Characterisation of microcrystalline cellulose from waste green pea pod sheath and its sunn hemp fibre-polyester composite: A step towards greener manufacturing

Abstract

In this study, a microcrystalline cellulosic biopolymer (MCB) made from Pisum Sativum (green pea) pod waste via a modified thermo-chemical process, and Crotalaria juncea (sunn hemp) fibre was used to create environment-friendly polyester composites. The main objective was to synthesise the MCB from domestic waste and characterize how the addition of hemp alters the strength of the polymeric composite. The MCB was synthesized using green pea pods. The sunn hemp fibres were used in mat form in this study. The composites were made using the hand layup method and post-cured at 110°C for 2 h. The results showed that the addition of sunn hemp fibre and MCB increased the mechanical properties. Similarly, the highest observed fatigue life count for the composite designated PSC3 (2.0 vol.% MCB) was 30862 at 30% ultimate tensile stress. Similarly, the composite PSC3 had the maximum penetration resistance with an absorbed energy of 14.2 J. Moreover, the addition of silane-treated cellulose and fibre provided an improved storage modulus of 6.8 GPa for the PSC3 composite, confirming the improved fibre-matrix fibre interaction and increased toughness. The scanning electron microscope images revealed improved fibre-matrix correlation. These eco-friendly composites with better load-bearing capabilities could be preferred in automated door panels, defence toolboxes, and home interior decoration applications.

1 INTRODUCTION

In the current era scientists are working to create eco-friendly materials to hamper the growing environmental pollution by using biodegradable materials (Zabermawi et al., 2022; Jagadeesh et al., 2023; Divakaran et al., 2023). However, synthetic polymer composites, due to their functionality, cost-effectiveness, and ease of production, have taken the lead in many industrial and technological applications over the past ten years (Joseph et al., 2023 and Boominathan et al., 2022). However, after its intended usage, the waste they create has caused the environment to become seriously polluted. To lessen the severity of pollution caused by the widespread use of synthetic plastics, researchers worldwide began to focus their research on generating biodegradable polymers or partially degradable ones for engineering applications (Ilyas et al., 2020 and Sunesh et al., 2023). Natural fibres and particles are frequently used to create bio composites because they are completely biodegradable, widely accessible and readily available (Palanikumar et al. 2022, Joe et al. 2023 and Divakaran et al., 2023). Some of the common fibres and particles utilized in the creation of bio-composite materials are jute, pineapple, ramie, abaca, hemp, flax, and kenaf (Kumar et al., 2019 and Nadh et al., 2021). In the same way, bioparticles, such as bio silica, cellulose, biochar, lignin, and carbon quantum dots, are also frequently used in bio-composite formation (Edayadulla et al., 2023). Among various natural fibres, the sunn hemp (Crotalaria juncea), which is easily available and different from other fiber. Sunn hemp belongs to the Fabaceae family and is a substantial source of lignocelluloses, thus, it has significant economic value. Usually, the stem is used to collect the bast fibre and has been found to have a fibre content of 13% of the dry weight (Rawat et al., 2023 and Narayana et al., 2023).

Jadhav et al. (2022) investigated the mechanical and thermal effects of incorporating sunn hemp fibre into the epoxy composites. At 30 vol. % loading, it was discovered that the grafted sunn hemp fibres had a tensile strength of 68.73 MPa, impact strength of 4.6 J, interlaminar shear strength of 68.9 MPa, and a microhardness of 63%. Similar research was conducted by Utara et al. (2019) on the effects of filler loading and surface treatments on the properties of hemp fibre/natural rubber composites. The authors indicated that at 5 phr fibre loading, the silane-treated hemp fibre dispersed in natural rubber composites showed improved tensile strength and cross-linking density. The link between the fine structure of the fibre and the impact of pretreatment on the mechanical and dielectric properties of a polymer composite, including short sunn hemp fibre, was investigated by Dash et al; in 2020. The increased cellulose crystallinity of the fibre and its rough surface, according to the author's theory, helped to create a fine interfacial bond between the fibre and the matrix. Thus, it is evident that the sunn hemp fibre enhances the mechanical properties of the composite materials and has the ability to manage applied loads.

Bioparticles could, however, alter the characteristics of the matrix at a microscopic level rather than the fibre (Kaliappan et al., 2023 and Veeman et al., 2021). The addition of particles changes the other significant properties of the matrix, while fibre addition of fibres contributes primarily to the load-bearing properties. The effectiveness of particle addition and its significant contribution to polymer matrix composites have been supported by more testimonials in recent decades (Mahalingam et al. 2022 and Kumar et al. 2022). Biopolymers, including cellulose, chitosan, chitin, and lignin, are notable biopolymers among ceramic and hard bioparticles that can strengthen the matrix material at the microscopic level and enhance its properties. One important biopolymer among them is cellulose, which is found in practically all plant species. It is a complex carbohydrate comprising oxygen, carbon, and hydrogen (Karthick et al. 2022).Because of its lengthy molecular structure, the polymer is significantly toughened by creating interpenetrating polymer networks and stiff bonding. To reinforce the composites, many researchers have obtained cellulose from diverse plant species and biowastes (Indran et al., 2015 and Pragadish et al., 2023).

A novel cellulosic fibre from Cissus quadrangularis roots was described by Indran et al. (2014). From the roots, the authors produced an eventual yield of 77% cellulose with a negligible wax percentage of 0.14%. Additionally, the researchers suggested that by using this cellulose as a secondary addition for composites, the load-bearing properties improved. Similarly, the Ficus religiosa tree was used to create a novel cellulosic fibre by Moshi et al. (2020). According to the author's characterisation, the generated cellulose hada moderate density of 1.246 g cc−1 and a higher thermal stability up to 325°C. It had a kinetic activation energy of 68.02 kJ mol−1 and proved to be available reinforcement for composite technology. Similar research was conducted on cellulosic stem fibre from the Cissus quadrangularis plant by Manimekalai et al. (2021). The authors claimed that the cellulose produced from the Cissus quadrangularis plant is both high-yielding and sustainable. This plant produces cellulose with a high crystalline index. It should be mentioned that significant progress has been made in the synthesis of cellulose from diverse plant byproducts, such as roots, peels and stems (Pradhan et al. 2022 and Ramaswamy et al. 2022). However, a sustainable plant source is still needed to support the continued increase in use of cellulose in the composite technology.

Peas are a commonly consumed legume, and thus, countless tons of pea pods are disposed of in landfills and occasionally burned, which results in significant air pollution (Srivastava et al 2014). However, the pea pods themselves are useful source of biopolymers, such as lignin, cellulose, and hemicelluloses, with about 40% of lignocellulose content altogether. Conversion of these pea pods would assist in the reinforcement of polymer composites (Abdel-Shafy et al. 2018). Kassab et al. (2020) investigated the formation of cellulose in broad bean (Vicia Faba) pods. The fibre achieved 79% crystallinity and showed increased thermal stability when reinforced with organic resins. Moreover, Singh et al. (2019) researched the thermal degradation kinetics and liquid crystalline behaviour of cellulose nanocrystals derived using pigeon pea sheath waste from the pea industry in the making of biodegradable products. According to the results of the study, the biofilm generated in this study exhibited higher tensile strength and modulus. Similarly, the size and mechanical behaviour of pea-based starch-protein composites produced by the extrusion procedure were studied by Jebalia et al., (2019) and Natrayan et al., (2021). The pea-based starch-protein composites exhibit superior strength and hardness, according to the results.

There is not much published on pea-based green goods and composites. The use of green pea pods and their by-products in composite applications has not been the subject of any specific studies. Furthermore, despite being a great source of cellulose, no experiments combining the cellulose from green pea pods with polymeric composites and natural fibres have been published. There are no studies that specifically report on the characteristics of polyester composites with the proposed fibre and biopolymer. The objective of the present study was to closes this research gap. The present study investigates the impact of adding a cellulosic biopolymer made from green pea pods along with fibre in polyester composites. These durable and mechanically robust composite materials could be employed in a wide range of engineering applications, including those in the automotive and industrial sectors, food packaging, medicine packaging, sports and domestic appliances.

2 MATERIALS AND METHODS

2.1 Materials

Unsaturated polyester resin (maleic anhydride) with a molecular weight of 6900 g mol−1, a viscosity of 1200 cps, and a density of 1.13 g cm−3 was procured from Huntsman India Ltd along with curing catalyst and accelerator. Sunn hemp fibre woven mat of 1.42 g cc−1 with a medium GSM of 270 was obtained from Metro composites research and development centre, Chennai, India. The fibre supplied had a diameter of 20 μm and a size of 300 x 300 mm.

2.2 Microcrystallinecellulosic biopolymer preparations

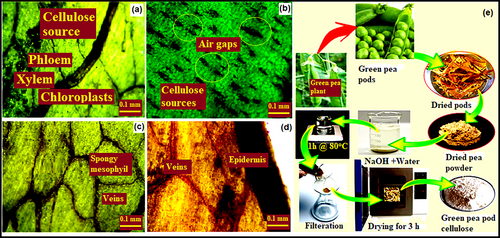

Figure 1(a-d) and (e) depict the green pea pod anatomy as seen through an optical microscope, as well as the stages involved in the production of MCB. The image shows air cavities as well as the fundamental components like xylem and phloem. The pea sheath contains bigger, spongy mesophyll than the peas, from which the cellulose can be separated. To get rid of the moisture, the discarded green pea pods were washed and dried for 4 h in a hot air oven. The pods were thoroughly dried before being mechanically processed into a fine powder. 4 g of pod powder was placed in a beaker and stirred for 2 h at 80°C with 12 mL of 1 mol NaOH and 88 mL of distilled water. After delignification, the powder was separated using a filtration process, and then dried for 24 h. A mixture of 50 mL sodium hypochlorite (NaOCl) and 50 mL distilled water was added to bleach the powdered green pea pods at 80°C for 1 h, and then allowed to cool. The leftover solution was put into the container after the particles were collected using filter paper. To neutralize and maintain the pH level, the particles were cleansed with distilled water and dried in a hot air oven for 3 h to create MCB (Tarchoun 2020). The prepared cellulose contains 34% cellulose, 13.6% holo-cellulose, 8.4% hemicellulose, 1.8% lignin and 0.4% wax.

2.3 Composite laminate preparation

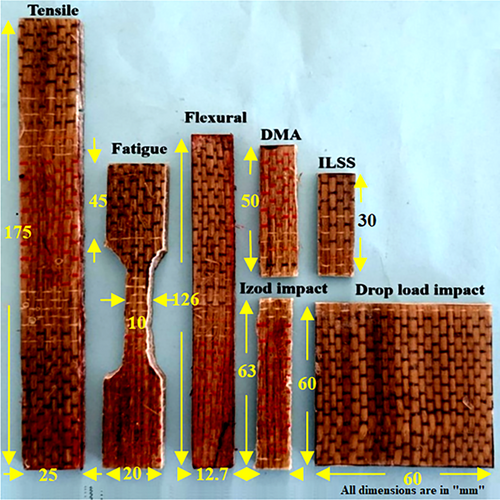

100 g of resin was taken in a clean glass beaker and mixed with MCB of quantities 0.5, 1.0, 2.0 and 4.0 vol.%. Using an ultrasonicater, the resin-MCB mixture was stirred for 20 min until a uniform solution was made. A curing catalyst, methyl ethyl ketone peroxide of 2 wt.% and cobalt naphthenate accelerator of 0.5 wt.% was mixed and stirred using a sonicator for 10 min. The final admixture was poured into a wax-coated metallic moulds, and a stacking order of 0-90o of sunn hemp fibre was laid one by one equal to 35 vol. %. Due to the slow polymerization, a 10-h cure period was offered at ambient temperature. Finally, a 3 mm thick plate was created using the composite after it had been post-cured at 110°C for 4 h in a closed hot air oven (Alshahrani et al., 2022). The composites are designated P, PS, PSC1, PSC2, PSC3 and PSC4. In this, P refers to plain resin, PS refers to resin with fibre and PSC1, PSC2, PSC3 and PSC4 refers to the addition of 0.5, 1.0, 2.0 and 4.0 vol. % of MCB, respectively. Figure 2 shows the polyester composite prepared from 5 vol. % of MCB and sunn hemp fibre.

3 CHARACTERIZATION OF COMPOSITES

The fabricated composites were machined using an abrasive water jet machine as per the American society of testing and materials dimensions. Five identical test samples were examined to get a mean of all properties. The specimens made from the composite, PSC1 is displayed in Figure 3. The mechanical properties, such as tensile, flexural, interlaminar shear strength, Izod impact properties, were assessed using an FMI 10 T universal testing machine with a transverse speed of 1.5 mm min−1. Similarly, a mini digital impact tester (Metro Precision Testing Equipments) with 25 J capacity was used to test the impact energy of the composites. Before testing the composites, the samples were ‘V' grooved and placed in a cantilever form in the fixture. In the same way, the hardness of the composites was assessed using a Shore durometer (Bluesteel). Moreover, the tension-tension fatigue behavior of the composites was studied using a servo-activated fatigue load frame (MTS Landmark 370). To test the fatigue life counts of the composites 30, 60 and 90% of stress values with a stress ratio of 1, test frequency of 5 Hz, and chamber temperature of 28°C were used. Similarly, the dynamic mechanical properties were evaluated using a dual cantilever DMA analyzer with sweep mode (SEIKO, DMS EXSTAR 6100). A heating rate of 50°C min−1 and frequency of 1 Hz were used as process parameters. In a similar way, the sudden impact resistance of the composites was assessed using a drop load impact tester (SPRANKTRONICS Pvt, Ltd.). The indenter used had a head diameter of 12.7 mm with a striking mass of 2.5 kg and 1.5 m falling height. Finally, the micron and sub-micron fractured behavior was analyzed using a scanning electron microscope (JEOL JEM).

4 RESULTS AND DISCUSSIONS

4.1 Confirmation analysis of cellulose

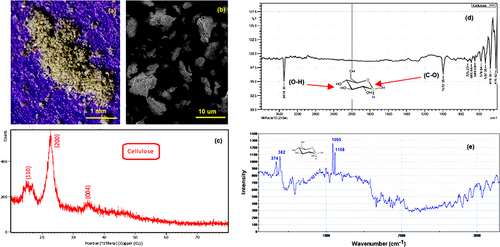

The confirmation analysis of the MCB is shown in Figure 4. The optical and SEM morphological pictures of the prepared MCB are shown in Figure 4a and b. As a result of the thermally decreased pathway, the particles have an uneven form. Further, the MCB produced had an average particle size of 5 μm and a density of 1.48 to 1.51 g cm−3. Figure 4c displays the X-ray diffraction pattern of MCB produced in this study. The diffraction peaks at 2θ = 15.9, 22.4, and 35.33o clearly demonstrate that the MCB has a crystalline structure according to the peak values and degrees, indicating a sizeable crystalline phase with (110), (200) and (004) planes. Additionally, Figure 4d displays the prepared MCB's FTIR spectra. The O-H and C-O molecular attachment are indicated by the high peaks at 1072.35 and 3478.32 cm−1. This shows that the material produced is cellulose and that no other functional peaks are present in any other form, indicating that the cellulose is of high purity. Finally, the measured and produced cellulose undergoes a Raman shift confirmation analysis. High-intensity observations of the peaks at 374, 382, 1095, and 1105 cm−1indicated the OH and CO molecules of the cellulose. Furthermore, the peaks at the lower frequency ranges are noticeably higher, showing that cellulose has a high degree of crystallinity. Overall, the analyses are confirming the prepared cellulose, and the results show that the preparation process is effective.

4.2 Mechanical properties

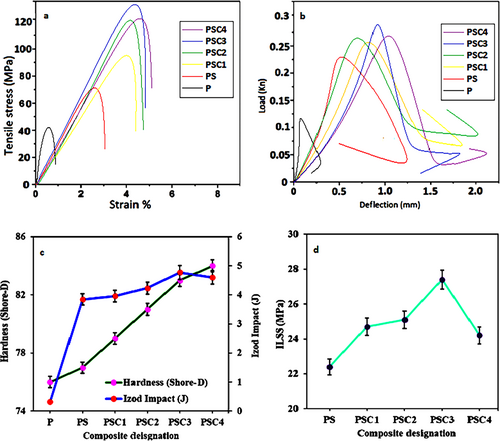

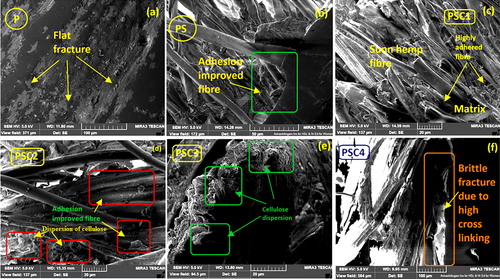

The mechanical properties of the polyester composite reinforced with MCB and sunn hemp fibre is shown in Figure 5 and Table 1. It is noted that the plain resin gives a tensile strength of 44 MPa, tensile modulus of 1.68 GPa, flexural strength of 82 MPa, flexural modulus of 2.88 GPa, hardness of 76 Shore-D, and Izod impact toughness of 0.32 J, respectively. These lower values are due to the extremely brittle molecular structure of the plain polyester resin and the absence of strengthening mechanisms within it. Since the matrix is highly cross-linked, more microcracks are formed and propagated further those results in plastic deformation (Prabhu et al., 2022). This phenomenon is also confirmed by the flat fracture SEM micrograph of the plain resin illustrated in Figure 6a. However, with the addition of 35 vol. % of sunn hemp fibre to the polyester resin, the load-bearing properties improved. An improved tensile strength of 78 MPa, modulus of 2.71 GPa, flexural strength of 136 MPa, flexural modulus of 3.84 GPa, hardness of 77 shore-D, Izod impact toughness of 3.8 J and ILSS of 24.6 MPa were observed for composite designation PS.

| Composite designation | Tensile strength (MPa) | δts | Tensile modulus (GPa) | δtm | Flexural strength (MPa) | δfs | Flexural modulus (GPa) | δfm |

|---|---|---|---|---|---|---|---|---|

| P | 44 | 1.4 | 1.68 | 1.2 | 82 | 1.4 | 2.88 | 1.4 |

| PS | 78 | 1.4 | 2.71 | 1.4 | 136 | 1.1 | 3.84 | 1.1 |

| PSC1 | 91 | 1.3 | 3.26 | 1.3 | 151 | 1.4 | 4.26 | 1.3 |

| PSC2 | 118 | 1.1 | 3.94 | 1.3 | 179 | 1.4 | 5.15 | 1.1 |

| PSC3 | 136 | 1.2 | 4.85 | 1.5 | 190 | 1.3 | 5.72 | 1.2 |

| PSC4 | 119 | 1.5 | 4.04 | 1.3 | 174 | 1.5 | 5.11 | 1.4 |

This improvement is due to the effective load-bearing properties of the fibrilar structured sunn hemp fibre, which transfer the applied load effectively in all directions, thereby improving the strength of the composite. Moreover, the fibre is treated with silane, thus, the adhesion with to a matrix also improves and reflects on the load-bearing effect (Sivamurugan et al; 2023). Because the fibre-matrix interfaces are effectively grafted, the load-bearing effect is greater in the composites. Figure 6b confirms this phenomenon by showing the tensile fractograph of the composite designation “PS”. The fibre adheres firmly to the resin matrix, and there is no evidence of pull-out. This indicates the improved adhesion of fibre with resin matrix and effective load-sharing phenomenon. Since the load transfer is smooth, the development of stress intensity zones is lower. Thus, the composite could stand for higher loads without plastic deformation (Arun et al., 2022).

However, further addition of green pea pod MCB to the sun hemp-polyester matrix improved the load-bearing effect of PSC1, PSC2, PSC3 and PSC4. Composites PSC1, PSC2, and PSC3 showed an improved trend in load-bearing properties, whereas, PSC4 showed slightly lower results. Among these 4 MCB dispersed composites PSC3 showed the highest tensile strength of 136 MPa, tensile modulus of 3.85 GPa, flexural strength of 190 MPa, flexural modulus of 5.72 GPa, shore D hardness of 83, Izod impact toughness of 4.77 J and ILSS of 27.4 MPa. This notable improvement in properties is the reason for the toughening action via the addition of MCB. The addition of MCB makes larger inter-penetrating polymer networks (IPN) within primary polymer chains and forms a highly strengthened matrix phase (Balaji et al., 2022). Moreover, the addition of MCB also reacts with the polyester molecules via hydrogen molecules and forms rigid polymer building blocks. This nature improves the load-bearing effect of the composite. Figures 6c and d show that the sunn hemp fibre reinforced polyester composites with an evenly distributed MCB resist fracture propagation. Figure 6e shows the incorporation of microcrystalline cellulosic biopolymers, which react with the polyester resin and forms a fine interface between fibre-matrix, thus, the load transfer is uniform. Moreover, the limited volume of cellulose dispersed in the matrix uniformly, thereby improving the load-bearing effect (Johnson et al., 2023). However, there is a noticeable decline in mechanical properties with the 4 vol. % MCB. A rise in the percentage of volume of MCB reveals agglomerations in the resin, which causes stress concentration sites that lead to failure and inferior mechanical properties due to increased brittleness (Alshahrani et al., 2022). There are more river marks, and fibre-matrix de-bonding evident in the composite designation PSC4 (Figure 6 f). Thus, the addition of MCB along with the sunn hemp fibre significantly improved the load-bearing effect of the composite.

4.3 Fatigue properties

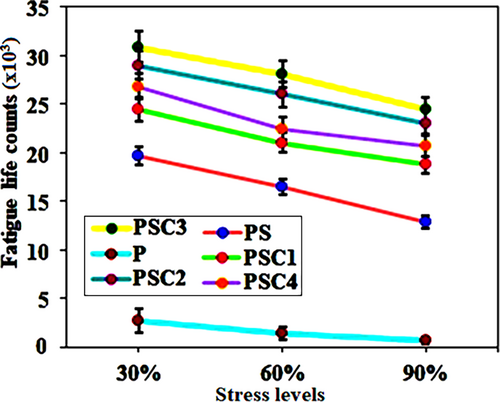

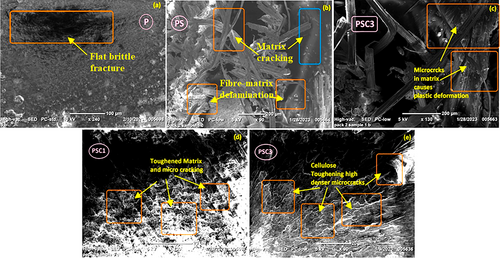

The life cycle behaviour of the tension-tension fatigue of the MCB and sunn hemp fibre reinforced polyester composites are shown in Figure 7. It is noted that the composite designation ‘P' gives a lowest values for fatigue life counts of 2736, 1417, and 731, for 30, 60, and 90% of ultimate tensile stress, respectively. These lower fatigue life counts are the reason for the highly brittle nature of plain resin, which could not withstand repeated load and storage of residual plastic strain. This phenomenon is evidenced by the Figure 8a, which shows an almost flat fracture after the break (Ben et al 2023). Furthermore, the addition of sunn hemp fibre increased the fatigue life cycles of the composite designation “PS” of about 19628, 16564, and 12877 for ultimate tensile stress levels of 30, 60 and 90%. This improvement is the reason for the effective suppression of the stress intensity factor zones and the storage of plastic strain up on every cycle complete (Arun Prakash et al., 2022). The isotropic distribution of load in the fibre is the reason for the minimization of stress at the matrix phase, thus, the matrix is evaded from early fracture due to repeated loading.

Figure 8b indicates the SEM fatigue fractograph of the composite designation PS. Although the fibre is treated with silane as a result of repeated loading, the composites are plastically deformed by interface cracking. This phenomenon is evidenced in the fractograph image. However, the inclusion of MCB at concentrations of 0.5, 1, 2, and 4 vol. % resulted in higher fatigue life counts. A maximum fatigue life count of the composite designation PSC3 was recorded as 31836, 28471, and 24528 for 30, 60, and 90% of UTS, respectively. This is because the matrix does not easily deform with the presence of MCB up to 2 vol. %. The addition of cellulose improved the cross-linking via IPN structures; thus, more load is required to activate the molecules and development of cracks (Raju et al. 2021). Figures 8c and d show the inclusion of MCB into the matrix and the improvement of toughness in the brittle matrix, resulting in the formation of little cracks rather than catastrophic failures. However, Figure 8e shows how the greater addition of cellulose leads to an increase in the number of fatigue cracks in the matrix. The increased MCB volume up to 4.0 marginally decreased fatigue life counts for composite designation PSC4 due to the dominance of the clustering effect and hampers smooth load transfer. Since the super saturation of cellulose alters the uniform load travel paths in the composites, the load-bearing effect is hampered, which causes failure in the fibre-matrix interfaces (Vinod et al., 2021). Thus, reduced fatigue life counts are found at higher loadings of MCB.

4.4 Dynamic mechanical analysis

Figure 9 shows the DMA properties of polyester composites reinforced with hemp and MCB. It is noted that the composite designation “P” gives a lower storage modulus of 2.6 GPa due to the brittle nature of the plain resin. Since the plain resin does not have any strengthening and load-bearing mechanisms, the cracks grow quickly and plastically deform the composite. Moreover, when the pure polyester resin is subjected to high temperatures and loading frequencies, the molecules are unable to store the energy that is provided as stress, and so the loss tangent is also larger (Kaliappan et al., 2023). However, when the sunn hemp fibre of 35 vol. % is added to pure polyester resin, the storage modulus reportedly increases to 3.2 GPa. This improvement is due to the fibres are layered into polyester resin, the storage modulus increases. As a result of the presence of surface-treated fibre, the rotation of the matrix molecules was hampered; and more energy was stored in the composite during the thermo-mechanical loading conditions. Similarly, the improved stiffness via the addition of fibre into the resin improved the load management on every cycle; the high dissipation of energy is also reduced, which in turn reduced the loss factor (Kaliappan et al., 2023).

Similar increments in the storage modulus and a decrease in the loss factor were observed when 0.5, 1.0, 2.0, and 4.0 vol. % of MCB were added. The PSC3 had the highest storage modulus and the lowest loss factor when an MCB volume of 2.0% was added. This is due to an improvement in bonding between the fibre matrix and the secondary molecules of the resin after the addition of MCB. The addition of MCB formed large branched polymer networks between the primary and secondary links of polyester. Therefore, the inertia to spin around the primary chains is rapidly increased upon the addition of MCB, and thus more heat energy is required to activate the same (Balaji et al. 2022). However, adding more volume of MCB marginally reduced the energy storage due to the agglomeration effect and inherent increase in the brittleness. Thus, the polymer molecules could not stretch during the thermo-mechanical loading condition, which in turn decreased the storage modulus.

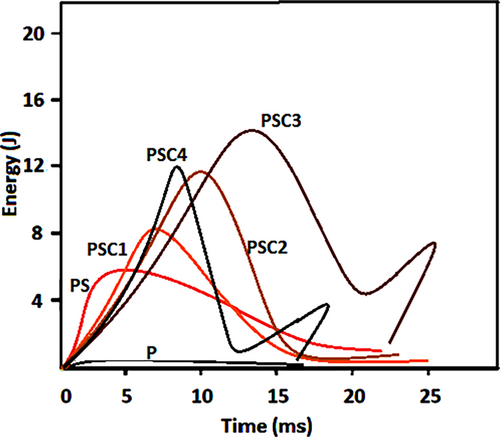

4.5 Drop load impact

Figure 10 depicts the impact energy absorbed by various composite types when subjected to a low velocity drop load. The composite designator P, which consists entirely of a polyester resin, has been determined to have a low energy absorption rate of 0.4 J. This lower energy absorption is due to the high brittle nature of the resin matrix. Furthermore, it is demonstrated that 35 vol. % of sunn hemp fibre in the polyester resin improved the ability of the material to absorb energy. Improved energy absorption of 5.8 J was noted for the composite designation “PS”, which is about 15 times better compared to the plain resin. This increase in energy absorption is the reason for sunn hemp fibre and the effective load-sharing ability in polyester resin (Ranakoti et al., 2022). When the sudden load hits the composite, the energy is transferred across the composite via the fibrilar nature of the sunn hemp fibre. Thus, the build-up of stress in a particular place is minimized, which in turn improved the penetration resistance.

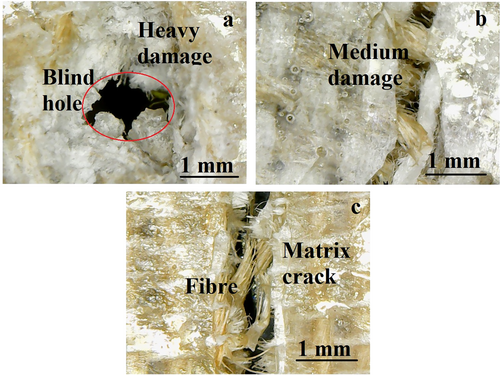

Moreover, the incorporation of MCB by 0.5, 1.0, 2.0, and 4.0 vol. % into the resin increased the energy absorption further. The composite designated PSC3 with 2.0 vol.% MCB had the highest drop load impact energy, 14.2 J, among all composites tested. Strong hydrogen bonding between the MCB and polyester resin is responsible for the increase in impact energy and boosts the capacity to absorb energy during fracture propagation (Habibi et al. 2022). The penetration is firmly hampered in the ¼th of the distance from the dropper hitting side of composite panel tested. However, when larger volume of MCB, up to 4 vol. %, is included into the resin the energy absorption is reduced and the matrix surface cracked after the sudden impactor load hit the composite. This phenomenon is the reason for the random improvement of brittleness in the different places of the composite, which reduced the energy absorption. Figure 11 shows a glimpse of the drop load impact damaged composite specimens. The PS composite shows heavy damage, while the PSC3 composite shows high penetration resistance. However, in PSC4, the penetration resistance is slightly reduced, and matrix cracking predominates.

5 CONCLUSIONS

- The microcrystalline cellulose biopolymer is developed via modified thermo-chemical route and confirmed as cellulose biopolymer.

- The mechanical properties are improved with addition of MCB up to 2 vol. %. A highest tensile strength of 136 MPa is observed for composite designation PSC3 and it is reduced beyond 2 vol. %.

- The SEM fractographs revealed highly reacted phases of treated fibre and MCB with resin.

- Similarly, the maximum fatigue life counts of the composite designated PSC3 is about 30862 at 30% of UTS. There is a drop in fatigue life counts once the stress and MCB volume is increased above 2%.

- Moreover, the composite designated as PSC3 with the addition of 2.0 vol.% of MCB a highest storage modulus and the lowest loss factor is observed.

- It is further concluded that the addition of MCB into the composite improved the sudden energy absorption. Maximum impact energy of 14.2 J was noted for composite PSC3 and it gives mere ¼th of penetration distance from the hitting side of composite.

- Based on these results, it is concluded that the microcrystalline cellulose biopolymer derived from green pea pods could be the worth-full alternative to strengthen the brittle thermoset plastics when aimed for moderate load bearing applications such as automotive door panels, lightweight defence products, domestic component and unmanned aerial vehicle manufacturing.

- Since the present study confirms the availability and capability of rich cellulose content in the biomass as well as its reinforcement effect on the polymer, similar legume-based biomass sources could be subjected as scope of future study.

ACKNOWLEDGMENTS

The authors are thankful to the Deanship of Scientific Research at Najran University for funding this work under the Research Priorities and Najran Research funding program grant code (NU/NRP/SERC/12/4).

Open Research

DATA AVAILABILITY STATEMENT

The data that support the findings of this study are available from the corresponding author upon reasonable request.