Criterion for Hydraulic Fracture Propagation Behavior at the Interface of a Coal Measure Composite Reservoir

Abstract

Regarding the three expansion modes of hydraulic fractures at the interface of a coal measure composite reservoir (arrested, deflection, and penetration), based on the coupling theory of fluid flow and solid elastic deformation, a criterion that considers the influences of the injection parameters (fracturing fluid injection rate and viscosity) is established to predict the propagation path of hydraulic fractures at the interface of a composite reservoir. The criterion judges the propagation behavior of the fractures by comparing the water pressure in the wellbore and the critical seam pressure of the penetration and deflection. The controlled variable method is used to analyze the influences of the various factors on the propagation behavior of hydraulic fractures at the interface between layers. The results show that the differences in in situ stress, the interface cohesion, and the included angle mainly affect the critical seam pressure of the fracture deflection. The differences in elastic modulus, fluid injection rate, and fracturing fluid viscosity directly affect the water pressure in the wellbore. The difference in the fracture toughness mainly affects the crack propagation path by affecting the critical seam pressure of the deflection. The smaller the difference in the in situ stress is, the more likely it is that the hydraulic fractures will penetrate the layer. Larger differences in the fracture toughness between layers, interfacial cohesion, fluid injection rate, and fracturing fluid viscosity are more conducive to the hydraulic fractures penetrating the layer. When the angle between the hydraulic fractures and the interface is 25–55°, the hydraulic fracture is more likely to expand along the interface. This criterion takes into account the influences of the injection parameters and is of great significance to gaining a better understanding of the propagation behavior of hydraulic fractures at an interlayer interface.

1. Introduction

Coal measure gas, which is characterized by the coexistence of coalbed methane, tight sandstone gas, and shale gas, is an important type of unconventional natural gas resource [1, 2]. In the combined fracturing of a coal measure composite reservoir, the vertical expansion range of the hydraulic fractures determines the sharing degree of the stimulation measures, which is the key factor determining the success or failure of the fracturing operation [3]. Therefore, before combined fracturing of a coal measure composite reservoir is conducted, it is necessary to predict the vertical expansion range and shape of the hydraulic fractures and to predict whether the hydraulic fractures will penetrate the layers. The corresponding criterion is the basis for determining whether a hydraulic fracture can penetrate through a layer, and understanding the factors influencing the fracture’s ability to penetrate the layer is the premise.

The propagation behavior of hydraulic fractures at the interface of a composite reservoir is mainly controlled by geological factors, including the differences in the physical properties (e.g., the elasticity modulus, Poisson’s ratio, fracture toughness, and in situ stress) and the characteristics of the interface between the different types of reservoirs (i.e., the interfacial bond strength and inclination angle). Through theoretical derivation and numerical simulation, Fung et al., Gu and Siebrits, and Li et al. [4–6] determined that the difference in the elastic moduli of the layers has little effect on the fracture height, and even if the elastic modulus of the crack initiation layer differs by a factor of 10 from that of the adjacent layer, the hydraulic fracture will penetrate the interface and extend into the layer with the higher modulus. Laboratory and field tests also revealed that the difference in the elastic moduli of the layers does not substantially affect the penetration of the cracks. However, the elastic modulus may affect the intrafracture pressure. In a reservoir with a large elastic modulus, the intrafracture pressure of the hydraulic fractures will also be relatively large, so the fracture is more likely to enter the layer with the lower elastic modulus from the layer with the higher elastic modulus [7]. Thiercelin et al. and Wu et al. [8, 9] studied the effects of the differences in the interlaminar fracture toughness and Poisson’s ratio on vertical crack propagation. They found that when the fracture toughness or Poisson’s ratio of the crack initiation layer is greater than that of the adjacent layer, this can promote the propagation of the crack through the layer; otherwise, it will inhibit the crack penetration. However, the ranges of the fracture toughnesses and Poisson’s ratios of different lithologic reservoirs are very small, so the influences of the fracture toughness and Poisson’s ratio on fracture penetration are very limited. The difference in the minimum horizontal in situ stress of different reservoirs is the most critical factor inhibiting fracture penetration [10]. Tan et al. [11] conducted fracturing tests on layered rock samples and found that when the difference in the minimum horizontal in situ stress of the layers is greater than 2 MPa, the penetration range of the hydraulic fractures is significantly reduced; and when the difference in the minimum horizontal in situ stress of the layers is greater than 4 MPa, the hydraulic fractures are basically confined within the initiation layer. Warpinski et al. also reported that when the difference in the minimum horizontal in situ stress of the layers is greater than 10 MPa, the cracks will not be able to propagate through the interface into the adjacent layers [12]. The properties of the interface are also an important factor affecting the propagation behavior of hydraulic fractures at an interface in a composite reservoir. Daneshy [13] studied the effect of the interfacial strength on the vertical expansion of a fracture through fracturing tests on layered rock combination samples and concluded that when the bonding strength of the interlayer interface is high enough, the interface basically does not undergo slip failure, and the fracture can easily penetrate the interface and propagate into the other layers. Later, this conclusion was also confirmed by Teufel and Clark, Wang et al., and Gao et al. [14–17]. The inclination angle of the interface is also an important factor affecting the vertical penetration of the fracture. Tan et al. [18] concluded through numerical simulation that the greater the inclination angle, the more likely the interface is to slip and fail, and the more difficult it is for the fractures to penetrate the layer.

When hydraulic fractures encounter natural weak surfaces such as natural fractures, bedding planes, and weakly bonded interfaces in order to predict the propagation behavior of the hydraulic fractures, scholars in China and abroad have successively proposed various criteria, such as the Warpinski criterion [19], R&P criterion [20], e-R&P criterion [21], and Llanos criterion [22]. These criteria are mainly used to discriminate the intersection behavior of hydraulic fractures and natural fractures. There are few criteria for discriminating the propagation behavior of hydraulic fractures when they encounter an interlayer interface. Zhao and Chen [23] adopted the method of rock fracture mechanics and fully considered the influence of the layered in situ stress, layered rock mechanical parameters, formation interface properties, and reservoir thickness to calculate the critical seam pressure for hydraulic fracture cessation, deflection, and penetration. The fracture propagation behavior is determined by comparing the water pressure in the wellbore with the two critical fracture pressures. However, this criterion only considers the case in which the hydraulic fracture is perpendicular to the interlayer interface. Due to the arbitrary distribution of the interfaces in a coal measure composite reservoir, it is necessary to extend this criterion to cases where the hydraulic fracture and the interface are not orthogonal. Moreover, this criterion does not consider the effects of the injection parameters on the crack propagation behavior at the interface.

In view of this, based on the research of Zhao et al. and the theories of fluid flow and solid elastic deformation, a criterion for fracture propagation through an interface in a coal measure composite reservoir for any interface dip angle was developed in this study. The criterion focuses on the influences of the fracturing fluid parameters on the pressure in the fracture. The propagation behavior of the hydraulic fracture at the interface between layers is determined by comparing the critical seam pressure for deflection, the critical seam pressure for penetration, and the water pressure in the wellbore. Based on the experimental data obtained in previous studies, the accuracy of the discriminant results of this criterion was compared under the same conditions. Finally, the control variable method was used to analyze the sensitivities of the influencing parameters.

2. Establishing the Judgment Criterion

2.1. Physical Model and Basic Assumptions

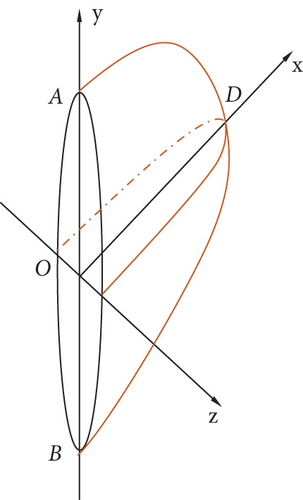

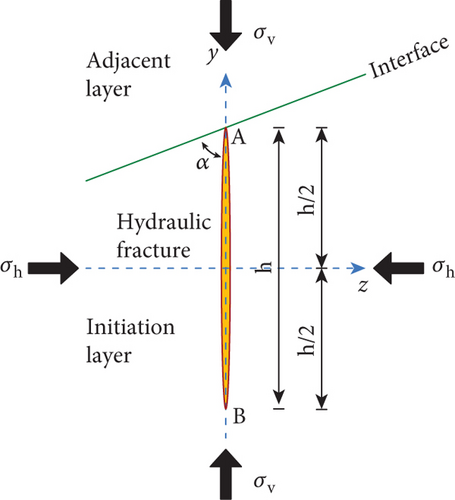

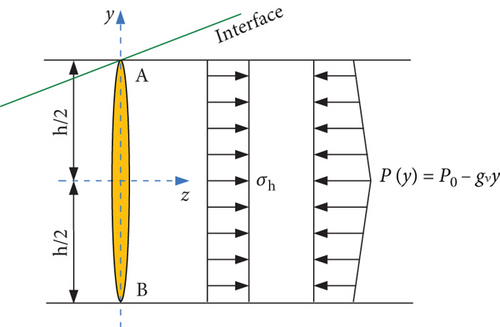

The expansion form of hydraulic fractures in a formation is shown in Figure 1. Figure 1(a) is a schematic diagram of the fracture propagation shape during the hydraulic fracturing process, and Figure 1(b) is a schematic diagram of the relative positions of the hydraulic fractures when they meet an interface in a coal measure composite reservoir. In Figure 1, σh is the horizontal minimum in situ stress of the composite reservoir; σV is the vertical in situ stress of the composite reservoir; h is the height of the hydraulic fracture; α is the angle between the hydraulic fracture and the interface between the layers; O is the crack initiation position; and A and B are the upper and lower ends of the hydraulic fracture in the height direction, respectively.

To simplify the calculations, the following basic assumptions were made in the model. (1) The hydraulic fracture is a quasi-three-dimensional elliptical fracture when a single formation expands, and the fracture surface is perpendicular to the direction of the minimum in situ stress and extends statically. (2) In the fracture expansion process, there is a tiny fracture process zone at the tip. (3) Each reservoir of the composite coal measure reservoir is an ideal homogeneous and isotropic body, the interlayer interface is well cemented, and the rock fracture obeys the theory of elastic fracture mechanics. (4) The flow of the fracturing fluid is one-dimensional laminar flow along the fracture length, the fluid is incompressible, and the filtration of the fracturing fluid is not considered.

2.2. Model of Water Pressure Distribution in Fractures

2.3. Critical Fracture Pressure for Different Propagation Behaviors of Fractures

2.3.1. The Cracks Directly Pass through the Interlayer Interface

By simultaneously solving Equations (3)–(6), the critical fracture pressure P1 at which the hydraulic fracture directly penetrates the interface and enters the adjacent layer can be obtained.

2.3.2. The Fractures Propagate along the Interlayer Interface

By combining Equations (5), (7), (10), (11), and (12), the critical fracture pressure P2 can be obtained when the hydraulic fractures expand along the interlayer interface.

2.4. Criterion

- (1)

If P0 < min(P1, P2), the hydraulic fracture stops spreading after it intersects with the interlayer interface

- (2)

If min(P1, P2) = P2 and P0 > P2, then the hydraulic fracture will spread along the interlayer interface after intersecting with the interlayer interface

- (3)

If min(P1, P2) = P1 and P0 > P1, then the hydraulic fracture intersects with the interlayer interface and passes directly through the interface into the adjacent layer

3. Verification of Discriminant Criteria

To test the accuracy of the criterion, the accuracy of the criterion was verified by comparing the results of the criterion under the same conditions with the experimental data of Zhou et al. [29] and the laboratory data of Jiang et al. [28]. The initial experimental parameters of Zhou et al. and Jiang et al. are presented in Table 1.

| Experimental group | E (GPa) | v | KIC (MPa·m1/2) | C (MPa) | μ | γ (mPa·s) | q (m3/min) | |

|---|---|---|---|---|---|---|---|---|

| Zhou et al. | Initiation layer | 8.402 | 0.23 | 0.59 | 135 | 2.52 × 10−7 | ||

| Adjacent layer | 8.402 | 0.23 | 0.59 | |||||

| Interface | 3.2 | 0.89 | ||||||

| Jiang et al. | Initiation layer | 3.63 | 0.19 | 0.52 | 1 | 2 × 10−5 | ||

| Adjacent layer | 2.75 | 0.23 | 0.20 | |||||

| Interface | 0 | 0.32 | ||||||

Table 2 presents the results obtained in Zhou et al.’s experiments and the judgment results of the discriminant criteria developed in this study, and it compares the two sets of results. The symbol ✔ in the table indicates that the judgment results are consistent with the experimental results, and the symbol ✘ indicates that the judgment results are inconsistent with the experimental results. Comparison of the results revealed that except for the last set of experiments, the judgment results of the criterion developed in this study are in good agreement with the experimental results of Zhou et al., which verifies the accuracy of the criterion.

| No. | α (°) | σh (MPa) | σv (MPa) | ∆σ (MPa) | rc (m) | Experimental results | Criterion results | Uniformity |

|---|---|---|---|---|---|---|---|---|

| 1 | 90 | 5 | 10 | 5 | 0.0011 | Penetration | Penetration | ✔ |

| 2 | 90 | 3 | 10 | 7 | 0.0019 | Penetration | Penetration | ✔ |

| 3 | 60 | 3 | 13 | 10 | 0.0026 | Penetration | Penetration | ✔ |

| 4 | 60 | 5 | 8 | 3 | 0.0026 | Penetration | Penetration | ✔ |

| 5 | 60 | 3 | 10 | 7 | 0.0026 | Deflection | Deflection | ✔ |

| 6 | 30 | 5 | 8 | 3 | 0.0012 | Deflection | Deflection | ✔ |

| 7 | 30 | 5 | 10 | 5 | 0.0012 | Deflection | Deflection | ✔ |

| 8 | 30 | 3 | 13 | 10 | 0.0021 | Arrested | Deflection | ✘ |

Jiang et al.’s experimental results were used to further verify the judgment method developed in this study. Table 3 presents Jiang et al.’s experimental results and the calculation results of the discriminant criteria developed in this study, and it compares the two sets of results. It can be seen from Table 3 that the results obtained using the judgment criterion developed in this study are consistent with Jiang et al.’s test results, which further verifies the accuracy of the criterion. It can be seen from the comparison of the results that only the last set of experimental comparison results is inconsistent. This is because the criterion established in this paper is based on the assumption that each coal measure is homogeneous and isotropic. Furthermore, the rock materials used in the actual fracturing tests were not uniform. There were obvious dents near the interface of the rock layer in the eighth group of tests (Table 2), and the heterogeneity near the interface was stronger than that of the previous seven groups, which in turn affected the propagation path of the hydraulic fractures in this set of experiments. Overall, the judgment results of the criterion developed in this study are in good agreement with Zhou et al.’s experimental results, which verifies the accuracy of the criterion.

| No. | α (°) | σh (MPa) | σv (MPa) | ∆σ (MPa) | rc (m) | Experimental results | Criterion results | Uniformity |

|---|---|---|---|---|---|---|---|---|

| 1 | 90 | 6 | 3 | 3 | 0.0011 | No penetration | Deflection | ✔ |

| 2 | 90 | 7 | 3 | 4 | 0.0019 | No penetration | Deflection | ✔ |

| 3 | 90 | 8 | 3 | 5 | 0.0026 | No penetration | Deflection | ✔ |

| 4 | 90 | 9 | 3 | 6 | 0.0026 | Penetration | Penetration | ✔ |

4. Parametric Analysis

Taking the sand-mudstone composite reservoir of the Shihezi Formation in the Linxing Block in the Ordos Basin as the geological background, the effects of the differences in the in situ stress, rock mechanical properties (elastic modulus and fracture toughness), fluid injection parameters (injection rate and viscosity of fracturing fluid), and interface properties (interface dip angle and cohesion) on the propagation behavior of the hydraulic fractures at the interface in the coal measure composite reservoir were studied. The hydraulic fracture propagation behavior at the interface in the coal measure composite reservoir under the influences of the different parameters was analyzed based on the critical seam pressure for the fracture deflection P1, the critical seam pressure for the fracture penetration P2, and the water pressure in the wellbore P0. Table 4 presents the basic parameters of the sand-mudstone composite reservoir.

| Type | Parameter | Number |

|---|---|---|

| Mudstone | Elastic modulus (GPa) | 20 |

| Poisson’s ratio | 0.25 | |

| Density (g/mm3) | 1.94 | |

| Tensile strength (MPa) | 4.1 | |

| Fracture toughness (MPa·m1/2) | 0.416 | |

| Horizontal minimum ground stress (MPa) | 25 | |

| Horizontal maximum ground stress (MPa) | 30 | |

| Overburden pressure (MPa) | 40 | |

| Layer thickness (m) | 10 | |

| Sandstone | Elastic modulus (GPa) | 25 |

| Poisson’s ratio | 0.2 | |

| Density (g/mm3) | 2.45 | |

| Tensile strength (MPa) | 6.7 | |

| Fracture toughness (MPa·m1/2) | 0.995 | |

| Horizontal minimum ground stress (MPa) | 25 | |

| Horizontal maximum ground stress (MPa) | 30 | |

| Overburden pressure (MPa) | 40 | |

| Layer thickness (m) | 20 | |

| Interface | Tensile strength (MPa) | 1.78 |

| Cohesion (MPa) | 1.15 | |

| Friction factor | 0.15 |

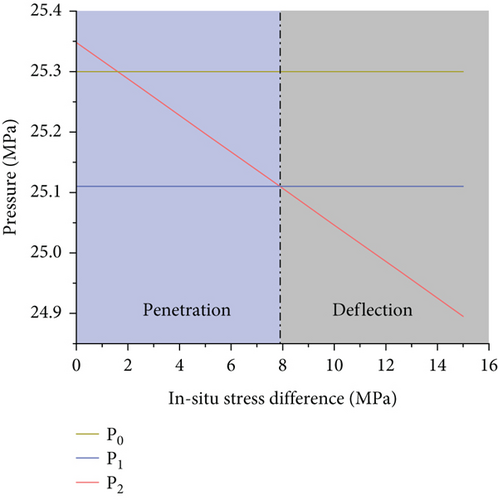

4.1. Difference in In Situ Stress

The main parameters of the model were set according to Table 4. The angle between the hydraulic fracture and the interface was set as 45°, and the vertical in situ stress of the reservoir was gradually changed. The difference between the ground stress and the horizontal minimum principal stress was set as 0, 2.5, 5, 7.5, 10, 12.5, and 15 MPa in sequence. The influence of the difference in the in situ stress on the propagation behavior of the hydraulic fractures at the interface in the coal measure composite reservoir was analyzed by studying the variations in the critical seam pressure for fracture deflection P1, the critical seam pressure for fracture penetration P2, and the water pressure in the wellbore P0 under different in situ stress differences. The results are shown in Figure 3.

It can be seen from Figure 3 that the water pressure in the wellbore P0 and the critical seam pressure for deflection P1 basically do not change under the different in situ stress differences. The critical seam pressure for penetration P2 decreases linearly as the in situ stress difference increases, and it intersects the line where the critical seam pressure for deflection P1 is located at point (7.9, 25.11). Since the water pressure in the wellbore P0 is always greater than the critical seam pressure for deflection P1 under these parameter values, the established criterion shows that when P1 is less than P2, the fracture spreads through the layer. Thus, when the in situ stress difference is less than 7.9 MPa (light blue area in Figure 3), the hydraulic fractures propagate through the layers at the interlayer interface; and when the in situ stress difference is greater than 7.9 MPa (light gray area in Figure 3), the hydraulic fractures propagate along the interface at the interlayer interface. It can be seen that the in situ stress difference is the main factor affecting the propagation path of the hydraulic fractures at the interlayer interface. When the other conditions remain unchanged, the in situ stress difference mainly changes the relationship between the three pressures by affecting the critical seam pressure for fracture deflection P2, thereby affecting the propagation path of the hydraulic fractures.

4.2. Rock Mechanical Properties

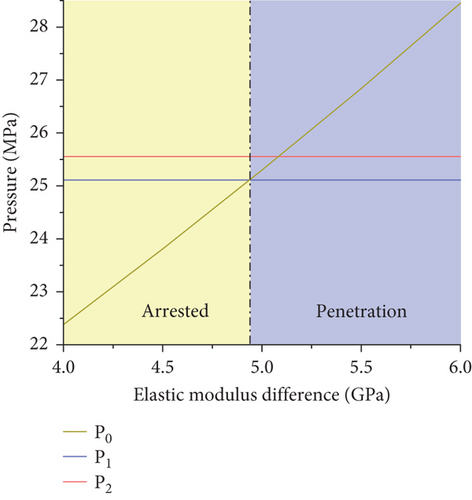

4.2.1. Difference in Elastic Moduli

The main parameters of the model were set according to Table 4, the angle between the hydraulic fracture and the interface was set as 45°, and the elastic modulus of the reservoir was gradually changed (24, 24.5, 25, 25.5, and 26 GPa). The difference in the elastic moduli was set as 4, 4.5, 5, 5.5, and 6 GPa. The effect of the difference in the elastic moduli of the reservoir layers on the propagation behavior of the hydraulic fractures at the interface in the coal measure composite reservoir was analyzed by studying the variations in the critical seam pressure for fracture deflection P1, the critical seam pressure for fracture penetration P2, and the water pressure in the wellbore P0 under different elastic moduli differences. The results are shown in Figure 4.

It can be seen from Figure 4 that the critical seam pressure for deflection P1 and the critical seam pressure for penetration P2 under the different elastic moduli differences basically do not change. The water pressure in the wellbore P0 increases linearly as the difference in the elastic moduli increases, and it intersects the line where the critical seam pressure for deflection P1 is located at point (7.9, 25.11). Because the critical seam pressure for penetration P1 is always smaller than the critical seam pressure for deflection P2 under these parameter settings, according to the established criterion, when P0 is less than P1, the fracture stops expanding after intersecting with the interlayer interface. Therefore, when the difference in the elastic moduli is less than 4.9 GPa (light orange area in Figure 4), and the fracture stops spreading after it intersects with the interlayer interface. When the difference in the elastic moduli is greater than 4.9 GPa (light blue area in Figure 4), the hydraulic fracture propagates through the layer at the interlayer interface. Thus, the difference in the elastic moduli of the reservoir layers affects the propagation path of the hydraulic fractures at the interface between layers. When the other conditions remain unchanged, the difference in the elastic moduli of the layers mainly changes the relationship between the three pressures by affecting the water pressure in the wellbore P0, thereby affecting the propagation path of the hydraulic fractures.

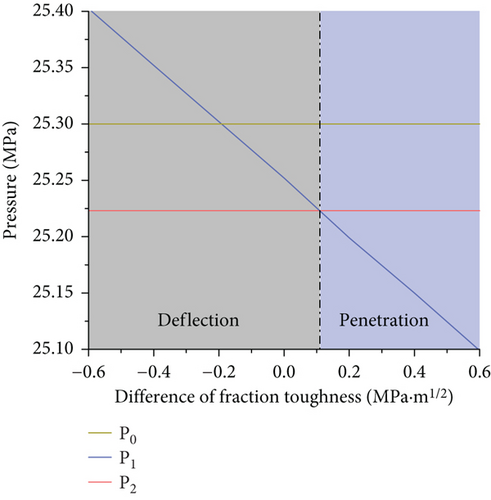

4.2.2. Difference in Fracture Toughness

The main parameters of the model were set according to Table 4. The angle between the hydraulic fracture and the interface was set as 75°, and the fracture toughness of the interlayer was gradually changed (0.395, 0.595, 0.795, 0.995, 1.195, 1.395, and 1.595 MPa∙m1/2). The difference in the fracture toughness between the reservoir and the interlayer was set as 0.6, 0.4, 0.2, 0, −0.2, −0.4, and 0.6 MPa∙m1/2. The effect of the difference in the fracture toughness on the propagation behavior of the hydraulic fractures at the interface in the coal measure composite reservoir was analyzed by studying the variations in the critical seam pressure for fracture deflection P1, the critical seam pressure for fracture penetration P2, and the water pressure in the wellbore P0 under different fracture toughness differences. The results are shown in Figure 5.

It can be seen from Figure 5 that the water pressure in the wellbore P10 and the critical seam pressure for penetration P2 basically do not change with the differences in the fracture toughness. The critical seam pressure for penetration P1 decreases linearly as the difference in the fracture toughness increases, and it intersects the line where the deflection critical fracture pressure P2 is located at point (0.1, 25.223). Since the water pressure in the wellbore P0 is always greater than the critical seam pressure for deflection P2 under these parameter settings, according to the established criterion, the fracture expands along the interface when P1 is greater than P2. Thus, when the fracture toughness difference is less than 0.1 MPa∙m1/2 (light gray area in Figure 5), the hydraulic fractures propagate along the interface at the interlayer interface; and when the fracture toughness difference is greater than 0.1 MPa∙m1/2 (light blue area in Figure 5), the hydraulic fractures propagate through the layers at the interlayer interface. It can be seen that the difference in the fracture toughness affects the propagation path of the hydraulic fractures at the interlayer interface. When the other conditions remain unchanged, the difference in the fracture toughness mainly changes the distance between the three pressures by affecting the critical seam pressure for fracture penetration P1, which in turn affects the propagation path of the hydraulic fractures.

4.3. Fracturing Parameters

4.3.1. Fracturing Fluid Injection Rate

The fracturing fluid injection rate is easy to control in engineering. Studying the effect of the fracturing fluid injection rate on the hydraulic fracture propagation behavior is helpful in determining whether the hydraulic fracture propagation mode can be directly controlled by controlling the fracturing fluid injection rate. The main parameters of the model were set according to Table 4. The angle between the hydraulic fracture and the interface was set as 90°. The fracturing fluid injection rate was gradually changed (3.444, 3.456, 3.468, 3.48, 3.492, 3.504, 3.516, 3.528, 3.54, 3.552, 3.564, and 3.576 m3/min). The effect of the liquid injection rate on the propagation behavior of the hydraulic fractures at the interface in the coal measure composite reservoir was analyzed by studying the variations in the critical seam pressure for fracture deflection P1, the critical seam pressure for fracture penetration P2, and the water pressure in the wellbore P0 under different fracturing fluid injection rates. The results are shown in Figure 6.

It can be seen from Figure 6 that the critical seam pressure for deflection P1 and the critical seam pressure for deflection P2 do not change substantially with the injection rate. The water pressure in the wellbore P0 increases linearly with increasing injection rate, and it intersects the line where the critical seam pressure of deflection P1 is located at point (3.484, 25.11). Since the critical seam pressure for deflection P1 is always lower than the critical seam pressure for deflection P2 under these parameter settings, according to the established criterion, the fracture stops expanding when P0 is less than P1. Thus, when the injection rate is less than 3.484 m3/min (light gray area in Figure 6), after the hydraulic fracture intersects with the interlayer interface, the expansion stops. When the injection rate is greater than 3.484 m3/min (light blue area in Figure 6), the hydraulic fracture propagates through the layer at the interlayer interface. It can be seen that the injection rate directly affects the propagation path of the hydraulic fractures at the interlayer interface. When the other conditions remain unchanged, the injection rate mainly changes the relationship between the three pressures by affecting the water pressure in the wellbore P0, which in turn affects the propagation path of the hydraulic fractures.

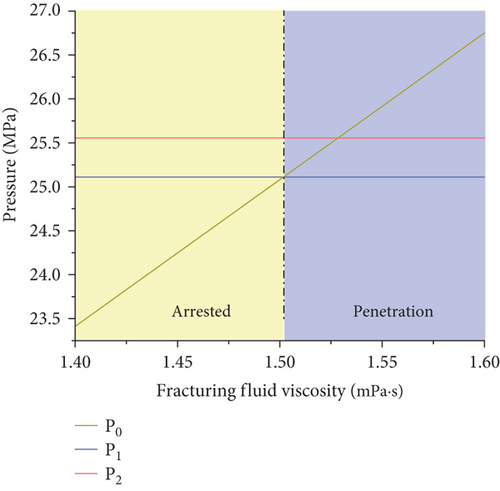

4.3.2. Fracturing Fluid Viscosity

The main parameters of the model were set according to Table 4. The angle between the hydraulic fracture and the interface was set as 90°, and the viscosity of the fracturing fluid was gradually changed (1.4, 1.45, 1.5, 1.55, and 1.6 mPa∙s). The effect of the fracturing fluid’s viscosity on the propagation behavior of the hydraulic fractures at the interface in the coal measure composite reservoir was analyzed by studying the variations in the critical seam pressure for fracture deflection P1, the critical seam pressure for fracture penetration P2, and the water pressure in the wellbore P0 under different fracturing fluid viscosities. The results are shown in Figure 7.

It can be seen from Figure 7 that the critical seam pressure for deflection P1 and the critical seam pressure for penetration P2 do not change substantially with the fracturing fluid viscosity. The water pressure in the wellbore P0 gradually increases with increasing fracturing fluid viscosity, and it intersects with the line where the critical seam pressure for deflection P1 is located at point (1.5, 25.11). Since the critical seam pressure for deflection P1 is always lower than the critical seam pressure for penetration P2 under these parameter settings, according to the established criterion, the fracture stops expanding when P0 is less than P1. Therefore, when the viscosity of the fracturing fluid is less than 1.5 mPa∙s (light gray area in Figure 7), the hydraulic fracture stops spreading after it intersects with the interface; and when the viscosity of the fracturing fluid is greater than 1.5 mPa∙s (light blue area in Figure 7), the hydraulic fractures propagate through the layers at the interlayer interface. It can be seen that changing the viscosity of the fracturing fluid affects the propagation path of the hydraulic fractures at the interface between the layers. When the other conditions remain unchanged, the viscosity of the fracturing fluid mainly changes the relationship between the three pressures by affecting the water pressure in the wellbore P0, which in turn affects the propagation path of the hydraulic fractures.

4.4. Interface Properties

4.4.1. Interface Dip Angle

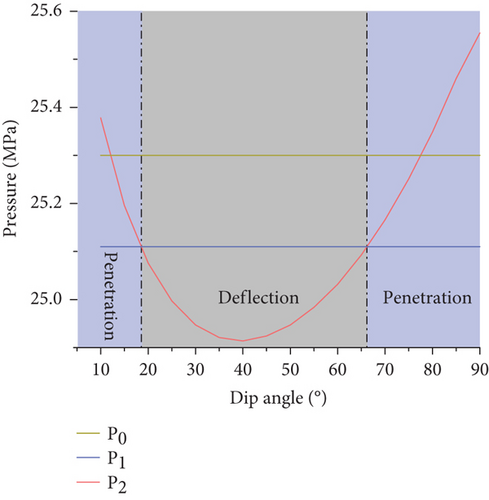

The main parameters of the model were set according to Table 4. The angle between the hydraulic fracture and the interlayer interface was gradually changed (10°, 20°, 30°, 40°, 50°, 60°, 70°, 80°, and 90°). The influence of the interface dip angle on the propagation behavior of the hydraulic fractures at the interface in the coal measure composite reservoir was analyzed by studying the variations in the critical seam pressure for fracture deflection P1, the critical seam pressure for fracture penetration P2, and the water pressure in the wellbore P0 under different interface dip angles. The results are shown in Figure 8.

It can be seen from Figure 8 that the water pressure in the wellbore P0 and the critical seam pressure for penetration P1 basically do not change with the interface dip angle. The critical seam pressure for deflection P2 initially decreases and then increases with increasing interface inclination angle, and it intersects the line where the critical seam pressure for penetration P1 is located at points (18.6, 25.11) and (66.16, 25.11). Under these parameter settings, the water pressure P0 in the wellbore is always greater than the critical seam pressure for penetration P1, while the critical seam pressure for deflection P2 changes from greater than the critical seam pressure for penetration P1 to less than the critical seam pressure for penetration P1 with increasing interface dip angle. According to the established criterion, when P1 is less than P2, the fracture propagates through the layer; and when P1 is greater than P2, the fracture expands along the interface. Thus, when the interface dip angle is less than 18.6° (light blue area in Figure 8), the hydraulic fractures spread through the layers at the interlayer interface. When the interface dip angle is 18.6–66.16° (light gray area in Figure 8), the hydraulic fractures spread along the interface at the interlayer interface. When the interface dip angle is greater than 66.16° (light blue area in Figure 8), the hydraulic fractures propagate through the layers at the interlayer interface. It can be seen that the interface dip angle affects the propagation path of the hydraulic fractures at the interlayer interface. When the other conditions remain unchanged, the interface dip angle mainly changes the relationship between the three pressures by affecting the critical seam pressure for fracture deflection P2, thereby affecting the propagation path of the hydraulic fractures.

4.4.2. Interfacial Cohesion

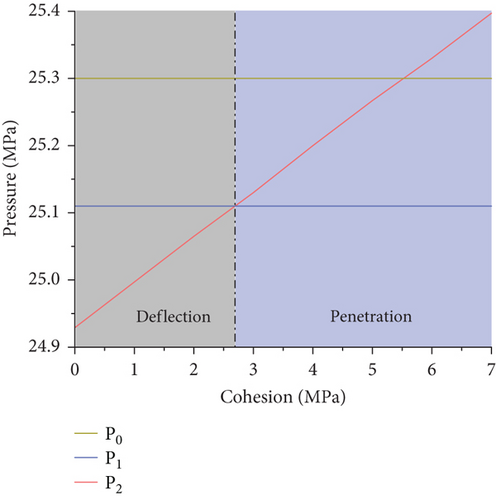

The main parameters of the model were set according to Table 4. The angle between the hydraulic fracture and the interface was set as 60°, and the interfacial cohesion between the reservoir layers was gradually changed (0, 1, 2, 3, 4, 5, and 6 MPa). The effect of the interfacial cohesion on the propagation behavior of the hydraulic fractures at the interface in the coal measure composite reservoir was analyzed by studying the variations in the critical seam pressure for fracture penetration P1, the critical seam pressure for fracture deflection P2, and the water pressure in the wellbore P0 under different interfacial cohesion values between the reservoir layers. The results are shown in Figure 9.

It can be seen from Figure 9 that the water pressure in the wellbore P0 and the critical seam pressure for penetration P1 basically do not change with the interfacial cohesion. The critical seam pressure for deflection P2 increases linearly with increasing interfacial cohesion, and it intersects the line where the critical seam pressure for penetration P1 is located at point (2.7, 25.11). Since the water pressure in the wellbore P0 is always greater than the critical seam pressure for penetration P1, under these parameter settings, according to the established criterion, the fracture expands along the interface when P2 is less than P1. Thus, when the interfacial cohesion is less than 2.7 MPa (light gray area in Figure 9), the hydraulic fracture spreads along the interface at the interlayer interface; and when the interfacial cohesion is greater than 2.7 MPa (light blue area in Figure 9), the hydraulic fracture spreads through the layer at the interlayer interface. It can be seen that changing the interfacial cohesion affects the propagation mode of the hydraulic fractures at the interlayer interface. When the other conditions remain unchanged, the interfacial cohesion mainly changes the relationship between the three pressures by affecting the critical seam pressure for fracture deflection P2, thereby affecting the propagation mode of the hydraulic fractures.

5. Conclusions

- (1)

The difference in the in situ stress, the interface dip angle, and the interfacial cohesion directly affect the critical seam pressure for deflection P2 when the fracture propagates along the interface. The critical seam pressure for deflection P2 decreases linearly as the in situ stress difference increases. When the in situ stress difference is less than 7.9 MPa, the hydraulic fracture spreads through the layer. The critical seam pressure for deflection P2 increases linearly with increasing interfacial cohesion. When the interfacial cohesion is greater than 2.7 MPa, the hydraulic fracture propagates through the layer. As the interface dip angle increases, the critical seam pressure for deflection P2 initially decreases and then increases, and the hydraulic fracture expands when the interface dip angle is 25–55°. This means that the smaller the in situ stress difference is, the greater the interfacial cohesion is, and the easier it is for the hydraulic fracture to spread through the layer. When the interface dip angle is 25–55°, the hydraulic fracture is more likely to expand along the interface

- (2)

The difference in the elastic moduli, the fluid injection rate, and the fracturing fluid’s viscosity directly affect the water pressure in the wellbore P0. As the difference in the elastic moduli, the injection rate, and the fracturing fluid’s viscosity increase, the water pressure in the wellbore P0 increases linearly. When the difference in the elastic moduli is greater than 4.9 GPa, the hydraulic fractures propagate through the layer; when the injection rate is greater than 3.484 m3/min, the hydraulic fractures propagate through the layer; and when the fracture fluid viscosity is greater than 1.5 mPa∙s, the hydraulic fractures propagate through the layer. The larger the difference in the interlayer elastic modulus, the faster the fluid injection rate, the greater the viscosity of the fracturing fluid, and the more likely it is that the hydraulic fractures will propagate through the layers

- (3)

The difference in the fracture toughness mainly changes the relationship between the three pressures by affecting the critical seam pressure for penetration P1, thereby changing the propagation mode of the hydraulic fractures. The critical seam pressure for propagation P1 decreases linearly as the difference in the fracture toughness increases. When the fracture toughness difference is greater than 0.1 MPa∙m1/2, the hydraulic fracture propagates through the layer at the interlayer interface, indicating that the larger the interlayer fracture toughness difference is, the more likely it is that the hydraulic fracture will penetrate the layer

Conflicts of Interest

The authors declare that they have no conflicts of interest.

Acknowledgments

The authors would like to give their sincere gratitude for the financial support from the National Natural Science Foundation of China (grant number 42102222).

Open Research

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.