Vibration and Sound Transmission Performance of Sandwich Panels with Uniform and Gradient Auxetic Double Arrowhead Honeycomb Cores

Abstract

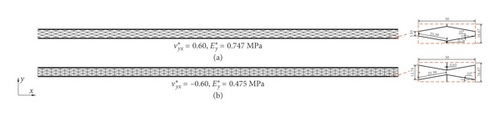

Auxetic mechanical metamaterials that exhibit a negative Poisson’s ratio (NPR) can be artificially designed to exhibit a unique range of physical and mechanical properties. Novel sandwich structures composed of uniform and gradient auxetic double arrowhead honeycomb (DAH) cores were investigated in terms of their vibration and sound transmission performance stimulated by nonhomogeneous metamaterials with nonperiodic cell geometries. The spectral element method (SEM) was employed to accurately evaluate the natural frequencies and dynamic responses with a limited number of elements at high frequencies. The results indicated that the vibrating mode shapes and deformations of the DAH sandwich models were strongly affected by the patterned gradient metamaterials. In addition, the sound insulation performance of the considered DAH sandwich models was investigated regarding the sound transmission loss (STL) from 1 Hz to 1500 Hz under a normal incident planar wave, and this performance was compared with that for hexagonal honeycomb sandwich panels. A programmable structural-acoustic optimization was implemented to maximize the STL while maintaining a constant weight and high strength. The results showed that the uniform DAH sandwich models with larger NPRs generally exhibited better vibration and acoustic attenuation behaviors and that the optimized gradient increasing NPR models yielded higher STL values than the optimized gradient decreasing NPR models for two specified frequency cases, with improvements of 6.52 dB and 2.52 dB and a higher bending stiffness but a lower overall STL. Thus, sandwich panels consisting of auxetic DAHs can achieve desirable vibroacoustic performance with a higher bending stiffness than conventional hexagonal honeycomb sandwich structures, and the design of gradient DAHs can be extended to obtain optimized vibration and noise-control capabilities.

1. Introduction

Metamaterials are artificial structures engineered to achieve unusual properties, and metamaterials that behave mechanically and have a negative Poisson’s ratio (NPR) are called “auxetic” mechanical metamaterials [1–4]. These metamaterials expand rather than contract when stretched under uniaxial loading, differing from most natural materials. There have been important developments in many fields of auxetic metamaterials, including auxetic cellular solids of foams and honeycombs [5–7], microporous polymers [8], 3D re-entrants [9], chiral structures [10], and rotating rigid structures [11]. Compared to traditional materials, these auxetic structures have superior mechanical properties such as enhanced shear resistance, indentation resistance, and fracture toughness in various automotive, aerospace, biomedicine, and intelligent system applications [1–4].

In recent decades, cellular solids have been progressively employed [6, 7], and auxetic foams and honeycombs have been used in numerous studies to explore the multiple functionalities of the cellular solid structures. Among the practical engineering applications involving cellular materials, sandwich structures (usually a simplified 2D sandwich beam) with in-plane (truss-like or prismatic) honeycomb cores have been explored for vibration and acoustic attenuation purposes, with the sound transmission loss (STL) frequently used as an evaluation metric [12–23]. These materials can be artificially tailored to create high-stiffness structures with low volumes and weights in contrast to cellular foams [13]. As a basis for the design of sandwiched core arrangements, previous scholars have reported that sandwich structures with embedded in-plane cellular cores transmit less sound than those with out-of-plane cellular cores [14], and core anisotropy can lead to a higher STL [15]. El-Raheb and Wagner [16] previously investigated the structural-acoustic performance of sandwich panels with periodic square truss-like cores. Ruzzene [17] analyzed the vibration and sound radiation performance of sandwich panels with in-plane hexagonal and re-entrant honeycomb cores, and Griese et al. [18] studied the effects of prismatic conventional and auxetic hexagonal honeycomb cell geometries on the sound transmission properties of sandwich panels. These studies indicated that sandwich panels with auxetic re-entrant cellular cores exhibit better sound insulation behavior than the conventional honeycomb sandwich structures with positive Poisson’s ratios. Spadoni and Ruzzene [19] designed an auxetic chiral truss-core sandwich beam and explored its potential benefit in terms of vibration isolation and sound transmission reduction. To obtain an optimized STL, Denli and Sun [20] performed structural-acoustic optimizations of prismatic random cellular cores for minimum noise radiation in different frequency regions but without considering their manufacturability. Franco et al. [21] optimized sandwich panels with innovative cellular core configurations to minimize the sound radiation responses to various sources of excitation. As an extension of the study mentioned in [18], Galgalikar and Thompson [22] optimized hexagonal honeycomb sandwich panels for maximum STL and discovered that the STL response strongly depends on the numbers of unit cells in the horizontal and vertical directions in addition to the cell internal angles. Li and Yang [23] optimized the STL responses of sandwich panels with hybrid hexagonal honeycomb cores and suggested that hybrid core configurations constitute a broader platform for optimal acoustic designs. Apart from these direct structural-acoustic optimizations to obtain an optimized STL, topology optimization based on the band gaps of periodic metamaterials has been applied for sound and vibration control [13] because the stop bands through which plane waves cannot propagate can be obtained via the corresponding dispersion curves [24, 25].

The aforementioned sandwiched cellular structures are usually characterized by repeating unit cells with a fixed geometry. However, most current metamaterials are generally classified into two types based on their structural arrangements: homogenous (with uniform periodic structures) and inhomogeneous (with nonuniform nonperiodic structures) [26]. Lim [27] theoretically pioneered a nonperiodic functionally gradient beam to attain Poisson curving in 2002. Then, sandwich structures with combined conventional and re-entrant hexagonal metamaterials were investigated based on various characteristics, such as the specified objective deformations [28]; the strength and failure properties under bending, compressive and impact loads [29–31]; the dynamic behavior [32, 33]; and the sound transmission performance [23, 34]. Moreover, functionally gradient auxetic metamaterials based on other topologies, such as double arrowhead honeycombs (DAHs), have been developed [35–38] in recent years. These nonuniform metamaterials have attracted considerable interest due to their high-order functionality and broad designability.

Accordingly, a novel sandwich panel with cellular cores of auxetic DAHs is proposed and investigated with respect to its vibration and acoustic characteristics. To the best of our knowledge, such structures have not been previously investigated. In addition, gradient double arrowhead cellular cores are designed and implemented in the direction of the panel thickness based on the features of the nonuniform metamaterials. Programmable structural-acoustic optimization processes are then implemented to design a modified-gradient DAH for an optimized sandwich panel that radiates less sound at different frequency regions. To precisely predict the structural vibroacoustic performance, the spectral element method (SEM) [17, 19] was employed to accurately compute the natural frequencies and dynamic responses of cellular structures at arbitrary frequencies with a largely reduced number of elements and few degrees of freedom (DOFs) [39, 40].

In the remainder of the paper, Section 2 describes the unit cell geometry and the configurations of the sandwich structures based on DAHs. Section 3 presents SEM formulations to compute the dynamic eigenfrequencies and responses and gives the computational procedures for sound radiation and transmission loss. Next, the vibroacoustic performance of the considered structures is discussed in Section 4. Moreover, a programmable structural-acoustic optimization process for maximum STLs is presented in Section 5. Finally, Section 6 concludes this study.

2. Geometries of the Sandwich Panels with Uniform and Gradient DAH Cores

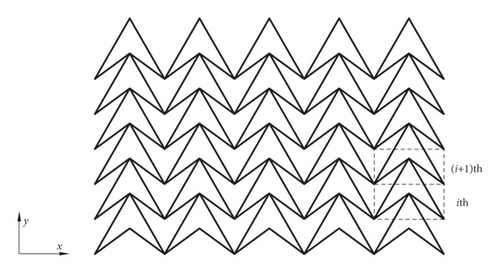

2.1. Cell Geometry of Auxetic DAH Arrays

2.2. Geometric Description of Sandwich Panels with Uniform and Gradient DAH Cores

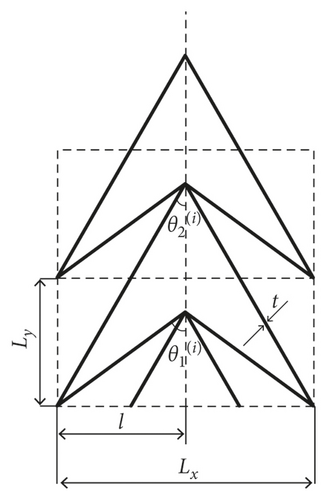

The considered sandwich panels with DAH cores are depicted in Figure 2. A DAH core is sandwiched between two constraining face sheets. Each model has an identical total length of 2 m, and each cellular core comprises 40 cells in the length direction and 5 cells across the thickness of the core. Lx is calculated to be 50 mm and Ly is 10 mm with α = 0.2. However, the total thickness of each model differs because the unit cell in the top layer has a varying cell angle . The constraint of > arctan(1/5α) is then set to limit the influence resulting from the distinction of the panel thicknesses. Therefore, varies from 45 to 65° without element overlap, and the total thickness ranges from 51.7 to 65 mm.

To maintain a constant weight, the thickness of the two face sheets is constrained by a constant value of ts = 2 mm. In addition, the thickness of the cellular cores is varied to maintain the weight equal to that of a baseline cellular sandwich panel with dimensions of 2 m × 50 mm and a relative density of 0.1. To this point in the study, both the overall length and weight have been held constant to compare the various properties of the sandwich models. The base material for the sandwich panel is aluminum with a Young’s modulus Es = 71.9 GPa, Poisson’s ratio ν = 0.33, and mass density ρs = 2700 kg/m3. The total weights of the two face sheets and core are 21.6 kg/m and 27.0 kg/m, respectively.

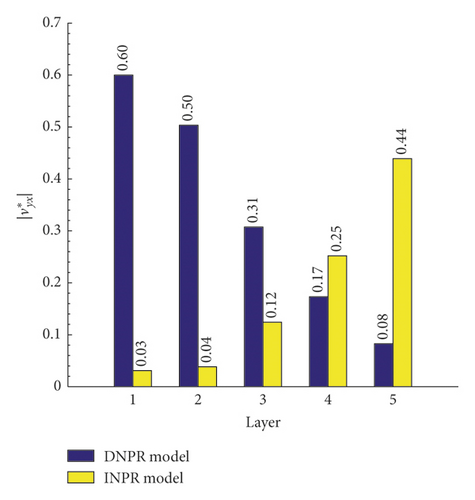

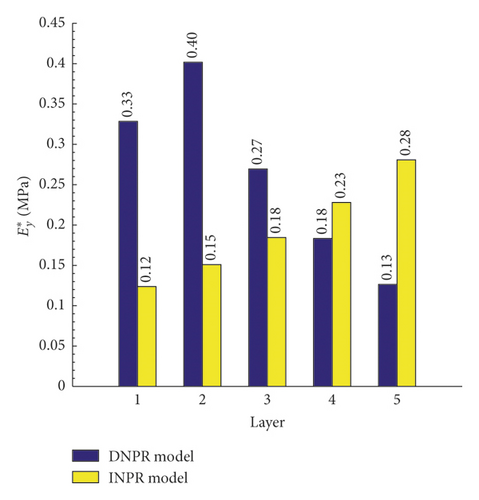

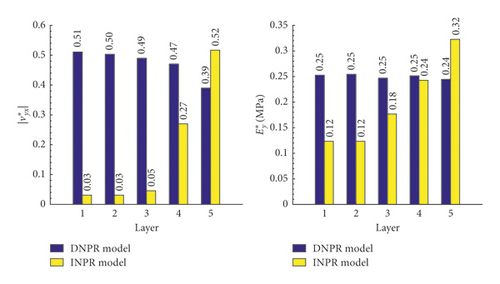

The first three models shown in Figure 2(a) are defined as uniform DAH sandwich panels with identical unit cells. The mechanical indices are plotted in Figure 3(a) based on equations (2) and (3) as θ2 increases from 45 to 65°. Both of these values monotonously decrease as θ2 increases. Here, we stipulate that a large NPR signifies a Poisson’s ratio with a large absolute value. Thus, the DAHs with larger NPRs yield large effective elastic modulus values. In contrast, as illustrated in Figures 2(b) and 2(c), the last two structures exhibit a varying pattern of DAHs across the panel thickness and are the so-called gradient DAH sandwich panels. As plotted in Figures 3(b) and 3(c), functionally increasing and decreasing sequences of Θ2 can generate sandwich models with DAHs of a decreasing NPR (DNPR) and an increasing NPR (INPR), respectively, particularly in this scenario. Regarding the gradient sandwich panels, the DAHs with large NPRs mainly yield large values, as do the uniform sandwich panels.

3. Theories of Vibration and Acoustic Analysis for DAH Cores

3.1. SEM for the Vibration of Cellular Structures

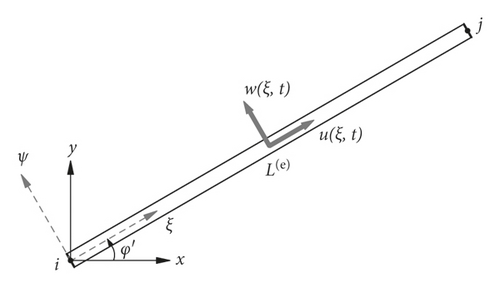

The considered sandwich panel is assumed to be infinite along the z-axis as a simplified 2D planar strain problem, following the method of modeling prismatic cellular cores in references [17–20, 22, 23, 40]. Therefore, the in-plane cellular structures are composed of rigidly connected beam elements treated as simplified 2D frames, and the long and thin frames are modeled as Bernoulli–Euler beams with an off-plane unit depth [17, 23, 40]. As shown in Figure 4, these elements are oriented in the xOy plane, and the element displacement is described in the local coordinate system (ξ, ψ) that rotates with respect to the global coordinate system (x, y) at an angle φ′. The DOFs of each element are u and w, which represent the longitudinal and transverse displacements, respectively.

For a significantly minimized system scale, the total numbers of nodes and elements are 447 and 881 for each sandwich model, respectively. Since the SEM can provide exact frequency-domain solutions without refined mesh discretization as the frequency increases [39], the mesh connections remain unchanged regardless of the material properties, structure size, or targeted frequencies. Although the spectral matrices in equation (16) need repeated assembly and computation at each frequency step, the SEM still provides an extremely accurate and time-saving alternative for dynamic problems involving cellular sandwich structures.

3.2. Sound Radiation and Transmission Loss Analysis

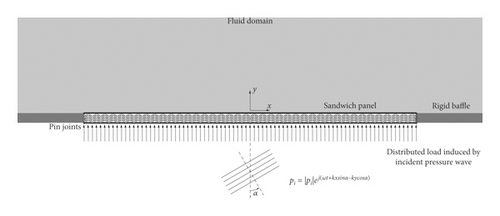

The considered sandwich model with DAH cores is exposed to a planar incident wave of acoustic pressure on the bottom face sheet as shown in Figure 6. The model is located between two rigid baffles of infinite length. The vibration of the bottom face sheet is transmitted through the cellular core to the upper face sheet; then, the sandwich structure radiates sound in the fluid domain. The ends of the structure, both ends of the face sheets, and the cellular core ribs adjacent to the ends, are all constrained in the x and y directions with pinned boundary conditions. The contribution of the airborne transmission to the total radiated sound power is neglected because of the high structural stiffness [40, 44], and thus only the structure-borne transmission is considered by following most of the relevant studies referred in Section 1.

4. Vibration and Sound Transmission Performance of the Sandwich Panels with DAH Cores

4.1. Natural Frequencies

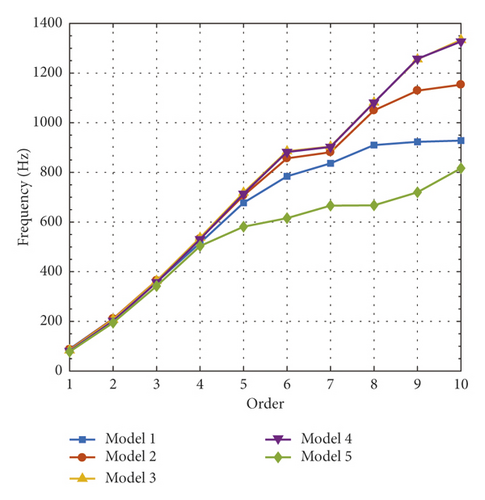

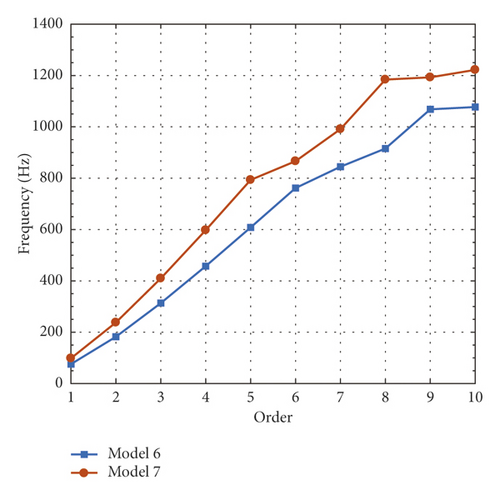

The considered models are treated as undamped linear elastic systems because the effects of damping on natural frequency searching are generally small [39]. The sandwich panels are simply-supported by pin joints, as illustrated in Figure 6. The natural frequencies that were computed via the W–W algorithm (SEM) are listed in Table 1 and plotted in Figure 7 for each considered model.

| Model | 1st | 2nd | 3rd | 4th | 5th | 6th | 7th | 8th | 9th | 10th |

|---|---|---|---|---|---|---|---|---|---|---|

| Model 1 | 88.8 | 210.5 | 357.8 | 516.1 | 677.5 | 784.2 | 836.4 | 910.0 | 923.1 | 928.0 |

| Model 2 | 86.6 | 210.6 | 364.3 | 532.4 | 706.7 | 856.6 | 881.2 | 1049.6 | 1129.2 | 1153.1 |

| Model 3 | 83.7 | 207.3 | 363.5 | 536.9 | 718.7 | 885.3 | 904.1 | 1081.8 | 1255.4 | 1333.3 |

| Model 4 | 80.6 | 201.9 | 357.0 | 530.6 | 713.6 | 882.0 | 902.6 | 1080.9 | 1257.4 | 1326.9 |

| Model 5 | 77.8 | 194.6 | 342.3 | 503.4 | 581.2 | 615.7 | 666.1 | 667.3 | 719.9 | 816.7 |

| Model 6 | 74.4 | 182.5 | 317.9 | 467.5 | 623.9 | 781.5 | 870.3 | 937.1 | 1087.5 | 1179.9 |

| Model 7 | 94.5 | 230.2 | 395.0 | 565.8 | 729.2 | 823.6 | 878.1 | 969.4 | 1003.0 | 1023.0 |

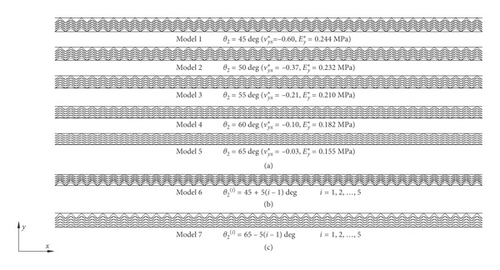

For the uniform models 1 to 5, the fundamental frequency that represents the structural bending stiffness decreases as the feature angle θ2 of the DAHs increases. This result is associated with the low of the unit cells with a large feature angle, as shown in Figure 3(a), and the deviations in the panel thicknesses also have an effect. However, the high-order natural frequencies of the uniform models with large θ2 values are larger than those of the models with small θ2 values until the feature angle exceeds 60°. This result implies that the static mechanical indices cannot completely reflect the structural dynamic behavior at high-order natural frequencies. Concerning the gradient models, the natural frequencies of model 7 are always higher than the frequencies of model 6, mainly due to the large differences in the panel thickness.

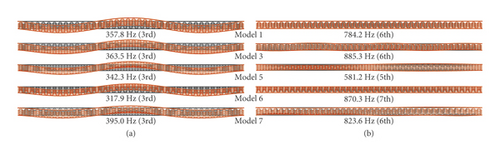

The vibrating modes of the corresponding natural frequencies for the representative models are depicted in Figure 8. The modes of a global vibrating mode shape correspond to global natural frequencies, and the others correspond to local natural frequencies. The figures in the left column illustrate the third global bending modes when the entire sandwich panel bends in the form of a curved beam in two dimensions. The figures in the right column present the foremost local frequencies when the cellular cores are partly distorted. It can be observed that the foremost local frequencies occur when the initially straight curves become bended as plotted in Figure 7. The varying core configurations of the considered models yield diverse mode shapes, and the gradient DAHs within nonuniform cellular cores further provide flexible vibrating deformation mechanisms.

4.2. Dynamic Responses and Sound Radiation

For dynamic responses, damping can be introduced by a complex modulus E∗ = Es(1 + jη) with a structural damping factor η = 0.01; in this case, aluminum damping is considered in addition to the damping effects of the hinged connections of the cell ribs [17]. The acoustic loading and boundary conditions are the same as illustrated in Figure 6, and the dynamic deformation of the considered models is depicted in Figure 9 at 500, 1000, and 1400 Hz.

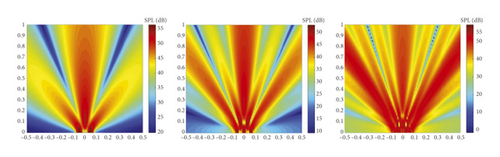

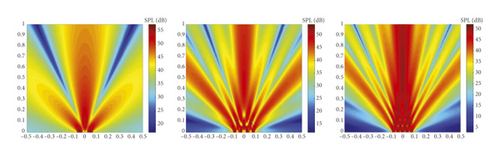

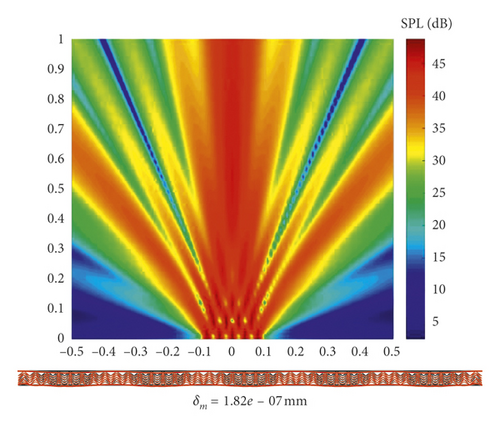

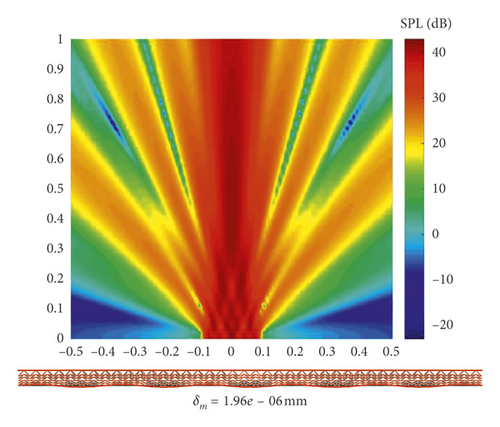

To visualize the sound radiation distributions after vibrating deformations as shown in Figure 9, the radiated sound pressure levels (SPLs) are also presented in Figure 10 for models 3 and 6 at 500, 1000, and 1400 Hz. The amplitude of the incident pressure is 1 Pa (94 dB), and the reference pressure p0 is 20 μPa. As plotted in Figure 10, the fluid observation area ranges from nondimensionalized values of x = –0.5 to x = 0.5 and from nondimensionalized values of y = 0 to y = 1. Additionally, the sandwich panels are located in the middle between x = –0.1 and x = 0.1 at y = 0.

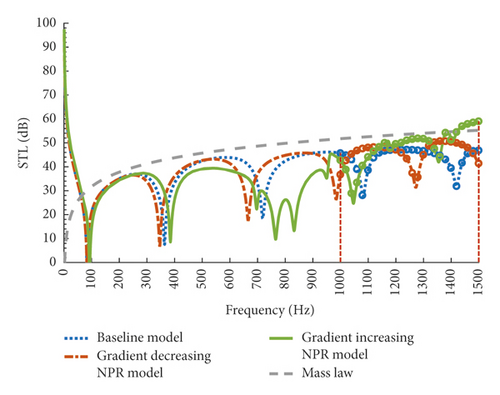

4.3. Sound Transmission Loss

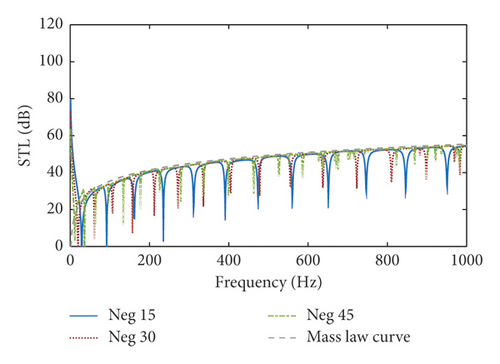

In this study, the STL responses of the considered models with varying tailored DAH cores were primarily investigated in the region from 1 to 1500 Hz, which covers the stiffness and resonance regions based on the natural frequencies discussed in Section 4.1. Thus, the acoustic performance at higher frequencies falls beyond the scope of this research. Two uniform hexagonal honeycomb sandwich models based on the configurations in [18, 22] are depicted in Figure 11, for comparison with the DAH sandwich panels. The compared hexagonal honeycomb sandwich models have the same unit cell arrangement of 40 × 5, overall dimensions of 2 m × 50 mm, and total weight of mp = 48.6 kg/m for the baseline panel introduced in Section 2.2.

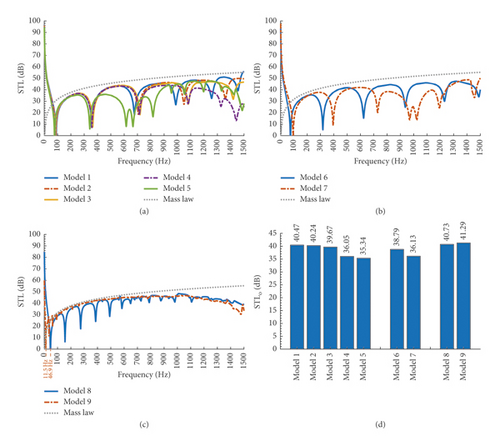

To verify the effectiveness and accuracy of the vibroacoustic calculation method in this paper, the numeric results compared with those of [18] are shown in Figure 12, which indicates that the sound transmission results via the proposed method agree quantitatively with those of the published materials. Moreover, the STLs of the considered models from 1 to 1500 Hz are shown in Figures 13(a)–13(c) where the mass law trends are also plotted. The STL dips as the low frequencies align with the odd-order bending modes listed in Table 1 because the considered symmetric models strongly vibrate under symmetric excitation when odd bending resonance is encountered. The effective Young’s modulus is selected as a function of the panel stiffness following [18, 22]. Although the DAHs in the considered models yield a smaller than the hexagonal honeycombs as shown in Figures 3 and 11, the modal density of the DAH sandwich models is much larger than the modal density of the sandwich panels with hexagonal cellular cores. This finding implies that sandwich panels with a DAH core yield a larger in-plane bending stiffness.

The overall average STL (STLo) of the considered models is shown in Figure 13(d) to assess the STL performance as an acoustic evaluation metric. A model that radiates less sound yields a larger STLo. It can be concluded that a uniform sandwich model with a small θ2 or large NPR yields the best sound insulation performance, as shown in Figures 13(a) and 13(d). The STLo of model 6 is larger than the STL of model 7, as shown in Figure 13(b), and the STL curve shapes of models 6 and 7 resemble the STL shapes of the uniform models (models 1 and 5) that feature the same θ2 for the bottom layer, respectively. As plotted in Figure 13(c), the STLo of model 9 with auxetic hexagonal honeycombs is larger than that of model 8, which is in agreement with the findings in [17, 18, 22]. Moreover, although both models 8 and 9 with conventional hexagonal honeycomb cores transmit less sound than the considered DAH sandwich models, their fundamental and high-order natural frequencies are far lower than those of the sandwich models with DAHs, as illustrated in Figure 13(c). This result indicates that the DAH sandwich panels have a stronger bending stiffness with desirable noise attenuation performance.

5. Programmable Structural-Acoustic Optimization of the Gradient DAHs for Maximum STLs

5.1. Mathematical Formulations for Structural-Acoustic Shape Optimizations

The programmable design was achieved via a global optimization method based on the MultiStart algorithm. As a workflow [23], the MultiStart algorithm can automatically distribute the tasks in a problem and simultaneously generate a series of stochastic starting points for multiple processes or processors with parallel computing. Subsequently, the problems run independently from the corresponding start points, and the MultiStart algorithm finally combines the distinct local minima into a global vector to obtain a relatively optimized solution, where the chosen local solver involves sequential quadratic programming (SQP). In this scenario, the procedure was executed with 1 × 102 random start points, and the iteration tolerance for the local solver was 1 × 10−3 to maintain computational efficiency and reasonability. The optimization procedures were executed for specified tonal and frequency band cases.

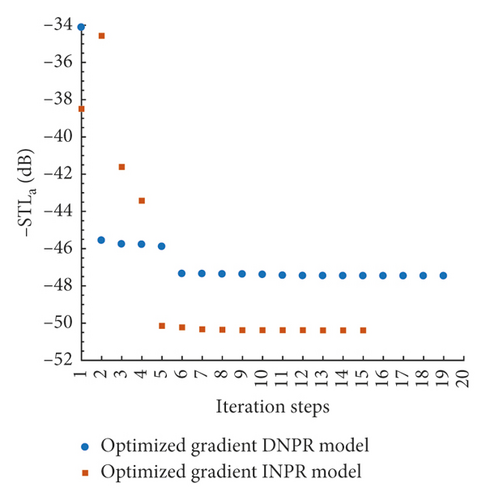

5.2. Optimal Design for Specified Tonal and Frequency Band Cases

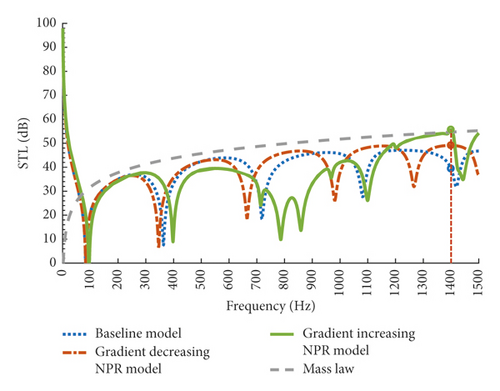

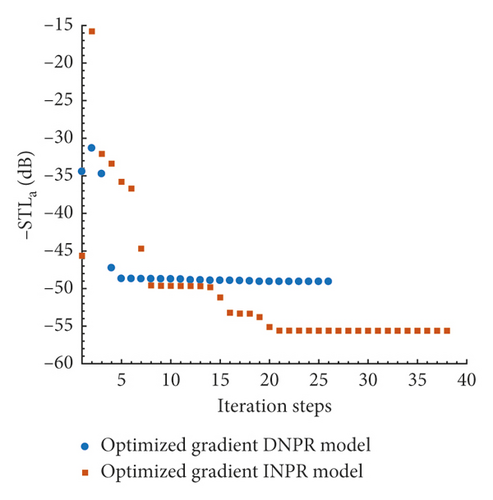

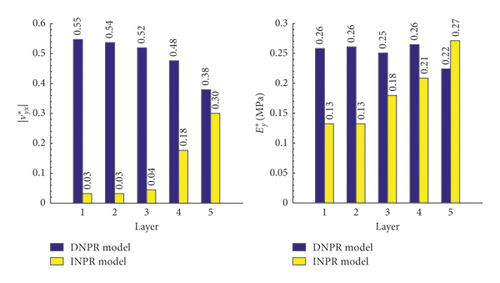

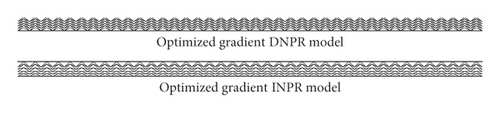

Here, a tonal excitation at 1400 Hz, which was close to an STL dip in the baseline model, was chosen for the tonal case. The STLs of the baseline and optimized gradient DAH sandwich models are compared in Figure 14(a), and the iterative curves converging to the optimum solutions are plotted in Figure 14(b). The configurations of the optimized models are shown in Figure 14(c), and the mechanical properties of the gradient DAH cores are given in Figure 14(d). In addition, the key parameters of the optimal design are listed and compared in Table 2, and both of the optimized models satisfy the high strength constraint and yield feasible core geometries. The STLa increments are approximately 9.72 dB for the optimized gradient DNPR model and 16.24 dB for the optimized gradient INPR model. The SPL distributions and dynamic deformations at 1400 Hz are illustrated in Figure 15 for the optimized models. As illustrated in Figures 15(b) and 14(a) for the optimized gradient INPR model, localized resonance occurs and the STL exceeds the mass law curve value at the target frequency. The double arrowhead unit cells adjacent to the bottom face sheet absorb the majority of the vibrating energy; hence, the optimized gradient INPR model effectively transmits the least sound as a result.

| Model | Θ2 (deg) | STLa (dB) | f0 (Hz) | STLo (dB) |

|---|---|---|---|---|

| Baseline | [55.00, 55.00, 55.00, 55.00, 55.00] | 39.37 | 83.72 | 39.67 |

| Optimized gradient DNPR | [45.98, 46.53, 46.53, 49.00, 51.03] | 49.09 | 83.99 | 40.24 |

| Optimized gradient INPR | [64.91, 64.91, 56.90, 54.96, 45.09] | 55.61 | 95.27 | 37.68 |

Here, the chosen computational frequency interval was 20 Hz for the frequency band from 1000 to 1500 Hz. The optimized information is depicted in Figure 16, and the characteristic parameters are listed in Table 3. The results demonstrate that the optimized solutions strictly satisfy the constraints of the bending stiffness and avoid element overlap. Furthermore, the reduction in average sound radiation power is approximately 2.51 dB for the optimized gradient DNPR model and 5.03 dB for the optimized gradient INPR model compared to the STLa of the baseline model. More optimized solutions could be obtained by increasing the number of start points, decreasing the iteration tolerance, or using larger integral orders.

| Model | Θ2 (deg) | STLa (dB) | f0 (Hz) | STLo (dB) |

|---|---|---|---|---|

| Baseline | [55.00, 55.00, 55.00, 55.00, 55.00] | 45.36 | 83.72 | 39.67 |

| Optimized gradient DNPR | [46.71, 47.14, 47.14, 48.31, 51.53] | 47.87 | 83.73 | 40.16 |

| Optimized gradient INPR | [65.00, 65.00, 55.51, 46.78, 46.25] | 50.39 | 92.91 | 38.31 |

5.3. Comparison and Discussion of the Sound Transmission Performance of the Optimized and Considered Models

The optimized gradient INPR models can achieve better insulation of radiated sound power than can the optimized gradient DNPR models, with improvements of 6.52 dB and 2.52 dB for the tonal and frequency band cases in this scenario, respectively. As plotted in Figures 14(d) and 16(d), the double arrowhead unit cells adjacent to the fluid domain feature a large and yield a low in the gradient INPR models, and vice versa. The gradient INPR models enable a programmable DAH core for a high STLa that even exceeds the mass law curve values and yield a high bending stiffness; however, the use of gradient INPRs generally sacrifices overall sound insulation, with a lower STLo. It can be concluded that the DAHs with large NPRs in upper layers improve the potential for obtaining an optimized STL within a specified frequency region, following the phenomenon that a uniform DAH sandwich model with a large NPR yields high sound insulation performance. Referring to the STL curves in Figures 14(a) and 16(a), the DAHs in the bottom layers mainly affect the STL curve shapes, as discussed in Section 4.3, and therefore, the overall noise insulation properties are limited.

6. Conclusions

- (1)

Regarding the vibration properties, the various core configurations of the gradient sandwich DAH panels yield more diverse mode shapes and provide more flexible vibrating deformation mechanisms than do the uniform models.

- (2)

With respect to the sound transmission performance with normal incidence, the uniform DAH sandwich models with large NPRs generally yield better sound insulation behaviors. Moreover, the considered DAH sandwich models insulate less sound but are far stiffer than the conventional hexagonal honeycomb sandwich models.

- (3)

The programmable optimized gradient INPR models yield higher STL values than the optimized DNPR models, with improvements of 6.52 dB and 2.52 dB for the specified frequency cases and a large bending stiffness; however, a lower overall sound insulation was observed. For the gradient sandwich models, the DAHs with large NPRs in the upper layers improve the potential for obtaining an optimized target STL, and the DAHs in the bottom layers affect mainly the STL curve shapes and govern the overall noise insulation properties.

- (4)

Further consideration could be given to the vibroacoustic performance and design of the proposed structures at high frequencies and under other excitation conditions. Furthermore, the design variables can also be extended to consider more than a single feature angle. Moreover, further studies could be conducted to investigate gradient auxetic metamaterials with varying topologies.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

Acknowledgments

The support for this work provided by the National Natural Science Foundation of China (51479115), High-Tech Ship Research Projects by MIIT ([2014]148 and [2016]548), and Opening Project by the State Key Laboratory of Ocean Engineering (GKZD010071) is gratefully acknowledged.

Open Research

Data Availability

The programming data used to support the findings of this study are available from the corresponding author upon request.