Effect of a High Magnetic Field on Eutectoid Point Shift and Texture Evolution in 0.81C-Fe Steel

Abstract

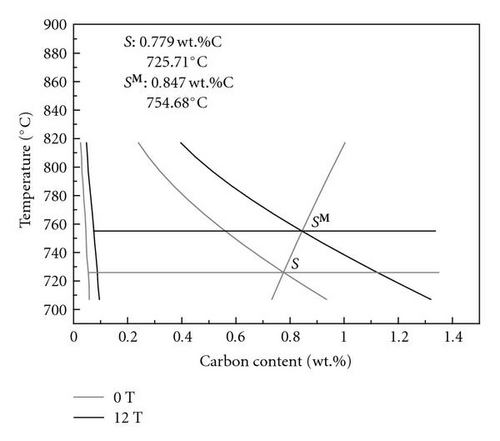

A 12 T magnetic field has been applied to the annealing process of a 0.81%C-Fe (wt.%). It is found that the magnetic field shifts the eutectoid carbon content from 0.77 wt.% to 0.83 wt.%. The statistical thermodynamic calculations were performed to calculate the eutectoid temperature change by the magnetic field. Calculation shows that the increase of the eutectoid temperature by a 12 T field is 29∘C. Synchrotron radiation measurements were performed to measure the pole figures of the samples and were analyzed by MAUD to determine the bulk texture of the ferrite phase In the field-treated and non field-treated samples. Results show that although there is no specific preferred orientation appearing by applying the magnetic field, slight enhancement of 〈001〉 fiber component occurs in both the sample normal direction (ND) and the transverse direction (TD). This effect might be related to the magnetic dipolar interaction between Fe atoms in the transverse field direction.

1. Introduction

Study of the effect of a high magnetic field on diffusional phase transformation in steels has attracted attention in recent years. So far most efforts have been made on revealing the effect of a magnetic field on phase transformation behaviors and microstructural characters in hypoeutectoid steels [1–8]. Results have shown that the magnetic field applied can increase the austenite-to-ferrite transformation temperature [1–3], accelerate the transformation process [5–7], and change the morphology and grain boundary character distribution of the product phases [5, 8]. In this work, a quasi-eutectoid steel, 0.81C-Fe, was selected and heat-treated without and with a 12 T magnetic field. The shift of the eutectoid point by the application of a high magnetic field was experimentally investigated and theoretically calculated. The influence of the magnetic field applied on the evolution of the texture of ferrite has been investigated by means of synchrotron radiation measurements.

2. Experimental

The material used in this study was a plain eutectoid steel with chemical composition (wt.%) 0.81%C, 0.22%Si, 0.20%Mn, 0.05%Cr, 0.014Cu, 0.019%P, 0.003%S, and bal. Fe. It was prepared by induction casting. The cast rod was twice forged in the longitudinal direction followed by the radial direction, in the temperature range 1100–868°C to homogenize and refine the microstructure. Samples of dimensions 30 mm × 10 mm × 2 mm were cut from the hot forged bar. They were austenitized at 830°C for 50 minutes and cooled at a rate of 2, 5, 10, and 23°C/min without and with a 12-Tesla high magnetic field. During the heat treatment, the samples were placed in the central (zero magnetic force) region (200 mm long in the field direction).

The transformed microstructure is observed with an Olympus BX61 microscope equipped with a digital camera and the analysis software package for materials science. The crystal structures of proeutectoid ferrite and proeutectoid cementite are confirmed by the indexing of the EBSD Kikuchi patterns acquired with a Jeol JSM 6500F FEG-SEM equipped with the HKL Channel 5 EBSD system. The area percentages of bulk ferrite appearing in the magnetic field-treated samples and the lamellar spacing of pearlite in both the field- and the non-field-treated samples were measured. The measurement was performed in 20 images of each sample to obtain a statistical representation of the results. As the lamellar spacing in each micrograph varies due to both the changing of formation temperature and the angles at which the lamellae intersect the sample-sectioning plane, the smallest lamellar spacing in each micrograph was measured. This smallest lamellar spacing obtained is related either to the pearlite formed at the very end of the transformation or to the angle, close to right angle, at which lamellae intersect the sample plane.

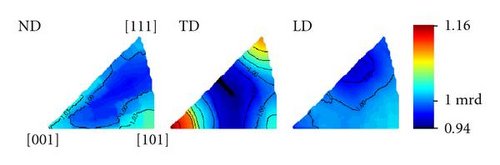

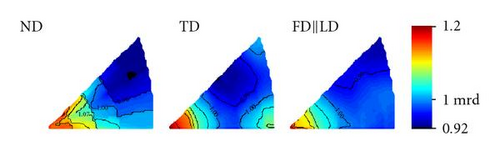

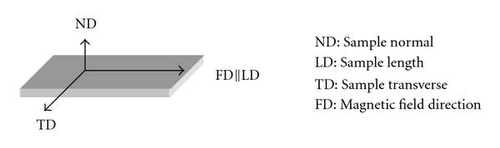

Synchrotron radiation measurements were performed at the Hamburg Synchrotron Radiation Laboratory (HASYLAB), German Electron Synchrotron (DESY), Hamburg, Germany, to measure the incomplete pole figures of the samples cooled at 2°C/min without and with a 12-Tesla high magnetic field. The measurements were carried out in transmission mode with a monochromatic synchrotron beam [9] of wavelength 0.164 Å (75.59 keV). The collimator was set to an area of 1 × 1 mm. The first slit was set to 1 × 1 mm and the second was set to 2 × 2 mm. During the measurement, the sample was rotated from −80° to +80° around the ω axis with a step size of 2°/step and a measurement time of 4 s/step. Data were recorded with an area detector (34.5 cm in diameter) placed behind the sample, at a distance of 115.5 cm. The data were analyzed with MAUD (“Materials Analysis Using Diffraction” program package by Lutterotti et al., University of Trento [10, 11]) and represented in inverse pole figures.

3. Results and Discussion

3.1. The Eutectoid Point Shift under a 12 T Magnetic Field

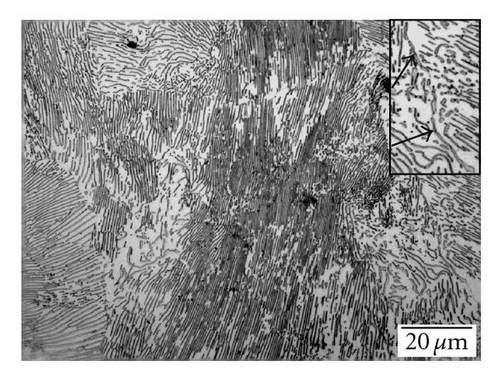

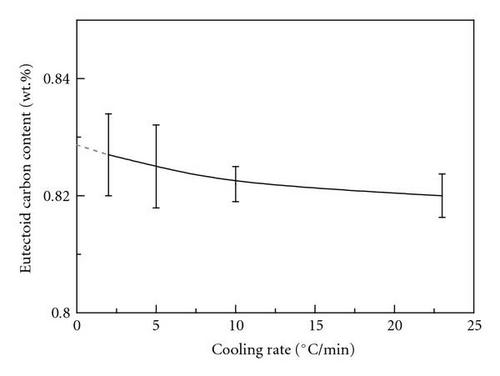

Figure 1 shows the microstructures of samples cooled at 2°C/min without (a) and with (b) a 12 T magnetic field. Besides the main constituent of lamellar pearlite, the striking difference between the two micrographs is that in the non-field-treated specimen we observed a slight amount of proeutectoid cementite (arrowed in the zoom image in the top right corner of Figure 1(a)), which characterizes the hypereutectoid microstructure, while in the field-treated specimen we find some bulk ferrite between pearlite colonies (white areas circled in Figure 1(b)) that is the typical component of hypoeutectoid microstructure, instead of proeutectoid cementite. The crystal structures of proeutectoid cementite and the proeutectoid ferrite observed with the optical microscope were further confirmed by the indexing of their Kikuchi patterns by EBSD technique. The average area percentages of the bulk ferrite measured in the field-treated specimens at various cooling rates are shown in Table 1. It is seen that the amount of the bulk ferrite decreases with the increase of the cooling rate. This is the normal influence of the cooling rate on proeutectoid transformation. The presence of the bulk ferrite in the field-treated specimens suggests that the magnetic field shifts the eutectoid point of the Fe-C binary system beyond the carbon content of the tested material (0.81C%wt.). Using the lever law, the carbon contents of the new eutectoid point under various cooling rates were calculated and displayed also in Table 1. As the carbon content of the equilibrium eutectoid point is obtained under equilibrium transformation condition, that is, under extreme slow cooling condition, the variation of the eutectoid carbon content with cooling rate is plotted in Figure 2 and extrapolated to zero cooling rate to obtain the equilibrium eutectoid carbon content. The extrapolated equilibrium eutectoid carbon content is 0.8287%(wt.). This value is noticeably different from that calculated in [3] (0.795 wt.%).

| Cooling rate (°C/min) | Area percentage of ferrite (%) | Eutectoid carbon content (wt.%) |

|---|---|---|

| 2 | 2.153 ± 0.850 | 0.827 ± 0.0070 |

| 5 | 1.905 ± 0.857 | 0.825 ± 0.0071 |

| 10 | 1.519 ± 0.372 | 0.822 ± 0.0030 |

| 23 | 1.277 ± 0.452 | 0.820 ± 0.0037 |

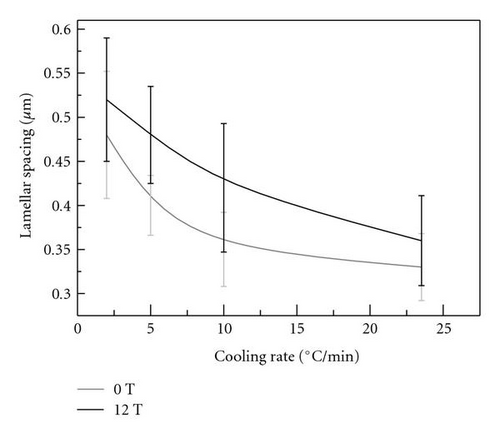

The lamellar spacing of samples fully austenitized and cooled at various cooling rates (2, 5, 10, and 23°C/min) without and with a 12 T magnetic field was also measured and is shown in Figure 3. It is seen that, at all the cooling rates tested, the lamellar spacing obtained is larger with the magnetic field than without. As the austenite to pearlite transformation is diffusional and involves the formation of the carbon-depleted ferrite and carbon-rich cementite, the lamellar spacing of pearlite depends on the diffusion length of carbon atoms that is temperature related. Therefore, the larger spacing corresponds to the higher formation temperature. This lamellar spacing increase resulting from the magnetic field applied evidences that the magnetic field also shifts the eutectoid point to the high temperature side. As it is almost impossible to measure—in temperature scale—the eutectoid point shift in situ under a high magnetic field, its determination through theoretical calculation may be useful.

3.2. Texture Evolution under the Effect of the Applied Magnetic Field

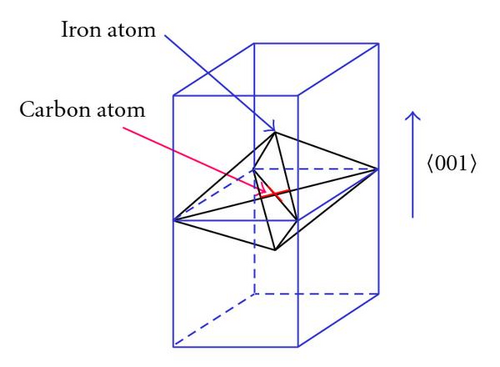

Figure 5 shows the inverse pole figures of the samples heat-treated at slow cooling rate (2°C/min) without and with the 12 T magnetic field and the corresponding sample coordinate system. Despite the textures are relatively weak, it is clearly seen that under the magnetic field there is slight enhancement of 〈001〉 fiber component in both the sample normal direction (ND) and the widthwise or transverse direction (TD), as seen in Figure 5(b). This result corroborates earlier results we found in a medium carbon plain steel heat-treated under a 12 T magnetic field [8]. Actually in the present case, both ND and TD are transverse field directions. It is known that each Fe atom carries a magnetic moment. Under the applied magnetic field, these moments tend to align along the field direction. Then, there exists the dipolar interaction between neighboring Fe atoms. They attract each other along the field direction but repel each other along the transverse field directions (ND and TD in the present study). Correlatively, the distance between neighboring atoms tends to decrease along FD and increase along ND and TD to minimize the total energy of the system. For ferrite, the carbon atoms are located in the octahedral interstices, as shown in Figure 6 [8]. The interstices are flat in the 〈001〉 direction. The occupation of the carbon atom in this interstice exerts an expansion stress on its neighboring iron atoms along the 〈001〉 direction. This gives rise to the lattice distortion and creates distortion energy. If such a 〈001〉 direction of a grain was parallel to the transverse field direction (ND or TD), the lattice distortion energy would be reduced through increasing the atomic spacing in such 〈001〉 direction by the magnetic field. Therefore, the nucleation and growth of the grains having such 〈001〉 parallel to the ND and TD are energetically favored by the magnetic field. In this way, the 〈001〉 component is enhanced in the transverse field directions (ND and TD).

4. Summary

The eutectoid carbon content and temperature of Fe-C binary system under a magnetic field have been examined quantitatively for the first time in the present work. The appearance of the proeutectoid ferrite confirms the shift of eutectoid carbon content. Under a 12 T magnetic field, it shifts from 0.77 wt.%C to 0.8287 wt.%C (determined from the experimental data). The increase of the pearlite lamellar spacing by the magnetic field qualitatively evidences the increase of the eutectoid temperature. By making use of the quasi-chemical model to calculate the corresponding activities of Fe and carbon in the related phases and considering the magnetic field influence through magnetic Gibbs free energy determined by the magnetization of the corresponding phases, the new phase equilibrium is calculated. Calculation shows that the increase of the eutectoid temperature by a 12 T field is 28.97°C.

In addition, the magnetic field enhances the 〈001〉 texture component along the sample normal and transverse directions that are both transverse field directions. This results from the dipolar interaction of the magnetic moments carried by the Fe atoms. The repelling interaction between Fe atoms in the transverse direction increases the atomic spacing that mitigates the lattice distortion induced by the solution of carbon atoms in the transverse field direction.

Acknowledgments

The authors acknowledge the National Science Fund for Distinguished Young Scholars (no. 50325102), NSF of China (no. 50234020 and 50571024), and PRA MX04-02 Project. They specially thank HASYLAB at DESY, Hamburg, Germany, for synchrotron pole figure measurements.