Superposed Incremental Deformations of an Elastic Solid Reinforced with Fibers Resistant to Extension and Flexure

Abstract

A comprehensive linear model for an elastic solid reinforced with fibers resistant to extension and flexure is presented. This includes the analysis of both unidirectional and bidirectional fiber-reinforced composites subjected to in-plane deformations. Within the prescription of the superposed incremental deformations, the fiber kinematics are approximated and used to determine the Euler equilibrium equations. The constraints of bulk incompressibility and admissible boundary conditions are also discussed for completeness. In particular, the complete systems of differential equations are obtained for the cases of Neo-Hookean and Mooney–Rivlin types of materials from which analytical solutions can be obtained.

1. Introduction

The mechanics of microstructured solids have consistently been the subject of intense research [1–5] for their practical importance in materials science and engineering. In particular, a considerable amount of attention is committed to the development of continuum models and analyses in an effort to predict the mechanical responses of fiber-matrix systems subjected to external forces and/or induced deformations (see, for example, [6, 7] and references therein). Continuum-based approaches postulate continuous distribution of fibers within the matrix materials so as to establish the idealized description of homogenized fiber-matrix composites. This is framed in the setting of anisotropic elasticity where the response function depends on the first gradient of deformations, typically augmented by the constraints of bulk incompressibility and/or fiber inextensibility. The latter condition often results highly constrained prediction models so that the corresponding deformation fields are essentially kinematically determinate, especially that arises in fibers [6, 7]. The approach has clear advantages in the prediction of deformation profiles of the system via the deformation mapping of an individual fiber, yet rather insufficient in the estimation of overall material properties of the fiber-matrix system. Nonetheless, the aforementioned models have been widely adopted in the analysis of composite materials for their merit in the continuum description and the associated mathematical framework [5–7]. For the estimation of resultant properties, one may also consider multiscale modeling method which integrates the material properties of continua assigned in different length scales by means of the Cauchy–Born rule. Examples of such practice can be found in the works of Shahabodini et al. [8, 9].

A considerable advance in the continuum theory of fiber-reinforced solids was made in recent years. This includes the incorporation of the bending resistance of fibers into the models of deformations where elastic resistance is assigned to changes in curvature of the fibers [10–12]. More precisely, the fibers are regarded as convected curves so that the bending deformation of fibers can be formulated via the second gradient of deformations explicitly [13]. The concept has been successfully adopted in a wide range of problems arising in materials science [14–17], and the mathematical perspective of the subject is discussed in [18–20]. The authors in [21] proposed a general theory for the mechanics of an elastic solids with fibers resistant to flexure, stretch, and twist within the simplified setting of the Cosserat theory of nonlinear elasticity [10, 22]. Further, the second gradient theory of elasticity for the mechanics of meshed structures is presented in [23–25]. To this end, the authors in [26–29] developed continuum-based models in the analysis of fiber-reinforced composites, where the extension and bending resistance of fibers are incorporated via the computations of the first and second gradient of deformations. The majority of the aforementioned studies address nonlinear continuum theory of fiber composites so that little has been devoted to the development of compatible linear models describing the mechanics of an elastic medium reinforced with fibers.

In the present work, we present comprehensive linear theory of the strain gradient elasticity for the mechanics of fiber-reinforced composites with fibers resistant to bending and extension. The kinematics of fibers is approximated with the prescription of the superposed incremental deformations. We formulate, in cases of Neo-Hookean types of materials, complete expressions of the linearized Piola stresses from which the Euler equilibrium equations and the admissible boundary conditions are obtained. Bidirectional fiber composites are accommodated via the decomposition of the deformation gradient tensor along the directions of fibers. In addition, the reduction of simultaneous differential equations into a single differential equation is demonstrated by utilizing the compatibility conditions of the response function. More importantly, we show that, even with the introduction of the second gradient of deformations, two different bases (referential and current coordinate) do indeed merge for “small” deformations superposed in large. Lastly, Mooney–Rivlin types of materials are elaborated where we show that the resulting Euler equilibrium equations are of the same form as those obtained from the Neo-Hookean model. The corresponding Piola stresses, on the other hand, are distinguished in that they demonstrate clear dependency on both the first and second invariant of the deformations gradient tensor. The obtained model can be easily adopted in the study of composite structures subjected to small in-plane deformations. For example, in the design stage of crystalline nanocelluloses (CNCs) composite, the overall responses and deformation profiles can be predetermined by utilizing the proposed model. In addition, the underlined theory can also be extended to the deformation analysis of lipid membranes (e.g., budding and thickness distension) [30–32], where phospholipids (microstructure) are aligned to the normal direction of the membrane, and therefore, their deformations can be mapped and computed using the proposed model.

Throughout the paper, we make use of a number of well-established symbols and conventions such as AT, A−1, A∗, and tr(A). These are the transpose, the inverse, the cofactor, and the trance of a tensor A, respectively. The tensor product of vectors is indicated by interposing the symbol ⊗ , and the Euclidian inner product of tensors A and B is defined by A · B = tr(ABT); the associated norm is . The symbol |∗| is also used to denote the usual Euclidian norm of three vectors. Latin and Greek indices take values in {1, 2} and, when repeated, are summed over their ranges. Lastly, the notation FA stands for the tensor-valued derivatives of a scalar-valued function F(A).

2. Incremental Elastic Deformations and Equilibrium Equations

3. Boundary Conditions and Solution to the Linearized System

The corresponding boundary conditions are given by [27]

Remark 1. In the above equation, δiAδjBuj,B is interpreted as δiAuB,B resulting δiAδjBuj,B = δiADivu in the reference configuration (Eulerian). However, one may also find δiAδjBuj,B = uj,j and thus obtain δiAδjBuj,B = δiAdivu in the current configuration (Lagrangian). This confirms the well-known result from the linear elasticity theory that the bases collapse in the event of small deformations superposed on large (i.e., Divu = divu and EA = ei). In the present problem, the result allows one to formulate linearized Euler equations without conflicting bases mismatch especially when operating linear transform of mixed basis tensors. Although there are no clear distinctions between the current and deformed configurations, caution needs to be taken that the Euler equation () is, in principal, defined in the reference frame together with the boundary conditions.

Now, in view of equations (5) and (6), the constraints of bulk incompressibility reduce to the following equation:

Equation (34) serves as the linearized bulk incompressibility condition (i.e., ui,i = 0), which needs to be solved together with equation (23). In addition, since Divu = Divu for small deformations (see Remark 1), we find Divu = Divu = 0 and thereby reduce equation (33) to the following equation:

3.1. Solutions to the Linearized System

4. Extensible Fibers

The solution of equation (58) is not accommodated by conventional methods such as the separation of variables method, Fourier transform, and polynomial solutions. Instead, a particular form of solution (φ = X(x)sin(my)) can be proposed, inspired by the modified Helmholtz equation.

5. Extensible Bidirectional Fibers

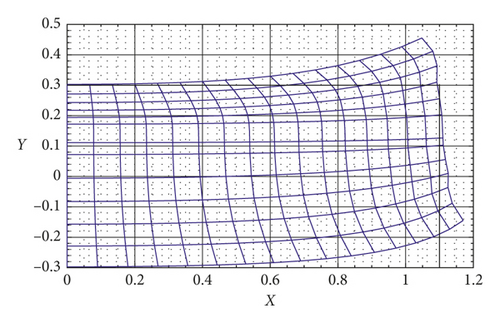

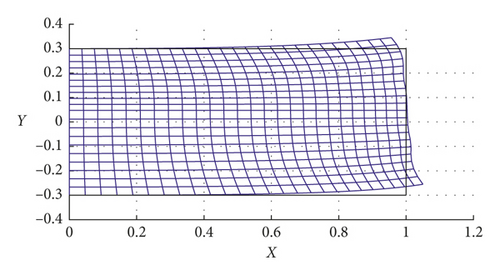

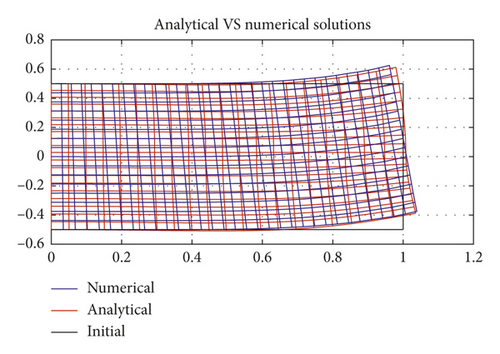

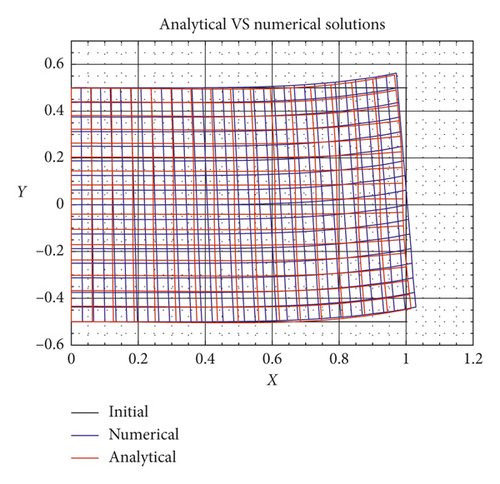

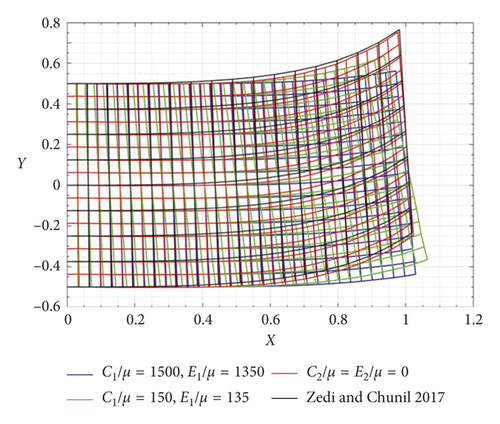

A complete analytical solution for equation (71) is available via the methods of iterative reduction and the principle of eigenfunction expansion (see, more details, [35–37]). Figures 1–4 illustrate the deformation profiles for the cases discussed through Sections 3–5. As the equations become mathematically compact, the corresponding deformation fields experience less oscillatory behaviors. This is clearly demonstrated by the results in Figures 3-4, bidirectional cases, which show a close agreement with the predictions from nonlinear models. We also mention here that equation (71) reduces to equations (42) and (58) in the limit of vanishing C2 and E2, respectively. This, in turn, suggests that unidirectional cases can be assimilated within the systems of equation (71) by setting C2 = E2 = 0 (see Figure 5). In fact, the latter model is recommended to use, since the bidirectional and extension fibers case is the most general and compact form (with minimal singular behaviors) and therefore produces more accurate prediction results.

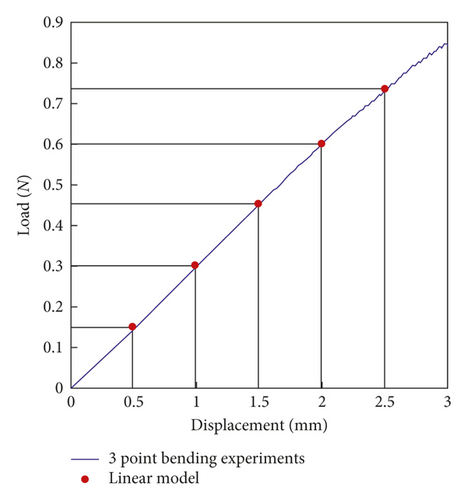

Using equation (74), we compute the maximum deflections of the CNC composite and illustrate the results in Figure 6. It is shown in Figure 6 that the proposed model successfully predicts the normal deflections of the CNC composite strip. Since the slope of the graph in Figure 6 indicates the moduli of the composite (when divided by the corresponding length scale), it can also be used in the estimation of the overall material properties of the composite. However, due to the paucity of available data, we are not able to provide the quantitative analysis other than those presented in Figure 6 at this time. The study is currently underway, and our intention is to present elsewhere when ready. We also mention here that the overall responses of composite materials can also be estimated using multiscale modeling methods (see, for example, Shahabodini et al. [8, 9]).

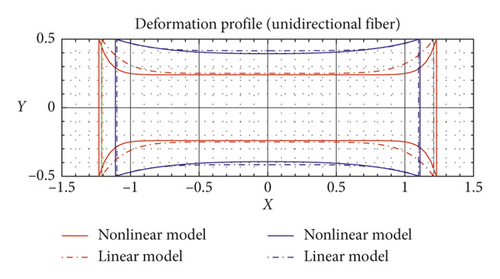

Lastly, we assimilate the case of single family of fiber composites subjected to the axial tension. The linear solution obtained from equation (56) demonstrates good agreement with the compatible nonlinear model [28] for small deformations superposed on large, while it shows discrepancies in the prediction of large deformations (See Figure 7). It is also noted here that we reserve the details in solving the corresponding differential equations (equation (56)) for the sake of conciseness. However, the procedures for the particular case of the present example can be found in [28].

6. Further Considerations

7. Conclusions

We present complete linear models for the mechanics of an elastic solid reinforced with fibers resistant to flexure and extension. Within the prescription of the superposed incremental deformations, the first and second gradient of deformations is approximated through which the kinematics of fibers is explicitly determined. The linearized Euler equilibrium equations and the Piola stress are then formulated for the Neo-Hookean types of materials. We also derive the corresponding boundary conditions and the conditions of bulk incompressibility for the sake of completeness. In addition, the cases of the bidirectional fiber composites are considered via the fiber decomposition of the deformation gradient tensor. It is found that the systems of PDEs for the bidirectional and extensible fibers reduce to those from single family of fibers in the limit of vanishing material parameters of fibers.

In particular, we demonstrate the well-known result from the linear theory of elasticity that the merging of the bases remains valid even with the incorporation of fibers’ bending and extension into the models of deformations. A Mooney–Rivlin material is also elaborated, where we show that there is no clear distinctions in the resulting Euler equations obtained from the two different strain energy models (i.e., Neo-Hookean and Mooney–Rivlin) as long as the small deformations are concerned. However, the resulting Piola stresses are of different forms in that the one from the Mooney–Rivlin model demonstrates clear dependency on both the first and second invariant of deformation gradient tensors, whereas the Piola stress, in the case of the Neo-Hookean model, depends only on the first invariant. Lastly, we mention here that the present model can be used in the approximation of the nonlinear theory of strain gradient elasticity arising in finite plane elastostatics.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

Acknowledgments

This work was supported by the Natural Sciences and Engineering Research Council of Canada via Grant #RGPIN 04742 and the University of Alberta through a start-up grant. The author would like to thank Dr. David Steigmann for many useful discussions.

Open Research

Data Availability

The data used to support the findings of this study are available from the corresponding author upon request.