Simple Hydrolysis Synthesis of Uniform Rice-Shaped β-FeOOH Nanocrystals and Their Transformation to α-Fe2O3 Microspheres

Abstract

In the synthesis of nanostructure materials a specific emphasis has been focused on the control of shape and orientation of nanocrystals to obtain prerequisite properties of the materials. Nanorice is a new hybrid nanoparticle prolate geometry of nanoshells with reduced symmetry having new exciting optical behavior. Rice-shaped β-FeOOH nanocrystals have been synthesized by a simple hydrolysis chemical method using ferric aqueous solution and urea as surfactant. The successive calcination of β-FeOOH nanocrystals at 650°C results in the formation of the porous α-Fe2O3 (hematite) microspheres. The as-synthesized yield of β-FeOOH nanocrystals was characterized by X-ray diffraction (XRD), scanning electron microscopy (SEM), energy dispersive X-ray analysis (EDAX), and optical spectroscopy. The successive transformation of rice-shaped β-FeOOH nanostructures into porous α-Fe2O3 (hematite) microspheres through calcination process was confirmed by XRD, SEM, and EDAX studies. The water contact angle of as-prepared α-Fe2O3 microspheres shows hydrophobic behavior of the material.

1. Introduction

The interest in nanomaterials has grown because of their distinct structural, optical, magnetic, electronic, mechanical, and chemical properties compared with those of the bulk materials. Magnetic nanoparticles with a size less than 100 nm represent an important class of nanostructure materials, which allow investigations of fundamental aspects of magnetic ordering phenomena and could lead to new technological applications. Magnetic iron oxides have been used in biomedicine for magnetic resonance imaging (MRI) and drug delivery and as a heating mediator for cancer thermotherapy [1]. In nonsurgical treatments of cancerous tumors, the heating is mainly achieved via magnetization relaxation in superparamagnetic state [2, 3] or hysteresis-loss heating [4]. The sensing capability of iron oxide (especially α-Fe2O3 and organic γ-Fe2O3 hybrid materials) in different gas sensors is a current research interest of many researchers [5–10]. The most common and interesting class of iron oxide are magnetite (Fe3O4), maghemite (γ-Fe2O3), and hematite (α-Fe2O3). Iron oxyhydroxide (β-FeOOH) is the most effective and important catalyst and precursor explored in the synthesis of different geometrical nanostructures of iron oxides [11]. Hematite (α-Fe2O3) is the most thermodynamically stable structure of iron oxide and has potential applications with different shapes and geometry in nanoregime [12, 13]. Several studies have demonstrated that the fundamental properties of metal nanostructures can be effectively tailored by controlling their size, shape, composition, crystallinity, and structure [14–17]. Magnetic nanostructure materials with novel morphologies and phases are often required for interesting applications. Rice-shaped metal nanoparticles synthesis of silver [17, 18] and iron oxide nanoparticles as templates with thin gold shell [19] to produce rice-shaped gold core-shell nanoparticles has been devised successfully. Various synthesis approaches such as coprecipitation [20–22], hydrothermal synthesis [23–25], thermal decomposition [26, 27], and sol-gel method [28–30] have been used by various research groups worldwide for the synthesis of iron-oxide based nanomaterials.

In the present study, we have reported a simple and novel high-yield hydrolysis method to prepare monodisperse rice-shaped β-FeOOH nanocrystals (precursor) and successive transformation of the former into porous α-Fe2O3 (hematite) microspheres through calcination process. The as-synthesized products are characterized by XRD, SEM, EDAX, and UV-VIS absorption spectroscopy studies. The hydrophobic properties were measured by contact angle goniometry (Kruss DSA 100 easy drop) using sessile drop method at room temperature.

2. Materials and Methods

2.1. Materials Preparation

All the chemicals used in the research work were of analytical grade and used without further purification. In a typical experimental procedure, in the first step, a designated molar ratio of iron chloride (FeCl3·6H2O) and urea [CO(NH2)2] was dissolved in deionized water for the preparation of β-FeOOH nanocrystals (precursor). The mixture was vigorously stirred for 1 hr at 90°C to form a homogenous solution and then cooled down to room temperature. Finally, the produced precipitates were collected by centrifugation, filtered and washed several times with deionized water followed by ethanol, and then dried at 70°C for 4 hrs. The as-prepared dry powder was further heated at 250°C for 1 hr, resulting in the formation of β-FeOOH nanocrystals. In the next step, the as-prepared product (β-FeOOH nanocrystals precursor) was annealed in a tube furnace at 650°C for 2 hours in air to get α-Fe2O3 phase microspheres. The resultant products β-FeOOH nanocrystals and α-Fe2O3 microspheres were used for further characterization.

2.2. Characterization Techniques

The phase of the samples was examined by X-ray powder diffraction (XRD) using a Bruker, D8 Advance X-ray diffractometer with CuKα radiation (1.5406 Å) over the 2θ range 20–70°. The morphology of the synthesized powders was investigated by scanning electron microscopy (SEM) with EDX analysis to investigate the details of their microstructure and composition. The instrument UV-VIS Spectrophotometer (Hitachi U-3400) was used to measure the absorption spectra of sample. Absorption measurements were performed in the wavelength spectral range 400−700 nm. Sessile drop method was employed to measure the water droplet contact angle by using contact angle goniometry (Kruss DSA 100 easy drop) to confirm the hydrophobic nature. The average contact angle was determined by dropping the distilled deionized water droplets at different positions on the α-Fe2O3 surface coating using a microsyringe.

3. Results and Discussion

3.1. X-Ray Diffraction (XRD) Studies

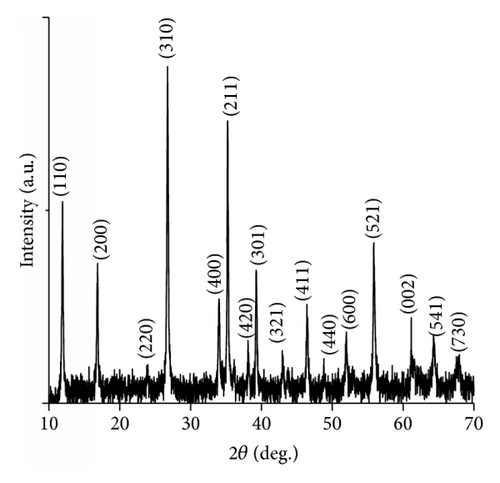

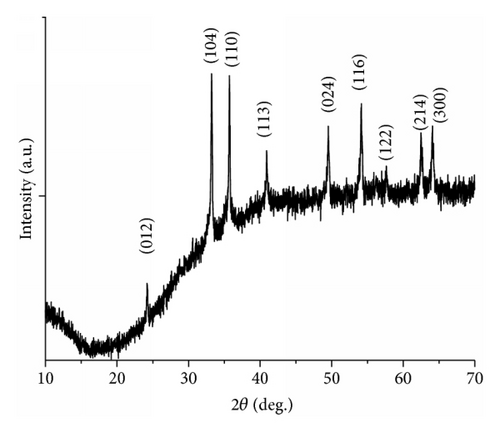

The phase of as-prepared β-FeOOH nanocrystals and their transformation to α-Fe2O3 phase was investigated by XRD. Figure 1 shows the XRD patterns of as-prepared β-FeOOH nanocrystals and α-Fe2O3 microspheres. All the diffraction peaks in Figure 1(a) are assigned to the tetragonal β-FeOOH phase according to JCPDS card number 34-1266, confirming the formation of well crystalline β-FeOOH structure heated at 250°C in air. Absence of other characteristic peaks of α-Fe2O3 and γ-Fe2O3 in the XRD pattern (Figure 1(a)) confirms the formation of β-FeOOH nanocrystals without any impurities whereas the clarity and sharpness of the all peaks indicate the good crystallization of as-prepared sample.

The as-prepared sample was calcined at 650°C for 2 hours to transform the β-FeOOH nanocrystals to α-Fe2O3 (hematite) phase as can be seen from XRD pattern reported in Figure 1(b). All diffraction peaks in Figure 1(b) are assigned to the rhombohedral α-Fe2O3 (hematite) phase according to JCPDS card number 33-0664, confirming the transformation of crystalline β-FeOOH to α-Fe2O3 (hematite) phase after calcining the former at 650°C in air. The α-Fe2O3 microspheres show good crystallinity with strong preferential orientations along (104) and (110) planes at 2θ values around 33.19° and 35.68°, respectively, showing a prospective in photocatalytic application due to the good conductivity for fast electron transfer in α-Fe2O3 [31]. Furthermore, the intense and sharp peaks in XRD (Figure 1(b)) are indicative of good crystalline nature of the sample without producing any impurities and mixing of other phases of iron oxide. The XRD results are consistent with the recent research work reported by various workers on iron oxides [11, 31, 32].

3.2. Scanning Electron Microscopy (SEM) and EDAX Studies

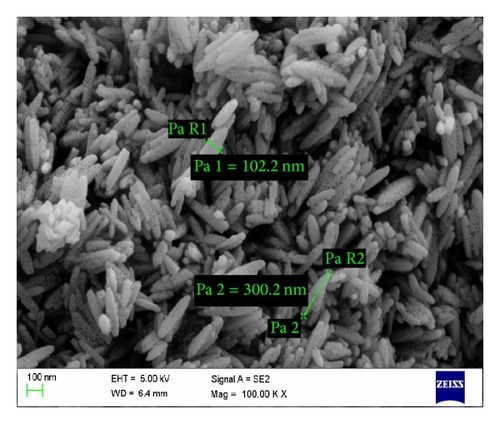

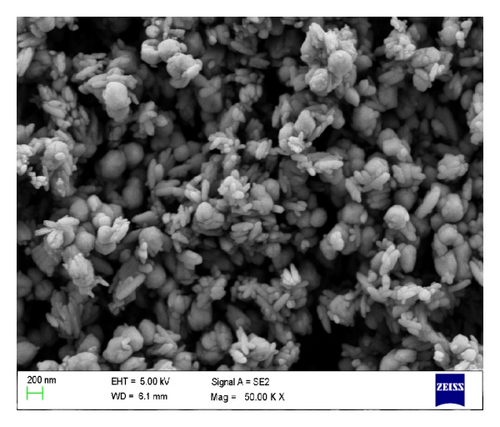

Field Emission Scanning Electron Microscope (FEI, Quanta 200F) with EDX analysis is used to study the microstructure and chemical composition of samples. Figure 2 shows the high magnification image of β-FeOOH nanocrystals and α-Fe2O3 microspheres. Figure 2(a) shows the formation of uniform rice-shaped nanocrystals of β-FeOOH precursor with maximum length of about 300 nm.

Figure 2(b) shows the high magnification image of α-Fe2O3 microspheres after calcining at 650°C for 2 hrs. As shown in this SEM image, it is clear that the calcination at 650°C affects the shape, size, and uniformity of the of α-Fe2O3 microspheres. The rice-shaped nanocrystals of β-FeOOH precursor were congregated and fused to form aggregated irregular microspheres of α-Fe2O3 with a maximum diameter of around 200 nm. The higher surface area (due to porosity) of α-Fe2O3 microstructures is much desirable because the intercalation capacities and affinities for Li+ to have potential use of hematite in lithium ion batteries [34].

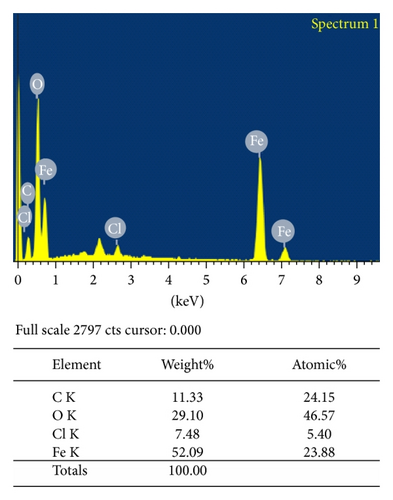

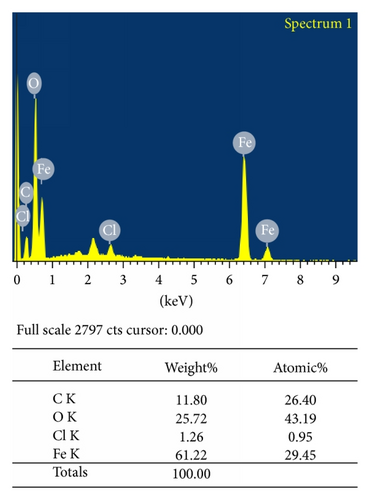

The SEM coupled EDAX technique was used to highlight the different chemical element present in the synthesized powder of β-FeOOH nanocrystals and α-Fe2O3 microstructures. Elemental composition of rice-shaped nanocrystals of β-FeOOH precursor and α-Fe2O3 microstructures was verified using EDAX as shown in Figure 3. The Atomic% of constituents of respective sample is shown in the underneath tables of Figure 3. The presence of Fe and O components in EDAX confirms the formation of desired material. EDX analysis has also shown the presence of C and Cl addition to Fe and O in both samples. The existence of the carbon peak at about 0.2 KeV in EDX spectrum is due to the carbon tape that was used in holding the sample during the SEM and EDX measurements. The peak of Cl in both samples is attributed to the chemical component present in synthesis materials (from the used FeCl3·6H2O). The average atomic percentage formation of Fe and O in β-FeOOH precursor is 23.88% and 46.57%, respectively, while the average atomic percentage formation of Fe and O in α-Fe2O3 microspheres is 29.45% and 43.19%, respectively. The underneath table of Figure 3(b) reveals that the O/Fe atomic percentage ratio of the α-Fe2O3 analyzed is 1.47, which is relatively consistent with the theoretical O/Fe atomic ratio of 1.50 for the α-Fe2O3. The energy dispersive X-ray analyses of both β-FeOOH precursor and α-Fe2O3 microstructures show the Fe and O composition to be that of β-FeOOH and α-Fe2O3, respectively.

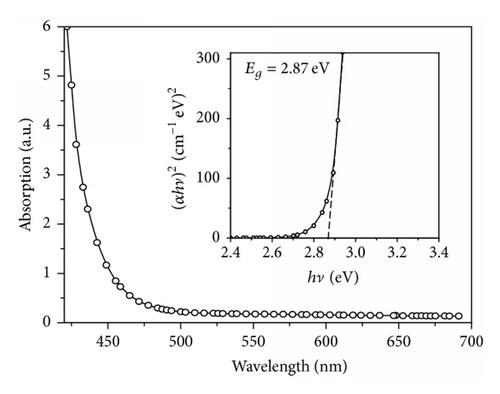

3.3. Absorption Spectra

3.4. Hydrophobic Properties

| Parameter | Owens-Wendt method | Wu method |

|---|---|---|

| γsv (m N/m) | 6.91 | 13.39 |

|

(m N/m) |

3.08 | 6.52 |

|

(m N/m) |

3.86 | 6.87 |

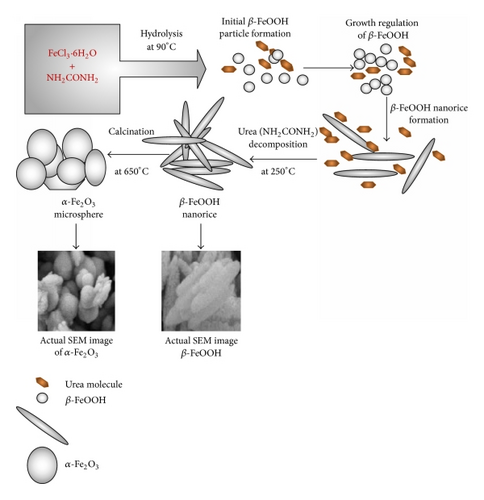

3.5. Possible Formation Mechanism

The possible formation mechanism of rice-shaped β-FeOOH nanocrystals and their transformation to α-Fe2O3 microspheres has been proposed and schematically illustrated in Figure 6. The complete process includes nucleation of iron hydroxide (particle formation) by hydrolysis of iron complexes, growth regulation, nanorice formation due to urea decomposition, and dehydration due to calcination process. Initially, crystal nucleation of β-FeOOH starts from the solution and tends to be regulated eventually in the form of anisotropic nanorice due to increases in temperature and shape directing molecules of urea [32]. The shape of the nanoparticles may be tuned by controlling many experimental parameters such as concentration of the precursor, reducing agents, and stabilizers with reaction conditions like temperature, ambient environment, and time. The exact role of these parameters in determining the morphology of the crystals is not yet fully understood and it has been proposed that synergistic effect of each one of these parameters has substantial influence on the final shape of the nanocrystal [39]. The anisotropic growth of β-FeOOH nanostructure material in the shape of nanorice might be mainly owing to the surfactant (urea) used in the synthesis. The complete decomposition of urea at 250°C results in the inclusive formation of rice-shaped β-FeOOH nanocrystals. Finally, the calcination of as-prepared β-FeOOH nanocrystals at 650°C for 2 hrs releases the H2O molecules in the structure of β-FeOOH [11] and ultimately rice-shaped β-FeOOH nanocrystals transform to mesoporous α-Fe2O3 microspheres.

4. Conclusions

In the present study, uniform rice-shaped β-FeOOH nanocrystals were successfully synthesized by a simple hydrolysis chemical method in presence of urea. The α-Fe2O3 microspheres were consecutively and straightforwardly prepared by calcining rice-shaped β-FeOOH nanocrystals precursor at 650°C. XRD patterns and SEM images demonstrated the phase transformation of as-prepared β-FeOOH nanocrystals to α-Fe2O3 microspheres. No other phases of iron oxide (e.g., Fe2O4 and γ-Fe2O3) were observed in the XRD patterns of the samples. The optical and hydrophobic properties were also studied. The possible formation mechanism of rice-shaped β-FeOOH nanocrystals and their transformation to α-Fe2O3 microspheres was proposed. The achieved new hybrid prolate nanorice geometry of β-FeOOH nanostructures and porous architecture of α-Fe2O3 (hematite) microspheres may have potential in new exciting optical behavior and sensing applications.

Conflict of Interests

The authors declare that there is no conflict of interests regarding the publication of this paper.