Effect of Viscosity Variation on the Micropolar Fluid Squeeze Film Lubrication of a Short Journal Bearing

Abstract

A theoretical study of the effect of the viscosity variation on the squeeze film performance of a short journal bearing operating with micropolar fluid is presented. The modified Reynolds equation accounting for the viscosity variation in micropolar fluid is mathematically derived. To obtain a closed form solution, the short bearing approximation under constant load is considered. The modified Reynolds equation is solved for the fluid film pressure and then the bearing characteristics, such as obtaining the load carrying capacity and the squeeze film time. According to the results evaluated, the micropolar fluid as a lubricant improves the squeeze film characteristics and results in a longer bearing life, whereas the viscosity variation factor decreases the load carrying capacity and squeezes film time. The result is compared with the corresponding Newtonian case.

1. Introduction

The application of squeeze film action is commonly seen in gyroscopes, gears, aircraft engines, automotive engines, and the mechanics of synovial joints in human being and animals. The squeeze film behaviour arises from the phenomenon of two lubricated surfaces approaching each other with a normal viscosity. Because of the viscous lubricant present between the two surfaces, it takes certain time for these to come into contact. Since the viscous lubricant has a resistance to extrusion, a pressure is built up during that interval, and the lubricant film then supports the load. If the applied load acts for a short enough time, it may happen that the two lubricated surfaces will not meet at all. Therefore, the analysis of squeeze film action focuses on the load carrying and rate of approach.

The theory of micropolar fluids introduced by Eringen [1] deals with a class of fluid which exhibits certain microscopic effects arising from the local structures and micromotion of fluid elements. These fluids can support stress moments and body moments and are influenced by the spin inertia. A subclass of these fluids is the micropolar fluids which exhibit the microrotational effects and microrotational inertia. Eringen’s micropolar fluid theory defines the rotation vector called microrotation vector setting up of stress-strain rate constitutive equations.

The study of micropolar fluids has received considerable attention due to their applications in a number of processes that occur in industries such as extrusion of polymer fluids, solidification of liquid crystal, cooling of metallic plate in a bath, animal blood exotic lubricants, and colloidal and suspension solution. In the study of all these problems, the classical Navier-Stokes theory is inadequate, as the micropolar fluid theory is a subclass of microfluid theory and is obtained by imposing the skew symmetric properties of the gyration tensor in addition to a condition of microisotropy.

- (1)

There exists a thermal equilibrium.

- (2)

The relationship for the variation of viscosity with temperature can be replaced by viscosity film thickness relation.

2. Mathematical Formulation of the Problem

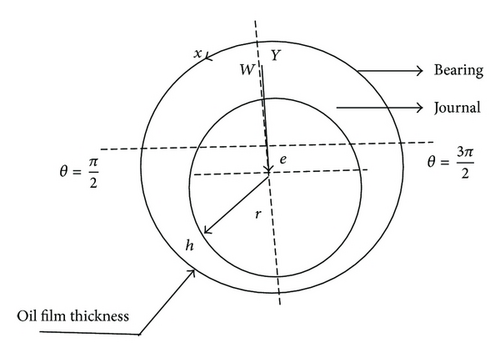

The physical configuration of the journal bearing is shown in Figure 1. The shaft of radius r approaches the bearing surface with velocity V. The film thickness h is a function of θ, (h = c + ecos θ), where c is the radial clearance and e is the eccentricity of journal centre. The lubricant in the region is assumed to be micropolar fluid.

The constitutive equations for micropolar fluids proposed by Eringen [1] simplify considerably under the usual assumptions of hydrodynamic lubrication. The resulting equations under steady-state conditions are as follows.

- (i)

at the bearing surface (y = 0),

- (ii)

at the journal surface (y = h),

3. Solution of the Problem

3.1. Short Bearing Approximation

The nondimensional load carrying capacity in (22) cannot be obtained by direct integration. It can be numerically evaluated by the method of Gaussian quadrature.

For constant load , the time taken by the journal centre to move from ε = 0 to ε = ε1 can be obtained by integrating (21) with respect to time.

4. Result and Discussion

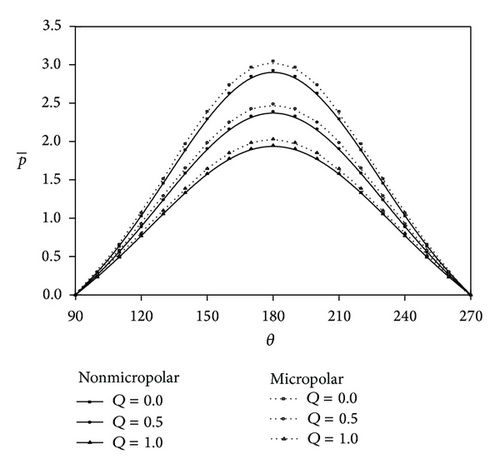

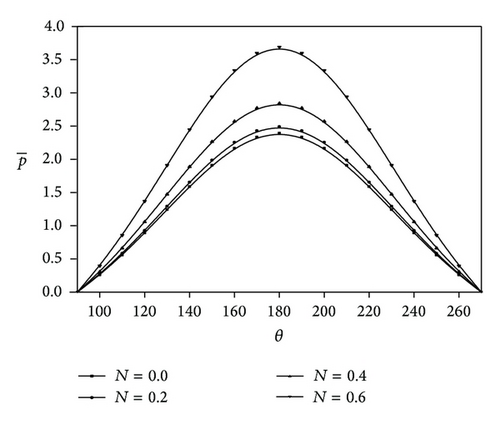

4.1. Squeeze Film Pressure

The variation of nondimensional squeeze film pressure with the angular coordinate θ for various values of Q is depicted in Figure 2. The dotted curves indicate the results of Newtonian case. It is observed that decreases for the increasing values of Q. Figure 3 depicts the variation of with θ for different values of N with and l = 0.4 and for the fixed values of Q = 0.5, ε = 0.2, and λ = 0.5. It is observed that increases for the increasing values of the coupling number N and the microstructure size parameter .

4.2. Load Carrying Capacity

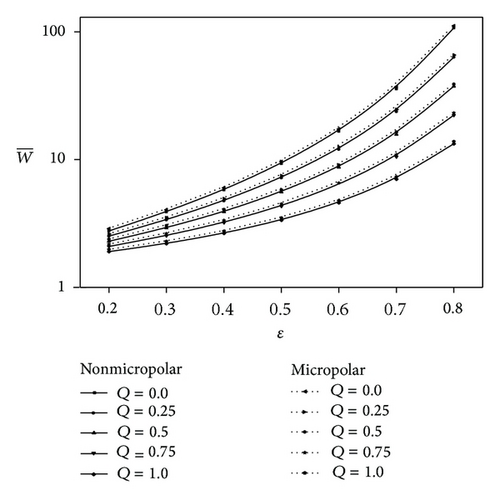

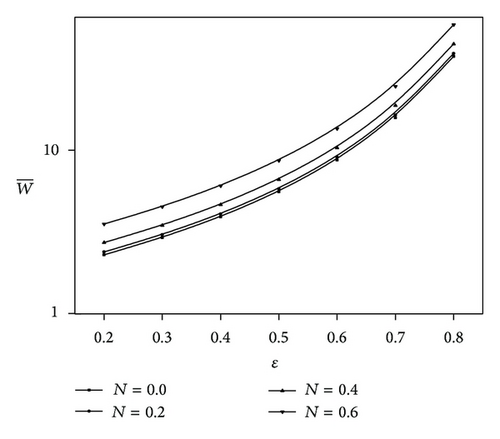

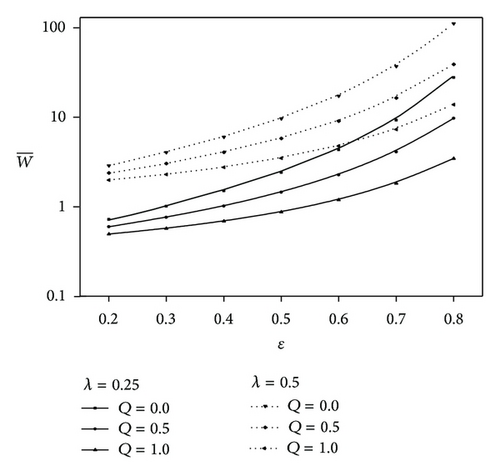

The variation of nondimensional load carrying capacity with the eccentricity ratio parameter ε is shown in the Figure 4 for various values of Q. It is observed that increases for increasing values of ε and decreases for increasing values of Q. Figure 5 shows the variation of with ε for different values of N and two values of (0, 0.4). It is clear that the effect of microstructure additives in the lubricant is to enhance the load carrying capacity as compared to the corresponding Newtonian case. An increase of nearly 4.16% in is observed at ε = 0.8 when , N = 0.2, Q = 0.5, and λ = 0.5. The effect of aspect ratio λ on the variation of with ε for different values of Q is shown in Figure 6. It is observed that when increases λ increases.

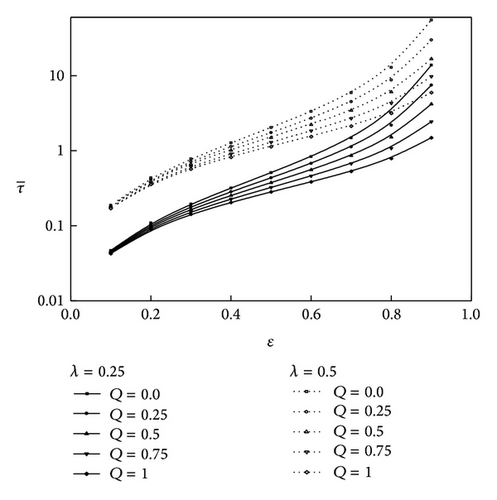

4.3. Squeeze Film Time

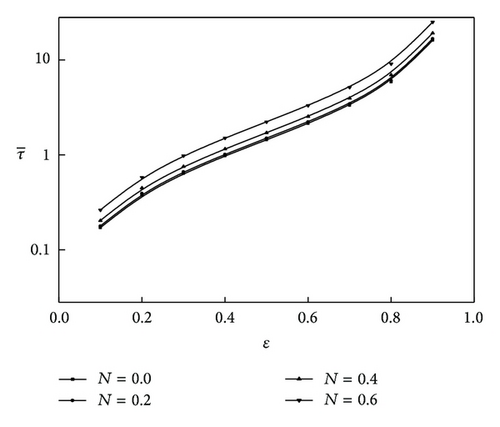

In Figure 7, ε depicts the variation of nondimensional squeeze film time as a function of ε for different values of Q and for two values of the aspect ratio parameter λ with and N = 0.2. It is observed that decreases for the increasing value of Q. The effect of coupling number on the variation of with ε is depicted in the Figure 8 for and . it is observed that increases for the increasing values of N and . Hence, the effect of micropolar lubricants is to increase the load carrying capacity and squeeze film time as compared to the corresponding Newtonian case by which the performance of squeeze film in journal bearings improves.

5. Conclusions

- (1)

The effect of variation in viscosity is to decrease the load carrying capacity and squeeze film time.

- (2)

The presence of microstructures present in the lubricant enhances the load carrying capacity and lengthens the squeeze film time as compared to the corresponding Newtonian case.

Nomenclature

-

- c:

-

- Radial clearance

-

- e:

-

- Eccentricity

-

- h:

-

- Film thickness (h = c + ecos θ)

-

- :

-

- Nondimensional film thickness ( = h/c)

-

- l:

-

- Characteristic length of the polar suspension ( = (γ/4μ)1/2)

-

- :

-

- Nondimensional form of l ( = l/c)

-

- L:

-

- Bearing length

-

- N:

-

- Coupling number ( = (χ/(χ+2μ))1/2)

-

- p:

-

- Lubricant pressure

-

- :

-

- Nondimensional pressure ( = pc2/μ1R2(∂ε/∂t))

-

- Q:

-

- Viscosity variation parameter

-

- r:

-

- Radius of the journal

-

- t:

-

- Squeezing time

-

- u, v, w:

-

- Components of fluid velocity in x, y, and z directions, respectively

-

- v1, v2, v3:

-

- Microrotational velocity components in the x, y, and z directions

-

- V:

-

- Squeeze velocity, (∂h/∂t)( = c(∂ε/∂t)cos θ)

-

- W:

-

- Load carrying capacity

-

- :

-

- Nondimensional load carrying capacity ( = Wc2/μLR3(∂ε/∂t))

-

- x, y, z:

-

- Cartesian coordinates

-

- ε:

-

- Eccentricity ratio ( = e/c)

-

- χ:

-

- Spin viscosity

-

- γ:

-

- Viscosity coefficient for micropolar fluids

-

- μ:

-

- Classical viscosity coefficient

-

- μ1:

-

- Inlet viscosity coefficient

-

- λ:

-

- Length to diameter ratio

-

- τ:

-

- Dimensionless response time

-

- θ:

-

- Circumferential coordinate.