Materials used to simulate physical properties of human skin

Abstract

Background

For many applications in research, material development and testing, physical skin models are preferable to the use of human skin, because more reliable and reproducible results can be obtained.

Purpose

This article gives an overview of materials applied to model physical properties of human skin to encourage multidisciplinary approaches for more realistic testing and improved understanding of skin–material interactions.

Methods

The literature databases Web of Science, PubMed and Google Scholar were searched using the terms ‘skin model’, ‘skin phantom’, ‘skin equivalent’, ‘synthetic skin’, ‘skin substitute’, ‘artificial skin’, ‘skin replica’, and ‘skin model substrate.’ Articles addressing material developments or measurements that include the replication of skin properties or behaviour were analysed.

Results

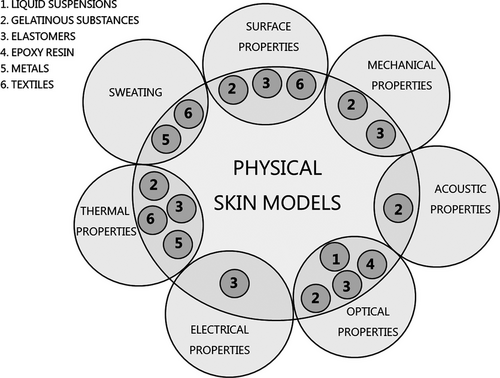

It was found that the most common materials used to simulate skin are liquid suspensions, gelatinous substances, elastomers, epoxy resins, metals and textiles. Nano- and micro-fillers can be incorporated in the skin models to tune their physical properties.

Conclusion

While numerous physical skin models have been reported, most developments are research field-specific and based on trial-and-error methods. As the complexity of advanced measurement techniques increases, new interdisciplinary approaches are needed in future to achieve refined models which realistically simulate multiple properties of human skin.

Tests on animals, humans, cadavers, and explants have been traditionally used to study materials-skin interactions 1-6. Such studies were useful in establishing safety margins and improved the characterisation of skin. However, experiments on human and animal skin raise ethical issues, are difficult to perform and the results are highly variable due to inherent skin variability. In the last decades, significant progress has been made in the reproduction of skin by culturing cells in vitro. Cell cultures simulating skin are commercially available and used for research and testing as well as for clinical purposes 7, 8. Despite their biological relevance, these skin models have still important limitations. For example, most of their physical properties have not yet come close to those of real skin and are also characterised by large variations. In addition, they are expensive and difficult to store and handle. This type of skin models is not yet suitable for experiments under realistic physical conditions. Models based on biologically inactive materials, which we call physical skin models in the following, are often preferable. By physical skin models, we understand non-living materials or physical systems that are able to reproduce one or more of the skin's properties, functions or behaviour. In the literature, such models are called skin model, skin phantom, skin equivalent, synthetic skin, skin substitute, artificial skin, skin replica, skin model substrate etc. depending on the research field.

Physical models of human skin have been proposed and described in numerous studies concerning testing and development of materials and methods. However, only in a few cases, the development and characterisation of the models themselves was the main research goal; usually, physical skin models were developed for the needs of testing, calibration, quality check of devices, or teaching.

Physical skin models allow obtaining long-term stability, lower costs, easy storage and manipulation and a better control over their physical properties. Therefore, these models are usually characterised by better reproducibility and reliability. Moreover, they are devoid of the above mentioned ethical issues.

This review article gives an overview of materials typically used to simulate human skin in engineering and material research and development. We summarise and discuss the progresses made in replicating skin-materials interactions to improve the knowledge transfer between different fields.

Human Skin: Basic Properties and Functions

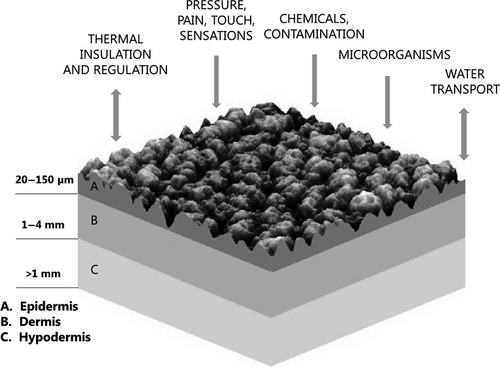

Human skin has complex properties and functions and is in a continuous change due to environmental, biochemical, and psychological factors 9, 10. Figure 1 shows schematically the human skin structure and important interactions with the environment.

As a result of this complexity, assigning exact numeric values for the properties as it is common for nonbiological materials is of limited use. Instead, statistical investigations based on subject studies and physical and numerical simulations are more meaningful to characterise the skin. Generally, skin properties are anisotropic, as well as time, site, temperature, and measurement method dependent. Furthermore, the presence of substances on the skin (e.g. sweat, water, dust, cosmetics) can strongly affect skin properties and interactions with the environment.

Human skin structure is organised in three main layers: epidermis, dermis and hypodermis. The epidermis is thin, with a typical thickness of about 20–150 μm 11, depending mostly on the body site except for the palms and soles that are thicker 12. It mainly consists of keratinocytes, which differentiate in the stratum basale and then migrate outwards changing their shape, physiology and functions. Dead keratinocytes, the corneocytes, are stored in the outermost layer forming the stratum corneum, which has a thickness of about 14 μm 13. The thickness of the dermis varies between 1 and 4 mm. The dermis is built up of collagen and keratin fibres, which provide structural strength to the skin. The hypodermis or the fat layer lies below the dermis and helps protect the body from heat and cold, and from mechanical shocks 4, 13.

The main functions of the skin are: protection (against mechanical, thermal, and chemical impacts, UV radiation, microorganisms etc.), repair and adaptation (self-healing and change in composition and structure when injured or exposed to stresses), sensation through its mechanoreceptors, thermoreceptors and nociceptors) and temperature regulation (e.g. control of the sweating and perfusion rate). The skin is also responsible for the synthesis of vitamin D3 and the excretion of water, urea, ammonia and uric acid. Besides these functions, the appearance of the skin has important implications on social interaction providing information about the health, age, gender etc.

Phases in the Development of Skin Models

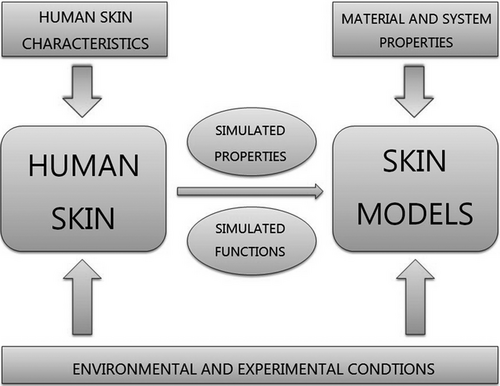

The development of skin models comprises several distinct phases. First of all, the main requirements such as skin characteristics, properties and functions, and environmental and experimental conditions have to be established. Table 1 summarises some of the most important requirements. The requirements can be based on the literature data and on the measurement systems specifications. Then, the materials and the processing methods have to be chosen accordingly. The third phase is the effective manufacturing and construction. This development phase is in feedback with the testing and characterisation phase in which simplified experiments are carried out to select the most promising skin models. The last phase in the development of the skin models is the validation. Validation of the skin models can be based on the comparison with in vivo skin, cadavers' skin, explants and excised skin, animals' skin (e.g. porcine skin), other validated skin models or on analytical calculations and theoretical modelling.

| Human skin characteristics | Simulated properties | Simulated functions | Environmental conditions | Experimental conditions |

|---|---|---|---|---|

|

Age Gender Body region Physical status -Fitness -Health Physiological status -Skin temperature -Sweating rate -Hydration -Sebum excretion |

Mechanical Optical Thermal Electrical Chemical Surface etc. |

Sensing Cooling Heating Protection Appearance etc. |

Temperature Relative humidity Air flow Precipitations Radiation etc. |

Parameters: -Speed -Time -Pressure -Frequency -Deformation -Hysteresis etc. Geometry: -Anthropomorphic -Simplified |

Figure 2 shows schematically the interplay of the factors summarised in Table 1. As discussed above, the properties of the human skin can vary over a wide range. For this reason, it is important to understand well the specifics of the skin to be simulated not only in all the relevant environmental and experimental conditions but also the behaviour of the physical skin models and of the materials they are made of.

Materials to Simulate Human Skin

From the material science point of view, skin is a very complex active open system consisting of highly inhomogeneous and anisotropic composite materials. Furthermore, the skin actively exchanges mass and heat with the body and the environment. Due to this complexity, physical skin models are often aimed at providing similar results to human skin while being strong simplifications that do not reflect the structure and the composition of the human skin. Physical skin models can be produced based on numerous combinations of materials, structures, and morphologies. There are not only skin models consisting of liquid suspensions, gelatinous substances, elastomers, resins, metals, and textiles incorporating nano- and micro-fillers but also uncommon skin models such as those based on albumen, or engineered skin models.

Liquid Suspensions

Various liquid suspensions have been used for simulating optical properties of tissues 14-17. Implicitly, to some extent, scattering and absorption properties of the skin are simulated. Suspensions of lipid, polymeric, and inorganic particles can be added in liquids such as water, milk or oils to obtain scattering properties similar to those of skin. Liquid based models can be produced using well-defined substances readily available commercially. Lipid solutions (used for intravenous delivery) 17, monodispersed polystyrene and titanium dioxide particles (used in various biomedical and chemical applications) 17, 18, are some of the most used scatterers. The light absorption is mainly determined by the liquid, but further control over it can be achieved by using absorbers and fluorophores of both biological and synthetic origin. Liquid skin models can provide good reproducibility for testing measurement systems and of theoretical models. However, as these models have to be embedded in solid recipients, care has to be taken as new interfaces are generated. Furthermore, these models are only useful for cases in which simulating the surface and mechanical properties are not critical.

Gelatinous Substances

Skin models based on gelatinous substances have an ability to interact with water, leading to reversible creation of gels. This property allows modifying and controlling various physical, mechanical and chemical properties, such as elastic modulus, hardness, optical, or surface properties. Specific behaviour of gelatine and related polymers can be influenced by pressure, pH and temperature, which can lead to further variability in properties 19, 20. Representatives of this group used in the production of skin models are gelatine, agar and agarose, collagens, and polyvinyl alcohol gels.

Gelatine

Gelatine is a protein produced by partial hydrolysis of collagen 21 and is an abundant component of the skin, bones, and the connective tissue. Dry gelatine can be stored for a long time without change in the quality.

Water-gelatine solutions closely simulate the density and viscosity of human tissue. Ordinance gelatine or ballistic gelatine has become the standard for ballistic testing and for wound ballistic forensic reconstructions 22. However, ballistic gelatine alone is not an accurate physical skin model. This is especially relevant at low kinetic energies, for example, for the testing of less lethal ammunition 23, 24. To overcome these limitations in a multilayer approach, a second layer made of a different material simulating the epidermis can be combined with the gelatine block 23-25.

The gelatine–water solutions simulate the deformation and kinetic dissipation of the projectile and provide a similar behaviour of cavity formation and tissue deformation that allows extrapolation of the results to those obtained with human tissue 22.

Other important areas in which gelatine mixtures are used as skin models are in elastography 26, testing of sun creams, self-tanning formulations and moisturisers 27, 28 and testing of adhesives 29, 30. Gelatine provides a matrix with density, stiffness, sound speed, absorption, and light scattering similar to that of human skin. Furthermore, through chemical or physical modification, it is possible to independently control each of these parameters that are essential for elastography.

Agar

Agar is a gelatinous substance made from seaweed polysaccharides. Skin models based on agar have been proposed first by Cubeddu et al. 31 as an alternative to resin and liquid skin models. Since then, many groups have adopted agar skin models 32, 33.

Although not very stable and with a limited life time, agar based skin models are versatile, easy to produce, with acoustic velocity, acoustic impedance, and density similar to those of skin 34. To produce the skin models, agar is mixed with deionised water or water based solutions (e.g. saline solution). In addition, other substances that allow the control of various properties can be incorporated. Chromophores and scattering media (synthetic and biological) are used to obtain a broad range of optical properties. Sodium chloride can be added to control the conductivity 33. The thermal transport can be studied by incorporating magnetic particles that are heated up using variable electro-magnetic fields 35.

Homogeneous mixture of the substances is obtained in the liquid phase that can then be poured in 3D-shaped moulds. Solidification occurs by polymerisation, which can be initiated by heating up to the boiling point in microwave ovens followed by rapid cooling (e.g. by immersion in cold water 31). The concentration of agar powder in solution is about a few percent and has an important influence on the density and mechanical properties of the resulting skin model.

The applications of agar based skin models are diverse, but limited to noncontact or light contact, without the necessity for long-term stability. Typical applications are related to optical imaging 31, 36, 37, thermal imaging and transport 38, 39, photoacoustic and ultrasound imaging 34, dosimetry 40, and body centric applications 32.

Polyvinyl alcohol gels

Poly(vinyl) alcohol (PVA) is a synthetic polymer commonly used in medical applications. It is highly soluble in water, but after cross-linking can form hydrogels 41. PVA cryogels are especially suitable to simulate tissue in magnetic resonance studies 42. Tissue mimicking models are very important for optimisation, testing, or development of imaging based diagnostic techniques. PVA is perceived as a skin and soft tissue phantom, e.g. for a wide group of magnetic resonance techniques 43, optical tomography 44, or X-ray examination 45. PVA is also used as a matrix in which further substances can be integrated. For example, Mazzoli et al. 46 used PVA as a matrix containing scatterers and absorbers. In addition, Indian ink was added to simulate melanin and pigmented lesions of malignant melanoma. It is also possible to tune the optical properties of PVA based products by adding nanoparticles 47.

Phantoms made of PVA are used in optoacoustics, such as acousto-optical elastography 48 or photoacoustic imaging 49. They are important models for ultrasound systems for testing, optimising, and educational purposes 34. PVA cryogels can be produced with properties similar to those of human skin 50. The mechanical properties of PVA cryogels are tunable within the range of those of soft tissues 44. Kim et al. proposed the usage of PVA thin films as a skin model to collect data for designing a computer game controller 51.

A big advantage of PVA cryogels is the possibility of adapting their scattering coefficient and stiffness by changing the amount of freeze/thaw cycles. PVA cryogels are relatively stable and easy to store.

Elastomers

Elastomers are polymers exhibiting rubber-like viscoelastic properties. The elastomers are either thermoplastic or thermoset, having the glass transition well below room temperature. This is directly related to their properties, which are similar to those of human skin 52-54. Moreover, elastomer-based composites allow tailoring the physical properties of skin models within a wide range.

The elastomers comprise a broad spectrum of natural and synthetic materials, inter alia silicones, polyurethanes, polyether block amides, polyisoprene, and polybutadiene. Human skin is primarily simulated by means of silicones and polyurethane.

Silicones

Silicones are inorganic-organic polymers containing Si, O, C, and H as well as other secondary elements 55. For skin models, silicone elastomers such as cross-linked polydimethylsiloxanes are widely used. Fillers are incorporated to strengthen and to tune the properties of silicone elastomers. Carbon black is added to control the electrical conductivity, titanium dioxide the dielectric constant, barium sulphate the radiopacity 56. Silicone is also applied for surface reproduction, allowing to produce surface morphologies with defined roughness as well as obtaining replicas directly from skin 57. This possibility is used to investigate the role of roughness in measurements and to develop skin models for which the surface properties are important.

Silicone alone has a refractive index similar to skin (1.3–1.5), which can be further tuned by incorporating other substances and structures that can alter the interaction with light (see Nano- and Micro-fillers section) and therefore simulate a broad range of human skin optical properties.

Skin models containing silicone are durable over long time periods and can be moulded to obtain various shapes from simple geometries to anthropomorphic, anatomical shapes.

The main advantages of silicone based models are related to the broad range of properties that can be simulated, easy manipulation, nontoxicity during and after preparation, and long-term stability. Silicone based skin models have been introduced to simulate skin in numerous applications such as optical imaging, measurement of the specific absorption rate 58, drug delivery 59, 60, needle penetration 61, 62, acoustic and photoacoustic imaging 34, tactile assessment 63, indentation 64, and friction 65-67.

Polyurethanes

Polyurethanes are addition polymers that can be thermosetting (in majority) or thermoplastic. A skin model based on polyurethanes was considered for an intradermal injection training system by Graham and Sabelman 68.

The properties of polyurethane based skin models can be influenced by using polyurethane elastomers with different soft to hard phase ratio, polyurethane sponges, or by incorporating reinforcing particles. Such an approach has been used for instance to develop tactile sensing robotic skin 69, 70. Due to their viscoelastic properties, polyurethanes can be used as mechanical skin models 71, 72, simulating the friction behaviour of human skin 57, 73-75. Lorica® artificial leather consisting of polyamide microfleece coated with polyurethane has been shown to realistically simulate human skin friction against textiles under dry conditions 56. In addition to friction properties, the Lorica® skin model reproduces surface properties of human skin (roughness, topography, water contact angle) and shows similar force-deformation characteristics 74, 76.

Polyurethane skin models can be found for training in the medical area, e.g. in intradermal injection, skin surgery or prediction of softness of real human skin, where polyurethane simulates the epidermis 68, 77, 78. Polyurethane sponges have been shown to simulate the human dermis in the biomechanical modelling of non-ballistic skin wounding 79, 80. The optical properties of polyurethanes (e.g. refractive index) make them an option also as optical skin models 78, 81.

Polyurethanes have a long shelf life and stability and due to their tunable properties, they could be useful in many other applications.

Epoxy Resin

Epoxy resins are components for obtaining cross-linked or thermoset plastics with a wide range of properties 82. As a skin model, they were proposed by White and Martin 83.

The properties of epoxy resins depend on the type of resin and can be controlled by mixing with other components, such as plasticisers and diluents 82.

Epoxy resins have a thermal diffusivity about 0.070–0.084 mm2/s, close to that of human skin, which is about 0.11 mm2/s, therefore making them a choice for thermal skin models 84, 85 or skin-simulant temperature sensor models for skin burn prediction 86, 87. Skin models based on epoxy resins have been used to observe the temperature profile inside or on the surface during cryogen spray cooling processes and to analyse the dependence of temperature changes on different conditions 85, 88, 89.

The refractive index of epoxy resin (1.54) is close to that of human skin and can be further adjusted by adding e.g. titanium dioxide and aluminium oxide particles into the material 90, 91. Epoxy resin based human skin models are used for Raman instrumentation calibration, validation of optical tomography (e.g. tomography of neonatal brain), or for calibration for near-infrared examinations 90-92. Skin phantoms made of epoxy resins are also suitable as the outer layer of breast phantoms used for the quality control of X-ray imaging systems or in education for mammography 93.

Metals

Metal-based skin models are mainly used in systems to probe thermal properties of clothing 94. The specific choice of the metal is not critical as these types of skin models rely strongly on the design of the whole system. The main advantage of these skin models is their high thermal responsiveness, stable properties, robustness, and the availability of technologies to produce various shapes. Heating and cooling elements can be incorporated and controlled via modern electronic systems. In addition, sweating and moving capabilities have been implemented. For example, in ISO 11092:201 a porous sintered metal plate, heated to 35°C is implemented as a ‘sweating guarded-hotplate’ that is used to assess the textile-physiological effects in steady state conditions simulating the evaporated sweat coming into contact with a textile.

Further on, such systems are often coupled with thermodynamical and thermophysiological models and placed in well controlled climatic conditions 95. Material testing and development, body monitoring systems, and human body thermophysiological response are the main areas of interest for these systems. Key parameters simulated by these models are skin temperature, sweating rate and heat transport. Some of the most important limitations are related to the mechanical properties and thermal inertia, which are not simulated realistically.

Textiles

Textile skin models based on natural (e.g. cotton, chamois) and synthetic materials (e.g. polytetrafluoroethylene, polyamide, polyester) are of great importance in systems simulating sweat distribution of humans 96-98. In addition, synthetic and natural leather such as Lorica® and chamois simulate the mechanical and frictional contact behaviour of skin (see ‘7.2’ section).

There are three main types of sweating textile based skin models: pre-wetted textile skin, textile skin with water delivered by sweating nozzles, and waterproof textile skin which is vapour permeable 99. Textile skin models are used to investigate the liquid and water vapour transport, thermal insulation as well as the combined effect on both the comfort and protective properties of clothing systems 98, 100. The textiles are placed over thermophysiological devices (e.g. thermal manikins, sweating guarded hot plate) and tightly fitted, and their main function is related to redistribution and transport of moisture.

By the appropriate choice of materials (fibre composition, surface properties, hygroscopicity, hydrophobicity etc.) and structural properties (thickness, construction, porosity, surface pattern etc.), the heat, moisture, and water vapour transport can be controlled simulating various physiological conditions.

Another vibrant research area is the integration of sensing elements in textiles motivated by the requirements of continuous body monitoring. Textile based flexible sensors can take advantage of the large available surface of textiles that is expected to provide unprecedented increase in spatial information of multiple parameters (e.g. heat flux, sweating rate, evaporative flux, skin temperature etc.) with minimum disturbances to the system.

Other Materials Used to Model the Skin

The list of materials used to replicate human skin can be easily extended especially if structure, morphology, surface properties, or design are taken into account 68, 101. From the less common solutions, but with important advantages, we mention albumin, which is able to simulate thermal damages of the skin 102. There are also less common examples such as onion, peach, and cellophane which were found to simulate the diffusion mechanism of human skin 103. A more systematic approach has been used to simulate the sweating of human skin in connection with water distribution in textiles using X-ray micro-computed tomography 104, 105. Similarly, Hou et al. simulated the sweating of skin by using a multilayer design consisting of a polycarbonate porous membrane and a skin replica membrane 106.

Nano- and Micro-fillers

To obtain skin models with tailored properties and functionality, nano- and micro-fillers such as nanoparticles, nanowires, chromophores, or fluorophores are added to a liquid or solid matrix. The incorporation of nanomaterials strongly influences various properties starting from the mechanical and thermal to optical, dielectric, and magnetic properties. In addition, unique functionalities can be obtained by exploiting quantum effects occurring at nanoscale or using the coupling between nanomaterials and matrix properties 107, 108. Sensing capabilities can be implemented into the skin models allowing the improved monitoring of experiments, or to serve as sensing robotic skin for machine-human interfacing.

The choice of nanomaterials is vast leading to a plethoric number of possible combinations to achieve a given property. Nano- and micro-particles such as metallic gold 109, 110, titanium dioxide 109, silicon dioxide 109, aluminium oxide 18, polystyrene 111, carbon black, graphite 58, lipid (Intra lipid) 17, 112-114 have been incorporated into solid and liquid matrices to tune the optical properties of the skin models. Mechanical properties have been adjusted by using carbon black, dielectric, and resistive properties by adding conductive (e.g. graphite 58, nickel 115), and ferroelectric fillers 69.

Concluding Remarks and Perspectives

In this article, we gave an overview of materials used for physical skin models to identify common approaches in various fields and applications related to the development of materials and measurement methods. The performed literature review revealed that a surprisingly large variety of materials is used to simulate specific physical properties of the human skin. The spectrum ranges from liquids and gels such as water, milk, albumin, gelatine, and agar over soft materials such as polyurethane, silicones, and polyvinyl alcohol gels to hard solids like epoxy resins or metals. The role of skin models is to mimic chosen properties of human skin in an appropriate way. Figure 3 illustrates and summarises the main materials used to simulate different categories of skin properties according to this review.

Historically, the development and adoption of physical skin models were closely related to their applications, which inevitably led to a high diversity. Most of the skin models appear to be adopted through a trial and error process by using materials that look, feel, have a structure or composition similar to skin. In the empirical selection of materials, an important criterion often was to apply materials and systems with properties that can be adjusted conveniently or provide measurement results comparable to skin, even if the physical mechanisms involved in the material behaviour differed for the skin models and the skin.

As a result of the complexity of the human skin, future skin models might still be based on empirical investigations in which incremental improvements of the existing solutions are achieved. For example, more realistic skin models can be obtained by combining suitable material compositions with skin-like structure, morphology and/or surface properties and topography. If scattering and absorption properties are important titanium oxide, gold and aluminium oxide nanoparticles, polymer microspheres and chromophores (e.g. dyes, blood, and yeast suspension) can be incorporated in the skin models.

The combination of different skin-like properties in the same skin model generally has a high potential. Interdisciplinary or multiphysics approaches leading to more realistic models would be especially beneficial in material science, as optimised materials have to meet different requirements. To be suitable for medical applications, for example, biocompatible materials and surfaces are needed that combine specific functions with skin-adapted thermal, mechanical, and tactile properties.

It is expected that the advance of new technologies and numerical simulation methods will stimulate the development of improved models that reproduce an increasing number of skin properties and functions and therefore are appropriate and valid for a wider range of conditions and applications. Another promising research area is related to tuneable and actively controllable skin models. Such systems would allow simulating the behaviour of skin in response to external influences more accurately and, thus, to better take into account the changes in the properties due to physiological and regulatory processes in objective measurements.