Experimental Investigation on Mechanical Properties of TiAlN Thin Films Deposited by RF Magnetron Sputtering

Abstract

The mechanical properties of TiAlN deposited on the steel are explained in this study. Thin films are deposited by RF magnetron sputtering on the steel substrates to improve the wear resistance and hardness of the samples. Due to their improved microstructure and nanograins, the nanofilms have improved the mechanical properties of the steel substrate surface. The thin film deposited has improved the wear resistance by 80% and has improved the hardness by 95%. The deposited thin films are tested for hardness by nanoindentation and wear test by the pin-on-disk test. SEM has tested films for their microstructure and adhesion by nanoscratch test.

1. Introduction

Titanium aluminium nitride (TiAlN) films have grown due to several notable mechanical characteristics, such as exceptional hardness, wear resistance, and corrosion resistance [1]. TiAlN films have several other advantages as well [2]. TiAlN also has a low thermal expansion coefficient and a high conductivity coefficient [3]. These coatings are used in various industries, including the semiconductor device business, where they serve as an electrode barrier to protect semiconductor devices from damage [4]. TiAlN films are also being used in bioapplications as coatings for bioimplants [5]. Titanium-based implants made using DMLS (direct metal laser sintered) technology are relatively new to the biomedical profession [6]. Even though cobalt-based and nickel-based alloys are still in use in the medical profession [7], titanium and its alloys are becoming increasingly popular in the field [8].

PVD coatings are responsible for both the gradient diffusion layer’s thickness and the layer’s adherence to the substrate [9]. Utilizing PVD methods for nitride layer formation to improve the properties of biomaterials or machining tools is a fairly popular method of improving performance [10]. This metal nitride is extremely resistant to oxidation due to the formation of a sublayer of titanium dioxide (TiO2) and protective aluminium oxide (Al2O3) protective film [11]. TiAlN thin film has already been applied using a variety of deposition techniques, including physical vapour deposition (PVD), thermogradient reactive deposition process (TRD), and magnetron sputtering [12]. Other deposition techniques, such as physical vapour deposition (PVD), thermogradient reactive deposition process (TRD), and magnetron sputtering process, are used [13]. Faults, such as interstitial faults, emptiness, and point defects, can occur in the design process [14]. When a coating is applied, residual stress and other defects impact the coating’s performance [15]. Kishi et al. investigated and found that the adhesion between polystyrene and CF reinforced epoxy ply should be improved for better flexural properties [16]. Cho et al. observed that incorporation of GO in to CF reinforced epoxy composites improves the interfacial strength between matrix and reinforcement due to hydrogen bonding and mechanical interlocking [17]. Kumar et al. found that the carbon black modified CFs possess better surface energy, due to the topology of the CFs than the untreated CFs and also observed that carbon black modified CF epoxy composites have better interfacial adhesion due to the wettability between matrix and CF [18]. Yogeshwaran et al. investigated and found that carbon fabric reinforced epoxy composite exhibits better shear response than UDCF reinforced epoxy composites because of the energy absorption capacity of fabric at ultimate levels of stress and strain [19].

AISI 304 is one of the most widely used modern structural materials [20]. These properties allow it to be welded, making it highly corrosion resistant and capable of withstanding mechanical stress [21]. However, only wear and cavitation erosion resistance is protected by this cap (CER) [22]. To strengthen the wear resistance of SS, apply several types of hard coatings, such as TiN, CrN, TiAlN, AlTiN, or AlCrN. As a result of advances in TiAlN or AlTiN technology, current TiAlN or AlTiN hard films are now extensively used to manufacture machine tools or machine components to reduce tribochemical and adhesive wear or to enhance their resilience to extreme heat conditions [23]. Therefore, if metal components undergo severe wear processes, their overall wear resistance can be enhanced by utilizing AlTiN and TiAlN coatings, with various Al/(Ti + Al) ratios. Another benefit of TiAlN or AlTiN-based universal ternary coating systems is their ability to significantly improve tribological properties, as well as resistance to cavitation erosion [24].

TiN and CrN hard thin film coatings have a higher CER on their steel substrates than steel substrates that have not been coated with hard thin films. When it comes to mechanical properties, ternary film systems are often preferable to binary coating processes in most cases. Furthermore, according to the literature, for CER and PVD coatings, film characteristics and substrate mechanical properties are critical considerations. In addition to this, research is looking into using an aluminium alloy coated with a thin TiAlN layer as a structural component [25]. The constant evolution of the metal machining industry has resulted in the introduction of continuous cutting and interrupted cutting methods of cutting. When milling is interrupted during cutting, the mechanical impact and heat induce mechanically and comb cracks to form in the material. Damage resistance and adhesion are critical for a successful application. Because coated milling tools are subjected to fractures that originate and propagate throughout the milling process, their cutting capabilities are severely limited. When the tool’s surface layers are alternately extended and contracted when the tool is being used, this is a highly common source of cracks in the tool. Since the tool coating promotes numerous comb cracks and the fact that the multilayered TiN/TaN combination allows the tools to interact with each other, stainless steel that is milled using cemented carbide tools coated with multilayered TiN/TaN and single-layered TiN and TaN tends to suffer from higher rates of failure when milled with tools with these coating combinations [26]. Cutting tools with high hardness, high toughness, high oxidation resistance, and high hot hardness are ideal for interrupting processes in the manufacturing process.

In this study, HSS steel of grade M35 is selected for the study and is coated by TiAlN by using RF sputtering deposition process. Samples were tested for their hardness, microstructure, wear resistance, and adhesion. Coatings are tested with nanoindentation, SEM, pin-on-disk, and nanoscratch test that were evaluated.

2. Materials and Methods

The RF sputtering procedure was used to coat TiAlN targets on steel to get a uniform coating. This material, which has a purity of 99.99%, a diameter of 50 mm, and a thickness of 3 mm were obtained and used in the current study. The experimental system is depicted in Figure 1. A magnetron is connected to the power source through an impedance matching network to hold the target material in place. In order to serve as an electrode, the chamber is connected to the ground, resulting in a fully functional circuit. Sputtering power is varied from 100 W to 250 W in steps of 50 W.

Steel is cut into 10 × 10 × 1 mm substrates and ground down to a degree of precision of order 0.2 m by utilizing several grades of abrasive papers and diamond polish to achieve this precision level. Steel samples that have been cleaned and etched are submerged in an acetone solution for ten minutes, after which they are sputter-etched in oxygen plasma for the remaining ten minutes [27]. Turbo pumps are used to keep the operating pressure in the vacuum chamber constant at 10-12 bar at all times. The total thickness of TiAlN films is 1000 nm. The nanoindentation procedure is used to investigate the mechanical behaviour of thin films (hardness, elastic modulus). Temperature and pressure are always maintained as constant. Figure 2 shows the nanoindentation instrument, which is used for both hardness and adhesion tests [28].

The scratch test is performed on the samples to determine the adhesion of the DLC coatings that have been developed. Furthermore, the scratch analysis of the film is carried out using the nanoindentation machine with Berkovich indenter. The critical load of coating peels offload gradually increased over a period of time. This load is considered the adhesion strength of the film, and it is considered the maximum load [29].

The scanning electron microscope (SEM) is used in the examination of the thin film microstructure. Pin-on-disk method is used for the wear resistance measurement. Pin made of uncoated steel samples is used to measure wear and friction in the laboratory. For the test, 100 gm of the load is utilized, and 5000 revolutions are completed.

3. Results and Discussions

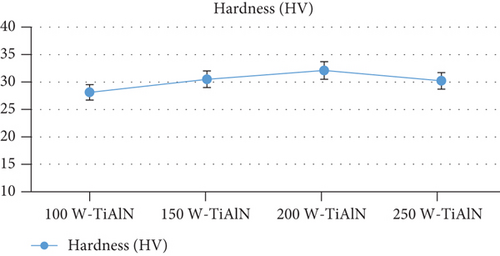

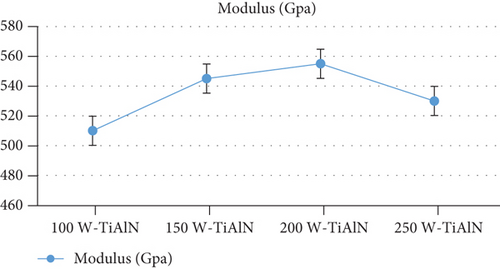

Tables 1 and 2 exhibit the developed thin film modulus and hardness values, determined using nanoindentation testing with a load vs. deflection measurement method [30]. A micro-Newton load was applied using the Berkovich indenter. Figure 3 shows the TiAlN thin film on a steel substrate.

| Sample | 100 W-TiAlN | 150 W-TiAlN | 200 W-TiAlN | 250 W-TiAlN |

|---|---|---|---|---|

| Hardness (HV) | 28.1 | 30.5 | 32.1 | 30.2 |

| Sample | 100 W-TiAlN | 150 W-TiAlN | 200 W-TiAlN | 250 W-TiAlN |

|---|---|---|---|---|

| Modulus (GPa) | 510 | 545 | 555 | 530 |

As the soft substrate takes away all the load, the underreported value is difficult to measure. It has hard to discern the hardness and elastic modulus of the coating with ordinary indentation. The soft substrate cushioned the rigid thin film coating. The DLC coating is extremely rigid, and it directly applies the load to the substrate [31]. When a load is applied, elastic deformation occurs to the substrate, and the hardness under load is measured. When a load is applied, the substrate exhibits elastic deformation, and the load-hardness relationship is examined. These findings resulted in the combined hardness of the coating and substrate, which degraded the quality of the coating. Many trials were performed on each sample, and the average hardness and elasticity modulus were determined. The exact hardness of the sample area is determined under the condition of unplugging the load. When the maximum load was reached, each trial was held for 15 seconds [32].

The hardness values of the thin films calculated are presented in Table 1. The highest hardness has been measured for the sample, which is coated at 200 W substrate power. The highest hardness is 14% higher than the least hardness measured. Although the nanohardness of the TiAlN sample is measured, there are high chances of getting defective measurements due to the presence of defects under the subsurfaces of the surface [33].

Due to these defects, the nanoindentation method is not suitable for bulk materials. However, the modulus of the materials can be compared. The modulus of M35 steel is 207 GPa, whereas the highest measured modulus in this study is 555 GPa. TiAlN is 168% higher than the M35 steel. Figures 4 and 5 expose graphical representations of hardness and modulus values of thin films deposited. It indicates that the TiAlN thin film has considerably increased the hardness and modulus of the substrate [34].

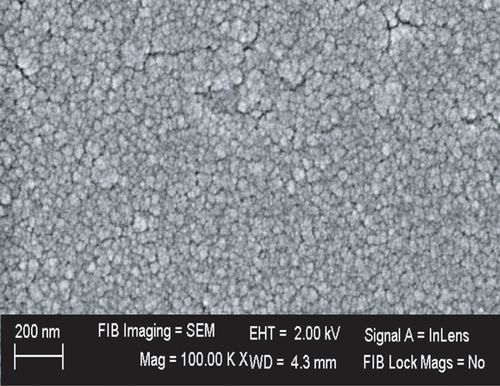

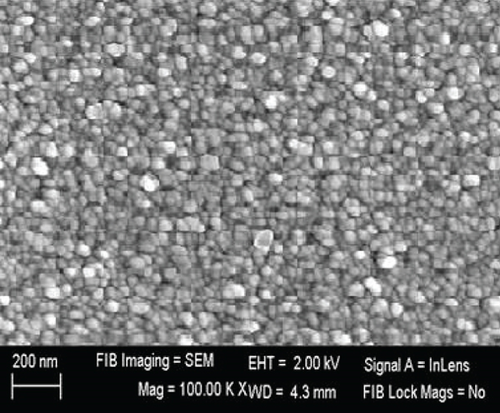

4. Microstructure

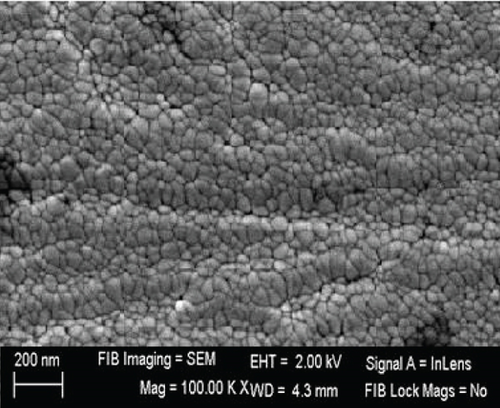

SEM micrograph of the TiAlN sample deposited at 200 W sputtering power is shown in Figure 6. The deposited thin film has a microstructure of size 5-6 nm. The microstructure is uniform in nature and has very few pinholes and defects. The nature of the film as it has nano-sized grains is responsible for the increase in hardness. The structure is similar to all the samples [35]. The remaining samples have the same microstructure but with higher defects. Due to these defects, it can be said that the hardness has been reduced for the other samples. The TiAlN particles are evenly distributed in the thin film. The defects present in the thin film are generated due to the stresses developed during the deposition process. As the incoming atoms come with high energy, the impact of the particles causes stresses in the film. There is no stress-relieving mechanism employed during the deposition like annealing. There is no film peel off that has been observed indicating the good affinity of the film with the sample [36]. For comparison purposes, the SEM micrographs of films deposited at 100 and 150 are given in Figures 7 and 8.

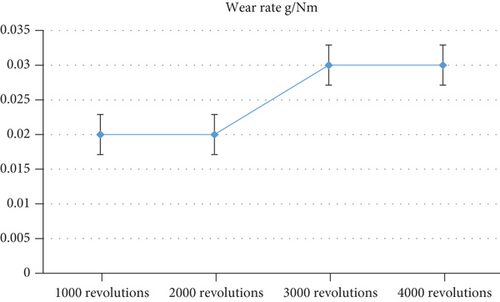

4.1. Wear Test

The coating samples were tested using pin-on-disk wear testing after being placed on a steel pin and subjected to wear. Wear values in the samples ranged between 0.02 and 0.04. There are some differences in the COF curves of the two samples. It means that the sample was subjected to abrasion wear during the testing process. Despite low COF concentrations, it is still possible to detect them. Figure 9 gives the wear rate behaviour of the sample tested.

All coating samples exhibited no signs of film chipping or peeling, indicating that the TiAlN coating adhered to the substrates effectively under the conditions used in the current test.

4.2. Adhesion Test

The nanoscratch test is used to determine the adhesion strength of TiAlN films. The values that are included in the results are shown in Table 3. The samples’ adhesive strength increases in direct proportion to the increase in substrate power up to 20 W. When the power output is increased from 200 W to 250 W, the adhesion strength decreases significantly. When the amount of sputtering energy supplied to an atom increases, so does the amount of energy transferred from that atom to the impact point, causing increased stress. Following the nondissipation of this stress, additional atoms are deposited on top of it, resulting in a stress build-up. The stress in the film increases as the sputtering power increases, resulting in a loss of adhesion between the film and the substrate.

| Sample | 100 W-TiAlN | 150 W-TiAlN | 200 W-TiAlN | 250 W-TiAlN |

|---|---|---|---|---|

| Adhesion strength (GPa) | 32.1 | 38.6 | 41.3 | 34.3 |

5. Conclusion

TiAlN thin films are successfully deposited onto the H35 steel substrate. The TiAlN thin films have remarkably improved the hardness and the modulus of the substrate. The modulus has increased by 168% compared to the substrate by the thin film application. The thin film generated has a microstructure of order less than 10 nm with a uniform surface. Further study is needed to make the film error-free with pinholes and cracks. The adhesion of the film is better when the sputtering power is maintained at 200 W. Overall, to obtain better adhesion and hardness along with wear resistance suggested maintaining sputtering power at 200 W.

Disclosure

It was performed as a part of the Employment of Kombolcha Institute of Technology, Wollo University, Kombolcha, Amhara, Ethiopia.

Conflicts of Interest

The authors declare that there are no conflicts of interest regarding the publication of this paper.

Acknowledgments

The authors thank Saveetha School of Engineering, SIMATS, Chennai, for providing characterization supports to complete this research work.

Open Research

Data Availability

The data used to support the findings of this study are included within the article. Should further data or information be required, these are available from the corresponding author upon request.