Synthesis of Zeolites Materials Using Fly Ash and Oil Shale Ash and Their Applications in Removing Heavy Metals from Aqueous Solutions

Abstract

Fly ash and oil shale ash generated from power plants can be transformed to suitable materials usable for removal of heavy metals. Due to their high silica content, fly ash and oil shale ash have been considered as the main stone of zeolite synthesis. In this work, we synthesized zeolites from class F fly ash (FA) and modified oil shale ash (MOSA) by alkaline fusion followed by refluxing. Our synthesis process focused on the effect of quantity of NaOH on the crystallinity of the reaction products: Na-P1 and Na-P2 type zeolites synthesized, respectively, from FA and MOSA. The effect of NaOH mass (1, 2, 4, and 8 g) was investigated with the following synthesis conditions: 2 h fusion at 650°C, 2 h agitation, and refluxing for 12 hours. The experimental results demonstrated that the crystallinity of Na-p1 and Na-P2 zeolites increased with increasing the mass of NaOH. The resulting products were characterized with X-ray diffraction, FTIR, and scanning electron microscopy. The reaction products ZV4 and ZM4 synthesized, respectively, from FA and MOSA and containing main zeolite phases with a crystallinity of 92.7% of Na-P1 and 83.6% of Na-P2, respectively, were chosen as adsorbents for the adsorption experiments. Series of experiments were carried out to study the removal of lead, zinc, and chromium by ZV4 and ZM4. The results allowed us to know the optimal conditions of adsorption for the three heavy metals. Adsorption data have been interpreted in terms of Langmuir and Freundlich isotherms. The results showed that lead has a higher affinity for ZM4 than ZV4 and zinc has similar adsorption efficiency for both sorbents that was remarkably reduced for chromium. The results of the present work suggest that zeolites synthesized from MOSA may be considered as effective as those synthesized from FA for heavy metals adsorption.

1. Introduction

Heavy metals are widespread in nature under many forms. Small concentrations of these elements have been demonstrated to be essential for human health, but in high levels, they can be harmful and may cause serious damage to central nervous system, lungs, kidneys, and liver. As heavy metals solubility increases when pH decreases, various treatment techniques have been proposed for their removal from aqueous solutions including chemical precipitation, membrane filtration, electrolytic processes (reverse osmosis and electrodialysis), solvent extraction, and adsorption [1–5]. Unfortunately, most of these techniques have been reported to be expensive and have many inconveniences like low selectivity, high energy requirement, and generation of other harmful waste. However, adsorption is believed to be an effective technique due to its high selectivity, and it can also ensure better environmental conditions.

As reported by the World Bank, the world currently produces about 4 billion tons of all types of waste per year [6]. Affecting seriously human health and ecological systems, waste management must be considered as a priority issue. The environmental impact of coal and oil shale industry consists of issues such as contamination of the atmosphere, soil, and waterways by toxic heavy metals [7, 8]. Therefore, it is quite important to promote efficient techniques for mine waste recycling and to produce high value-added products [9]. The synthesis of zeolites from ashes, generated by the combustion of oil shale [10] or coal, has become a promising way to valorize their residues. Zeolites are widely considered as potential adsorbent for removing heavy metals from aqueous solutions.

Numerous laboratories around the world have synthesized zeolites from fly ash used for removing heavy metals [11-14]. Shawabkeh et al. have synthesized zeolites using oil shale ash by alkaline hydrothermal treatment and used them to remove cadmium and lead [15], Visa removed heavy metal ions from aqueous solutions by new zeolite materials synthesized from fly ash [16], Bao et al. have synthesized cancrinite-type zeolite from fly ash for the removal of lead, copper, nickel, cobalt, and zinc [17], Bao et al. have synthesized Na-A zeolite from oil shale ash to be used as adsorbent for copper removal [18]. In this paper, zeolites have been synthesized from fly ash (FA) and modified oil shale ash (MOSA) under identical experimental conditions. We examined the adsorption efficiency of zeolites, synthesized from modified oil shale ash (MOSA), for removing heavy metals with respect to the adsorption efficiency of zeolites synthesized from fly ash (FA). A comparative adsorption study was conducted in order to evaluate the potential of the synthesized products for the removal of lead, zinc, and chromium. The influence factors such as pH value, adsorbent mass, and initial concentration of metal ions have been examined, and the equilibrium adsorption data were fitted to Langmuir and Freundlich adsorption isotherm models.

2. Materials and Methods

2.1. Starting Materials

Fly ash used in our study is a class F fly ash [19], and it was collected from Jorf Al Asfar thermal power plant (117 Km from Casablanca, Morocco), while oil shale was obtained from the ONYHM (National Office of Hydrocarbons and Mines) [20]. Oil shale was grinded to small sizes (<1 mm). Fly ash and oil shale underwent a heat treatment at 900°C under atmospheric conditions. Modified oil shale ash (MOSA) was prepared by nitric acid treatment of oil shale ash as described in our previous work [6]. The chemical composition of FA and MOSA was determined by X-ray fluorescence (Philips, PW 2404, Magic Pro) (Table 1).

| Components | FA (% of mass) | MOSA (% of mass) |

|---|---|---|

| Na2O | 0.98 | 0.09 |

| MgO | 2.10 | 3.34 |

| Al2O3 | 34.13 | 5.67 |

| SiO2 | 49.11 | 76.37 |

| P2O5 | 1.48 | 0.07 |

| SO3 | 0.67 | 0.10 |

| K2O | 1.87 | 0.31 |

| CaO | 3.50 | 8.14 |

| TiO2 | 1.23 | 0.75 |

| Fe2O3 | 4.40 | 4.81 |

| MnO | 0.05 | 0.02 |

| Trace element | 0.48 | 0.33 |

| Total | 100 | 100 |

2.2. Zeolites Synthesis

Our synthesis method consists of introducing an alkaline fusion step prior to the refluxing treatment. It was found that this step plays an important role in the optimization of reaction conditions [21]. Larger amounts of aluminosilicates can be dissolved, and a high crystalline zeolite phase can be obtained employing this method. In a typical synthesis process, 5 g of raw material (FA or MOSA) was dry mixed with 1, 2, 4, and 8 g NaOH pellets for 30 min and the resultant mixture was fused at 650°C for 1 h. The fused product was ground in a porcelain mortar, weighed, and then was dissolved in distilled water (mass-to-liquid ratio = 1/10) under stirring conditions for 2 hours to form the amorphous precursors. Refluxing process was carried out in Pyrex one-neck round-bottom flask in a heating mantle, and temperature was maintained at 100°C. The refluxing period was fixed at 24 hours. Mineralogical and composition of the raw materials and the reaction productions were determined by powder X-ray diffraction (panalytical’s X’pert pro-X-ray diffractometer with Cu Kα radiation (Kα = 1.5418 A°)), with the 2θ angle varying between 3° and 90°. Major and minor phases were performed with semiquantitative method on the basis of the intensity counts of specific reflections, the density, and the mass adsorption coefficient of the identical mineral phases [22]. FTIR characterization of FA, MOSA, and the reaction products was conducted with a VERTEX 70 spectrometer equipped with the digitec detector. The samples were prepared according to the KBr pellet method and then were scanned in a transmission mode with 4 cm−1 resolution at the range of 4000 to 400 cm−1. The morphological characteristics of FA, MOSA, and synthetic products were observed by JEOL JMS 5500 scanning electron microscope, equipped with SUTW-Sapphire detector for EDX analysis using ZAF method for the quantification. The experimental conditions and the percentage crystallinity of the reaction products are summarized in Table 2.

| Starting material | Experimental conditions | Reaction product | Crystallinity (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Test symbol | NaOH mass | Fusion | Agitation (h) | Refluxing | |||||

| T (°C) | t (min) | T (°C) | t (h) | ||||||

| FA (5 g) | ZV1 | 1 | 650 | 2 | 2 | 100 | 12 | — | — |

| ZV2 | 2 | 650 | 2 | 2 | 100 | 12 | Na-P1 | 20.1 | |

| ZV3 | 4 | 650 | 2 | 2 | 100 | 12 | Na-P1 | 64.4 | |

| ZV4 | 8 | 650 | 2 | 2 | 100 | 12 | Na-P1 | 92.7 | |

| MOSA (5 g) | ZM1 | 1 | 650 | 2 | 2 | 100 | 12 | — | — |

| ZM2 | 2 | 650 | 2 | 2 | 100 | 12 | Analcime | 81.1 | |

| ZM3 | 4 | 650 | 2 | 2 | 100 | 12 | Na-P2 | 72.1 | |

| ZM4 | 8 | 650 | 2 | 2 | 100 | 12 | Na-P2 | 83.6 | |

2.3. Adsorption Experiments

3. Results and Discussion

3.1. Characterization of Raw Materials and Synthesized Zeolites

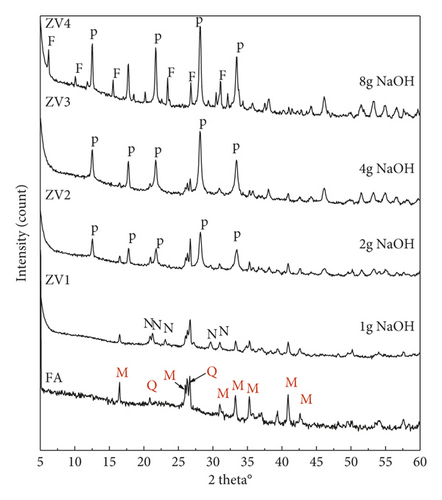

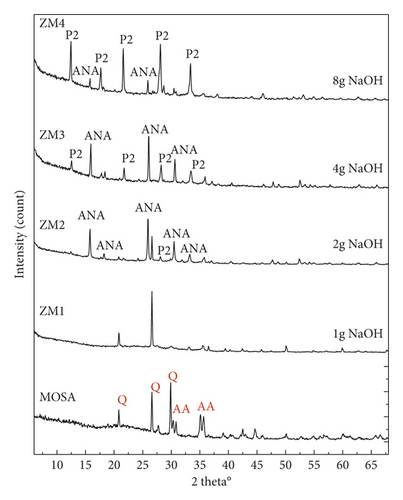

The chemical composition of fly ash and modified oil shale ash is given in Table 1. Heat treatment of FA led to the complete reduction of organic matter, while heat and acid treatment of OSA reduced considerable amount of CaO (from 38.74% to 8.14%) [6]. Figures 1 and 2 display the X-ray diffraction patterns of the zeolite synthesis from FA and MOSA, respectively. The semiquantitative X-ray diffraction analysis of fly ash, by the reference intensity ratio method, showed that mullite constitutes more than 50% of the mineralogical composition. Hematite and magnetite do not exceed 1% of this composition while amorphous phase constitutes 27.5%. When the fly ash was activated with 1 g of NaOH, peaks of mullite and quartz decreased but no zeolite was formed; however, new peaks corresponding to sodium aluminosilicate (NaAlSiO4) have been detected. The zeolite Na-P1 appeared only when 2 g of NaOH was used. The intensity of its peaks increased with increasing the mass of NaOH. An excess of NaOH led to the total disappearance of mullite and quartz peaks and to the formation of Na-X faujasite type zeolite while the crystallinity of Na-P1 attained 92.7% [23]. For MOSA, we observed that the amorphous phase was the major content (50%), while augite and quartz contents were 34.3% and 15.7%, respectively. The treatment of MOSA with 1 g of NaOH resulted in complete augite dissolution while quartz was not affected. When MOSA was activated with 2 g of NaOH, analcime type zeolite was formed with a crystallinity of 81.1%. Also, a minor amount of Na-P2 type zeolite was detected. The crystallinity of Na-P2 increased with increasing the amount of NaOH while that of the analcime decreased. In the meantime, quartz disappeared completely when MOSA was treated with 4 g of NaOH. The crystallinity of Na-P2 has reached its maximum (83.6%) with 8 g of NaOH [24].

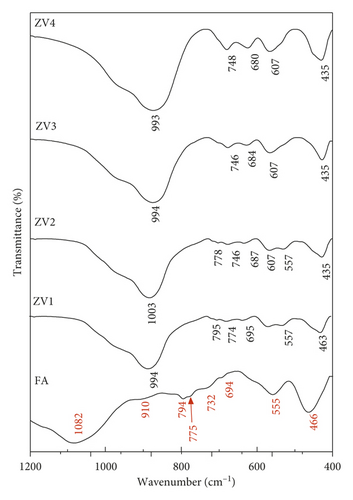

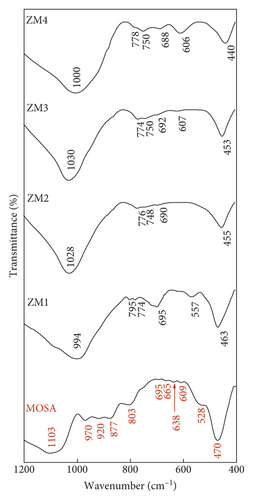

Figures 3 and 4 show the FTIR spectra of the products obtained after reaction of FA and MOSA with 1 g, 2 g, 4 g, and 8 g of NaOH, respectively. The characteristic peaks of fly ash disappeared while new peaks were detected indicating the formation of new products. The bands in the region 420–500 cm−1 were attributed to the internal deformations of the zeolite tetrahedron δ O–(Si; Al)–O. The original band at 466 cm−1 shifted to lower frequencies with increasing the amount of NaOH. The bands in the region 500–650 cm−1 were associated with the vibrations of the double rings (4-membered ring and 6-membered ring). The intensity of the initial band at 555 cm−1 decreased until its total disappearance as the mass of NaOH increased. A new band was detected at 607 cm−1, and its intensity increased in function of the mass of NaOH. The bands characterizing the AlIV–O stretching vibrations of the mullite tetrahedron at 732 cm−1 and 910 cm−1 disappeared. A new band was formed around 747 cm−1, and its intensity gradually increased. The intensity of characteristic doublet of quartz at 774 cm−1 and 794 cm−1 decreased until total disappearance, while the band at 694 cm−1 disappeared in the beginning, giving rise to a new band around 684 cm−1, and it can be attributed to symmetric stretching of (Si; Al)–O–(Si; Al). The bands in the region 950–1200 cm−1 were attributed to asymmetric stretching of O–(Si; Al)–O bonds. From Figure 3, it can be seen that the original band at 1082 cm−1 was replaced by a new band at 994 cm−1. This band moved to low frequencies before returning to its original position [25]. Figure 4 illustrates the FTIR spectra of the products obtained after the reaction of MOSA with 1 g, 2 g, 4 g, and 8 g of NaOH, respectively. The spectrum corresponding to the activation of MOSA with 1 g of NaOH shows the disappearance of the peaks associated with augite, and the peaks remaining in the spectrum were almost identical to those with characteristic peaks of quartz. The original band located at 470 cm−1 shifted to 440 cm−1. Its intensity decreased slowly as the mass of NaOH progressed, and this band was attributed to the internal deformations of the zeolite tetrahedron δ O–(Si; Al)–O. In the range 500–650 cm−1, a new band appeared at 607 cm−1, and it was associated with the vibrations of the double rings (4-membered ring and 6-membered ring). The initial band at 528 cm−1 disappeared. In the region 650–850 cm−1, new bands were detected around 690 cm−1 and around 750 cm−1 and their intensities increased with the increase of the mass of NaOH, while the band around 776 cm−1 decreased in intensity, and these bands were attributed to symmetric stretching of (Si; Al)–O–(Si; Al) bonds. The peaks in the 950–1200 cm−1 region were attributed to asymmetric stretching of O–(Si; Al)–O bonds. The initial bands at 1103 cm−1 and 970 cm−1 were replaced by a band at 994 cm−1. This band first moved to high frequencies to 1030 cm−1 and then returned to the low frequencies [25, 26].

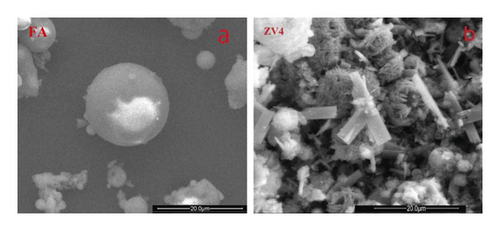

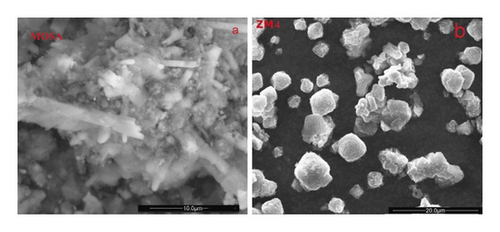

Figure 5(a) illustrates the SEM-determined microstructure characteristics of fly ash, and generally, the particles are distinguished by their spherical shape and smooth surface [26]. Figure 5(b) shows the synthesized product ZV4. We noticed the presence of lamellar structures identified by X-ray diffraction as zeolite Na-P1 [26]. The observation of Figure 6(a) shows brighten whiskers (nanowires) types which were detected in different regions of the MOSA sample. They were attributed to augite, a glass-ceramic. The morphology of the synthesized product ZM4 obtained by alkaline fusion of MOSA followed by refluxing was shown in Figure 6(b). We noticed the presence of aggregates consisting of flat shapes oriented in all directions. They could be attributed to the zeolite Na-P2 [24, 27].

3.2. Sorption Experiments

3.2.1. Effect of pH

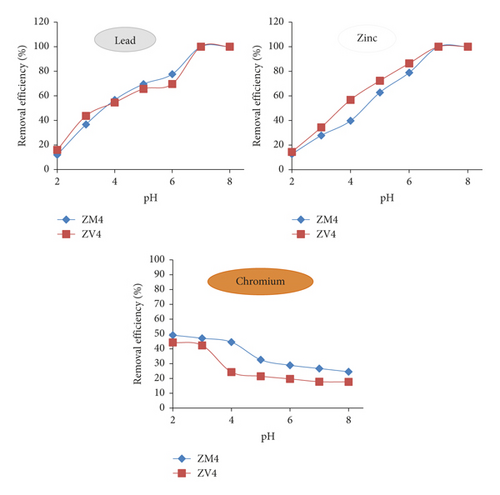

At low pH, metal ions adsorption was difficult and this could be attributed to the competition between the excess of proton H+ and the ion metal on the surface of the adsorbent. Therefore, increasing the pH value led the augmentation of the removal efficiency of Pb(II) and Zn(II) by ZV4 and ZM4. However, we cannot emphasize the role of our synthesized products in the removal of lead and zinc for pH > 7 because above this value, the effect of adsorption was deregulated by the phenomenon of precipitation of lead (Pb(OH), Pb (OH)2) and zinc (Zn (OH), Zn (OH)2) [29]. For chromium, it can be seen from the results shown in Figure 7 that its removal efficiency reached the maximum when the pH = 2, and then the yield decreased progressively with pH. Considering that in acidic solution, hexavalent chromium exists in the anionic form (Cr2O72−, HCrO4−, Cr3O102−, and Cr4O132−) and that the sites of the synthesized products become protonated adsorption and then was favored [31]. At high pH, there was a competition between OH− and the Cr2O72− form, the protonation of the active sites of the adsorbents was weakened, and the adsorption was difficult [32].

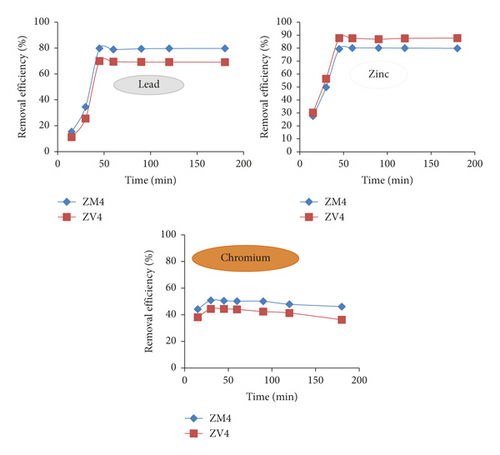

3.2.2. Effect of Contact Time

Figure 8 shows that the removal efficiency of heavy metals varies with stirring time, and the removal efficiency of lead, zinc, and chromium reached the maximum after 45 min for ZM4 as well as for ZV4. Then metal concentration remained almost constant for the rest of the time intervals. On the contrary, the removal efficiency of chromium decreased gradually, which can be explained by the desorption phenomena. Based on the experimental results, we can conclude that lead has an affinity for ZM4 greater than that for ZV4 with a maximum removal efficiency of 79.77% and 69.97%, respectively, while zinc has a remarkable affinity for ZV4 (85.7%) superior than this for ZM4 (79.29 %). In the end, chromium has only a limited affinity for the two adsorbents (46.56% and 44.13%, respectively, for ZM4 and for ZV4), despite the favorable conditions of the acidic pH. This result can be attributed to other factors that influence the adsorption phenomena such as polarity, polarizability, and adsorbed ion size [26].

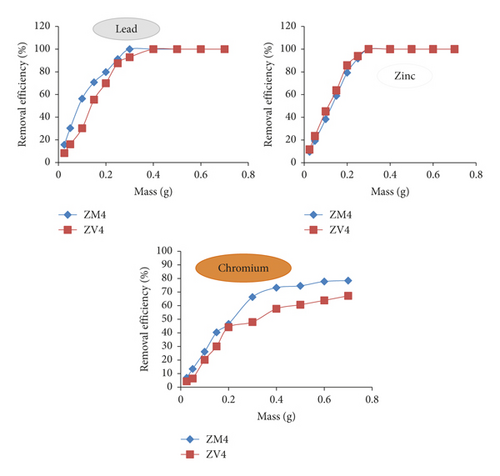

3.2.3. Effect of Adsorbent Dosage

The effect of the adsorbent dosage on the removal of heavy metals was conducted with mixing a mass of adsorbent ranging from 0.05 g to 0.4 g into 100 ml of each metal solution (C0 = 100 mg/l)). As it can be seen from Figure 9, the percent removal of lead and zinc increased with increasing the mass of adsorbent. The total removal of zinc was reached with 0.3 g of both adsorbents (ZM4 and ZV4) while for the removal of lead, it was reached with 0.3 g of ZM4 and 0.4 g of ZV4. In fact, with increase of the adsorbent mass, negatively charged exchange sites became more numerous, and consequently, the probability of adsorption increased [26]. For chromium, we observed that its removal efficiency increased rapidly in the first stage and then progressed slowly. A mass of 0.7 g of ZM4 and ZV4 removed only 78.43% and 67.23% of chromium, respectively.

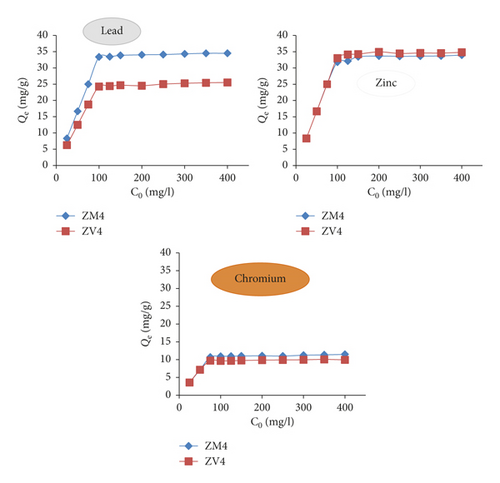

3.2.4. Effect of Initial Metal Concentration

Figure 10 depicts the effect of initial concentration on the removal of heavy metals at various concentrations from 25 to 400 mg/l with 0.3 g and 0.7 g mass of both adsorbents, respectively, for the adsorption of zinc and the adsorption of chromium while for the adsorption of lead, the mass of ZM4 and ZV4 was fixed at 0.3 g and 0.4 g, respectively. As we can observe from the same figure, when the initial concentration of lead and zinc increased from 25 to 100 mg/l, the adsorption capacity of ZV4 increased, respectively, from 6.25 to 24.28 mg/g for lead and from 8.33 to 33.02 mg/g for zinc while the adsorption capacity of ZM4 increased from 8.33 to 33.38 mg/g for lead and from 8.33 to 31.81 mg/g for zinc. The adsorption capacity of ZM4 and ZV4 for chromium started with a value of 3.57 mg/g and attained values of 10.93 mg/g and 9.67 mg/g, respectively, when the initial concentration of chromium increased from 25 mg/l to 75 mg/l. However, the adsorption capacity of ZV4 and ZM4 remained nearly constants when the initial concentration of lead and zinc was higher than 100 mg/l due to the saturation of all active sites on the pore surface of the adsorbents [33]. Nevertheless, the stagnation of the adsorption capacity of ZM4 and ZV4 when the initial concentration of chromium exceeded the value of 75 mg/l can be explained by the fact that the maximum adsorption capacity was reached under the effect of other factors that influenced the adsorption phenomena such as charge, size, and polarizability of the metal ion [28].

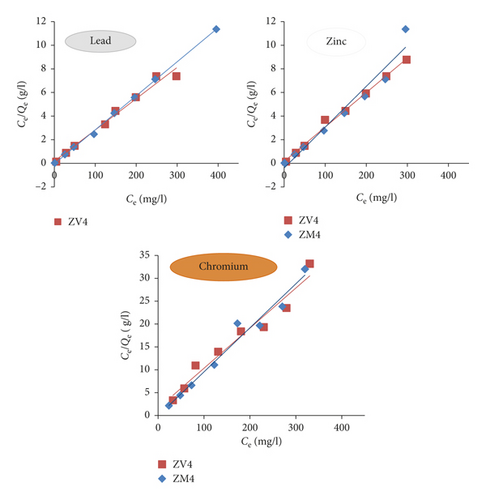

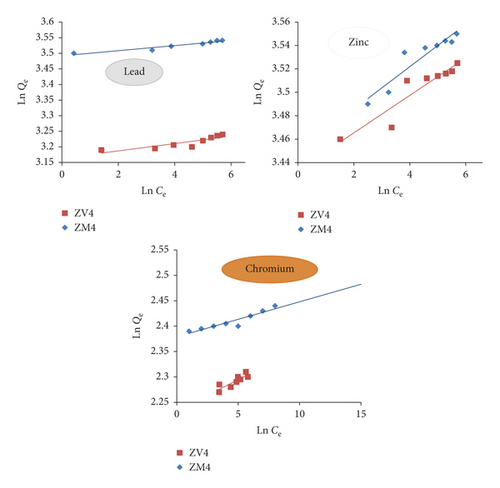

3.2.5. Adsorption Isotherm

| ZV4 | ||||||

|---|---|---|---|---|---|---|

| Metal ions | Langmuir model | Freundlich model | ||||

| Qm (mg/g) | b (l/mg) | R2 | Kf (mg/g) | nf | R2 | |

| Lead | 25.64 | 0.48 | 0.990 | 23.57 | 0.01 | 0.751 |

| Zinc | 34.24 | 0.58 | 0.993 | 30.87 | 0.02 | 0.867 |

| Chromium | 10.41 | 0.8 | 0.957 | 9.29 | 0.01 | 0.745 |

| ZM4 | ||||||

| Lead | 34.96 | 0.4 | 0.991 | 32.78 | 0.008 | 0.918 |

| Zinc | 29.41 | 0.87 | 0.957 | 31.50 | 0.02 | 0.880 |

| Chromium | 11.49 | 0.05 | 0.971 | 10.69 | 0.006 | 0.889 |

4. Conclusion

This work investigates the possibility of fly ash (FA) and modified oil shale ash (MOSA) as starting materials for zeolites synthesis under identical experimental conditions. Characterization of synthesis products was made by several analytical techniques. The products ZV4 and ZM4, produced from the conversion of FA and MOSA and composed mainly of Na-P1 and Na-P2 type zeolites, respectively, were selected for the adsorption tests. The crystallinity of Na-P1 and Na-P2 was found to be 92.7% and 83.6%, respectively. A comparative adsorption study was conducted in order to evaluate the potential of these reaction products for heavy metals adsorptions. The results of the removal experiments suggest that ZV4 and ZM4 can be considered as efficient and low-cost adsorbents. The affinity of ZV4 for the removal of heavy metal adsorption was in decreasing order Zn > Pb > Cr while the ZM4 affinity is reported to follow the decreasing order Pb > Zn > Cr. The maximum adsorption capacities for Pb, Zn, and Cr estimated from Langmuir adsorption isotherms were found to be 25.64, 34.24, and 10.41 mg/g and 34.96, 29.41, and 11.49 mg/g for ZV4 and ZM4, respectively. From these results, the following conclusion can be drawn: zeolites synthesized from MOSA may be considered as effective as those synthesized from FA for heavy metals adsorption.

Conflicts of Interest

The authors declare that they have no conflicts of interest regarding the publication of this paper.

Acknowledgments

Analytical instrument facilities were provided by the UATRS-CNRST (Unité d’Appui à la Recherche Scientifique-Centre National de la Recherche Scientifique et Technique), Rabat, Morocco. The authors would like to thank the technicians and the engineers of UATRS.

Open Research

Data Availability

The data that support the findings of this study are available on request from the corresponding author.