Dynamic Reliability Design of Multicomponent Structure with Improved Weighted Regression Distributed Collaborative Surrogate Model Method

Abstract

For dynamic reliability design of complex structures with multiple components, an improved weighted regression distributed collaborative surrogate model method (IWRDCSMM) is developed from the extremum response surface method (ERSM), decomposed-coordinated thought, and improved weighted regression principle. The ERSM is used to address the dynamic reliability and sensitivity analyses of multicomponent structures and enhance the computing efficiency. The decomposed-coordinated thought is applied to handle the relationship among multiple components. The improved weighted regression method is used to find the efficient samples with smaller errors to improve the modeling accuracy. The proposed method is first introduced for dynamic probabilistic analysis (including reliability analysis and sensitivity analysis) of multicomponent structures. The method is then mathematically modeled by adopting the efficient samples selected based on the improved weighted regression method. Finally, the radial deformation dynamic probabilistic analysis of an aeroengine turbine blisk assembled by blade and disk is accomplished, in respect of the IWRDCSMM, fluid-thermal-structure interaction, and the randomness of input parameters within the time domain [0, T]. The results illustrate that the reliability degree of turbine blisk radial deformation is 0.9951 when the allowable value uallow is 2.30 × 10−3 m, and all the input parameters affecting the turbine blisk radial deformation are gas temperature, angular speed, inlet velocity, outlet pressure, material density, and inlet pressure, successively. As revealed by the comparison of different methods, the IWRDCSMM has high fitting speed and simulation efficiency with the guarantee of accuracy. The efforts of this study provide a promising dynamic probabilistic analysis technique for complex structures with multiple components and enrich mechanical reliability theory.

1. Introduction

Mechanical system generally comprises multiple complex structures, and the complex structure is assembled by multiple components. For instance, turbine blisk in an aeroengine contains blade and disk [1]. Each structure plays a key role and is subjected to rigorous workloads during operation. The failure of complex structures easily results in the disorder of the whole mechanical system and even causes a catastrophic accident in the working process [2]. Therefore, it is required to investigate the probabilistic analysis of the complex structure to improve the performance and safety of the mechanical system with the consideration of the effects of dynamic loads. Probabilistic analysis generally includes reliability analysis and sensitivity analysis [3].

Lots of works have emerged on the probabilistic analysis. Chowdhury et al. [4] applied Monte Carlo (MC) simulation and finite element (FE) method to evaluate the reliability of the cracked structure. Naess et al. [5] employed MC simulation to estimate the reliability of the complicated structure considering the randomness of inputs. Tomasson and Soder [6] discussed the reliability evaluation of composite power systems using an improved way of applying MC simulation with the cross-entropy method. Jahani et al. [7] utilized interval MC simulation to perform the reliability analysis of the complex structure. Gao et al. [8] presented a mixed perturbation MC method for structural reliability analysis. Zhang et al. [9] studied multiobject reliability analysis of turbine blisk with multidiscipline under multiphysical field interaction by the MC method. Shayanfar et al. [10] sought a correction for the first-order reliability method by employing MC simulation to calculate the failure probability of a structure. Zhao and Ang [11] evaluated the reliability of the mechanical structure by the first-order third-moment method and random parameters. Alibrandi and Koh [12] used the first-order reliability method and secant hyperplane method to estimate the reliability of floating production systems. Lu et al. [13] used the second-order fourth-moment method to derive the structural reliability based on the first-order fourth-moment method [14]. Lin et al. [15] proposed the score function method with kernel density estimation for structural stochastic sensitivity analysis. All the above efforts complete the probabilistic analyses of the complex structure by only adopting direct simulation methods such as the MC method and first-order reliability method. Although it is precise for these methods, the computational burden is rather unbearable for most of the computing platforms.

To address the computational efficiency with the acceptable accuracy, the surrogate model method (also known as the response surface method (RSM)) was developed for probabilistic analysis. Cheng and Li [16] employed RSM to solve the inverse structural reliability problems with implicit functions. Allaix and Carbone [17] used an improved RSM to evaluate structural reliability. Fang and Tee [18] proposed a novel method for structural reliability analysis based on RSM and improved genetic algorithm. Li et al. [19] applied the RSM to fulfill the seismic reliability evaluation of steel-timber hybrid shear wall systems. Cheng and Liu [20] performed the reliability analysis of steel cable-stayed bridges based on the RSM. Zhang and Bai [21] presented extremum RSM (ERSM) to derive the dynamic reliability analysis of a two-link flexible robot manipulator. Lu et al. [22] developed multiple ERSM to finish the dynamic probabilistic analysis of an aeroengine turbine blisk assembled by disk and blade. Fei et al. [23–25] derived the ERSM-based least-squares support vector machine and demonstrated it to be efficient in the nonlinear dynamic probabilistic analysis of turbine components. Kaymaz and Gaspar et al. applied the Kriging model method to study the structural reliability analysis [26, 27]. Chojaczyk et al. [28] applied artificial neural network model to study the structural reliability analysis of steel structures. Lehky and Novak [29] used artificial neural network model to solve the inverse structural reliability problem. Cheng [30] integrated the advantages of the artificial neural network method, first-order reliability method, and importance sampling updating method for the serviceability reliability analysis of prestressed concrete bridges. The above efforts can accomplish the reliability and sensitivity analyses with acceptable efficiency, but the problem of unacceptable computational precision still exists since the limitation of quadratic polynomials is regarded as a surrogate model. Besides, these methods are only applicable to the probabilistic analysis of one component and one failure mode. Therefore, there is an urgent need for the dynamic probabilistic analysis of the multicomponent structure to develop an efficient method.

This paper is oriented to develop an efficient and accurate analytical method for the dynamic reliability design of the multicomponent structure by integrating the ERSM [23], decomposed-coordinated thought [31, 32], and the developed improved weighted regression method. This method is called improved weighted regression distributed collaborative surrogate model method (hereafter, IWRDCSMM). The ERSM is used to address the transient problem in the dynamic probabilistic analysis of the multicomponent structure to enhance the computing efficiency and accuracy. The decomposed-coordinated thought is applied to process the relationship among multiple components. The improved weighted regression method is used to find the samples with smaller errors or larger weight to improve the modeling accuracy. The model is adopted for the dynamic probabilistic analysis of the multicomponent structure within the time domain [0, T]. The dynamic probabilistic analysis of the radial deformation of the blisk is completed regarding fluid-thermal-structural interaction, to demonstrate the feasibility and reasonability of the proposed method.

The remaining of this paper is organized as follows. In Section 2, we elaborate the proposed IWRDCSMM. Section 3 applies this developed technique to the dynamic probabilistic analysis for the blisk radial running deformation, by considering the randomness of input variables of inlet velocity, inlet pressure, outlet pressure, gas temperature, material density, and angular speed. Section 4 verifies the feasibility and effectiveness of the method from the accuracy and efficiency of modeling and simulation by the comparison of the IWRDCSMM with other methods. Some conclusions on this study are given in Section 5.

2. Basic Theory

This section mainly introduces the basic theory of the IWRDCSMM. We first describe the procedure of the dynamic probabilistic analysis for multicomponent structure with the method. The details of ERSM and IWRDCSMM are then given in next two subsections. We finally discuss the thoughts of structural dynamic reliability and sensitivity analyses.

2.1. Procedure of Multicomponent Structural Dynamic Probabilistic Analysis

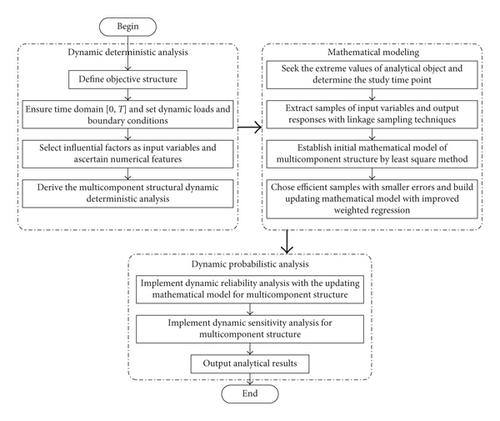

For the dynamic probabilistic analysis of multicomponent structure, IWRDCSMM is developed form ERSM, decomposed-coordinated thought, and improved weighted regression principle. The flow chart of multicomponent structural dynamic probabilistic analysis with IWRDCSMM is shown in Figure 1.

- (1)

Define objective structure with multicomponent, ensure analytical time domain [0, T], and set dynamic loads and boundary conditions.

- (2)

Select influential factors as random input variables, ascertain their numerical features, and then derive the dynamic deterministic analysis of multicomponent structure.

- (3)

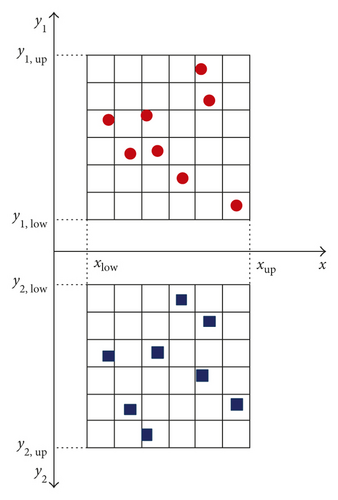

Find the extreme values of analytical object and determine the time point and obtain samples of input parameters and output responses with linkage sampling technique [9]. The linkage sampling method fuses the extremum selection method [33] and Latin hypercube sampling method [34, 35], which is defined as using a group input sample to obtain the output responses of multiple objectives at the same time. The linkage sampling method with one input parameter x and two output responses y1 and y2 is shown in Figure 2.

- (4)

Establish the initial mathematical model of multicomponent structure by the least square method [22, 36, 37] based on the acquired samples and choose efficient samples with smaller errors or large weights which are selected from the acquired samples and the build updating model in line with improved weighted regression principle.

- (5)

Implement the probabilistic analysis with the updating model for multicomponent structure.

2.2. Extremum Response Surface Method

2.3. Improved Weighted Regression Distributed Collaborative Surrogate Model Method

Despite the DCSMM reasonably handles the dynamic probabilistic analysis of the complex structure [37], the least square method is difficult to handle high-nonlinear function and large-scale samples in mathematical modeling. The conventional weighted regression principle is used to establish the mathematical model with few samples relative to the least square method. The weighted values are obtained by the ratio of the minimum output response to the output responses [38, 39]. The selected minimum output response may not be the optimal value, so that the fitting accuracy of mathematical model is unprecise. In this case, the improved weighted regression (IWR) method is developed to compute the weighted values by the ratio of the minimum error to the errors, and the efficient samples with smaller errors or larger weights are selected as the training samples of the fitting model. The errors are the absolute difference between the real value and the computing value. The minimum error is the minimum value of all obtained errors. The efficient samples are the samples with smaller errors or larger weighted values, selected from all samples. The IWR model is established using the selected efficient samples, the fitting performance of which is superiority to the least square method. The detailed validation procedure is stated in Section 4.

Based on the above theories, the unknown coefficients in (8) are acquired, and the mathematical model of IWRDCSMM is established.

2.4. Dynamic Probabilistic Analysis

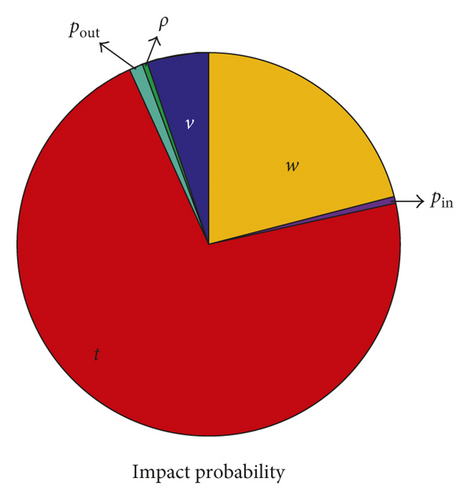

Sensitivity analysis of multicomponent structure can reflect the effect of the variation of input variables on failure probability or reliability probability, which help us determine the important degrees of input parameters on the output response of analytical object and then provide guidance for the design parameters of complex structures [1, 23, 40]. Sensitivity analysis typically contains sensitivity degree (Sd) analysis and impact probability (Id) analysis [25]. Sensitivity degree reflects the influence level of an input variable on the output response, and impact probability indicates how much an input variable affects the output response relative to the other input parameters.

In the light of the above analyses, the reliability degree and sensitivity indexes (sensitivity degree and impact probability) of random input variables on failure probability are acquired to evaluate the design quality of the complex structure.

3. Case Study: Dynamic Probabilistic Analysis of Turbine Blisk

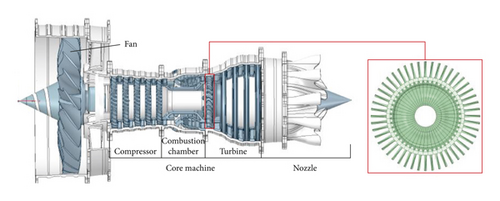

In this section, the high-pressure turbine blisk of an aeroengine, which comprises blade and disk, is selected to demonstrate the proposed method in this paper. The dynamic probabilistic analysis of turbine blisk radial running deformation is accomplished to verify the feasibility and applicability in engineering practice, by considering the fluid-thermal-structural interaction.

3.1. Finite Element Model and Input Variables

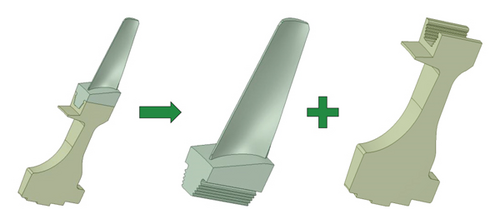

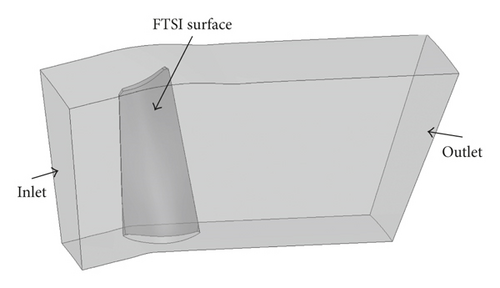

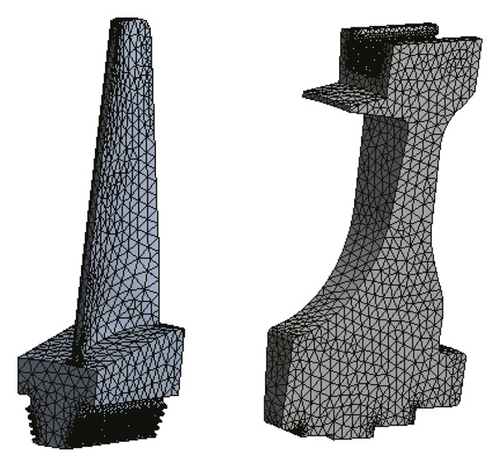

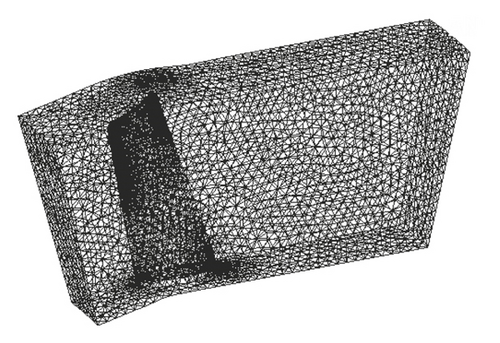

As an important structure of an aeroengine, high-pressure turbine blisk suffers high gas temperature and pressure from main combustion chamber and high centrifugal force due to angular speed. The schematic diagram of a blisk is shown in Figure 3. From Figure 3, it is obvious that the turbine blisk is a typical cyclic and symmetric structure. To save modeling burden and improve simulation time, 1/48 of the blisk model is selected as the object of study. The simplified three-dimensional models of the blisk and flow field are drawn in Figures 4 and 5, respectively. In Figure 5, the FTSI surface indicates the fluid-thermal-structural interaction surface which is to transfer fluid loads and thermal loads to the structure.

In view of Figures 4 and 5, the FE/FV models of turbine blisk and flow field are established in Figures 6 and 7, respectively. As illustrated in Figures 6 and 7, the FE models of turbine blade and disk are consisted of tetrahedrons with 48,551 elements, 75,097 nodes and 33,885 elements, 57,213 nodes, and the FV model of flow field has the tetrahedrons with 338,917 elements and 472,930 nodes.

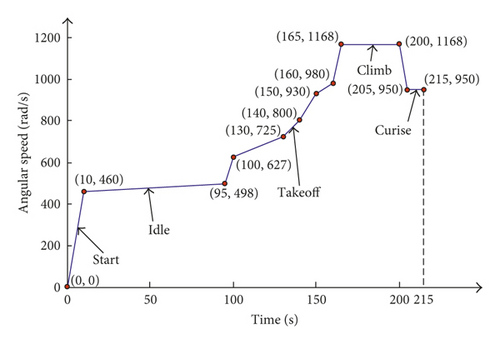

To study the influence of fluid-thermal-structural interaction on the radial deformation of turbine blisk, nickel-based superalloy GH4133 [42] is selected as the material of turbine blisk. The variation of angular speed within a time domain [0 s, 215 s] is shown in Figure 8. Here, 12 points are sampled as the calculation points [43]. The inlet velocity, inlet pressure, outlet pressure, and gas temperature are regarded as input variables to perform the deterministic analysis, and their means are assumed to be 160 m/s, 2 × 106 Pa, 5.88 × 105 Pa, and 1,200 K, respectively.

Substantially, the input variables process uncertainties and affect the blisk radial deformation, so that the randomness of input parameters needs to be considered. Therefore, the above parameters are regarded as random variables. Assuming that all random input variables obey normal distribution and are independent mutually; the distribution characteristics of the random variables are listed in Table 1.

| Variables | Distribution | Mean μ | Standard deviation σ |

|---|---|---|---|

| Inlet velocity, v (m/s) | Normal | 160 | 3.2 |

| Inlet pressure, pin (Pa) | Normal | 2 × 106 | 4 × 104 |

| Outlet pressure, pout (Pa) | Normal | 5.88 × 105 | 1.176 × 104 |

| Gas temperature, t (K) | Normal | 1,200 | 24 |

| Material density, ρ (kg/m3) | Normal | 8,560 | 171.2 |

| Angular speed, w (rad/s) | Normal | 1,168 | 23.36 |

3.2. Dynamic Deterministic Analysis

Based on the determined values of input variables, the dynamic deterministic analysis of blisk radial deformation is carried out by the close-coupling analysis technique [22] with fluid-thermal-structural interaction. The procedure of dynamic deterministic analysis of blisk radial deformation contains fluid analysis, thermal analysis, structural analysis, and iterative solution.

The fluid analysis is based on the standard k-ε turbulence model with respect to the boundary conditions of the flow field and finite volume method. With regard to the thermal analysis, the law of energy conservation is utilized to resolve the property of turbine blisk flow flied, and then the pressure and gas temperature are transferred to turbine blisk through the FTSI surface. The structural analysis is performed by means of the FE method, in which the tetrahedron shape equation and geometric equation are applied to perform blisk radial deformation analysis. The dynamic deterministic analysis of radial deformation is finished by using the iterative solution.

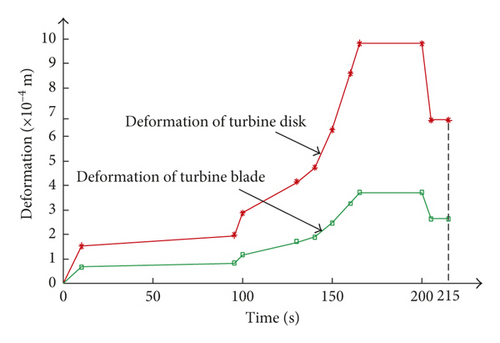

According to the theory of the close-coupling analysis method, the dynamic deterministic analysis is accomplished, and the changing curves of the radial deformations of blade and disk with time are shown in Figure 9.

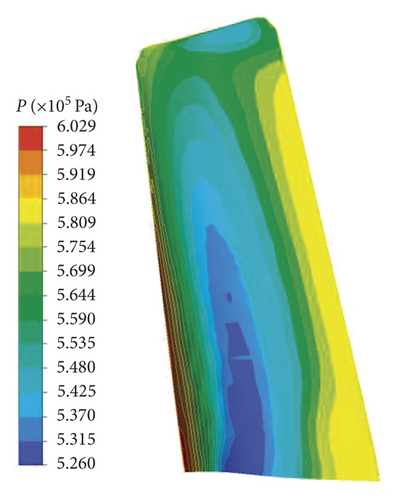

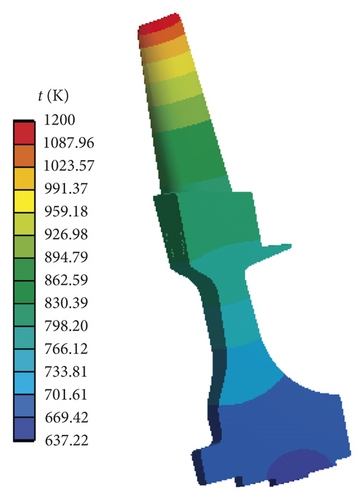

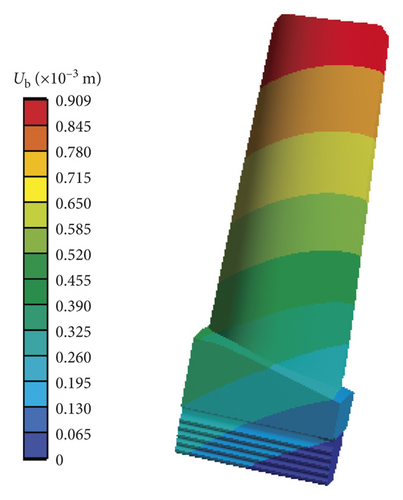

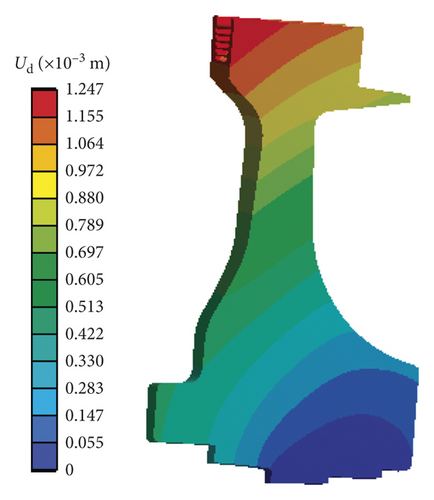

As shown in Figure 9, it is obvious that the radial deformation of turbine blisk increases with the increase of angular speed and the maximum emerges in the time domain [165 s, 200 s]. T = 175 s is chosen as the computing point. At this moment, the distributions of pressure on FTSI surface, temperature on turbine blisk, and the nephograms of blade and disk radial deformations are displayed in Figures 10–12, in which P indicates pressure, t expresses temperature, and ub and ud represent the radial deformations of blade and disk, respectively.

As illustrated in Figure 12, the maximum of radial deformation of turbine blisk occurs at the tip of blade and disk. Hence, the risk section responses of turbine blade and disk tip are selected as the output responses of the blisk and are also the maximum output responses of the blisk. The blisk is safe as the risk section is secure. Therefore, the output responses of turbine blade and disk tip are treated as the computational points in the blisk dynamic probabilistic analyses.

3.3. Derivation of Mathematical Model

To derive the IWRDCSMM model for the blisk radial deformation, the linkage sampling method is applied to extract 60 samples for random input variables following the numerical characteristics in Table 1. And then 60 samples for the corresponding output response are obtained by dynamic deterministic analyses. From this pool of 60 samples, 40 samples (as shown in Table 2) are selected to establish the initial mathematical model of blade and disk radial running deformations. The two models are displayed in (19). The remaining 20 samples are treated as the testing samples for the purpose of accuracy assessment.

| v (m/s) | pin (×106 Pa) | pout (×105 Pa) | t (K) | ρ (kg/m3) | w (rad/s) | ub (×10−3 m) | ud (×10−3 m) | Errb (×10−6 m) | Errd (×10−6 m) | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 153.94 | 2.075 | 5.762 | 1225.56 | 8698.60 | 1198.13 | 0.961 | 1.292 | 1.041 | 3.829 | 0.161 | 0.062 |

| 159.27 | 1.967 | 5.661 | 1163.76 | 8455.30 | 1122.44 | 0.904 | 1.207 | 1.158 | 4.312 | 0.144 | 0.055 |

| 147.73 | 1.902 | 5.844 | 1178.88 | 8598.03 | 1104.22 | 0.908 | 1.247 | 2.808 | 9.975 | 0.060 | 0.024 |

| 156.39 | 2.114 | 5.738 | 1238.16 | 8662.91 | 1130.85 | 0.967 | 1.273 | 1.673 | 6.615 | 0.010 | 0.036 |

| 148.39 | 1.912 | 5.973 | 1230.6 | 8526.67 | 1149.07 | 0.966 | 1.255 | 6.694 | 24.59 | 0.025 | 0.009 |

| 168.15 | 2.001 | 6.064 | 1188.9 | 8549.37 | 1168.70 | 0.921 | 1.275 | 4.823 | 17.96 | 0.035 | 0.013 |

| 155.50 | 2.111 | 6.002 | 1257.12 | 8604.52 | 1220.56 | 0.984 | 1.339 | 2.439 | 8.694 | 0.069 | 0.027 |

| 167.93 | 1.881 | 5.733 | 1230.12 | 8636.96 | 1217.75 | 0.968 | 1.296 | 2.534 | 9.045 | 0.066 | 0.026 |

| 150.39 | 1.938 | 5.834 | 1179.96 | 8611.01 | 1214.95 | 0.918 | 1.289 | 3.089 | 12.01 | 0.054 | 0.020 |

| 149.28 | 1.929 | 6.012 | 1191.24 | 8711.57 | 1158.88 | 0.931 | 1.248 | 1.865 | 6.947 | 0.089 | 0.034 |

| 152.39 | 1.895 | 5.781 | 1184.52 | 8633.72 | 1219.15 | 0.926 | 1.281 | 0.715 | 2.842 | 0.234 | 0.084 |

| 149.07 | 1.974 | 6.040 | 1253.94 | 8497.47 | 1118.24 | 0.975 | 1.285 | 0.934 | 3.518 | 0.178 | 0.068 |

| 153.28 | 1.941 | 6.021 | 1189.98 | 8478.01 | 1101.42 | 0.922 | 1.229 | 0.703 | 2.381 | 0.238 | 0.100 |

| 160.61 | 1.972 | 5.916 | 1222.62 | 8627.23 | 1123.84 | 0.951 | 1.267 | 0.388 | 0.239 | 0.431 | 1 |

| 151.51 | 2.118 | 5.676 | 1238.88 | 8406.64 | 1112.63 | 0.965 | 1.258 | 0.588 | 1.609 | 0.284 | 0.148 |

| 164.16 | 2.070 | 5.752 | 1222.14 | 8653.18 | 1143.47 | 0.950 | 1.279 | 1.673 | 6.128 | 0.099 | 0.039 |

| 163.49 | 1.922 | 5.930 | 1186.98 | 8461.79 | 1230.37 | 0.930 | 1.274 | 1.058 | 3.973 | 0.158 | 0.060 |

| 158.39 | 2.068 | 6.098 | 1173.72 | 8536.40 | 1164.49 | 0.909 | 1.260 | 4.719 | 18.38 | 0.035 | 0.013 |

| 148.62 | 1.994 | 5.704 | 1223.58 | 8649.94 | 1102.82 | 0.951 | 1.259 | 0.857 | 3.332 | 0.195 | 0.072 |

| 148.18 | 2.046 | 5.728 | 1208.1 | 8539.64 | 1139.26 | 0.944 | 1.244 | 5.296 | 19.75 | 0.032 | 0.012 |

| 153.06 | 1.984 | 5.810 | 1229.94 | 8578.57 | 1167.29 | 0.963 | 1.276 | 2.960 | 11.30 | 0.056 | 0.021 |

| 164.61 | 2.037 | 5.887 | 1147.74 | 8601.28 | 1185.52 | 0.894 | 1.235 | 2.274 | 8.451 | 0.073 | 0.028 |

| 168.82 | 2.058 | 5.647 | 1217.22 | 8630.47 | 1147.67 | 0.949 | 1.269 | 0.403 | 1.348 | 0.414 | 0.177 |

| 149.73 | 1.948 | 5.685 | 1222.02 | 8588.30 | 1165.89 | 0.949 | 1.297 | 5.475 | 19.84 | 0.031 | 0.012 |

| 161.27 | 1.910 | 5.920 | 1186.02 | 8429.35 | 1223.36 | 0.932 | 1.256 | 3.458 | 13.09 | 0.048 | 0.018 |

| 158.18 | 1.996 | 6.007 | 1183.62 | 8565.59 | 1121.04 | 0.915 | 1.248 | 2.699 | 9.584 | 0.062 | 0.025 |

| 163.05 | 2.030 | 5.988 | 1192.08 | 8409.88 | 1196.73 | 0.935 | 1.248 | 3.370 | 12.84 | 0.049 | 0.019 |

| 160.39 | 1.931 | 6112 | 1209.72 | 8646.69 | 1129.45 | 0.947 | 1.236 | 3.587 | 13.91 | 0.047 | 0.017 |

| 169.27 | 1.883 | 5.882 | 1234.86 | 8708.33 | 1132.25 | 0.960 | 1.287 | 3.253 | 12.08 | 0.051 | 0.020 |

| 152.62 | 2.003 | 5.872 | 1200.78 | 8413.13 | 1154.68 | 0.929 | 1.276 | 6.247 | 23.22 | 0.026 | 0.010 |

| 162.16 | 1.946 | 6.108 | 1169.34 | 8575.33 | 1216.35 | 0.913 | 1.266 | 1.908 | 6.999 | 0.088 | 0.034 |

| 163.72 | 1.898 | 5.829 | 1205.64 | 8435.83 | 1172.90 | 0.937 | 1.276 | 4.354 | 15.77 | 0.038 | 0.015 |

| 154.62 | 2.013 | 5.949 | 1201.44 | 8510.45 | 1235.97 | 0.939 | 1.301 | 1.051 | 3.649 | 0.159 | 0.065 |

| 164.83 | 2.063 | 6.026 | 1155.66 | 8500.71 | 1160.29 | 0.900 | 1.219 | 3.314 | 12.45 | 0.050 | 0.019 |

| 152.84 | 2.015 | 5.959 | 1157.22 | 8675.89 | 1175.70 | 0.899 | 1.251 | 1.935 | 7.252 | 0.086 | 0.033 |

| 150.62 | 1.917 | 5.968 | 1215.78 | 8458.54 | 1142.07 | 0.947 | 1.261 | 0.167 | 0.767 | 1 | 0.311 |

| 166.60 | 1.989 | 6.045 | 1183.74 | 8562.35 | 1182.71 | 0.927 | 1.242 | 4.745 | 17.35 | 0.035 | 0.014 |

| 166.16 | 2.025 | 6.055 | 1156.74 | 8594.79 | 1153.28 | 0.898 | 1.230 | 0.464 | 1.897 | 0.360 | 0.126 |

| 157.50 | 1.958 | 5.714 | 1194.54 | 8672.65 | 1199.53 | 0.937 | 1.265 | 1.675 | 5.936 | 0.099 | 0.040 |

| 169.49 | 2.056 | 5.642 | 1257.24 | 8507.20 | 1226.16 | 0.987 | 1.327 | 1.007 | 3.836 | 0.166 | 0.062 |

3.4. Dynamic Probabilistic Analysis

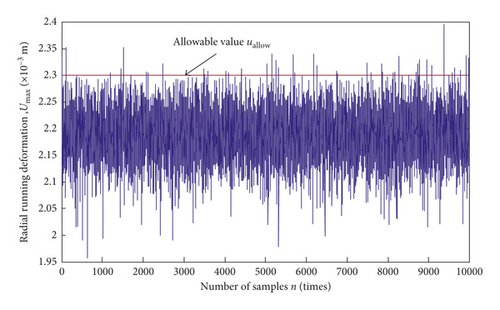

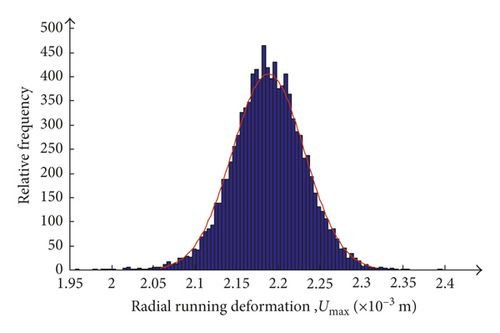

For the dynamic reliability analysis of blisk radial deformation, the allowable value uallow is 2.30 × 10−3 m in respect of engineering experience. Based on the value and the limit state function, the MC method is applied to obtain 10,000 samples of input variables. The simulation history and histogram distribution of the blisk radial deformation are shown in Figures 13 and 14, respectively, in which umax indicates the maximum of blisk radial deformation.

From Figures 13 and 14, it is obvious that the radial deformation of turbine blisk follows a normal distribution with the mean μ = 2.19 × 10−3 m and the variance σ2 = 1.87 × 10−9 m. And the reliability degree R = 0.9951 is acquired, which satisfies the requirement of engineering design.

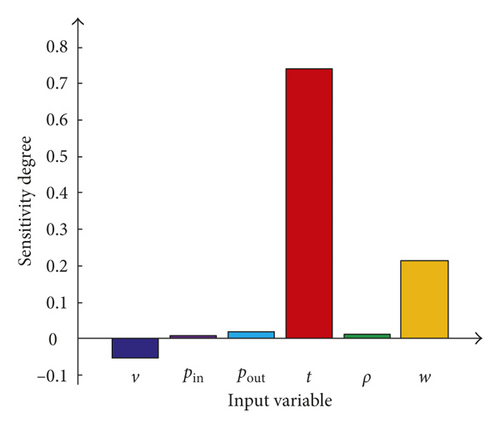

Additionally, the sensitivity analysis of blisk radial running deformation with respect to all input parameters is implemented. The analytical results including sensitivity degree and impact probability are obtained as depicted in Figure 15 and Table 3, respectively.

| Variable | Inlet velocity, v | Inlet pressure, pin | Outlet pressure, pout | Gas temperature, t | Material density, ρ | Angular speed, w |

|---|---|---|---|---|---|---|

| Sd | −0.054 | 0.004 | 0.012 | 0.740 | 0.006 | 0.216 |

| Id (%) | 5.23 | 0.39 | 1.16 | 71.67 | 0.62 | 20.93 |

As demonstrated in Figure 15 and Table 3, the sensitivity degrees of all input parameters have either positive or negative values. The signs are related to whether the variation of an input variable has a positive or negative correlation with the output response [23, 33]. Hence, the blisk radial deformation increases with the increase of inlet pressure, outlet pressure, gas temperature, material density, and angular speed, while with the decrease of the inlet velocity. Besides, the impact probability reveals the importance of an input variable relative to other variables. The importance of all input parameters affecting the blisk radial running deformation are successively gas temperature, angular speed, inlet velocity, outlet pressure, material density, and inlet pressure.

In view of the above analysis, the effects of all input parameters on the blisk radial running deformation are acquired. This information might be used to guide the design of turbine blisk as well as update the model of the complex structure.

4. IWRDCSMM Verification

This section is to validate the effectiveness and feasibility of the developed IWRDCSMM. The fitting properties of both fitting efficiency and computing accuracy are firstly focused to validate the IWRDCSMM by comparing with distributed collaborative surrogate model method-based least square method (LSDCSMM) and distributed collaborative surrogate model method-based weighted regression principle (WRDCSMM). And then, these models and MC simulation are utilized to implement the dynamic reliability analysis of turbine blisk radial deformation to verify the superiority of the proposed method.

4.1. Fitting Property

The analytical results including the fitting time and accuracy are listed in Table 4.

| Variables | LSDCSMM | WRDCSMM | IWRDCSMM | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| v (m/s) | pin (×106 Pa) | pout (×105 Pa) | t (K) | ρ (kg/m3) | w (rad/s) | Values (×10−3 m) | Err. (×10−4 m) | Values (×10−3 m) | Err. (×10−5 m) | Values (×10−3 m) | Err. (×10−5 m) | |

| Testing samples | 157.05 | 1.951 | 5.757 | 1164.00 | 8448.81 | 1184.11 | 2.589 | 4.487 | 2.147 | 0.628 | 2.146 | 0.588 |

| 154.83 | 1.970 | 6.031 | 1225.74 | 8523.42 | 1111.23 | 2.625 | 3.975 | 2.213 | 1.511 | 2.220 | 0.827 | |

| 160.83 | 1.914 | 5.700 | 1200.30 | 8581.81 | 1234.57 | 2.688 | 4.501 | 2.233 | 0.499 | 2.237 | 0.019 | |

| 149.95 | 2.073 | 5.906 | 1228.32 | 8643.45 | 1178.51 | 2.638 | 4.245 | 2.256 | 4.166 | 2.255 | 2.123 | |

| 162.82 | 2.102 | 6.103 | 1136.16 | 8481.25 | 1116.84 | 2.576 | 5.071 | 2.077 | 0.846 | 2.087 | 0.871 | |

| 161.05 | 2.104 | 6.069 | 1223.94 | 8494.23 | 1233.17 | 2.723 | 4.678 | 2.266 | 1.046 | 2.273 | 1.259 | |

| 165.71 | 1.943 | 5.743 | 1195.92 | 8555.86 | 1119.64 | 2.658 | 4.818 | 2.173 | 0.311 | 2.164 | 0.876 | |

| 159.94 | 1.886 | 5.863 | 1168.98 | 8503.96 | 1105.62 | 2.607 | 4.952 | 2.125 | 1.327 | 2.126 | 1.263 | |

| 151.06 | 2.099 | 5.901 | 1171.08 | 8400.15 | 1150.48 | 2.575 | 4.187 | 2.143 | 1.339 | 2.135 | 1.162 | |

| 147.51 | 2.032 | 5.925 | 1154.40 | 8666.16 | 1170.10 | 2.538 | 3.995 | 2.142 | 0.341 | 2.142 | 0.409 | |

| 149.51 | 1.893 | 5.652 | 1166.16 | 8529.91 | 1237.37 | 2.576 | 4.018 | 2.181 | 0.726 | 2.191 | 0.743 | |

| 162.38 | 1.934 | 5.944 | 1170.42 | 8484.49 | 1200.93 | 2.641 | 4.625 | 2.168 | 1.012 | 2.168 | 1.050 | |

| 165.93 | 2.006 | 5.772 | 1174.08 | 8465.03 | 1136.46 | 2.635 | 4.982 | 2.143 | 0.673 | 2.131 | 0.528 | |

| 161.49 | 2.094 | 5.776 | 1258.62 | 8422.86 | 1188.32 | 2.696 | 3.895 | 2.291 | 1.656 | 2.291 | 1.059 | |

| 153.72 | 2.051 | 5.815 | 1193.52 | 8559.11 | 1179.91 | 2.627 | 4.260 | 2.201 | 0.038 | 2.198 | 0.256 | |

| 155.94 | 1.900 | 5.805 | 1164.12 | 8487.74 | 1231.77 | 2.620 | 4.472 | 2.176 | 0.308 | 2.184 | 1.090 | |

| 163.93 | 1.986 | 5.935 | 1225.38 | 8546.13 | 1144.87 | 2.681 | 5.462 | 2.229 | 9.395 | 2.225 | 8.491 | |

| 161.94 | 2.020 | 6.084 | 1263.90 | 8490.98 | 1161.69 | 2.672 | 3.681 | 2.286 | 1.766 | 2.300 | 0.414 | |

| 155.72 | 2.044 | 5.853 | 1155.84 | 8682.38 | 1109.83 | 2.587 | 4.784 | 2.115 | 0.639 | 2.118 | 0.921 | |

| 169.04 | 2.027 | 5.997 | 1165.62 | 8640.21 | 1157.488 | 2.659 | 5.171 | 2.149 | 0.697 | 2.138 | 0.384 | |

| Absolute errors | Maximum, Errmax | 5.462 | 9.395 | 8.491 | ||||||||

| Minimum, Errmin | 3.681 | 0.038 | 0.019 | |||||||||

| Mean, Errmean | 4.513 | 1.446 | 1.167 | |||||||||

| Fitting time (s) | 4.278 | 0.673 | 0.673 | |||||||||

As revealed in Table 4, the fitting time of the IWRDCSMM model is less than that of the LSDCSMM model and is equal to that of the WRDCSMM model. The reason is that the number of samples for the IWRDCSMM is less than that of LSDCSMM and is equal to that of the WRDCSMM in mathematical modeling. The maximum absolute error, minimum absolute error, and average absolute error for the IWRDCSMM are only 0.155, 0.001, 0.026 and 0.904, 0.500, 0.807 for these of the LSDCSMM and WRDCSMM, respectively. The IWRDCSMM model holds less error and higher precision than the LSDCSMM and WRDCSMM.

4.2. Computational Property of Dynamic Reliability Analysis

To further validate the effectiveness and feasibility of the developed method, MC simulation, LSDCSMM, WRDCSMM, and IWRDCSMM are employed to perform the dynamic reliability analyses of turbine blisk radial running deformation based on the same input variables in Table 1 and computational environment. The computing time and precision of different simulations for different methods are listed in Tables 5 and 6.

| Methods | Computing time (s) | ||

|---|---|---|---|

| 102 | 103 | 104 | |

| MC direct simulation | 22,680,000 | 190,800,000 | — |

| LSDCSMM | 0.212 | 0.954 | 1.736 |

| WRDCSMM | |||

| IWRDCSMM | |||

| Number of samples | Reliability degree R | Precision (%) | |||||

|---|---|---|---|---|---|---|---|

| MC simulation | LSDCSMM | WRDCSMM | IWRDCSMM | LSDCSMM | WRDCSMM | IWRDCSMM | |

| 102 | 0.99 | 0.96 | 0.97 | 0.99 | 93.94 | 97.98 | 1 |

| 103 | 0.993 | 0.975 | 0.987 | 0.992 | 98.19 | 99.40 | 99.90 |

| 104 | — | 0.9937 | 0.9945 | 0.9951 | — | — | — |

As shown in Table 5, in the computing time the IWRDCSMM is far less than the MC simulation and is equal to the LSDCSMM and WRDCSMM. In the computational efficiency, the IWRDCSMM becomes higher with the increasing simulations. As demonstrated in Table 6, the analytical precision of the IWRDCSMM is almost consistent with that of the MC simulation and is higher than those of LSDCSMM and WRDCSMM. As revealed in Tables 5 and 6, the proposed method can effectively accomplish the dynamic reliability analysis of complex structure with multiple components, while the MC simulation cannot when the number of simulation is over 103.

In short, it is fully illustrated that the IWRDCSMM holds high precision and efficiency in modeling and simulation for the nonlinear transient reliability analysis of turbine blisk. The promising approach in this work is testified by the dynamic reliability and sensitivity analyses of complex structure with multiple components.

5. Conclusions

- (1)

Through the dynamic deterministic analysis of aeroengine turbine blisk, the changing rules of the blade and disk radial running deformations from start to cruise for aircraft are gained by adopting the close-coupling analysis technique within the time domain [0, T]. The turbine blisk radial running deformation reaches the maximum at t = 175 s.

- (2)

The reliability degree of radial running deformation of turbine blisk is R = 0.9951 based on the dynamic reliability analysis of IWRDCSMM, when the allowable value of turbine blisk radial running deformation uallow is 2.30 × 10−3 m.

- (3)

From sensitivity analysis, the importance of all input parameters affecting the blisk radial deformation are successively gas temperature, angular speed, inlet velocity, outlet pressure, material density, and inlet pressure.

- (4)

In fitting property, the IWRDCSMM needs smaller samples in modeling than other surrogate models and holds higher fitting efficiency and accuracy.

- (5)

By the comparison of different methods, the proposed IWRDCSMM is promising to enhance computing efficiency with the guarantee of acceptable analytical precision in the dynamic probabilistic analysis of multicomponent structure.

Conflicts of Interest

The authors declare that there are no conflicts of interest regarding the publication of this article.

Acknowledgments

This study was supported by the National Natural Science Foundation of China (Grant no. 31601220), the School Cultivate Project Funding Scheme of Heilongjiang Bayi Agricultural University (Grant no. XZR2017-03), the Key Laboratory of Agricultural Mechanization Engineering, and The R & D Team for Sowing and Harvesting Equipment(Group no. TDJH201803). The authors would like to thank them.

Open Research

Data Availability

The data used to support the findings of this study are available from the corresponding author upon request.