Tailoring Aerogel for Thermal Spray Applications in Aero-Engines: A Screening Study

Abstract

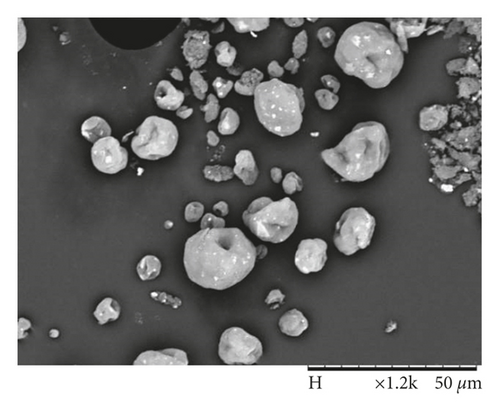

Irregular silica aerogel particles had been tailored to a regular spherical shape within the proper granulometric size range for thermal spraying. Silica aerogel is an ultralow dense and highly porous nanomaterial with its thermal conductivity being the lowest than any solids. Although silica aerogels possess fascinating physical properties, their implementation is limited to aerogel-doped blankets in the aerospace industry. Due to space constraints, these heat insulative and fireproof blankets are not encouraged by aero-engine manufacturers, and hence, alternatives are being sought. Although it was thought that an aerogel-based thermally sprayed coating may be applicable, aerogel powders are extremely challenging to be injected and deposited by thermal spray guns because of their inappropriate granulometric and morphological properties. Consequently, this study intends to tailor the aerogel powders accordingly. Aerogel-based slurries with yttria-stabilized zirconia as a secondary ceramic were prepared and spray-dried according to a modified Taguchi experimental design in order to appreciate the effect of both the slurry formulation and drying conditions such as the solid content, the ratio of yttria-stabilized zirconia : aerogel added, the amount of dispersant and binder, inlet temperature, atomization pressure, and feeding rate on the aforementioned characteristics of the resulting spray-dried powder. Uniformity was found to be the most influenced one (F-ratio = 62.40) by the overall spray-drying process. Solid content had the most significant effect on median particle size (p value = 0.035) and volume fraction (p value = 0.010) but did not affect uniformity significantly (p value = 0.065). Furthermore, a strong positive and significant correlation existed (Pearson’s r = 0.930) between median particle size and volume fraction. Based on the derived relationships, an optimised condition to achieve the maximum median particle size was then predicted and verified experimentally. The optimised aerogel-based spray-dried powder had a median particle size, volume fraction, and uniformity of 28.93 ± 0.726 μm, 64.45 ± 0.535, and 0.475 ± 0.002, respectively. Finally, the morphology of the optimised powder was noticed to have been changed from irregular shapes to spherical or donut-like granules which made them within the frame of thermally sprayable. However, when the optimised spray-dried powder was weighed, the quantity was found to be 10% only from the total weight of ceramics within the slurry prior to spray-drying, which makes it uneconomically reasonable for subsequent thermal spraying.

1. Introduction

Silica aerogel [1], invented in 1931, sometimes considered as a state of matter on its own, is a highly porous material with extraordinary physical properties which has attracted increasingly more attention since the turn of the millennium due to its potential in resolving various existing problems. The usage of aerogels was restricted until recently due to their relatively high manufacturing cost that arises owing to the expensive synthetic source of silica and/or the supercritical drying during the synthesis process, thereby making the material impracticable compared to conventional materials. Silica aerogel is prepared via the sol-gel method and initially followed by supercritical drying [2, 3]. Nowadays, manufacturers of aerogels have modified the synthesis technique, such as modifying the sol-gel route, applying ambient drying instead of subjecting on supercritical conditions, and also using the cheaper natural source of silica such as rice husk in the place of synthetic matter, to save energy and time and hence the overall manufacturing cost. Intensive research was carried out in the academia prior to the commercialised ecofriendly and/or cheaper aerogels [4–10]. The actual trend which depicts an increasing interest in aerogels by manufacturers is not because of the new advances in the nanotechnology of the material itself but, instead, to meet the tailored demands by consumers requiring innovative and yet cost-effective solutions. As a result, the aerogels market has recently seen a surge in the number of patents filed on aerogels in the recent history. Published patents started to rise rapidly from about 80 published in 2000 to in excess of 400 in 2009 [11]. This demonstrates the increase in nanomaterials research in recent years in the field of aerogels. One of the most promising implementations of these nanostructured materials is high-performance thermal insulation because of its relatively low thermal conductivity, ∼0.012 W/mK, and ultralow density which can go as low as 0.003 g/cm3 [12]. Comparatively, the same property of air is approximately 0.0012 g/cm3, that is, thrice lower than that of silica aerogel which may be considered as significant. In the powder form, silica aerogel is normally denser and may range from 0.06 to 0.3 g/cm3 or even a higher value depending on the source of silica and drying process [13, 14]. This illustrates the potential substantial weight savings that can be attained if aerogels are used for thermal insulation. It is nevertheless noticed that powdered aerogels are preferred over monoliths and are being integrated into various innovative solutions. For instance, thick thermally insulated aerogel-based blankets of millimetre order are being continuously studied and used in aerospace [15], while thin aerogel-doped insulative paints and granulate glazing systems are currently being employed for architectural purposes [16]. The issues, challenges, and applications of aerogels in aerospace have been addressed elsewhere [17].

However, up to now, silica aerogel has not been applied as a heat- or fire-resistive coating. It is thought that thermal spraying is a potential class of coating technology that can be opted to achieve so. The technique is one in which the feedstock in the powder form is propelled onto a substrate at high velocity and temperature to melt the particles partially so as they adhere on the surface to form a coating. Typically, thermal spray coatings are typically produced with a thickness between 30 μm and 2 mm [18]. One vital requisite amongst others while considering conventional thermal spraying is that the particles should be spherical ranging within a certain range of particle size, typically 10–100 μm[18], with a median particle size within 20–60 μm [19].

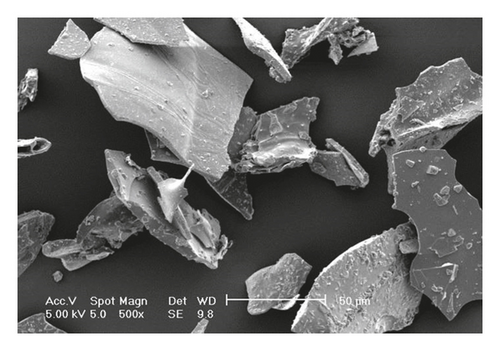

However, the as-received aerogel powder intended to be thermal sprayed had irregular shapes, granule particle range of 2–300 μm, and median particle size of 81 μm which made it inappropriate for thermal spraying. In consequence, the objective of this paper is to tailor the particles of silica aerogel obtained from the manufacturer into spherical ones with granulometric properties via spray-drying as an intermediate process for subsequent air plasma spraying (APS), which will be conducted and reported later. APS is regarded as the most versatile thermal spray process which allows deposition even on critical substrates, such as polymer matrix composites [20, 21]. Spray-drying has been chosen because of its superiority in producing thermal-spray-graded spherical free-flowing powders within a wide range of sizes economically compared to those prepared as precipitation [22], sintering/crushing [23], and hollow-spherical powder [24]. It is a process by which a fluid feed material is transformed into a dry powder by spraying the latter which is a water-based suspension with air as drying gas [25]. Some spray-dryers operate with alcohol-based suspensions but instead use nitrogen as the drying gas. It is a well-established statement that the significant factors to influence the characteristics of spray-dried powders are suspension composition, drying temperature, atomising pressure, and feeding rate [26]. Considering the fact that no academic study has investigated the feasibility of spray-drying aerogel powders, this investigation takes into consideration all these factors as its independent variables and studies their effect on three measurable responses, namely, median particle size, volume fraction, and uniformity. The optimised condition to achieve the maximum median particle size and volume fraction was subsequently predicted after which an assessment on the morphology of on the resulting spray-dried powders was carried out.

2. Materials and Methods

2.1. Materials

Ecological GEATM 0.125 aerogel was supplied by Green Earth Aerogel Technologies, whilst commercialised yttria-stabilised zirconia (YSZ), ZrO28Y2O3 (Metco 240NS-G), was purchased from Oerlikon Metco (previously Sulzer Metco). Polyvinyl alcohol (Mowiol® 4-88) and polyethylene glycol were bought from Sigma-Aldrich. Darvan 821-A was provided by Vanderbilt Minerals, LLC. Distilled water was available at the facility, Advanced Materials Research Centre (AMREC, SIRIM). All the materials were used as obtained with no further treatment. YSZ was added as a secondary ceramic material in order to improve the flowability of the slurry through the nozzle of the spray-dryer as aerogel in ultralight. Also, YSZ is a thermal-spray-graded powder which is used as a heat insulative coating in aero-engines. PVA which is a binder was opted because of its water soluble nature and its ability to be readily ball-milled without degradation, hence creating extremely stable solutions. The uniformity or polydispersity index (PDI) of the powders of aerogels, which gives an indication of the heterogeneity of sizes of the granules, was measured using particle size analysis via the Mastersizer 2000E/Hydro 2000MU. It was found that the uniformity of the GEATM 0.125 aerogel powders was 1.993 which is relatively high for a thermal spray powder, as compared to the uniformity of the thermal-spray-graded YSZ having a value of 0.433. YSZ had an apparent density of 2.300 ± 0.200 g/cm3, while the aerogel was considerably less dense with a value of 0.129 ± 0.010 g/cm3.

2.2. Slurry Formulation and Granulation

A strict mixing procedure was carried out, whereby the amount of each aforementioned material and the amount of each aforementioned chemical were added according to the formulation with respect to Table 1. For a constant slurry volume of 1000 cm3, firstly, Darvan 821-A as a dispersant was first dropped to distilled water at 95°C and stirred for 10 min. The water-soluble polyvinyl alcohol, PVA, of molecular weight ∼31,000 was then added into the mixture and mixed at the same temperature for 20 minutes until being completely dissolved followed by a specific amount of plasticizer polyethylene glycol, PEG, of 0.5 wt.% for an additional 10 min at 95°C. The solution was left to be cooled until room temperature and was weighed. The loss of water during the heating was compensated. Yttria-stabilised zirconia was then mixed gradually, and the suspension was blended for another 15 min at room temperature. Finally, aerogel was added and mixed for an additional 15 min. The resulting mixture was ball-milled in stainless steel jars and zirconia balls for 25 hours to attain a well-stabilized and dispersed slurry. The ratio of slurry : ball was kept 1 : 2 at all times. The ball-milled slurry was then weighed again so that the amount of the spray-dried powder collected could be correlated with the amount of the slurry being granulated, in other words, the yield. It is the ratio of the amount of powder collected after every spray-drying experiment to the initial amount of solids in the feed solution and expressed in percentage.

| Symbol | Factors | Levels | |||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | ||

| A | Powder content (vol.%) | 15 | 20 | 25 | 30 | 35 | 40 |

| B | YSZ : aerogel (wt.) | 1 : 1 | 1 : 3 | 1 : 5 | |||

| C | Dispersant (wt.%) | 0.3 | 0.6 | 0.9 | |||

| D | Binder (wt.%) | 4 | 6 | 8 | |||

| E | Inlet temperature (°C) | 150 | 175 | 200 | |||

| F | Atomization pressure (bar) | 0.9 | 1.0 | 1.1 | |||

| G | Feeding rate (ml/min) | 18 | 21 | 24 | |||

- Note: each experiment was carried out in triplicate.

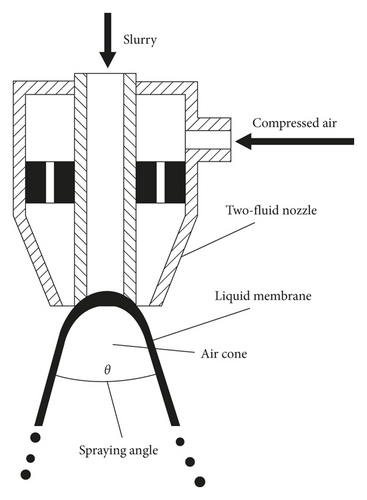

A LabPlant SD-05 spray-dryer with a two-fluid nozzle was used in this investigation. In this type of nozzle, a spray is obtained by using two fluids, the feed and the compressed gas. The compressed gas, in this case, air atomised, is breaking down the feed solution into individual spheres as it emerged from the jet to form the required fine spray. The jet nozzle had an internal diameter of 0.5 mm in order to obtain the desired particle size distribution of 20–60 μm. The operating procedure of the spray-dryer was followed in accordance with the manual. Heated air was blown through the main chamber evaporating the liquid content of the atomised spray leaving the solid particles of the material to be separated from the exhaust air flow by a cyclone and collected in the sample collection bottle. During operation, the values of the design parameters under study were ensured to remain constant at all times, and the suspension was kept on stirring magnetically in the beaker until completion. The spray-dried aerogels were then transferred into a clean container and labelled accordingly. Afterwards, the components of the spray-dryer were meticulously cleaned before the next run.

2.3. Design of Experiment

The Taguchi design of experiment was employed as the statistical tool to minimize effort and time required without compromising the process. It is a powerful tool being used within the scientific community for the design of high-quality systems through screening and optimisation by using a strategically designed experiment being derived mathematically and empirically. In this work, the influence of the spray-drying process and the effect of each spray-drying parameter on the responses were screened, and their significances were appraised accordingly to enable optimization. A modified orthogonal array L18 was used to examine a seven-factor system with a combined number of levels, wherein one of the factors consists of six levels and the remaining were with three levels, as shown in Table 1. As a note, L denotes the Latin square and 18 represents the number of runs to be undertaken. The independent variables were powder content (vol.%), mass ratio of YSZ : aerogel, dispersant (wt.%), binder (wt.%), inlet temperature (°C), pressure (bar), and feeding rate (ml/min). The first four factors are related to the composition, while the remaining ones are attributed to the operating settings of the spray-dryer. On the contrary, the responses were median particle size (D50), volume fraction representing the amount of particles within the range of 20–60 μm [19] which is considered to be the appropriate granule size for air plasma spraying (APS), and uniformity. It is to be noted that the volume fraction is obtained from the particle size distribution generated by the Mastersizer 2000E/Hydro 2000MU. Each run was performed in triplicate, and the average was calculated for each response. The statistical analysis of the data collected was done via the Minitab® software to determine any significance, correlations, and optimization.

2.4. Characterisation

A laser particle size analyser (Mastersizer 2000E by Malvern Instruments) was used to obtain the granulometric properties, while a Hitachi TM3000Benchtop Scanning Electron Microscope was employed for morphological analysis of the as-received aerogel powders and a Philips XL-30 Scanning Electron Microscope was used to observe the spray-dried aerogel-based powders.

3. Results

The comparison amongst the prepared spray-dried YSZ-aerogel samples highlights diagrammatically how each response, that is, median particle size, volume fraction, and uniformity, was affected from treatment 1 to treatment 18 when subjected to different conditions according to Table 2. The effect of the spray-drying variables on the responses is discussed in the next section.

| Treatment | Independent variables | Responses (mean ± SD) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Powder content (vol.%) | YSZ : aerogel | Dispersant (wt.%) | Binder (wt.%) | Inlet temperature (°C) | Atomization pressure (bar) | Feeding rate (ml/min) | D50 (μm) | Volume fraction | Uniformity | |

| 1 | 15 | 1 : 1 | 0.3 | 4 | 150 | 0.9 | 18 | 16.531 ± 0.483 | 35.89 ± 1.356 | 0.423 ± 0.003 |

| 2 | 15 | 1 : 3 | 0.6 | 6 | 180 | 1.0 | 21 | 17.761 ± 1.022 | 41.19 ± 1.267 | 0.417 ± 0.002 |

| 3 | 15 | 1 : 5 | 0.9 | 8 | 200 | 1.1 | 24 | 16.882 ± 0.971 | 37.39 ± 1.124 | 0.417 ± 0.001 |

| 4 | 20 | 1 : 1 | 0.3 | 6 | 180 | 1.1 | 24 | 20.309 ± 0.481 | 51.27 ± 1.159 | 0.431 ± 0.003 |

| 5 | 20 | 1 : 3 | 0.6 | 8 | 200 | 0.9 | 18 | 20.793 ± 1.145 | 53.09 ± 2.050 | 0.416 ± 0.003 |

| 6 | 20 | 1 : 5 | 0.9 | 4 | 150 | 1.0 | 21 | 16.173 ± 0.590 | 34.43 ± 1.083 | 0.427 ± 0.002 |

| 7 | 25 | 1 : 1 | 0.6 | 4 | 200 | 1.0 | 24 | 21.227 ± 0.484 | 54.30 ± 1.024 | 0.442 ± 0.004 |

| 8 | 25 | 1 : 3 | 0.9 | 6 | 150 | 1.1 | 18 | 19.803 ± 0.749 | 49.44 ± 2.101 | 0.414 ± 0.002 |

| 9 | 25 | 1 : 5 | 0.3 | 8 | 180 | 0.9 | 21 | 19.464 ± 0.281 | 48.22 ± 1.040 | 0.448 ± 0.002 |

| 10 | 30 | 1 : 1 | 0.9 | 8 | 180 | 1.0 | 18 | 22.892 ± 1.592 | 57.79 ± 1.294 | 0.458 ± 0.002 |

| 11 | 30 | 1 : 3 | 0.3 | 4 | 200 | 1.1 | 21 | 21.484 ± 0.932 | 55.23 ± 1.842 | 0.437 ± 0.002 |

| 12 | 30 | 1 : 5 | 0.6 | 6 | 150 | 0.9 | 24 | 20.252 ± 0.994 | 51.11 ± 1.134 | 0.418 ± 0.002 |

| 13 | 35 | 1 : 1 | 0.6 | 8 | 150 | 1.1 | 21 | 22.587 ± 0.826 | 57.52 ± 1.443 | 0.450 ± 0.007 |

| 14 | 35 | 1 : 3 | 0.9 | 4 | 180 | 0.9 | 24 | 21.702 ± 1.442 | 55.07 ± 2.002 | 0.454 ± 0.002 |

| 15 | 35 | 1 : 5 | 0.3 | 6 | 200 | 1.0 | 18 | 22.003 ± 0.545 | 54.60 ± 0.644 | 0.488 ± 0.016 |

| 16 | 40 | 1 : 1 | 0.9 | 6 | 200 | 0.9 | 21 | 27.272 ± 0.666 | 60.39 ± 1.111 | 0.511 ± 0.007 |

| 17 | 40 | 1 : 3 | 0.3 | 8 | 150 | 1.0 | 24 | 20.916 ± 0.641 | 51.96 ± 1.261 | 0.473 ± 0.004 |

| 18 | 40 | 1 : 5 | 0.6 | 4 | 180 | 1.1 | 18 | 20.599 ± 0.540 | 51.72 ± 2.216 | 0.466 ± 0.002 |

- Each experiment was carried out in triplicate. Values of responses are reported by Mastersizer 2000E analyser in 3 significant figures. SD: standard deviation.

3.1. Effect of Spray-Drying Variables on Responses

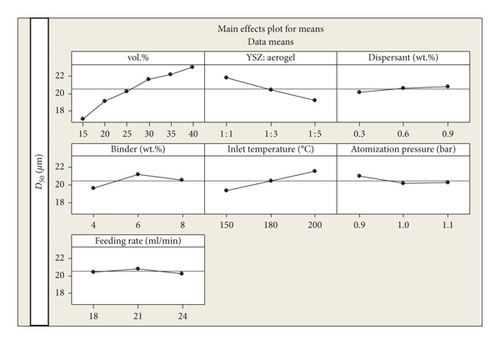

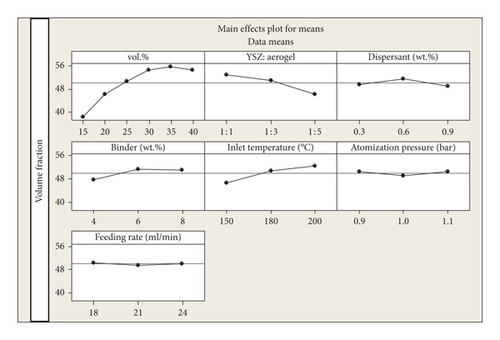

The regression coefficients derived from ANOVA were employed to analyse the effect of the independent spray-drying variables on the targeted responses. This coefficient is, by definition, the mean change in the response variable for one unit of change in the independent variable while holding other predictors in the model constant [27]. Figures 1–3 present the effect of each control factor viz., the solid content, the weight ratio YSZ : aerogel, dispersant, binder, inlet temperature, atomisation pressure, and feeding rate on the median particle size, volume fraction, and uniformity of the prepared spray-dried aerogel-YSZ powders.

From Figures 1–3, it can be seen that each control factor had an effect on the spray-dried granules at different degrees of significance and inclination on the responses. The effect of the control factors on the two primary responses, that is, median particle size and volume fraction, has been discussed simultaneously because of their strong correlation which has been proven statistically later. Atomization pressure and feeding rate contribute in the first step of spray-drying. Atomization is the process of breaking up bulk liquids into droplets, and hence, the pressure being applied to do the task refers to atomization pressure. It was observed that the particle size was affected in such a way that an increase in pressure led to a decrease in D50 (Figure 1). Figure 4 depicts the schematic diagram of a two-fluid nozzle with the external mix and the sequence involved during the formation of droplets. First, the slurry was forced into the two-fluid nozzle by the aid of the compressed air which caused the formation of an air cone covered by the liquid membrane, dictated by the cone angle or spray angle, θ. For a constant feeding rate, an increase in the atomization pressure would enlarge the spray angle causing the thickness of the liquid membrane to decrease. Consequently, the diameter of the droplet would decrease which in turn would reduce the diameter of the spray-dried particle, in other words, D50, as observed in Figure 1. Increasing the feeding rate of the slurry from 18 ml/min to 21 ml/min, on the contrary, would increase the thickness of the membrane leading to the formation of larger particle size, as pointed out in the corresponding diagram (Figure 1). However, when the feeding rate was augmented to 24 ml/min, D50 shrank. A higher feed rate would cause an increase in the drying load as the sample is sucked into the drying chamber and sprayed at a faster rate. In order words, the thickness of the liquid membrane did not have enough time to be formed, hence shrinking the droplet. Volume fraction seemed to be also affected by both atomization pressure and feeding rate. Increasing the pressure had a similar dual effect as in D50, whilst an increase in the feeding rate had an inverse effect compared to D50. This means that pumping more slurry in a faster speed from 18 ml/min to 21 ml/min produced spray-dried powder in the range of 20–60 μm (volume fraction) in a larger quantity than when increasing the rate from 21 ml/min to 24 ml/min because higher amount of the extract was not dried due to accumulation in the drying chamber resulting in the decreased yield. This phenomenon is different for different powders as Bai et al. observed that increasing the feeding rate increases both the volume fraction and D50 [19], while Maskat et al. observed the opposite [29].

The second step in the spray-drying process is related to the slurry formulation and inlet temperature. It could be observed (Figures 1 and 2) that increasing the solid content in the slurry had a strong influence on both D50 and volume fraction. This could be explained by the fact that a rise in the powder content results in an increase of suspension viscosity, as proposed by Cao et al. [26]. In addition, the particle size is intrinsically the summation of the hollow centre part and the wall thickness. It was reported in the quoted study that the lower the solid content in the slurry, the larger the ballooning but the thinner the wall thickness. Increasing the concentration of the solid content in the slurry caused a rise in the volume fraction of the spray-dried powder, as it could be expected. However, when the amount of YSZ and aerogel was too high (>40 vol.%), a lesser volume of spray-dried powder was recovered. In this case, the increase in the volume of the powder content which was done mainly by adding aerogel powder which is much lighter than common ceramics experienced clotting at the nozzle, thereby decreasing the amount of spray-dried powder collected. Furthermore, the decrease in D50 and volume fraction with an increase in the ratio of YSZ : aerogel could be possibly justified by the fact that the suspension was less viscous, thereby inhibiting the liquid feed to be turned into droplets in the drying chamber on time. The required amount of powder according to the ratio of YSZ : aerogel, considerable quantity of aerogel powder, had to be added due to its relatively ultralow density, causing the suspension to be much thicker. YSZ had an apparent density of 2.300 ± 0.200 g/cm3, while the aerogel was considerably less dense with a value of 0.129 ± 0.010 g/cm3. These phenomena may not be observed in the spray-drying process of common ceramics. Changing the amount of the dispersant from 0.3 wt.% to 0.9 wt.% increased the median particle size negligibly compared to the other three slurry formulation parameters, that is, solid content, YSZ : aerogel, and binder. Besides, it should be pointed out that ball-milling was carried out for a minimum of 24 hours which could have enhanced the dispersion of the particles making them a homogeneous suspension. Mahdjoub et al. [30] studied the effect of the slurry formulation upon the morphology of spray-dried YSZ particles by measuring the relative sediment height (RSH) which denotes the state of dispersion of the suspension and is an influential factor controlling the droplet drying. It was found that granules with hollow shapes are formed in the case of dispersed slurries (low ratio sediment height (RSH) < 53%), whilst full spherical granules were obtained with flocculated slurries (high RSH > 62%). Adding binder in the slurry had two effects: D50 was increased when polyvinyl alcohol (PVA) was added with a quantity of 0.4 wt.% to 0.6 wt.%, whilst a decrease was observed when the amount was brought to 0.8 wt.%. Binder is practically required in order to produce solid compact granules. It was shown in [31] that the RSH value can be drastically modified by the addition of a binder, subsequently affecting the state of dispersion of the suspension being stable or unstable and hence the overall granule morphology upon spray-drying. When particles are completely dispersed in a suspension with no interaction between each other, which is the case of a simple slurry (without binder or dispersant), they are very mobile. During spray-drying, the water migrates outside the granules and evaporates. When a binder is added, the water particles and the binder are attracted to form a dense shell leaving behind an internal void. This is because PVA is water-soluble, and hence, it is attracted with water. Because of the difference in pressure between the internal void and the ambient atmosphere, one part of the granule collapses generating hollow powder. In contrast, when the suspension is flocculated, the particles are almost immovable; the shell does not appear and granules are shaped. Hence, the dual effect due to an addition of PVA in the aerogel-based slurry can be appreciated.

Increasing the inlet temperature resulted in larger particle size and more spray-dried powder, as observed by Wang et al. [32]. When the aqueous aerogel-based suspension was forced into the drying chamber, the compressed air converted it into small droplets which shrunk as rapid evaporation of the water in the suspension took place due to the high temperature of the air. During that process of moistness moving from the inside to the outside of the drop, the solid content, binder, and dispersant were also carried along. Overall, for granulation, increasing the drying temperature causes a greater loss of water of the resultant spray-dried powder as the higher rate of heat transfers into particles; the faster is the water removal [33]. However, if the inlet temperature was set above 200°C in this study, it could be anticipated that the evaporation rate of moisture inside the droplet would become higher than the diffusion rate through the droplet surface which would cause a decrease in the resulting spray-dried powder [19].

Increasing the powder content caused a rise in the uniformity of the particles as in the case of D50 and volume fraction. However, it could be observed that it had a dual effect for uniformity with a change in the ratio of YSZ : aerogel. Adding more aerogel from a ratio of 1 : 1 to 1 : 3, the uniformity of the spray-dried particles decreased, but when additional aerogel was added up to a ratio of 1 : 5, the uniformity increased again. The amount of dispersant had a greater effect than that of the binder but in an opposite manner. The three settings of the spray-dryer contributed as well in the alteration of the uniformity. Particles tend to be more uniform at higher temperature. On the contrary, too much pressure (1.1 bar) can lead to a higher PDI. A similar change happened with a rise in the feeding rate. The significance of each of these variables towards uniformity is provided in Table 3.

| Responses | Spray-drying variables | ||||||

|---|---|---|---|---|---|---|---|

| Powder content (vol.%) | YSZ : aerogel | Dispersant (wt.%) | Binder (wt.%) | Inlet temperature (°C) | Atomization pressure (bar) | Feeding rate (ml/min) | |

| Median particle size | |||||||

| p value | 0.035 ∗ | 0.048 ∗ | 0.424 | 0.113 | 0.063 | 0.289 | >0.9 |

| F-ratio | 27.87 | 19.71 | 1.36 | 7.84 | 14.81 | 2.46 | — |

| Volume fraction | |||||||

| p value | 0.010 ∗ | 0.019 ∗ | 0.124 | 0.056 | 0.025 | 0.237 | >0.9 |

| F-ratio | 100.44 | 50.44 | 7.09 | 16.74 | 38.46 | 3.22 | — |

| Uniformity | |||||||

| p value | 0.065 | 0.219 | 0.248 | 0.770 | 0.208 | 0.269 | >0.9 |

| F-ratio | 14.59 | 3.57 | 3.04 | 0.30 | 3.82 | 2.71 | — |

- Values are generated by Minitab®. Significance indicators are derived from ANOVA. Higher F-ratio and lower p value refer to more significance, and vice versa. ∗Statistically significant results (p < 0.05).

Table 3 displays the statistical significance of each independent variable of the spray-drying process on the three spray-dried powder characteristics under study to further support the above justifications. The volume of the solid in the suspension had the most significant effect (p = 0.035) on the median particle size followed by the amount of YSZ : aerogel (p = 0.048). Conversely, the amount of dispersant and binder added, the inlet temperature, and the atomisation pressure of the spray-dryer did not significantly affect that response (p > 0.05). As for the volume fraction, again the powder content followed by the ratio of YSZ : aerogel contributed significantly (p = 0.010 and p = 0.019, respectively) compared to the inlet temperature (p = 0.025). The other independent variables were insignificant towards volume fraction. Uniformity was not influenced significantly by any of the spray-drying variables (p > 0.05).

3.2. Correlation amongst Responses

A correlation coefficient measures the extent to which two variables tend to change together. The coefficient describes both the strength and the direction of the relationship. In this study, the Pearson correlation was used. It is one which evaluates the linear relationship between two continuous variables. A relationship is linear when a change in one variable is associated with a proportional change in the other variable.

Table 4 shows the correlation (Pearson’s r coefficient) which existed between the three responses which were the physical characteristics of the spray-dried YSZ-aerogel powder and their significance degree (p value) of correlation. It can be seen that there was a strong positive significant correlation (Pearson’s r = 0.930; p value = 0.001) between the median particle size, D50, and volume fraction. Bai et al. [19] observed a similar correlation but did not provide any statistical evaluation.

| Variable | D50 | Volume fraction |

|---|---|---|

| Volume fraction | ||

| Pearson’s r | 0.930 | — |

| p value | 0.001 | |

| Uniformity | ||

| Pearson’s r | 0.754 | 0.599 |

| p value | 0.001 | 0.009 ∗ |

- Values are generated by Minitab®. D50: median particle size. Pearson’s r coefficient of 1 means perfect linear relationship results. ∗Statistically insignificant (p > 0.05).

The median particle size was also correlated with the uniformity of the spray-dried powder but with a lesser positive linear interaction (Pearson’s r = 0.754), and the relationship was still statistically significant (p = 0.001). A positive correlation between volume fraction and uniformity was drawn (Pearson’s r = 0.599) but was nevertheless insignificant (p = 0.009).

3.3. Precision of the Spray-Drying Process

The consistency of the spray-drying process carried out to reconstitute the aerogel particles was evaluated for each response. It was found that the three characteristics, median particle size, volume fraction, and uniformity, were all consistent (CV < 4%) as shown in Table 5, with an indication from the most consistent data to least consistent data in the order of uniformity > volume fraction > median particle size. It can therefore be argued that the overall process undertaken is repeatable.

| Treatment | Coefficient of variation (%) | ||

|---|---|---|---|

| D50 | Volume fraction | Uniformity | |

| 1 | 2.924 | 3.779 | 0.696 |

| 2 | 5.756 | 3.076 | 0.518 |

| 3 | 5.751 | 3.006 | 0.339 |

| 4 | 2.370 | 2.261 | 0.656 |

| 5 | 5.509 | 3.861 | 0.708 |

| 6 | 3.649 | 3.146 | 0.506 |

| 7 | 2.282 | 1.885 | 0.977 |

| 8 | 3.782 | 4.249 | 0.394 |

| 9 | 1.443 | 2.156 | 0.482 |

| 10 | 6.954 | 2.240 | 0.472 |

| 11 | 4.338 | 3.334 | 0.374 |

| 12 | 4.907 | 2.219 | 0.517 |

| 13 | 3.655 | 2.509 | 1.485 |

| 14 | 6.645 | 3.636 | 0.476 |

| 15 | 2.064 | 1.179 | 3.205 |

| 16 | 2.442 | 1.840 | 1.393 |

| 17 | 3.066 | 2.427 | 0.752 |

| 18 | 2.619 | 4.285 | 0.464 |

| Average CV (%) | 3.898 | 2.838 | 0.801 |

- D50: median particle size; CV: coefficient of variation. Higher CV refers to less consistency or lower precision, and vice versa. Low CV (<4%) indicates high precision of data.

3.4. Optimisation of YSZ-Aerogel Spray-Dried Powder

The Taguchi design provides an optimisation technique, wherein the conditions are limited to only the levels incorporated into the experimental design, and hence, it is considered to provide only an approximation of the optimisation points and not the exact ones in between these levels because the design is discrete and not continuous. From the regression analysis by ANOVA which was also presented earlier (Figures 1–3), three optimal treatments were possible as tabulated in Table 6.

| Treatment | Independent variables | Responses | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Powder content (vol.%) | YSZ : aerogel | Dispersant (wt.%) | Binder (wt.%) | Inlet temperature (°C) | Atomization pressure (bar) | Feeding rate (ml/min) | D50 (μm) | Volume fraction | Uniformity | |

| 19 ∗ | 40 | 1 : 1 | 0.9 | 6 | 200 | 0.9 | 21 | 28.932 ± 0.726 | 64.450 ± 0.535 | 0.475 ± 0.002 |

| 20 | 40 | 1 : 1 | 0.6 | 6 | 200 | 1.0 | 21 | 24.478 ± 0.526 | 59.520 ± 0.751 | 0.481 ± 0.001 |

| 21 | 40 | 1 : 1 | 0.3 | 6 | 200 | 1.0 | 21 | 26.719 ± 0.271 | 63.090 ± 0.660 | 0.468 ± 0.004 |

- ∗Optimised treatment for YSZ-aerogel for maximum D50, volume fraction, and uniformity. Values of responses are reported by Mastersizer 2000E analyser in 3 significant figures. D50: median particle size.

Considering that all three responses had to be maximised because (1) the median particle size should be at least within the range of 20–60 μm, (2) the volume fraction of particles within that range should be larger, and (3) the uniformity should be close enough to the sprayable YSZ powder with a value of 0.433 ± 0.001, the-larger-the-better option was opted. From Figure 1, a maximum median particle size could be predicted (treatment 19) by using a powder content of 40 vol.%, a 1 : 1 ratio of YSZ : aerogel, 0.9 wt.% of dispersant, 6 wt.% of binder, an inlet temperature of 200°C, an atomization pressure of 0.9 bar, and a feeding rate at 21 ml/min. Treatments 20 and 21 followed the settings from Figures 2 and 3 to obtain the maximum volume fraction and uniformity, respectively.

It was found that treatment 19 surpassed the remaining two (treatments 20 and 21) in terms of median particle size (28.932 ± 0.726 μm) and volume fraction (64.450 ± 0.535). The D50 was within the targeted range of 20–60 μm. On the contrary, the uniformity was lower (0.475 ± 0.002) than that obtained by treatment 20 (0.481 ± 0.001) but nevertheless higher than that obtained by treatment 21 (0.468 ± 0.004). A polydispersed powder of that extent (0.475 ± 0.002) could be regarded as acceptable for APS as the uniformity of the sprayable YSZ is actually 0.433 ± 0.001. Hence, the YSZ-aerogel spray-dried powder obtained under treatment 19 was considered to be the optimised powder to carry out APS. The morphological analysis carried out afterwards to appreciate the shape of the spray-dried granules collected indicated an improvement from the irregular shapes (Figure 5) to a more regular morphology having spherical donut-like forms as shown in Figure 6. Such granules can be considered as sprayable by APS [31]. It is worthy to attest that the hollow centre part was formed as the evaporation rate of moisture inside the droplet was higher than the diffusion rate through the droplet surface [19].

Having obtained an optimised aerogel-based powder to carry out APS, a drawback was however encountered; the amount of spray-dried YSZ-aerogel collected was relatively low. More precisely, only 10% of the amount of powder content added in the slurry was obtained as spray-dried. The rest was trapped in the spray chamber. This could be probably because of the ultralight weight of the aerogel when the amount of aerogel was more than that of YSZ; that is, for ratios 1 : 3 and 1 : 5, the volume fraction was lower. Hence, most of the aerogel powder was seemingly to be trapped. It was therefore thought that the spray-drying intermediate route was not economically feasible even though the reconstitution of the GEATM 0.125 aerogel powder succeeded.

4. Conclusion

The integration of nanostructured silica aerogel in aeropropulsion systems has continuously intrigued engineers due to its extremely low thermal conductivity, nonflammable, and low density characteristics inter alia. Aerogel-doped blankets have been developed, but no study has been brought forward yet to investigate the possibility of developing an aerogel-based thermally sprayed coating for aerospace applications. One of the reasons is because of the inappropriateness of silica aerogel powders in terms of their granulometric and morphological characteristics for thermal spraying. This study addresses this issue in attempting to reconstitute silica aerogel powders via spray-drying. A detailed statistical analysis was carried out prior to optimization to appreciate the effect of the spray-drying process (slurry preparation and granulation) and the effect of the spray-drying variables on the three characteristics under study, namely, median particle size, volume fraction, and uniformity. Correlations amongst the responses were also derived. It was found that the spray-drying technique had the most significant effect on uniformity (F-ratio = 62.40), followed by volume fraction (F-ratio = 55.94) and lastly median particle size (F-ratio = 18.54). Out of the seven spray-drying independent variables which comprised the powder content, ratio of YSZ : aerogel, and amount of dispersant and binder as the slurry formulation and inlet temperature, atomization pressure, and feeding rate as the settings for granulation (spray-dryer), it was found that the first two factors contributed significantly (p < 0.05) towards the median particle size and volume fraction. A strong correlation (Pearson’s r = 0.930) between D50 and volume fraction was obtained. Although the optimised spray-dried powder had an improved median particle size of 28.932 ±0.726 μm with a volume fraction of 64.450 ± 0.53 having uniformity of 0.475 ± 0.002 and an improved morphology than the starting aerogel, the yield of the granulated aerogel-based powder was only 10% which was thought to be uneconomically feasible to be used for subsequent air plasma spraying at this stage. If the yield is increased, the spray-dried YSZ-aerogel can be tried to be deposited using the thermal spray if a mechanically robust superinsulative coating is sought. This feasibility study has nevertheless provided an insight into the reconstitution of silica aerogel powders via the spray-drying process prior to thermal spraying. Based on this study, air plasma spraying using as-received aerogel powders will be tried even though it is practically challenging.

Conflicts of Interest

The authors have no conflicts of interest to declare.

Acknowledgments

Part of this work was partially supported by the Fundamental Research Grant Schemes (FRGS), Funding Nos. 5524611 and 5524896. The first author wishes to express his appreciation to the Ministry of Education of Malaysia for their financial support. SEM of the as-received GEATM 0.125 was carried out at Laboratory of Science of Ceramic Processing and Surface Treatments, University of Limoges, under the observation of Prof. Dr. Lech Pawlowski who also shared his valuable opinions.

Open Research

Data Availability

The data used to support the findings of this study are available from the first author upon request.