[Retracted] Detection of Particle Concentration and Particle Size Based on Aerodynamic Particle Size Spectrometer

Abstract

In order to solve the problem of the continuous online monitoring of the fixed pollution source emission particles, on the basis of the advantages and disadvantages of the comprehensive analysis of the extinction method, the β-ray absorption method, the micro-oscillating balance method, the charge transfer method, and the light scattering method, the particle size distribution and concentration optical detection system based on aerodynamic particle size spectrometer is designed according to the Mie light scattering principle. A high-performance aerodynamic particle size spectrometer is designed using a single-wavelength method to measure the concentration of particulate matter, and the equipment and the detection system are used in the continuous monitoring of particulate matter emitted by thermal power plants and compared with the ES632 equipment. Through the system test, the results show that compared with the ES632 equipment performance, the lowest concentration measured by the design of aerodynamic particle size spectrometer equipment can reach 0.1 mg/m3 with a measurement accuracy of 0.01 mg/m3. Compared with the ES632 equipment, the measurement concentration value is 8% higher, which meets the test requirements.

1. Introduction

In recent years, the development of industry has provided great help to the overall progress of China’s economy, but the rapid development of industry has also caused a series of problems. Particularly, the air pollution caused by the rapid development of industry has gradually become an important issue concerning the international people’s livelihood. How to ensure the reasonable development of industry and at the same time to implement pollution control work is a popular topic of concern in all fields of the current society [1]. However, the particulate matter pollution is the most serious air pollution, and the regional development of industrialization also leads to an increasing frequency of severe air pollution in a wide range in the region. For example, fine particulate matter will not only harm the human health, but even directly lead to the reduction in visibility in the city and the region, and the corrosion of buildings. At the same time, the formation of the cloud condensation nuclei by the scattering and absorbing solar radiation will also affect the climate and the normal life. Based on the condition, the current phase of the concentration of the particle size and particle size detection has received the widespread attention. On the basis of the advantages and disadvantages of the comprehensive analysis of the extinction method, the β-ray absorption method, the micro-oscillating balance method, the charge transfer method, and the light scattering method, the particle size distribution and concentration optical detection system based on aerodynamic particle size spectrometer is designed. The feasibility of the system is also verified by the system test [2].

2. Literature Review

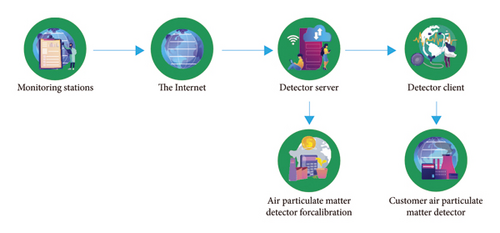

The atmospheric particulate concentration is one of the basic parameters to characterize the spatial distribution of particulate matter, which is generally expressed by mass concentration and quantity concentration. The particle size is related to the life and transmission characteristics of particles in the atmosphere, and is an important parameter affecting the environment and human health. The observation of particle concentration and particle size distribution (Figure 1) can provide important parameters for the in-depth understanding of the nature of particulate matter and its impact on climate and environment [3]. In the past few decades, the effects of atmospheric particulate matter on human health and the global environment and climate have been recognized. Europe and the United States and other developed countries took the lead in carrying out the relevant research [4]. At the beginning of the research (around the 1960s and 1970s), the main focus was on the chemical composition of atmospheric aerosols and the analysis of pollution sources. With the increase in people’s understanding, the study of atmospheric particulate matter has been gradually extended to many fields, including the temporal and spatial distribution, the chemical composition, the pollutant emission inventory, the particle size distribution, and the generation and growth of new particulate matter. Since 2012, China has started to monitor the concentration of particulate matter PM2.5 and PM10. Automatic on-line monitoring stations for the atmospheric environment have been established throughout the country. From national control stations, provincial control stations, municipal control stations to county control stations and township-level monitoring stations under construction, there have been tens of thousands of environmental particulate matter monitoring stations under the national standard method. There are hundreds of thousands of other small and micro-monitoring sites. Most of the methods used to monitor the concentration of particulate matter are the beta-ray method, the oscillating balance method, or the optical dispersion method. Pollution monitoring work, such as the source analysis, is widely carried out with these methods. Since 2012, many different types of particle size analysis instruments have been used nationwide to observe and study particle size in the air, especially taking the aerodynamic particle size spectrometer as the main monitoring means [5].

3. Detection Technology of Concentration and Particle Size

At present, the commonly used continuous monitoring methods of particulate matter concentration from fixed pollution sources include the extinction method, the β-ray absorption method, the micro-oscillating balance method, the charge method, and the light scattering method. This chapter will introduce the principles and characteristics of each method.

3.1. Extinction Method

In formula (1), I0 is the incident light intensity; I is the light intensity through the flue gas; α is the light absorption rate of particulate matter; C is the concentration of particulate matter; and L is the optical path. The concentration of particulate matter can be calculated by calculating the ratio of the light intensity before and after the laser passes through the flue gas. Land-4200 of foreign Land Company and LDM-100 of domestic Concentrating Technology are all made use of this method [6]. The method is easy to understand and simple in structure, but it has the following shortcomings: low sensitivity, easy to be affected by changes in particle size distribution and refraction coefficient, and the bad measurement effect. It is generally applicable to the scenes with the high particle concentration (more than 300 mg/m3), little changes in dust particle size and composition, and low humidity.

3.2. β-Ray Absorption Method

The principle of the β-ray absorption method is that β rays are absorbed when they pass through the particles. When the energy of emitted rays is constant, the absorbed energy is proportional to the mass of particles. During the measurement, the flue gas is sampled with a cutter, and the particles are adsorbed with a filter membrane. The concentration of particulate matter in the air can be calculated by measuring the attenuation coefficient of the time intensity of the β ray through the filtration membrane [7]. The characteristic of the β-ray absorption method is that the measurement results are only related to the quality of the particles, and have nothing to do with the types, particle size distribution, refraction coefficient, and other factors of the particles. It is suitable for the occasion of high humidity and large changes in particle size and composition. However, because constant velocity measurement is required, it is not suitable for scenarios with large velocity changes. At the same time, the instrument using this method is not suitable for the online monitoring because of its high cost, long measurement time, and poor real-time performance when the accuracy is higher. The products using this method include the BETA 5M dust meter of ESA in France, which is widely used in environmental monitoring stations.

3.3. Micro-Oscillating Balance Method

The principle of the micro-oscillating balance method is to use an oscillating hollow conical tube in the mass sensor. The oscillating frequency depends on the characteristics and mass of the conical tube. The replaceable membrane filter is installed at the oscillation end. When the sample gas passes through the membrane, particles will be adsorbed on the membrane filter, which makes the quality of the membrane filter change, resulting in the change of the oscillation frequency. The mass of particles deposited on the filter membrane is calculated according to the change in oscillation frequency, and then, the mass concentration of particles is calculated according to the flow rate, ambient temperature, and atmospheric pressure. The advantages of this method are that the concentration of particulate matter can be continuously monitored and that the accuracy and real-time performance are very good [8]. A suitable cutter is used to sample the smoke and also measure PM2.5 and PM10. However, it also has the disadvantages of the filter membrane being easy to block and being greatly affected by the temperature and humidity.

3.4. Charge Transfer Method

The measurement principle of the charge transfer method is that when the probe is impacted by particles, friction, or charge induction, a certain static charge will be generated, and the amount of charge is proportional to the number of particles. By detecting the electrostatic signal and measuring the airflow velocity, it is converted to the measurement of concentration [9]. When using this method, the system is relatively simple and can be used for the continuous online monitoring. However, it has the following disadvantages: The variation in particle size, composition, and droplet concentration has a great influence on the measurement accuracy, so it needs to be calibrated before use. It cannot be used for monitoring particulate matter after the electrostatic dust removal. During the detection, the flow rate needs to be measured, so it is not suitable for occasions where the flow rate changes greatly. The products using this method are mainly used for the leakage monitoring of the bag dusting.

3.5. Light Scattering Method

The basic principle of the light scattering method is the Mie scattering theory. The light irradiation on particles will be absorbed and scattered; the intensity of scattered light is related to the particle size, concentration, incident light wavelength, and scattering angle. Using scattered light intensity, the concentration and particle size distribution and other parameters can be calculated [10].

When a dust particle is illuminated, it emits light of different intensity in all directions, which is called scattering. The intensity of the scattered light is closely related to the concentration, particle size, and wavelength intensity of the light source. Under the condition of the stable particle size distribution and stable light source wavelength and intensity, the intensity of scattered light is linearly related to the concentration of particles. The light scattering method can simultaneously measure various particle sizes, avoiding the problem of inverted particle concentration, and no sample enrichment process reduces daily consumables such as the filter film and the filter paper tape [11]. The light scattering method is greatly interfered with by the particle composition and moisture. The light scattering method instrument with a single wavelength is basically used in the monitoring of dust, coal powder, and other components and environmental conditions in the workshop. In recent years, multiwavelength, wide spectrum light scattering principle instruments appear in the market, which have passed the certification of EPA in the United States and TUV in Germany and have been applied in the national air quality monitoring network. Because of its advantages of wide application range, large measurement range, fast measurement speed, high accuracy of measurement data, and good repeatability, it has become the main way of the international online monitoring of particle concentration. However, the instruments of this method are prone to interference and pollution from the water vapor and particulate matter, so necessary measures should be taken to protect the optical instruments from contamination. As can be seen, each method is different in principle and each method has its own advantages and disadvantages. The details are shown in Table 1.

| Methods | Advantages | Disadvantages |

|---|---|---|

| Extinction method | Simple structure, easy to implement | The sensitivity is not high and is affected by particle size distribution and refractive index |

| Beta-ray absorption method | The measurement results are independent of particle size, color, and composition | It requires constant sampling, high cost, and long measurement time |

| Micro-oscillating balance method | The measurement results are independent of particle size, color, and composition | Affected by humidity, the membrane is easy to plug |

| Charge transfer method | The system is simple and mainly used for engine exhaust concentration detection | Due to the influence of particle size change, composition change, and water droplets, calibration is required before use |

| Light scattering method | Large measuring range, fast speed, high-precision data, good repeatability | The measurement results are related to particle size, color, and composition, and need to be calibrated. |

In the research, based on the advantages and disadvantages of various methods, the Mie light scattering method is selected. The Mie scattering theory is a strict solution of Maxwell’s equations for a single uniform particle under the monochromatic light, which can be used to describe the scattering effect of uniform particles on the monochromatic light accurately [12].

In formulas (8) and (9), Jn+1/2(x) is a Bessel function of order half-integer, and Hn+1/2(x) is a Hankel function of order half-integer.

If the distance between particles is large enough, the scattering of particles will not be affected by the scattering of other particles. In this case, it can be regarded as the irrelevant scattering. In fact, the scattering light of a certain particle and other particles in the same direction has a certain coherence, because the small displacement of particles or the small change in scattering angle will change its phase difference so that the scattering effect of a large number of small particles randomly distributed can be regarded as the addition of the scattering light intensity of each particle [14]. Yet when the particles are very close to each other, the interaction between the particles must be considered, and the scattering phenomenon is called the relevant scattering. Table 2 shows the conditions when the particles meet the irrelevant scattering. Particulate matter in the flue gas emitted by coal-fired power plants is mainly PM2.5. After the desulfurization and the dust removal, the concentration of particulate matter is low, which meets the condition of the irrelevant scattering.

| Particle size (μm) | Quantity concentration of particulate matter (one particulate matter/cm3) | Volume concentration of particulate matter (%) |

|---|---|---|

| 0.1 | 1015 | Less than 0.510 |

| 1.0 | 1010 | |

| 10.0 | 107 | |

| 100.0 | 104 | |

| 1000.0 | 10 |

4. Design of the Particle Size Spectrometer Based on the Detection of Particle Concentration and Particle Size

4.1. Research Objectives and Content

For scientific research applications, a forward detector is designed to obtain both forward scattering and backward scattering data at the same time of the lateral detection. By obtaining more underlying data, it can make postprocessing more accurate [15].

The optical path optimization is carried out based on TSI aerodynamic particle size spectrometer. On the basis of the lateral detection, a forward detector is added so that the forward and backward data can be processed simultaneously to increase the detection sensitivity. The ratio of the forward scattering and the backward scattering is used to further distinguish the size of particles, so as to further distinguish the shape, diameter, and surface area of particles. Refrigeration APD combined with a high-precision operation amplifier circuit can further increase the detection sensitivity of aerodynamic particle size spectrometer, so as to improve the detection limit. The laser diode, APD detector, and its operational amplifier circuit are controlled by the constant temperature to ensure accurate measurement of the instrument and avoid the range drift. In view of TSI’s time-of-flight (TOF) data processing by the analog circuit, the research uses FPGA to collect data for the dual-channel 14-bit, 250-Msps, and above high-speed ADC. The processing algorithm after the data acquisition is implemented in FPGA to perform the rapid and accurate measurement [16]. The dynamic gas path control method is adopted to ensure the constant jet velocity of the nozzle to avoid measurement errors. The rotatable real-time 3D display function is added in upper computer software to improve the human-computer interaction.

Based on the above assumption that the particle size distribution will not change during the measurement process, it draws the conclusion that the scattered light intensity is proportional to the concentration of particles, and a single-wavelength measurement system for the concentration of particles is designed according to this principle. However, in actual measurement, the particle size distribution does not always remain constant, resulting in the inaccurate concentration measurement. Therefore, the particle size needs to be monitored in real time. When the particle size changes, the β-ray concentration meter is started to calibrate and then solve the particle concentration.

4.2. Influence of the Particle Size Distribution Changes on the Concentration Measurement

In order to verify the above analysis, the CMAG 3475 aerosol generator of TSI Company is used to generate particles with different particle sizes for experiments, and the relationship between the concentration of particles with different particle sizes and the scattered light intensity is recorded [17]. CMAG 3475 is an aerosol generator using the Sinclair–Lamer condensation technology, which can produce aerosols of different sizes by setting the temperature and airflow. The particle size distribution of the product is concentrated, the size is stable, and the experiment has a good repeatability. Aerosol generators are used to generate 1.72 μm and 1.87 μm particles, respectively, and the responses of detectors to the scattering light of the two particles at different concentrations are recorded. The responses of detectors to the particle concentration are fitted in a linear relationship. The result is shown in Figure 2. It can be seen that the slope of fitting line of particles with a median particle size of 1.72 μm and 1.87 μm is different, so the concentration of particles is different when the scattering light intensity is the same. The light intensity ratio under different median particle sizes and standard deviations is shown in Table 3.

| Standard deviations | Median particle sizes | |||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| 1.0 | R1 | 2.5440 | 2.7854 | 1.5987 | 0.1984 | 0.4685 |

| R2 | 0.1360 | 0.5999 | 0.8758 | 0.8888 | 1.3000 | |

| R3 | 0.3277 | 2.5642 | 1.3592 | 0.5689 | 3.6000 | |

| 1.2 | R1 | 2.2526 | 3.0290 | 1.3858 | 0.4686 | 0.5332 |

| R2 | 0.1706 | 0.5768 | 0.8254 | 1.4256 | 3.2654 | |

| R3 | 0.3843 | 1.8974 | 1.5420 | 1.0075 | 1.7489 | |

| 1.3 | R1 | 2.3506 | 2.5778 | 1.2340 | 0.7207 | 0.6273 |

| R2 | 0.3548 | 0.6272 | 0.9467 | 1.8765 | 2.9714 | |

| R3 | 0.5378 | 1.6169 | 1.1673 | 1.3237 | 1.8640 | |

4.3. Optical Structure Design of the Multiwavelength Cascade System

- (1)

It can reduce the space occupied by the system and simplifies the device installation

- (2)

Particles are not evenly distributed everywhere in the flue, so it is necessary to make the measurement area of the three-way wavelength as close as possible so that the characteristics of the particles measured are the same

During the measurement, the flue gas passes through the main optical axis of each incident laser in turn in the measurement area to generate scattered signals so that the scattered light signals of each path are generated by the adjacent particles, reducing the measurement error caused by the uneven distribution of the flue gas.

- (1)

The light hole of the baffle is designed as a bell shape with narrow front and wide back. This design can make the corresponding scattered light signal received by the photodetector larger, but the scattered light signal with scattering angle greater than a certain range cannot pass through the light hole. So, the scattered light signal that causes interference will be blocked, reducing the interference to other signals and improving the signal-to-noise ratio [20].

- (2)

Through the geometric optical analysis, the following model is constructed to limit the distance between the main optical axes so that the interference of scattered light without affecting the airflow in the measurement area can be reduced. Finally, the mechanical structure of the equipment is determined. The total length of the equipment is 825 mm; width, 188 mm; and height, 77 mm. The incident end is 686 mm long, which can effectively separate the laser and the back-end circuit from the measurement area to ensure that the electronic components will not overheat. The measurement area is 40 mm wide, and the distance between adjacent main optical axes is 70 mm. The reflector end is 99 mm long; the internal reflector is fixed, and optical devices such as optical trap are installed. The incident end and the reflection end are fixed through the blue inner tube in the middle, so as to align the light path.

4.4. Experimental Test

APS3321 of TSI Company is used as the reference group in the experiment to measure particle size distribution at the same time with the system. The principle of APS3321 is an aerodynamic method, which calculates the flight speed of particles through the flight time between two laser beams, and then calculates the particle size according to the corresponding relationship between the speed and the particle size. The parameters of the standard dust detected in the experiment are shown in Tables 4 and 5.

| Chemical composition | Percentage by weight |

|---|---|

| SiO2 | 68–75 |

| AL2O3 | 10–15 |

| Fe2O3 | 2–4 |

| Na2O | 2–5 |

| CaO | 2–5 |

| MgO | 1.5–2 |

| TiO | 1.5–1 |

| K2O | 2–5 |

| Size (μm) | Cumulative volume percentage |

|---|---|

| 1 | 2.5–5.5 |

| 2 | 10.5–12.5 |

| 3 | 18.5–22.0 |

| 4 | 25.5–29.5 |

| 5 | 30.1–36.0 |

| 7 | 41.0–45.0 |

| 10 | 50.0–54.0 |

| 20 | 70.0–74.0 |

| 40 | 88.0–99.0 |

| 80 | 99.5–100 |

| 120 | 100 |

During the measurement, the system records data once per second, some of which are shown in Table 6. It can be seen from the table that different detectors have different background values before the measurement, because the stray light exists in the environment during the measurement and different detectors have different response values to the stray light. In order to eliminate the influence of the stray light and obtain the scattered light intensity, the background value needs to be subtracted after the initial measurement.

| Time | Detector response value | Increment (response value-background value) | ||||

|---|---|---|---|---|---|---|

| Blu-ray | Infrared | Infrared | Blu-ray | Infrared | Infrared | |

| Wavelength | 450 nm | 940 nm | 1550 nm | 450 nm | 940 nm | 1550 nm |

| Background value | 52 | 428 | 197 | 0 | 0 | 0 |

| 8:33:42 | 61 | 437 | 187 | 9 | 9 | −8 |

| 8:33:43 | 54 | 465 | 191 | 5 | 4 | −8 |

| 8:33:44 | 43 | 442 | 191 | −10 | 15 | −8 |

| 8:33:45 | 15 | 458 | 192 | −6 | 35 | −6 |

| 8:33:46 | 48 | 443 | 195 | −6 | 18 | −4 |

| 8:33:47 | 40 | 436 | 205 | −10 | 8 | −1 |

| 8:33:48 | 40 | 445 | 195 | −5 | 15 | 6 |

| 8:33:49 | 52 | 438 | 199 | −2 | 11 | −1 |

| 8:33:50 | 60 | 437 | 202 | 10 | 9 | 1 |

| 8:33:51 | 57 | 437 | 198 | 5 | 8 | 5 |

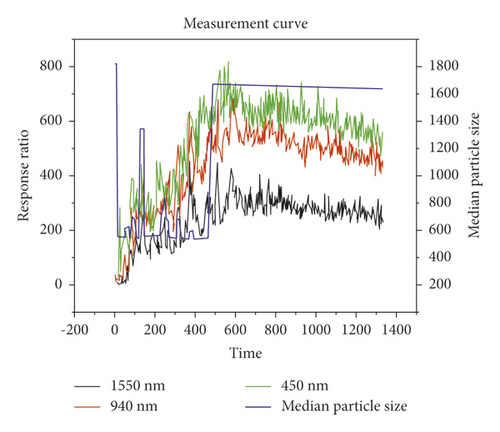

According to the response data of different-wavelength scattered light with time, the median particle size can be obtained according to the relationship between the median particle size and the net response of three-wavelength scattered light. The change in the response of scattered light over time and the median particle size obtained in real time are plotted as a curve, as shown in Figure 3.

It is clear that from Figure 3, the system is influenced by the environment in the stray light in the process of the measurement and the background value is produced. Although at each time, the current response value is subtracted from the background value at the initial time, if the ambient light is changed, it still has an impact on the system of measurement, which makes some irregular fluctuations in the curve. To solve this problem, the measurement area should be placed in a dark room and the response values should be averaged. The response curve of the system is relatively stable to the scattering light with the wavelength of 1550 nm, while the jitter amplitude is relatively large to the scattering light with the wavelength of 940 nm [21].

According to the response value of the three scattered light, the ratio (R1, R2, R3) can be obtained, and then, (μ, σ) can be solved. In the actual calculation of the median particle size of this system, the table lookup method is used. To be specific, a conversion table from (R1, R2, R3) to (μ, σ) is constructed through the established (μ, σ)-to-(R1, R2, R3) model. When the ratio of three scattered light signals is obtained, the (R1, R2, R3) closest to it in the conversion table is found according to the measured ratio. Finally, (μ, σ) is obtained by searching the conversion table. A portion of the conversion table is shown in Table 7. By looking up the table, the measured median particle size is 1700 nm, the standard deviation is 1.5, and the measured concentration is 5.69 mg/m3. With the back-end software system, the final result display diagram can be obtained.

| R1 | R2 | R3 | μ (nm) | σ |

|---|---|---|---|---|

| 2.5044 | 0.1359 | 0.3272 | 1000 | 1.10 |

| 1.4785 | 0.5999 | 1.6575 | 2500 | 1.10 |

| 2.9864 | 0.3011 | 0.8889 | 1700 | 1.15 |

| 1.4859 | 0.8328 | 1.2325 | 3500 | 1.20 |

| 1.3865 | 0.8330 | 1.0544 | 3000 | 1.20 |

| 0.7568 | 1.4268 | 1.0075 | 4000 | 1.20 |

| 0.5359 | 3.5843 | 1.7852 | 4500 | 1.25 |

After the particle size distribution is obtained, the concentration of particles is calculated according to the response of scattered light intensity at 450 nm. In the initial measurement stage, the air pump begins to pour particles in the smoke chamber, and both curves show an upward trend. After reaching a certain time, the two curves show a downward trend due to the suspension of particulate matter into the smoke chamber. Over time, the decline trend becomes slow. The change trend of the two curves is consistent with the real change of the concentration of particulate matter in the smoke chamber. Comparing the two curves, it can be found that in the initial stage, the concentration measured by the system is less than that measured by ES632, and there is a certain delay compared with ES632 in terms of time. The reason for this result is that during the experiment, the position of the particles we pass into is close to ES632, so the measurement results obtained by the equipment lag behind ES632 in the initial stage. With the passage of time, the distribution of particles in the smoke chamber is more uniform, and their concentration curves almost coincide [22].

As shown in Table 8, some measurements are extracted to compare the performance of the device with that of the ES632. From the measurement results, the lowest concentration measured by the equipment can reach 0.1 mg/m3, and the measurement accuracy can reach 0.01 mg/m3. Compared with ES632, the deviation of the measured concentration value is about 8%, which meets the design requirements.

| Time | Concentration measurement value (mg/m3) | ||

|---|---|---|---|

| This equipment | ES632 | Relative deviation (%) | |

| 21:50:24 | 3.617 | 3.785461 | 3.00 |

| 21:50:54 | 3.448 | 3.668595 | 5.97 |

| 21:51:24 | 3.541 | 3.595246 | 1.0 |

| 21:51:54 | 3.450 | 3.689845 | 4.59 |

| 22:20:24 | 2.150 | 2.978528 | 13.12 |

| 22:20:54 | 2.049 | 2.597448 | 9.58 |

| 22:21:24 | 2.098 | 2.986428 | 8.99 |

| 22:21:54 | 2.065 | 2.598724 | 20.25 |

| 23:50:24 | 0.296 | 0.189422 | -0.05 |

| 23:50:54 | 0.287 | 0.359728 | 14.98 |

| 23:51:24 | 0.259 | 0.248722 | 5.78 |

| 23:51:54 | 0.157 | 0.249782 | -4.59 |

| 0:20:24 | 0.159 | 0.154358 | 5.89 |

| 0:20:54 | 0.059 | 0.154781 | 10.31 |

| 0:21:24 | 0.014 | 0.167245 | 15.88 |

| 0:21:54 | 0.024 | 0.159713 | 9.43 |

In this chapter, an experimental scheme is designed to verify the performance of the measurement system in particle size distribution and concentration measurement using two industrial products, TSIAPS3321 and Met One ES632. The response of the detector to the scattering light of three wavelengths is recorded, and the particle size distribution parameters and mass concentration are calculated, respectively [23]. The measurement results of the system are compared with those of reference products, and the performance of the system is analyzed. Some shortcomings of the system are found, and the reason for data jitter is explained.

5. Conclusions

In addition to affecting the human health, fine particulate matter PM2.5 suspended in the atmosphere will reduce the visibility of cities and regions directly, corrode buildings, and affect the climate and human normal life by scattering and absorbing solar radiation and forming condensation nuclei of clouds. As a manifestation of the existence of matter, particles constitute a side of the colorful tangible world. In addition, particle size also has a great influence on the taste of food, the utility of medicine, the sintering capacity of metallurgical powder, and the explosive strength. Therefore, according to the actual social needs, and with the development of science and technology, the simultaneous measurement technology of particle concentration and particle size has been widely valued by people, and has gradually developed into an important branch of the modern measurement.

With the aggravation of air pollution and the deepening of human research on particulate matter, the continuous monitoring of particulate matter emitted from fixed sources has become a subject of great environmental protection value and research significance. In the research, based on the Mie scattering theory, the light scattering model and the numerical calculation method of single particle are firstly studied, and the macroscopic description conditions of applying single-particle light scattering model to particle swarm are analyzed. On the basis of these, a kind of particle concentration using single-wavelength measurement equipment is designed. And on the basis of the single-wavelength prototype equipment, the equipment for simultaneous measurement of particle size distribution and concentration using three wavelengths is developed, which overcomes the defect of inaccurate measurement of single wavelength equipment when the particle size distribution changes, and improves the performance of the equipment.

Since it needs to assume the constant particle size distribution for the single-wavelength measurement method, the concentration measurement may be inaccurate in the actual measurement. In the research, the influence of particle size distribution on concentration measurement is analyzed, and then, the particle size distribution characteristics in the flue gas emission from thermal power plants are studied. The particle size distribution satisfies the lognormal distribution approximately, with the median particle size ranging from 0.5 μm to 10 μm and the standard deviation generally ranging from 1.1 to 1.5. Based on this feature, a (μ, σ)-to-(R1, R2, R3) model is established based on the response of the detector to three scattered light signals of different wavelengths and the characteristic that the ratio (R1, R2, R3) of the response is independent of the concentration. Finally, according to the method of three-wavelength detection, the structure design of three-wavelength equipment and the selection of key parameters are completed. In the research, an experimental platform is set up using the existing conditions. Taking the similar products as a reference, the performance of the equipment is verified by the experiments. Compared with the ES632 equipment, it is found from the system test results that compared with the ES632 equipment performance, the aerodynamic particle size spectrometer designed in the research can measure the lowest concentration of up to 0.1 mg/m3 with a measurement accuracy of 0.01 mg/m3. Compared with the ES632 equipment, the measurement concentration value is 8% higher, which meets the test requirements. The experimental results show that the particle size distribution and concentration can be obtained using the equipment, but the anti-interference ability is still defective compared with that of the industrial products.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

Acknowledgments

This study was supported by the Beijing Science and Technology Plan Project (Z201100007920009).

Open Research

Data Availability

The dataset can be accessed upon request.