Influence of Fiber Type on Low-Temperature Fracture Performance of Presawed Asphalt Mixture Beams

Abstract

In order to improve the durability of asphalt pavement, low-temperature fracture performance of AC-13 asphalt mixture with different fiber types were studied by three-point bending fracture test under different temperatures and presawed positions. Test results show that the improvement effect of basalt fiber is obvious and stable. The improvement effect of polyester fiber is not obvious to resist I crack, and the resistance effect of I-II compound crack is obvious. Lignin fiber mixed in the asphalt mixture has no obvious effect on improving the crack resistance property under low temperature. Fiber cooperated with asphalt mixture can improve the ability of low-temperature fracture performance, while the improvement degree is effected by fiber type. Low-temperature fracture performance of asphalt mixture improves with the increase of temperature within a certain temperature range. The presawed position has significant effect on the low-temperature fracture performance of asphalt mixture. The larger the horizontal distance of the presawed position and center load is, the stronger the low-temperature fracture performance of asphalt mixture presents.

1. Introduction

Low-temperature cracking is one of the common diseases in asphalt pavement engineering. The asphalt pavement cracks affect the integrity and continuity of the pavement; moreover, it also makes water easier to invade the pavement structure, resulting in the decreased adhesion of asphalt and aggregate, which induced other diseases. Therefore, it is significant to study the low-temperature fracture performance of asphalt mixture for improving the durability of asphalt pavement. Many scholars have conducted a series of studies on the low-temperature performance of asphalt mixture [1, 2]. In 1964, Monismith et al. [3] first applied the experimental method to study the low-temperature fracture performance of asphalt mixture at different temperatures. Study results show that adding 20% crumb rubber with 3% Sasobit warm-mixed asphalt can improve the low-temperature anticracking ability of asphalt concrete. The research methods of low-temperature performance of asphalt mixture are the bending test, direct or indirect tensile test, freeze-thaw test, stress relaxation test [4, 5], and presawed beam bending test. Gao and Huang [6] studied the effect of fiber volume fraction and aspect ratio on the low-temperature fracture performance of AC-13F asphalt concrete by the freeze-thaw test and determined the appropriate performance index of the fiber. The effects of aging on warm mix asphalt were studied experimentally by Song et al. [7]; Zhang et al. [8] and Ran et al. [9] applied the bending test to study the low-temperature performance of epoxy asphalt mixture, and the low-temperature splitting strength was suggested as the evaluation index; Wagoner et al. [10] carried out the bending test on the unilateral saw beam of asphalt mixture. To evaluate the bond strength between Portland cement concrete (PCC) and asphalt concrete (AC) layers, Wang [11] studied the effect of the fiber property index on the low-temperature fracture performance of the saw beam, and Cheng et al. [12] studied the effect of presawed position on the fracture expansion behavior of AC-16 asphalt mixture. The brittle fracture of bituminous binder at low temperature is one of the important mechanisms of low-temperature cracking of asphalt mixture. Domestic and foreign scholars have conducted some researches on the low-temperature performance of presawed asphalt mixture trabecular. However, researches are limited to the single factor, such as fiber property and the position of the presawed. In this study, the temperature, presawed position, and fiber type are considered as the test parameters affecting the property of asphalt mixture, and the effects of those three parameters on the low-temperature performance of asphalt mixture are studied to provide an experimental basis for improving the durability of asphalt pavement.

2. Material Selection and Specimen Molding

2.1. Material Selection

The test aggregate gradation of AC-13 asphalt mixture is shown in Table 1. Asphalt used heavy oil on the 70th road asphalt, and the technical indexes are shown in Table 2. The aggregate was made of limestone, and the packing was made of high calcium lime powder.

| Sieve size (mm) | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 |

|---|---|---|---|---|---|---|---|---|---|

| Passing rate (%) | 100 | 92.1 | 76.9 | 50.9 | 35.3 | 22.9 | 16.2 | 13.3 | 10.3 |

| Indicator | Quality indicators | Measured values | |

|---|---|---|---|

| Penetration (25°C 100 g 5 s) | 60–80 | 65 | |

| PI | −1.5 to +1.0 | −1.1 | |

| Ductility (10°C 5 cm/min) (cm) ≥ | 20 | 42 | |

| Ductility (15°C 5 cm/min) (cm) ≥ | 100 | >150 | |

| Softening point (°C) ≥ | 46 | 47.5 | |

| Dynamic viscosity (60°C) ≥ | 180 | 218 | |

| Wax content (distillation method) (%) ≥ | 2.2 | 1.8 | |

| Flash point (°C) | 260 | 300 | |

| Solubility (%) | 99.5 | 99.88 | |

| Density (15°C) (g/cm3) | Measured | 1.035 | |

| TFOT residue | Quality (%) ≤ | ±0.8 | −0.044 |

| Penetration ratio (25°C) (%) ≥ | 61 | 62.2 | |

| Ductility (10°C) ≥ | 6 | 6.9 | |

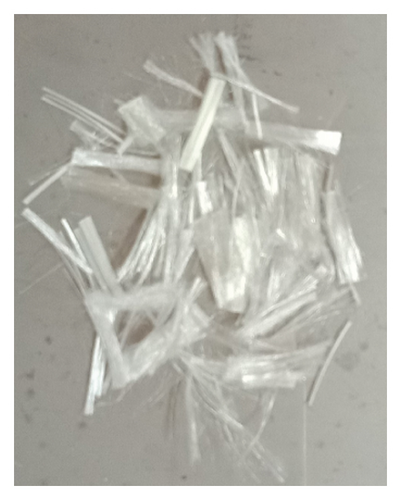

In order to study the influence of fiber type on the low-temperature performance of asphalt mixture, three fiber types, such as polyester fiber, basalt fiber, and lignin fiber, were mixed with the asphalt mixture, and the fiber content was 0.3% in mass. In contrast, nonfiber was used as a control group. The fiber index is shown in Table 3. The optimum asphalt dosage was determined by the Marshall test, which were 5.4%, 5.6%, and 6.0% for nonfiber, spiked basalt fiber, and spiked lignin fiber, respectively.

| Fiber type | Diameter (μm) | Length (mm) | Tensile strength (MPa) | Young’s modulus (GPa) | Tensile elongation (%) | Melting point (°C) | Density (g/cm3) |

|---|---|---|---|---|---|---|---|

| Polyester fiber | 20 ± 4 | 12 | >550 | >13.5 | 15–30 | 259 | 1.36–1.4 |

| Basalt fiber | 15 ± 2 | 12 | 3900 | >40 | 3.2 | 1050 | 2.60 |

| Lignin fiber | 45 | 3 | <300 | 3.5 | 15–20 | 170 | 0.91 |

2.2. Specimen Molding

The size of the test beam specimen is 250 mm × 50 mm × 50 mm, which is cut from a 300 mm × 300 mm × 50 mm plate specimen formed by a wheel rolling method. At the bottom of the test piece, a smooth U-shaped crack was cut by a hand-held chainsaw, and the crack depth of each specimen was 10 mm to simulate the initial crack in the asphalt pavement.

3. Test Design

The low-temperature bending test is one of the simple and effective methods to study the crack resistance of asphalt mixture. To study the effect of temperature on the low-temperature fracture performance of asphalt mixture, considering the working temperature of asphalt pavement in the winter of southern China, we chose the test temperature of −10°C, 0°C, and 10°C, respectively.

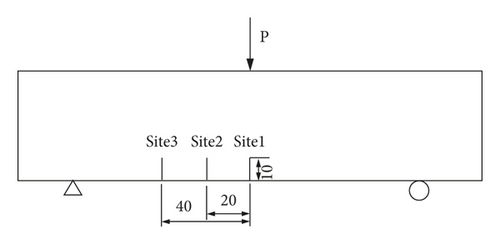

Preincision precast at the bottom of the asphalt mixture specimens to simulate the initial existence of asphalt pavement cracks. The design load P is loaded at the center of the beam. Preincision position is divided into three parts, located at the center of the beam, 20 mm away from the center and 40 mm away from the center, respectively, as shown in Figure 1.

According to the fiber type, specimens are divided into three groups; at the same time, specimens without fiber are set as the compared group; hence, this test has four groups and each group has four parallel specimens. Test methods and the treatment of test results can refer to “Road Engineering Bitumen and Asphalt Mixture Test Procedures” JTG E20-2011 requirements, using a universal material testing machine for three-point bending test specimens with the loading rate of 50 mm/min.

4. Analysis of Test Results

During the bending test, the maximum load and the midspan deflection of the specimen corresponding to destruction were measured; thus, we can obtain the bending tensile strength, the maximum bending strain, and the bending stiffness modulus, which were used to evaluate the low-temperature fracture performance of the asphalt mixture. The test results are shown in Table 4.

| Fiber type | Temperature (°C) | Presawed migration 0 mm | Presawed migration 20 mm | Presawed migration 40 mm | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Rb (MPa) | εb/ε | Sb (MPa) | Rb (MPa) | εb/ε | Sb (MPa) | Rb (MPa) | εb/ε | Sb (MPa) | ||

| Plain | −10 | 4.649 | 0.0168 | 277 | 5.047 | 0.0165 | 306 | 7.214 | 0.0175 | 412 |

| 0 | 5.117 | 0.0200 | 256 | 4.860 | 0.0192 | 253 | 7.135 | 0.0234 | 305 | |

| 10 | 5.052 | 0.0239 | 211 | 5.856 | 0.0260 | 225 | 7.068 | 0.0257 | 275 | |

| Polyester fiber | −10 | 5.016 | 0.0174 | 288 | 4.704 | 0.0139 | 338 | 6.871 | 0.0158 | 435 |

| 0 | 5.196 | 0.0210 | 247 | 5.436 | 0.0190 | 286 | 7.860 | 0.0226 | 348 | |

| 10 | 4.656 | 0.0204 | 228 | 5.105 | 0.0216 | 236 | 8.513 | 0.0275 | 310 | |

| Basalt fiber | −10 | 4.944 | 0.0174 | 284 | 4.560 | 0.0107 | 426 | 6.893 | 0.0148 | 466 |

| 0 | 4.865 | 0.0179 | 272 | 6.221 | 0.0221 | 281 | 7.469 | 0.0235 | 318 | |

| 10 | 5.465 | 0.0227 | 241 | 6.149 | 0.0226 | 272 | 7.721 | 0.0253 | 305 | |

| Lignin fiber | −10 | — | — | — | 5.484 | 0.0182 | 301 | 8.196 | 0.0194 | 422 |

| 0 | 5.165 | 0.0197 | 262 | 5.196 | 0.0203 | 256 | 7.637 | 0.0209 | 365 | |

| 10 | 5.016 | 0.0223 | 225 | 5.215 | 0.0212 | 246 | 7.598 | 0.0272 | 279 | |

4.1. Temperature Effects

As can be seen from Table 4, under the same fiber type and presawed position, with the increase of test temperature, the stiffness modulus of asphalt mixture tends to decrease; for example, for asphalt mixture mixed with polyester fiber with 20 mm presawed migration, the average value of the stiffness modulus is 236 MPa at 10°C, which is significantly lower than the value of 286 MPa at 0°C, which has a 17.5% decrease degree; moreover, it has a 30.2% decrease degree compared with that at −10°C under the same condition. Indicating that the lower the temperature, the greater the ability of the specimen to resist bending and pulling is, and the stronger the ability of the specimen to resist cracking is. At the same time, it can also be seen that the stiffness modulus of asphalt mixture at −10°C is obviously higher than that at 0°C and 10°C. For example, for asphalt mixture mixed with basalt fiber with 20 mm presawed migration, the stiffness modulus increased by 51.6% with the temperature decrease from 0°C to −10°C, which is much higher than that of 3.2% when the decrease is from 10°C to 0°C. The ability of the specimen to resist cracking improves greatly. It shows that the temperature has significant influence on the low-temperature fracture performance of asphalt mixture. In a certain temperature range, low temperature can improve the fracture performance of asphalt mixture.

Research shows that temperature has no obvious effect on the crack resistance of asphalt concrete specimens or pavement. The environment temperature drops sharply in cold regions, the asphalt mixture cracks when the stress caused by the temperature decreasing exceeds the ultimate tensile strength of the asphalt mixture. In the working environment of asphalt mixture, the temperature drops sharply, which will lead to the increase of the stiffness modulus of asphalt mixture. Although it improves the crack resistance performance of materials, when the stiffness modulus exceeds the limit stiffness of the material cracking, asphalt mixture will be ruptured due to temperature action instead.

4.2. Preincision Location Effects

From Table 4, it can be seen that under the same test temperature and fiber type, with the increase of horizontal distance of the presawed position relative to the load P, the stiffness modulus of asphalt mixture gradually increases, indicating that the ability of asphalt mixture to resist the bending effect is also gradually enhanced; in other words, the ability to resist low-temperature cracking gradually increases. The stiffness modulus of asphalt mixture significantly increases when the presawed offset increased from 20 mm to 40 mm. For asphalt mixture mixed with polyester fiber at −10°C, the stiffness modulus increases from 338 MPa to 435 MPa with the presawed migration increasing from 20 mm to 40 mm, which indicates that the low-temperature resistance cracking performance of asphalt mixture is improved significantly. Thus, the ability of asphalt mixture to resist low-temperature cracking increases with the increase of the horizontal offset distance of the presawed position and load P, and the larger the offset distance of incision, the more it can be improved.

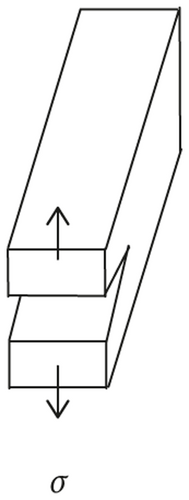

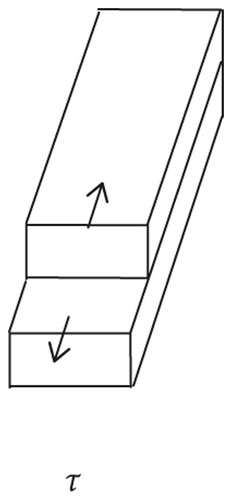

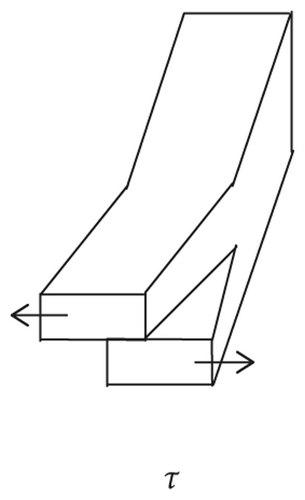

Cracks can be divided into type I (open type), type II (slipping open type), and type III (tearing open type) according to the shape of the fracture expansion. Type I fractures are generated by a symmetrical tensile stress σ, which is vertical to the plane where the cracks lie and the fracture is open type, as shown in Figure 2(a). Type II fractures are generated by a pair of shear stresses τ parallel to the fracture direction, and the development of the crack presents a forward and backward sliding type, which is shown in Figure 2(b). Type III cracks are not common in the asphalt pavement, which is shown in Figure 2(c).

In the three-point bending test, the presawed position leads to the different crack expansion paths of asphalt mixture. When the presawed position locates at the center of the specimen, the offset is 0 mm, and type I cracks appear in the asphalt mixture, which cracks due to tensile stress σ and extends perpendicularly upward along the presawed direction, as shown in Figure 3(a). When the presawed position is from the center load offset 20 mm and 40 mm, complex type I-II cracks appear in the asphalt mixture, whose destructive form is different from type I. The crack tip is mainly subjected to the combined action of vertical stress σ with lateral horizontal stress τ. All cracks do not expand along the presawed direction; however, it expands toward the centering direction of the test specimen [13, 14], as shown in Figures 3(b) and 3(c).

4.3. Fiber-Type Effects

It can be seen from Table 4 that the incorporation of polyester fiber, basalt fiber, and lignin fiber into the test specimen can increase the stiffness modulus of asphalt mixture; hence, the incorporation of fiber into the asphalt mixture can improve its low-temperature resistance cracking performance, and the improvement effect is influenced by the fiber type [15–17]. For the presawed is in the bottom of the middle mixed with polyester fiber, the stiffness modulus of the asphalt mixture has not been improved but declined. Therefore, polyester fiber can improve low-temperature resistance cracking performance of asphalt mixture to a certain degree, and it has a good improvement on the expansion of I-II complex fractures. However, the improvement on the expansion of type-I fractures is not obvious.

It can be clearly seen from Table 4 that asphalt mixture mixed with basalt fiber has good ability to resist low-temperature cracking. For all the presawed location conditions, the stiffness modulus of asphalt mixture mixed with basalt fiber is higher compared with that of the unadulterated fiber, indicating that the basalt fiber has a significant improvement on the stiffness modulus of asphalt mixture at different presawed positions. The incorporation of basalt fiber can significantly improve the ability of asphalt mixture to resist type I and I-II complex fractures.

Taking a comprehensive analysis of Table 4, we can obtain that the change of the stiffness modulus of asphalt mixture mixed with lignin fiber is not stable; hence, its low-temperature crack resistance performance is not very stable. Therefore, it is not recommended to add lignin fibers in asphalt mixture considering the low-temperature performance. The mechanism behind this phenomenon can be clarified as follows; in this test, both the strength and elasticity modulus of polyester fiber are larger than that of asphalt mixture; hence, reinforcing effect can be observed when fibers are mixed in the asphalt mixture. In addition, the surface of polyester fiber absorbs a large number of asphalt, which can be called “interface layer” [18, 19], and the viscosity of asphalt located near the “interface layer” is much larger than that located far away from “interface layer”; as a result, the reinforcing effect and bridge connection effect caused by polyester fiber are more obvious, leading to the increase of strength of polyester fiber asphalt. Asphalt mixture is heterogeneous composite material, which contains joints, cracks, and natural flaws. And the expansion of internal crack and the generation of new fracture surface happen under the coupled temperature stress and external loading. However, appropriate number of fiber will distribute as three-dimensional network structure within the asphalt mixture. Hence, the expansion of cracks and joints will be restricted with the addition of polyester fiber, resulting in the increase of crack resistance property under low temperature.

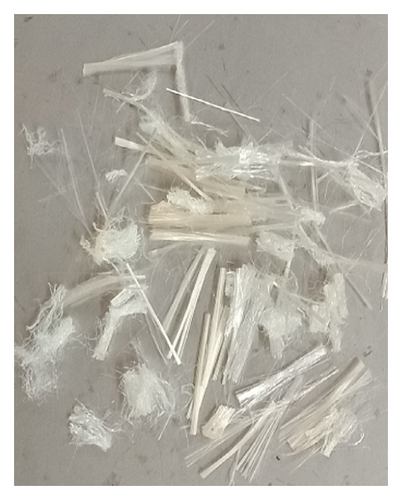

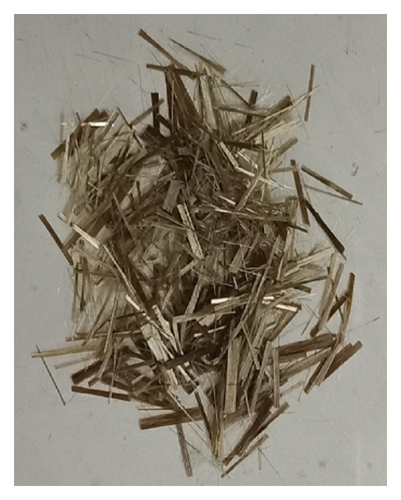

Fiber type has significant influence on the reinforced effect. For polyester fiber, in the process of mixing polyester fiber under high-temperature condition, a part of fiber is bended and the end of them is hardened, as shown in Figure 4, resulting in the decrease of crack resistance effect. For lignin fiber, spalling phenomena happen for the asphalt absorbed on the surface of lignin fiber attributed to the strong water-absorbing capacity of lignin fiber, which will reduce the thickness of asphalt film. For basalt fiber, it has better thermal stability in the mixing process under high-temperature condition, as shown in Figure 5. Furthermore, the asphalt absorbed on both ends of basalt fiber presents convex shape, and this contributes to the bond between basalt fiber and asphalt. Therefore, incorporating basalt fiber could improve the crack resistance property under low temperature compared with polyester fiber and lignin fiber.

4.4. The Calculation of Fracture Toughness KIC

| Temperature (°C) | Presawed migration (mm) | KIC (MPa·mm0.5) | |||

|---|---|---|---|---|---|

| Plain | Polyester fiber | Basalt fiber | Lignin fiber | ||

| −10 | 0 | 9054.489 | 9769.687 | 9629.451 | 9839.804 |

| 20 | 9830.455 | 9162.002 | 8881.533 | 10681.212 | |

| 40 | 14051.52 | 13383.07 | 13425.14 | 15963.390 | |

| 0 | 0 | 9966.015 | 10120.27 | 9475.193 | 9068.513 |

| 20 | 9465.84427 | 10587.722 | 12116.281 | 10120.273 | |

| 40 | 13897.26 | 15308.960 | 14547.020 | 14874.230 | |

| 10 | 0 | 9839.804 | 9068.513 | 10643.820 | 9769.686 |

| 20 | 11405.758 | 9942.642 | 11976.046 | 10157.669 | |

| 40 | 13766.38 | 16580.420 | 15037.84 | 14799.440 | |

From Table 5, it is noticed that under the same fiber type and temperature, the fracture toughness increases with the increase of horizontal distance. For example, when the temperature is −10°C, without adding fiber, the distances of presawed position are 0 mm, 20 mm, and 40 mm, and the fracture toughness values of KIC are 9054.489 MPa·mm0.5, 9830.455 MPa·mm0.5, and 14051.52 MPa·mm0.5, respectively. The increase of the load is the most direct manifestation of the specimen to resist the crack expanding. Test results agree with the conclusion of the effect of the fracture position on the cracking performance of the specimen [12].

Table 5 reveals that under the same fiber type and the presawed position, with the increase of temperature, the fracture toughness value of KIC decreases. From the formula (3), it is easily obtain that the maximum load of the specimen and the stress that the stress tip can bear before cracking decreases. For specimens without fiber with 40 mm presawed, when the temperature increases from −10°C to 0°C, 10°C, the fracture toughness values of KIC are 14051.52 MPa·mm0.5, 13897.26 MPa·mm0.5, and 13766.38 MPa·mm0.5, respectively.

Under the same temperature and the presawed position, the fracture toughness value of KIC increases for three kinds of fiber. For example, when the temperature is −10 °C, and the distance of presawed position is 0 mm, the fracture toughness values of KIC of asphalt mixture mixed with polyester fiber, basalt fiber, lignin fiber, or unblended fiber were 9769.687 MPa·mm0.5, 9629.451 MPa·mm0.5, 9839.804 MPa·mm0.5, and 9054.489 MPa·mm0.5, respectively, which decreased by 7.9%, 6.4%, and 8.7% compared with that of asphalt mixture without fiber, respectively. It is obvious that after adding the fiber, the bearing capacity of asphalt mixture has been improved, which is consistent with the result of the effect of fiber type on the cracking performance of the specimen.

5. Conclusions

- (1)

Within a certain temperature range, the lower the temperature, the more obvious the stiffness modulus of asphalt mixture presents, and the stronger the resist ability of asphalt mixture to low-temperature cracking is. When the stiffness modulus reaches the limit stiffness of asphalt mixture cracking, the pavement cracking occurs.

- (2)

The presawed position has significant influence on the low-temperature cracking performance of asphalt mixture. The larger the horizontal distance of the presawed position from the center load, the more the stiffness modulus of the asphalt mixture increases, and the more the ability of asphalt pavement to resist low-temperature cracking is.

- (3)

The addition of fiber can improve the resist ability of asphalt mixture to low-temperature cracking; however, the degree of improvement is affected by the fiber type. The improvement effect of basalt fiber is obvious and stable. Polyester fiber is not obvious enough to improve the ability of asphalt mixture to resist the development of type-I crack expanding but is obvious to resist the development of type I-II complex crack. The improvement effect of Lignin fiber is unstable. Asphalt mixture with basalt fiber addition can significantly improve the crack resistance property under low temperature.

Conflicts of Interest

The authors declare that there are no conflicts of interest regarding the publication of this paper.

Acknowledgments

This research was funded by the National Natural Science Foundation of China (nos. 51174004 and 51374012). This research was also funded by the Open project Program Foundation of Engineering Research Center of Underground Construction, Ministry of Education (Anhui University of Science and Technology) (KJ2017A096).

Open Research

Data Availability

The datasets generated and analyzed during the current study are available from the corresponding author upon reasonable request.