Combined Heat and Power Dynamic Economic Dispatch with Emission Limitations Using Hybrid DE-SQP Method

Abstract

Combined heat and power dynamic economic emission dispatch (CHPDEED) problem is a complicated nonlinear constrained multiobjective optimization problem with nonconvex characteristics. CHPDEED determines the optimal heat and power schedule of committed generating units by minimizing both fuel cost and emission simultaneously under ramp rate constraints and other constraints. This paper proposes hybrid differential evolution (DE) and sequential quadratic programming (SQP) to solve the CHPDEED problem with nonsmooth and nonconvex cost function due to valve point effects. DE is used as a global optimizer, and SQP is used as a fine tuning to determine the optimal solution at the final. The proposed hybrid DE-SQP method has been tested and compared to demonstrate its effectiveness.

1. Introduction

Recently, combined heat and power (CHP) units, known as cogeneration or distributed generation, have played an increasingly important role in the utility industry. CHP units can provide not only electrical power but also heat to the customers. While the efficiency of the normal power generation is between 50% and 60%, the power and heat cogeneration increases the efficiency to around 90% [1]. Besides thier high efficiency, CHP units reduce the emission of gaseous pollutants (SO2, NOx, CO, and) by about 13–18% [2].

In order to utilize the integrated CHP system more CO2 economically, combined heat and power economic dispatch (CHPED) problem is applied. The objective of the CHPED problem is to determine both power generation and heat production from units by minimizing the fuel cost such that both heat and power demands are met, while the combined heat and power units are operated in a bounded heat versus power plane. For most CHP units the heat production capacities depend on the power generation. This mutual dependency of the CHP units introduces a complication to the problem [3]. In addition, considering valve point effects in the CHPED problem makes the problem nonsmooth with multiple local optimal point which makes finding the global optimal challenging.

In the literature, several optimization techniques have been used to solve the CHPED problem with complex objective functions or constraints such as Lagrangian relaxation (LR) [4, 5], semidefinite programming (SDP) [6], augmented Lagrange combined with Hopfield neural network [7], harmony search (HS) algorithm [1, 8], genetic algorithm (GA) [9], ant colony search algorithm (ACSA) [10], mesh adaptive direct search (MADS) algorithm [11], self adaptive real-coded genetic algorithm (SARGA) [3], particle swarm optimization (PSO) [2, 12], artificial immune system (AIS) [13], bee colony optimization (BCO) [14], differential evolution [15], and evolutionary programming (EP) [16]. In [2, 13–15], the valve point effects and the transmission line losses are incorporated into the CHPED problem.

In the CHPED formulation the ramp rate limits of the units are neglected. Plant operators, to avoid life-shortening of the turbines and boilers, try to keep thermal stress on the equipments within the safe limits. This mechanical constraint is usually transformed into a limit on the rate of change of the electrical output of generators. Such ramp rate constraints link the generator operation in two consecutive time intervals. Combined heat and power dynamic economic dispatch (CHPDED) problem is an extension of CHPED problem where the ramp rate constraint is considered. The primary objective of the CHPDED problem is to determine the heat and power schedule of the committed units so as to meet the predicted heat and electricity load demands over a time horizon at minimum operating cost under ramp rate constraints and other constraints [17]. Since the ramp rate constraints couple the time intervals, the CHPDED problem is a difficult optimization problem. If the ramp rate constraints are not included in the optimization problem, the CHPDED problem is reduced to a set of uncoupled CHPED problems that can easily be solved. In the literature an overwhelming number of reported works deal with CHPED problem; however, the CHPDED problem has only been considered in [17].

The traditional dynamic economic dispatch (DED) problem which considers only thermal units that provide only electric power has been studied by several authors (see the review paper [18]). The emission has been taken into the traditional (DED) formulation in three main approaches. The first approach is to minimize the fuel cost and treat the emission as a constraint with a permissible limit (see, e.g., [19–21]). This formulation, however, has a severe difficulty in getting the trade-off relations between cost and emission [22]. The second approach handles both fuel cost and emission simultaneously as competing objectives [23–25]. The third approach treats the emission as another objective in addition to fuel cost objective. However, the multiobjective optimization problem is converted to a single-objective optimization problem by linear combination of both objectives [19, 26–30]. In the second and third approaches, the dynamic dispatch problem is referred to as dynamic economic emission dispatch (DEED) which is a multiobjective optimization problem, which minimizes both fuel cost and emission simultaneously under ramp rate constraint and other constraints [19, 24]. In this paper, we incoroporate the CHP units into the DEED problem. Combined heat and power dynamic economic emission dispatch (CHPDEED) is formulated with the objective to determine the unit power and heat production so that the system’s production cost and emission are simultaneously minimized, while the power and heat demands and other constraints are met [17]. The emission has been taken into consideration in the CHPED and CHPDED in [17, 31], respectively. In [17], both fuel cost and emission are simultaneously handled as competing objectives and the multiobjective problem is solved using an enhanced firefly algorithm (FA). In the present paper, the multiobjective optimization problem is converted into a single-objective optimization using the weighting method. This approach yields meaningful result to the decision maker when solved many times for different values of the weighting factor. In [17], the simulation results for test system are shown, but the data of the heat demand is not explicitly tabulated; instead it is expressed graphically (see Figure 12 in [17]). In this case a comparison of our proposed method and FA cannot be performed. In our paper, all the data and the solutions of the test system are available for comparison.

Differential evolution algorithm (DE), which was proposed by Storn and Price [32] is a population based stochastic parallel search technique. DE uses a rather greedy and less stochastic approach to problem solving compared to other evolutionary algorithms. DE has the ability to handle optimization problems with nonsmooth/nonconvex objective functions [32]. Moreover, it has a simple structure and a good convergence property, and it requires a few robust control parameters [32]. DE has been applied to the CHPED and CHPDED problems with non-smooth and non-convex cost functions in [15, 33], respectively.

The DE shares many similarities with evolutionary computation techniques such as genetic algorithms (GA) techniques. The system is initialized with a population of random solutions and searches for optima by updating generations. DE has evolution operators such as crossover and mutation. Although DE seem to be good methods to solve the CHPDEED problem with non-smooth and non-convex cost functions, solutions obtained are just near global optimum with long computation time. Therefore, hybrid methods such as DE-SQP can be effective in solving the CHPDEED problems with valve point effects.

The main contributions of the paper are as follows. (1) A multi-objective optimization problem is formulated using CHPDEED approach. The multi-objective optimization problem is converted into a single-objective optimization using the weighting method. (2) Hybrid DE-SQP method is proposed and validated for solving the CHPDEED problem with nonsmooth and nonconvex objective function. DE is used as a base level search for global exploration and SQP is used as a local search to fine-tune the solution obtained from DE. (3) The effectiveness of the proposed method is shown for test systems.

2. Problem Formulation

In this section we formulate the CHPDEED problem. The system under consideration has three types of generating units, conventional thermal units (TU), CHP units, and heat-only units (H). The power is generated by conventional thermal units and CHP units, while the heat is generated by CHP units and heat-only units. The objective of the CHPDEED problem is to simultaneously minimize the system’s production cost and emission so as to meet the predicted heat and power load demands over a time horizon under ramp rate and other constraints. The following objectives and constraints are taken into account in the formulation of the CHPDEED problem.

2.1. Objective Functions

In this section, we introduce the cost and emission functions of three types of generating units, conventional thermal units which produce power only, CHP units which produce both heat and power, and heat-only units which produce heat only.

2.1.1. Conventional Thermal Units

2.1.2. CHP Units

2.1.3. Heat-Only Units

2.2. Constraints

There are three kinds of constraints considered in the CHPDEED problem, that is, the equilibrium constraints of power and heat production, the capacity limits of each unit, and the ramp rate limits.

2.3. The Optimization Problem

3. Differential Evolution Method

4. Sequential Quadratic Programming Method

SQP method can be considered as one of the best nonlinear programming methods for constrained optimization problems [38]. It outperforms every other nonlinear programming method in terms of efficiency, accuracy, and percentage of successful solutions over a large number of test problems. The method closely resembles Newton’s method for constrained optimization, just as is done for unconstrained optimization. At each iteration, an approximation is made of the Hessian of the Lagrangian function using Broyden-Fletcher-Goldfarb-Shanno (BFGS) quasi-Newton updating method. The result of the approximation is then used to generate a quadratic programming (QP) subproblem whose solution is used to form a search direction for a line search procedure. Since the objective function of the CHPDEED problem is non-convex and non-smooth, SQP ensures a local minimum for an initial solution. In this paper, DE is used as a global search and finally the best solution obtained from DE is given as initial condition for SQP method as a local search to fine-tune the solution. SQP simulations can be computed by the fmincon code of the MATLAB Optimization Toolbox.

5. Simulation Results

In this section we present two examples. The first example shows the efficiency of the proposed DE-SQP method for the DED problem. In the second example, the hybrid DE-SQP method is applied to the CHPDEED problem. In DE-SQP method, the control parameters are chosen as NP = 80, ℱ = 0.423 and CR = 0.885. The maximum number of iterations are selected as 20,000. The results represent the average of 30 runs of the proposed method. All computations are carried out by MATLAB program.

Example 1. This example consists of ten conventional thermal units to investigate the effectiveness of the proposed DE-SQP technique in solving the DED problem with valve point effects and transmission line losses. The technical data of the units as well as the demand for the 10-unit system are taken from [24]. The best solution of the DED problem is given in Table 1. Comparison between our proposed method (DE-SQP) and other methods is given in Table 2. It is observed that the proposed method reduces the total generation cost better than the other methods reported in the literature.

| H | Loss | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 150.0000 | 135.0000 | 73.0000 | 70.3333 | 222.9974 | 155.1682 | 99.2918 | 120.0000 | 20.0000 | 10.0000 | 19.7912 |

| 2 | 150.0000 | 135.0000 | 101.9485 | 120.3333 | 222.6154 | 123.7029 | 129.2918 | 90.0000 | 48.7980 | 10.7150 | 22.4058 |

| 3 | 150.0000 | 135.0000 | 181.9485 | 170.3333 | 174.2621 | 130.9190 | 129.6896 | 120.0000 | 53.5785 | 40.7150 | 28.4468 |

| 4 | 150.0000 | 135.0000 | 183.1516 | 218.2899 | 223.5485 | 160.0000 | 129.3947 | 120.0000 | 80.0000 | 42.0564 | 35.4415 |

| 5 | 150.0000 | 135.0000 | 258.8414 | 249.7412 | 224.0147 | 160.0000 | 128.5373 | 120.0000 | 80.0000 | 13.2136 | 39.3484 |

| 6 | 150.0000 | 135.0000 | 315.1962 | 299.7412 | 243.0000 | 160.0000 | 129.8624 | 120.0000 | 80.0000 | 43.2136 | 48.0136 |

| 7 | 150.0000 | 176.9470 | 340.0000 | 300.0000 | 243.0000 | 160.0000 | 130.0000 | 120.0000 | 80.0000 | 55.0000 | 52.9470 |

| 8 | 178.2448 | 228.3049 | 340.0000 | 300.0000 | 243.0000 | 160.0000 | 129.9436 | 120.0000 | 80.0000 | 54.9118 | 58.4054 |

| 9 | 258.2448 | 308.3049 | 340.0000 | 300.0000 | 243.0000 | 160.0000 | 130.0000 | 120.0000 | 80.0000 | 55.0000 | 70.5500 |

| 10 | 289.0490 | 384.5331 | 340.0000 | 300.0000 | 243.0000 | 160.0000 | 130.0000 | 120.0000 | 80.0000 | 55.0000 | 79.5821 |

| 11 | 368.7363 | 397.1230 | 340.0000 | 300.0000 | 243.0000 | 160.0000 | 130.0000 | 120.0000 | 80.0000 | 55.0000 | 87.8595 |

| 12 | 374.8564 | 439.5807 | 340.0000 | 300.0000 | 243.0000 | 160.0000 | 130.0000 | 120.0000 | 80.0000 | 55.0000 | 92.4378 |

| 13 | 342.1737 | 386.2429 | 340.0000 | 300.0000 | 243.0000 | 160.0000 | 130.0000 | 120.0000 | 80.0000 | 55.0000 | 84.4166 |

| 14 | 262.1737 | 306.2429 | 340.0000 | 300.0000 | 243.0000 | 160.0000 | 130.0000 | 120.0000 | 80.0000 | 53.1527 | 70.5693 |

| 15 | 182.1737 | 226.2429 | 340.0000 | 299.9639 | 243.0000 | 160.0000 | 130.0000 | 120.0000 | 80.0000 | 53.0342 | 58.4148 |

| 16 | 150.0000 | 146.2429 | 294.7660 | 249.9639 | 223.6700 | 160.0000 | 129.6353 | 120.0000 | 80.0000 | 43.3613 | 43.6398 |

| 17 | 150.0000 | 135.0000 | 258.1720 | 249.5279 | 223.9121 | 160.0000 | 128.8682 | 120.0000 | 80.0000 | 13.8650 | 39.3459 |

| 18 | 150.0000 | 151.6366 | 298.4749 | 299.5279 | 243.0000 | 160.0000 | 129.7933 | 120.0000 | 80.0000 | 43.6183 | 48.0511 |

| 19 | 227.2425 | 231.6366 | 299.3393 | 300.0000 | 243.0000 | 160.0000 | 130.0000 | 120.0000 | 80.0000 | 43.5728 | 58.7914 |

| 20 | 307.2425 | 311.6366 | 340.0000 | 300.0000 | 243.0000 | 160.0000 | 130.0000 | 120.0000 | 80.0000 | 55.0000 | 74.8793 |

| 21 | 265.4293 | 301.1183 | 340.0000 | 300.0000 | 243.0000 | 160.0000 | 130.0000 | 120.0000 | 80.0000 | 55.0000 | 70.5476 |

| 22 | 185.4293 | 221.1183 | 263.3759 | 250.0000 | 225.8767 | 160.0000 | 129.8685 | 120.0000 | 80.0000 | 41.1109 | 48.7801 |

| 23 | 150.0000 | 141.1183 | 183.3759 | 200.0000 | 223.4887 | 155.9437 | 128.7427 | 120.0000 | 50.0000 | 11.1109 | 31.7806 |

| 24 | 150.0000 | 135.0000 | 173.1056 | 180.5739 | 173.7249 | 118.1382 | 128.6826 | 120.0000 | 20.0000 | 10.0000 | 25.2260 |

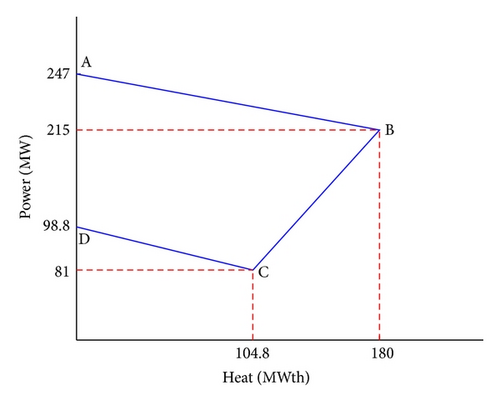

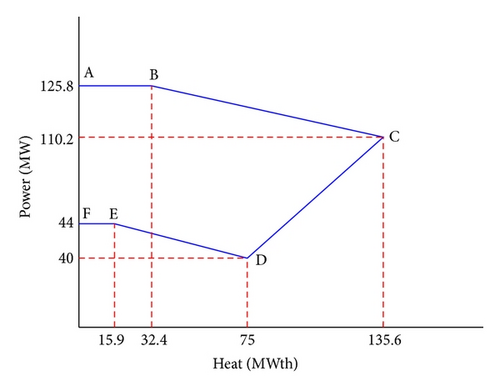

Example 2. This example is 11-unit system (eight conventional thermal units, two CHP units, and one heat-only unit) for solving the CHPDED, CHPDEED, and CHPPDED problems using DE-SQP method. We shall solve the CHPDEED problem when w = 0.5, in addition to the CHPDED and CHPPDED problems which correspond to w = 1 and w = 0, respectively. The technical data of conventional thermal units, the matrix B, and the demand are taken from the 10-unit system presented in [24]. The 5th and 8th conventional units in [24] were replaced by two CHP units. The technical data of the two CHP units and the heat-only unit are taken from [17] and are given in Table 3. The heat demand for 24 hours is given in Table 4. The feasible operating regions of the two CHP units are given in Figures 1 and 2 (see [4, 14]).

| CHP units | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| j = 1 | 2650 | 14.5 | 0.0345 | 4.2 | 0.030 | 0.031 | 0.00015 | 0.0015 | 70 |

| j = 2 | 1250 | 36 | 0.0435 | 0.6 | 0.027 | 0.011 | 0.00015 | 0.0015 | 50 |

| Heat-only units | |||||||||

| k = 1 | 2695.2 | 0 | 950 | 2.0109 | 0.038 | 0.0008 | 0.0010 | ||

| Time (h) | Demand (MWth) |

|---|---|

| 1 | 390 |

| 2 | 400 |

| 3 | 410 |

| 4 | 420 |

| 5 | 440 |

| 6 | 450 |

| 7 | 450 |

| 8 | 455 |

| 9 | 460 |

| 10 | 460 |

| 11 | 470 |

| 12 | 480 |

| 13 | 470 |

| 14 | 460 |

| 15 | 450 |

| 16 | 450 |

| 17 | 420 |

| 18 | 435 |

| 19 | 445 |

| 20 | 450 |

| 21 | 445 |

| 22 | 435 |

| 23 | 400 |

| 24 | 400 |

The best solutions of the CHPDED, CHPDEED, and CHPPDED problems for DE-SQP algorithm are given in Tables 5, 6, and 7, respectively. The best cost, the amount of emission, and the transmission line losses are also given in Tables 5–7. It is seen that the cost is 2.5257 × 106 $ under CHPDED, but it increases to 2.6945 × 106 $ under CHPPDED. The emission obtained from CHPDED is 2.8287 × 105 lb, but it decreases to 2.4195 × 105 lb under CHPPDED. Under the CHPDEED problem, the cost is 2.5295 × 106 $ which is more than 2.5257 × 106 $ and less than 2.6945 × 106 $. Moreover, the emission is 2.7209 × 105 lb which is less than 2.8287 × 105 lb and more than 2.4195 × 105 lb.

| H | Loss | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 150.0000 | 135.0000 | 74.5372 | 72.0784 | 124.5129 | 124.4302 | 20.0000 | 10.0000 | 236.8041 | 110.1974 | 21.5630 | 57.3450 | 135.5994 | 197.0556 |

| 2 | 150.0000 | 135.0000 | 98.1135 | 122.0784 | 122.2113 | 101.6179 | 48.2025 | 10.0000 | 236.8011 | 110.1974 | 24.2248 | 57.3614 | 135.5994 | 207.0392 |

| 3 | 150.0000 | 135.0000 | 178.1135 | 172.0784 | 120.7640 | 98.7468 | 78.2025 | 10.0000 | 235.3275 | 110.1974 | 30.4319 | 65.6496 | 135.5994 | 208.7509 |

| 4 | 150.0000 | 135.0000 | 188.0106 | 218.5077 | 160.0000 | 126.3142 | 80.0000 | 40.0000 | 235.2182 | 110.1974 | 37.2496 | 66.2643 | 135.5994 | 218.1363 |

| 5 | 150.0000 | 135.0000 | 268.0106 | 244.7145 | 128.0292 | 129.9179 | 80.0000 | 42.2707 | 233.2313 | 110.1974 | 41.3736 | 77.4390 | 135.5994 | 226.9616 |

| 6 | 150.0000 | 135.0000 | 334.4706 | 294.7145 | 160.0000 | 130.0000 | 80.0000 | 48.0931 | 235.6609 | 110.1974 | 50.1383 | 63.7746 | 135.5994 | 250.6260 |

| 7 | 150.0000 | 199.1593 | 340.0000 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 49.7990 | 238.0991 | 110.1974 | 55.2549 | 50.0614 | 135.5994 | 264.3392 |

| 8 | 189.7336 | 229.5497 | 340.0000 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 242.2569 | 110.1974 | 60.7377 | 26.6766 | 135.5994 | 292.7240 |

| 9 | 265.3596 | 309.5497 | 340.0000 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 247.0000 | 110.1974 | 73.1068 | 0.0 | 135.5994 | 324.4006 |

| 10 | 303.6024 | 378.5162 | 340.0000 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 246.9410 | 110.1974 | 82.2580 | 0.3317 | 135.5994 | 324.0689 |

| 11 | 368.8317 | 405.6648 | 340.0000 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 247.0000 | 110.1974 | 90.6945 | 0.0 | 135.5994 | 334.4006 |

| 12 | 367.7179 | 455.4472 | 340.0000 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 247.0000 | 110.1974 | 95.3624 | 0.0 | 135.5994 | 344.4006 |

| 13 | 352.0071 | 385.0034 | 340.0000 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 247.0000 | 110.1974 | 87.2079 | 0.0 | 135.5994 | 334.4006 |

| 14 | 272.0071 | 305.0034 | 340.0000 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 244.9090 | 110.1974 | 73.1169 | 11.7604 | 135.5994 | 312.6402 |

| 15 | 193.6233 | 225.0034 | 340.0000 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 242.9121 | 110.1974 | 60.7362 | 22.9917 | 135.5994 | 291.4089 |

| 16 | 150.0000 | 145.0034 | 296.8330 | 250.8703 | 160.0000 | 129.9573 | 80.0000 | 43.4626 | 233.2660 | 110.1974 | 45.5900 | 77.2439 | 135.5994 | 237.1567 |

| 17 | 150.0000 | 135.0000 | 260.0109 | 250.0000 | 160.0000 | 100.0000 | 80.0000 | 40.9143 | 235.3888 | 110.1974 | 41.5121 | 65.3046 | 135.5994 | 219.0959 |

| 18 | 150.0000 | 151.0646 | 319.4485 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 40.0577 | 237.4722 | 110.1974 | 50.2419 | 53.5869 | 135.5994 | 245.8137 |

| 19 | 229.4141 | 231.0646 | 313.3779 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 46.0360 | 237.0065 | 110.1974 | 61.0988 | 56.2062 | 135.5994 | 253.1943 |

| 20 | 309.4141 | 311.0646 | 340.0000 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 247.0000 | 116.9757 | 77.4552 | 0.0 | 90.7694 | 359.2306 |

| 21 | 272.4577 | 300.8037 | 340.0000 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 247.0000 | 111.8344 | 73.0959 | 0.0 | 124.7723 | 320.2277 |

| 22 | 192.4577 | 220.8037 | 260.6669 | 250.0000 | 160.0000 | 124.1397 | 80.0000 | 45.9763 | 234.6724 | 110.1974 | 50.9154 | 69.3338 | 135.5994 | 230.0668 |

| 23 | 150.0000 | 140.8037 | 180.6669 | 200.0000 | 127.6584 | 130.0000 | 50.0000 | 40.0000 | 236.4213 | 110.1974 | 33.7482 | 59.4980 | 135.5994 | 204.9026 |

| 24 | 150.0000 | 135.0000 | 100.6669 | 177.0362 | 123.2649 | 128.6636 | 42.3316 | 10.0000 | 234.6572 | 109.5624 | 27.1834 | 69.4196 | 135.0513 | 195.5291 |

- Cost ($) = 2.5257 × 106. Emission (lb) = 2.8287 × 105. Total loss (MW) = 1.3443 × 103.

| t | Loss | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 150.0000 | 135.0000 | 77.5875 | 65.0188 | 122.5177 | 129.0996 | 20.0000 | 10.0000 | 238.1722 | 110.1974 | 21.5935 | 49.6499 | 135.5994 | 204.7506 |

| 2 | 150.0000 | 135.0000 | 73.0000 | 115.0188 | 123.4971 | 126.6027 | 50.0000 | 13.3209 | 237.5744 | 110.1974 | 24.2115 | 53.0122 | 135.5994 | 211.3884 |

| 3 | 150.0000 | 135.0000 | 135.6390 | 143.2389 | 123.5028 | 130.0000 | 80.0000 | 43.3209 | 237.2689 | 110.1974 | 30.1680 | 54.7308 | 135.5994 | 219.6698 |

| 4 | 150.0000 | 135.0000 | 197.2495 | 193.2389 | 160.0000 | 130.0000 | 80.0000 | 46.3828 | 241.1942 | 110.1974 | 37.2630 | 32.6533 | 135.5994 | 251.7473 |

| 5 | 150.0000 | 135.0000 | 227.7945 | 243.2389 | 160.0000 | 130.0000 | 80.0000 | 46.9362 | 238.0276 | 110.1974 | 41.1946 | 50.4634 | 135.5994 | 253.9371 |

| 6 | 150.0000 | 148.0006 | 307.4622 | 293.2389 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 244.2131 | 110.1974 | 50.1122 | 15.6745 | 135.5994 | 298.7261 |

| 7 | 153.7715 | 216.0682 | 309.3974 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 242.8740 | 110.1974 | 55.3090 | 23.2061 | 135.5994 | 291.1945 |

| 8 | 204.6091 | 224.9723 | 327.2185 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 244.8130 | 110.1974 | 60.8102 | 12.3003 | 135.5994 | 307.1003 |

| 9 | 269.9376 | 304.9723 | 340.0000 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 247.0000 | 110.1974 | 73.1072 | 0.0 | 135.5994 | 324.4006 |

| 10 | 302.8816 | 379.1708 | 340.0000 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 247.0000 | 110.2066 | 82.2590 | 0.0 | 135.5384 | 324.4616 |

| 11 | 374.8455 | 398.1777 | 340.0000 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 247.0000 | 111.6628 | 90.6861 | 0.0 | 125.9076 | 344.0924 |

| 12 | 396.3649 | 416.9874 | 340.0000 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 247.0000 | 119.8750 | 95.2273 | 0.0 | 71.5941 | 408.4059 |

| 13 | 353.1036 | 382.7187 | 340.0000 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 247.0000 | 111.3732 | 87.1956 | 0.0 | 127.8228 | 342.1772 |

| 14 | 273.1036 | 302.7187 | 339.8378 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 246.2562 | 110.1974 | 73.1138 | 4.1831 | 135.5994 | 320.2175 |

| 15 | 213.0095 | 222.7187 | 321.3321 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 244.5974 | 110.1974 | 60.8552 | 13.5127 | 135.5994 | 300.8879 |

| 16 | 150.0000 | 142.7187 | 291.8181 | 250.0000 | 160.0000 | 130.0000 | 80.0000 | 46.1485 | 238.7061 | 110.1974 | 45.5889 | 46.6476 | 135.5994 | 267.7530 |

| 17 | 150.0000 | 135.0000 | 228.5656 | 240.9760 | 160.0000 | 130.0000 | 80.0000 | 45.7659 | 240.7225 | 110.1974 | 41.2275 | 35.3065 | 135.5994 | 249.0941 |

| 18 | 150.0000 | 207.5152 | 294.3486 | 250.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 241.3976 | 110.1974 | 50.4588 | 31.5093 | 135.5994 | 267.8913 |

| 19 | 227.0251 | 235.5649 | 297.1019 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 242.1587 | 110.1974 | 61.0481 | 27.2289 | 135.5994 | 282.1716 |

| 20 | 307.0251 | 315.5649 | 340.0000 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 247.0000 | 114.8749 | 77.4649 | 0.00 | 104.6636 | 345.3364 |

| 21 | 270.9950 | 301.2766 | 340.0000 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55.0000 | 247.0000 | 112.8155 | 73.0871 | 0.00 | 118.2834 | 326.7166 |

| 22 | 190.9950 | 221.2766 | 260.0000 | 250.0000 | 157.3134 | 126.2505 | 80.0000 | 43.7439 | 239.1773 | 110.1974 | 50.9541 | 43.9973 | 135.5994 | 255.4033 |

| 23 | 150.0000 | 141.2766 | 180.0000 | 200.0000 | 154.2635 | 126.4607 | 51.1156 | 13.7439 | 238.8386 | 110.1974 | 33.8966 | 45.9019 | 135.5994 | 218.4987 |

| 24 | 150.0000 | 135.0000 | 100.0000 | 150.0000 | 118.3525 | 129.7054 | 78.8178 | 10.0000 | 235.4040 | 103.7586 | 27.0385 | 65.2191 | 130.0411 | 204.7398 |

- Cost ($) = 2.5295 × 106. Emission (lb) = 2.7209 × 105. Total loss (MW) = 1.3439 × 103.

| H | Loss | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 150.0000 | 135.0000 | 73.0000 | 60.0000 | 84.3406 | 63.6438 | 64.0384 | 55 | 247 | 125.8 | 21.8228 | 0.0 | 31.4722 | 358.5278 |

| 2 | 150.0000 | 135.0000 | 75.2831 | 75.5559 | 107.4058 | 83.4606 | 80.0000 | 55 | 247 | 125.8 | 24.5054 | 0.0 | 32.4074 | 367.5926 |

| 3 | 150.0000 | 146.7217 | 108.1787 | 108.2058 | 154.2362 | 113.4606 | 80.0000 | 55 | 247 | 125.8 | 30.6030 | 0.0 | 18.2661 | 391.7339 |

| 4 | 187.3290 | 187.7229 | 135.7677 | 135.7127 | 160.0000 | 130.0000 | 80.0000 | 55 | 247 | 125.8 | 38.3323 | 0.0 | 32.4074 | 387.5926 |

| 5 | 209.9448 | 210.5929 | 152.0706 | 152.2866 | 160.0000 | 130.0000 | 80.0000 | 55 | 247 | 125.8 | 42.6949 | 0.0 | 32.4074 | 407.5926 |

| 6 | 252.6588 | 252.9491 | 188.3610 | 188.4287 | 160.0000 | 130.0000 | 80.0000 | 55 | 247 | 125.8 | 52.1977 | 0.0 | 25.5244 | 424.4756 |

| 7 | 272.2261 | 272.7171 | 208.2382 | 208.3486 | 160.0000 | 130.0000 | 80.0000 | 55 | 247 | 125.8 | 57.3300 | 0.0 | 26.7637 | 423.2363 |

| 8 | 290.5854 | 291.0583 | 229.5277 | 229.7367 | 160.0000 | 130.0000 | 80.0000 | 55 | 247 | 125.8 | 62.7082 | 0.0 | 32.4074 | 422.5926 |

| 9 | 323.8400 | 324.1415 | 276.1324 | 276.3023 | 160.0000 | 130.0000 | 80.0000 | 55 | 247 | 125.8 | 74.2162 | 0.0 | 25.5487 | 434.4513 |

| 10 | 346.7105 | 346.8973 | 313.1106 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55 | 247 | 125.8 | 82.5184 | 0.0 | 32.4074 | 427.5926 |

| 11 | 379.2210 | 379.5185 | 340.0000 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55 | 247 | 125.8 | 90.5395 | 0.0 | 29.4012 | 440.5988 |

| 12 | 403.5504 | 403.8291 | 340.0000 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55 | 247 | 125.8 | 95.1796 | 0.0 | 31.9845 | 448.0155 |

| 13 | 361.7512 | 362.0812 | 337.4700 | 300.0000 | 160.0000 | 130.0000 | 80.0000 | 55 | 247 | 125.8 | 87.1023 | 0.0 | 32.0189 | 437.9811 |

| 14 | 323.7805 | 324.1252 | 276.7607 | 275.7492 | 160.0000 | 130.0000 | 80.0000 | 55 | 247 | 125.8 | 74.2157 | 0.0 | 25.5863 | 434.4137 |

| 15 | 291.7264 | 292.3796 | 231.0966 | 225.7492 | 160.0000 | 130.0000 | 80.0000 | 55 | 247 | 125.8 | 62.7519 | 0.0 | 31.8710 | 418.1290 |

| 16 | 229.7976 | 230.1379 | 167.7688 | 175.7492 | 160.0000 | 130.0000 | 80.0000 | 55 | 247 | 125.8 | 47.2535 | 0.0 | 31.3306 | 418.6694 |

| 17 | 210.0699 | 210.4074 | 152.1822 | 152.2351 | 160.0000 | 130.0000 | 80.0000 | 55 | 247 | 125.8 | 42.6946 | 0.0 | 32.3578 | 387.6422 |

| 18 | 252.7542 | 253.2318 | 188.2091 | 188.2081 | 160.0000 | 130.0000 | 80.0000 | 55 | 247 | 125.8 | 52.2031 | 0.0 | 29.7791 | 405.2209 |

| 19 | 288.2429 | 288.7410 | 226.6332 | 237.2113 | 160.0000 | 130.0000 | 80.0000 | 55 | 247 | 125.8 | 62.6285 | 0.0 | 27.4724 | 417.5276 |

| 20 | 335.1319 | 335.4397 | 294.6392 | 287.2113 | 160.0000 | 130.0000 | 80.0000 | 55 | 247 | 125.8 | 78.2222 | 0.0 | 31.3390 | 418.6610 |

| 21 | 332.6192 | 333.0535 | 282.3523 | 252.7233 | 160.0000 | 130.0000 | 80.0000 | 55 | 247 | 125.8 | 74.5483 | 0.0 | 32.3100 | 412.6900 |

| 22 | 252.6192 | 253.0535 | 202.3523 | 202.7233 | 149.4115 | 112.3565 | 80.0000 | 55 | 247 | 125.8 | 52.3163 | 0.0 | 27.3503 | 407.6497 |

| 23 | 172.6192 | 173.0535 | 122.3523 | 152.7233 | 135.8629 | 102.0552 | 80.0000 | 55 | 247 | 125.8 | 34.4664 | 0.0 | 25.1547 | 374.8453 |

| 24 | 150.0000 | 135.0000 | 90.3380 | 102.7233 | 128.7354 | 96.7805 | 80.0000 | 55 | 247 | 125.8 | 27.3771 | 0..0 | 31.5331 | 368.4669 |

- Cost ($) = 2.6945 × 106. Emission (lb) = 2.4195 × 105. Total loss (MW) = 1.3684 × 103.

6. Conclusion

This paper presents a hybrid method combining differential evolution (DE) and sequential quadratic programming (SQP) for solving dynamic dispatch (CHPDED, CHPDEED, and CHPPDED) problems with valve-point effects including generator ramp rate limits. In this paper, DE is first applied to find the best solution. This best solution is given to SQP as an initial condition that fine tunes the optimal solution at the final. The feasibility and efficiency of the DE-SQP were illustrated by conducting case studies with system consisting of eight conventional thermal units, two CHP units, and one heat-only unit.

Conflict of Interests

The authors declare that there is no conflict of interests regarding the publication of this paper.

Acknowledgment

This work was funded by the Deanship of Scientific Research (DSR), King Abdulaziz University, Jeddah, under Grant no. (130-107-D1434). The authors, therefore, acknowledge with thanks DSR technical and financial support.