinate represents the thermal conductivity of the fabric, and the broken line in the figure represents the change of the thermal conductivity of the fabric with the increase of the moisture content.

- (1)

Variation law of thermal conductivity of woven fabrics affected by moisture content

- (2)

Variation law of thermal conductivity of knitted fabrics affected by moisture content

It can be seen from Figure 4 that the thermal conductivity of knitted 6#-knitted 10# fabrics shows a continuous increasing trend with the increase of moisture content. When the moisture content is less than 40%, the thermal conductivity of different knitted fabrics, the increasing trend of thermal conductivity of different knitted fabrics is different, and when the moisture content is greater than 40%, the increasing trend of thermal conductivity of different knitted fabrics is close to the same. This is mainly due to the different forms of moisture in the fabric, which may be because when the moisture content is less than 40%, the moisture in the fabric mainly exists in the state of bound water and intermediate water.

Among them, when the moisture content of the knitted 8# fabric reaches 20%, the thermal conductivity of the fabric increases significantly, which is almost 2.3 times that of the fabric when the moisture content is 10%. This is mainly because when the moisture content of the fabric is 10%, the surface of the fabric has almost no wet feeling and is similar to the nonmoist state. When the moisture content is 20%, the fabric begins to feel wet, and because the knitted 8# fabric is larger, and when the moisture in the fabric increases, the air content in the fabric decreases significantly, resulting in an increase in the thermal conductivity of the fabric and a significant decrease in the thermal conductivity of the fabric.

When the moisture content of knitted 10# fabric is less than 40%, the heat transfer rate of the fabric changes slowly with the increase of the moisture content, which may be because the cotton fiber has hygroscopic expansion after blending with cotton and polyester, and the thickness of the fabric increases after moisture content.

6.3. Influence of Different Moisture Content on the Thermal Insulation Rate of Fabrics

In the equation, W0 is the thermal power of the empty plate, and W1 is the thermal power when the fabric is covered.

The following will take the average of the five test results of each fabric, import the data into the origin software, draw a line graph of the change of the thermal insulation rate of the fabric with the moisture content, and analyze the woven fabrics and knitted fabrics, respectively. As shown in Figure 5, the abscissa in the broken line graph represents the moisture content of the woven fabric and the knitted fabric, the ordinate represents the thermal insulation rate of the fabric, and the broken line in the figure represents the change of the thermal insulation rate of the fabric with the increase of the moisture content happening.

- (1)

The variation law of the thermal insulation rate of woven fabrics affected by the moisture content

- (2)

The variation law of the thermal insulation rate of knitted fabrics affected by the moisture content

It can be seen from Figure 5(b) that the thermal insulation rate of knitted 6# and knitted 10# fabrics shows a continuous decreasing trend with the increase of moisture content. When the moisture content is between 10% and 20%, the decreasing trend of the thermal insulation rate of the fabric is the most obvious. This is mainly because when the moisture content is 10%, the surface of the fabric has almost no moisture feeling similar to the state without moisture and has a certain thermal insulation performance, while when the moisture content is 20%, the surface of the fabric feels wet, and the thermal insulation performance of the fabric changes significantly different.

6.4. Significant Analysis of the Influence of Different Moisture Contents on the Thermal Insulation Performance of Fabrics

In order to accurately judge the significance of the influence of different moisture contents on the thermal insulation performance of fabrics, the analysis of variance was carried out on the test results for further exploration.

ANOVA is usually divided into one-factor, two-factor, and multifactor experimental data analysis of variance according to the number of experimental factors studied. It is an important method for analyzing experimental data in experimental research. It can analyze the respective functions of various factors and make quantitative estimates. Since the factors that affect the thermal performance of fabrics in this experiment include different fabrics and different moisture content, the analysis of variance method of the results of the two-factor independent observation value test is selected.

The experimental results of the thermal conductivity of fabrics under different moisture contents and the thermal insulation rate of fabrics under different moisture contents were processed and analyzed by SPSS software, and the following results were obtained.

The statistical results of variance analysis of the effect of different moisture content on the thermal conductivity of woven fabrics are shown in Table 6, where factor A is the moisture content of the fabric, which is divided into 4 levels, and factor B is different woven fabrics, which is divided into 5 levels.

| Source | Type 3 sum of squares | df | Mean square | F | Sig |

|---|---|---|---|---|---|

| Calibration model | .001a | 7 | .000 | 57.488 | .000 |

| Intercept | .027 | 1 | .027 | 8506.917 | .000 |

| Moisture content | .000 | 3 | 5.109E-5 | 16.295 | .000 |

| Textile | .001 | 4 | .000 | 88.384 | .000 |

| Error | .3.763E-5 | 12 | 3.135E-6 | ||

| Total | .028 | 20 | |||

| Total corrected | .001 | 19 |

- a. R square = 971 (adjust R square = 954).

In the table, the sum of squares and sig of the moisture content of different factors are 0.0003, 5.109E-5, 16.293, and 0.0003, respectively. The sum of squares, degrees of freedom, mean square, F of different woven fabrics, and sig value are 0.001, 4, 0.000, 88.383, and 0.000, respectively. The sig value represents the result of the significance test. When it is less than 0.05, the null hypothesis is rejected, and the factor is considered to have a significant impact on the result; when it is greater than 0.05, the null hypothesis is accepted, and the factor is considered to have no significant result on the result, and the higher the F value, the more significant the result. Larger values indicate more significant differences.

In Table 6, the sum of squares and sig of the moisture content of different factors are 0.0003, 5.109E-5, 16.293, and 0.0003, respectively. The sum of squares, degrees of freedom, mean square, F of different woven fabrics, and sig value are 0.001, 4, 0.000, 88.383, and 0.000, respectively. The sig value represents the result of the significance test. When it is less than 0.05, the null hypothesis is rejected, and the factor is considered to have a significant impact on the result; when it is greater than 0.05, the null hypothesis is accepted, and the factor is considered to have no significant result on the result, and the higher the F value, the more significant the result. Larger values indicate more significant differences.

It can be seen from Table 7 that the sig<0.001 of the factors with different moisture contents indicates that there is a significant difference in the thermal conductivity of the fabrics under different moisture contents; the sig. <0.001 of the woven fabrics with different factors indicates the thermal conductivity between different woven fabrics. There is a significant difference in the thermal conductivity of woven fabrics, which indicates that moisture content has a significant effect on the thermal conductivity of woven fabrics.

| Source | Type 3 sum of squares | df | Mean square | F | Mean square |

|---|---|---|---|---|---|

| Calibration model | .038a | 9 | .004 | 26.185 | .000 |

| Intercept | .360 | 1 | .360 | 2232.307 | .000 |

| Moisture content | .034 | 5 | .007 | 42.705 | .000 |

| Textile | .004 | 4 | .001 | 5.536 | .004 |

| Error | .003 | 20 | .000 | ||

| Total | .401 | 30 | |||

| Total corrected | .041 |

- a. R = .922 (adjust R = .887).

The statistical results of variance analysis of the effect of different moisture content on the thermal conductivity of knitted fabrics are shown in Table 7, where factor A is the moisture content of the fabric, which is divided into 6 levels, and factor B is different knitted fabrics, which is divided into 5 levels.

In the table, the sig of knitted fabrics with different moisture content and different factors are 0.000 and 0.004, respectively. The factors with different moisture content sig<0.001 indicate that there are significant differences in thermal conductivity of fabrics under different moisture content; sig<0.001 for different knitted fabrics indicates that there are significant differences in thermal conductivity between different knitted fabrics. Therefore, the moisture content has a significant effect on the thermal conductivity of knitted fabrics.

7. Conclusion

Fabric is the material basis of clothing production, playing an indispensable carrier role, fabric and clothing interdependent, closely related. Usually the heat and moisture transfer performance of fabric affects the heat and moisture comfort performance of human wearing clothes, and the two have a close correlation. In this paper, the comfort performance of clothes is studied by different algorithms. Firstly, the thermal and moisture comfort performance of clothes under different wet environments is evaluated by real person wearing experiments, and the thermal and moisture transfer performance of fabrics under different moisture content rates is tested by physics testing methods. Then a suitable clustering method was selected to cluster and analyze the known classified data to establish a suitable data classification model. Finally, the clustered data are divided into two parts to learn by vector machine or discriminant analysis method to determine the classification rule and then use the rule to discriminate the data in the remaining part to determine its type, so as to determine the accuracy of the discriminant rule. The sig of woven fabrics with different moisture contents and factors are 0000 and 0.148, respectively. Sig<0.001 for factors with different moisture contents indicates that there is a significant difference in the insulation rate of fabrics with different moisture contents, while sig. >0001 for woven fabrics with different factors indicates that there is no significant difference in the insulation rate of different woven fabrics.

Conflicts of Interest

The authors declared that they have no conflicts of interest regarding this work.

Acknowledgments

This study is supported by the Research on Friction Comfort of New Clothing Fabrics Based on Long-Distance Running (No. jz180909).

Open Research

Data Availability

The experimental data used to support the findings of this study are available from the corresponding author upon request.