Preservation of fruits through drying—A comprehensive review of experiments and modeling approaches

Abstract

A significant part of the world's population still has problems in accessing food. The growing world population will exacerbate this issue in the future. Innovative studies conducted in this field play a crucial role in addressing the issue of drying and storage of foods. Atmospheric drying methods, such as rotary, tunnel, conveyor, cabinet, tower, and kiln dryers, offer advantages in relation to high production capacities, cost-effective initial setup, and economical operating conditions. However, concurrently, the weaknesses of these methods arise from factors such as drying duration, uneven moisture content, and space requirements. The solar dryer method is especially effective in dehydrating agricultural products, offering an energy-saving advantage compared to other methods. However, it is important to note that this approach, which involves exposing crops to direct sunlight, comes with several drawbacks affecting both food quality and health. In cases where the quality of highly valued foodstuffs is crucial, subatmospheric drying methods like vacuum, freeze, and microwave freeze are typically preferred. However, the primary drawback of this approach lies in its high operating costs, particularly in terms of energy consumption. Artificial neural networks (ANNs) can be used for predictive modeling, helping to forecast drying behavior and optimize process parameters in food drying applications especially nonlinear connections among variables. ANNs are adept at managing nonlinearities, offering a more precise depiction of the intricate interactions within food drying systems. This review examines articles from the last 5 years in the literature, synthesizing research conducted in food drying. The findings indicate a predominant interest among researchers in methodologies with lower environmental impact, prompting increased attention to studies addressing this aspect. There is a notable emphasis on the frequent exploration of energy-efficient systems. The ongoing research focuses on the development of methods utilizing ultrasonic, infrared radiation, and electrohydrodynamic techniques to achieve more effective, shorter-duration, energy-efficient drying processes with enhanced control over the final product.

Abbreviations

-

- AID

-

- air impingement drying

-

- CTC

-

- convective transfer coefficient

-

- FD

-

- freeze-drying

-

- FEM

-

- finite element method

-

- GFM

-

- Green's function method

-

- HAD

-

- hot air drying

-

- IR

-

- infrared radiation

-

- MDF

-

- microwave freeze-drying

-

- Nav.-Stok.

-

- Navier–Stokes equation

-

- PCM

-

- phase change material

-

- RF

-

- radio frequency

-

- ScCO2

-

- supercritical carbon dioxide

-

- VFD

-

- vacuum freeze-drying

1 INTRODUCTION

In order to meet the food demand in the increasing world population, the solutions of existing problems are increasingly gaining importance. Dehydration of foodstuffs especially fruits and vegetables constitute main issue for food supply. Dried fruit production processes can be built with many different convective drying methods with aspects to type of fruits, contents of nutrients, moisture contents, and so forth.

For both industrial applications and everyday use, convective drying methods have served as foundational practices over an extended period. Despite their historical prevalence, these methods continue to captivate the interest of researchers (Ren et al., 2022; Xu et al., 2022). In this regard, Gulati et al. (2016) examined microwave drying method for a porous medium in order to understand the behavior of mechanistic model. Intercorrelation behavior between solid mechanics, multiphase transport, and electromagnetism have been formed as regards moisture removal and temperature. Developed model predicts variations of volume, temperature, and moisture contents reasonably. Kaya et al. (2006) studied a two-dimensionally rectangular model which is performed implicit finite difference method. From the obtained results, they indicated that heat transfer coefficient variations along the surface area of the model. Hürdoğan et al. (2022) investigated the experimental performance of a solar dryer, employing an innovative drying chamber design to enhance drying efficiency and promote uniform drying. According to findings, the temperature distribution on the products within the chamber was more uniform in the newly designed drying chamber compared to the conventional one.

Defraeye, Blocken, and Carmeliet (2012) convective transfer coefficients (CTCs) of drying based on airflow and porous medium. Created conjugate model has demonstrated the impact of spatial and temporal conditions on convective drying approach. Aregawi et al. (2013) investigated water distribution characteristics and mechanical deformation behavior of apple samples experimentally. A developed multiphysics model was performed to analyze moisture removal and deformation of the samples during the process. Neutron tomography accomplished to visualize drying processes of the fruits. Also developed model results were good agree with the experimental data. In this context, Defraeye et al. (2016) also examined quantitative neutron imaging moisture content of sliced fruits for dry processes. In this study, they evaluated different flow and temperature conditions as well as radiation effects. Neutron imaging method was able to analyze the temperature and humidity distributions of fruit slices well. Obajemihi et al. (2023) studied the fundamental principles and features of infrared (IR)-accelerated drying, delves into its energy-saving potentials, examines simulation and optimization methodologies to enhance efficiency, and reviews advancements in diverse acceleration approaches, including their integration with other drying techniques to achieve superior end-products. The study also addresses challenges associated with this novel accelerated drying technology and outlines avenues for future research and development. The synergistic effects arising from the sequential or simultaneous combination of drying methods in most IR-accelerated drying technologies result in a substantial reduction in both total drying time and energy consumption. This leads to noteworthy enhancements in the sensory, nutritional, and safety attributes of dried food products, contributing to improved appearance and overall quality.

Luo et al. (2021) improved an analytical method to analyze the taste and color profile of a type of mushroom. The study compares air impingement drying with vacuum freeze-drying and hot air drying as respect to sensor qualities of the mushroom. Evaluated analysis emphasize that in respect to shrinkage characteristics and rehydration profiles, air impingement drying method results are not different with vacuum freeze-drying method results but are better than hot air-drying method results. Also, with respect to heat degradation and Maillard reaction, air impingement drying method outperformed vacuum freeze-drying method and hot air-drying method in moist removal efficiency. Sturm et al. (2014) investigated fruit quality and drying characteristics with constant airflow and product temperature. The applied processes showed that drying method has a significant impact on shrinkage profile and color changes. It was determined that controlling temperature changes on the product has a crucial impact on drying time and color changes. It was also deduced from the study that differences of drying rate significantly depend on air inlet position on the product. Chapchaimoh et al. (2016) investigated performance of a heat pump on convective drying of fresh ginger with air and nitrogen as work fluids. Air drying has required more input energy than nitrogen drying for the closed system. Xiao et al. (2010) studied drying of seedless grapes with air-impingement jet dryer experimentally. It was determined that the effect of drying temperature was more effective factor than air velocity for drying time. Also, the most influential factor on retention of vitamin C was the air temperature according to the results. Laurienzo et al. (2010) studied the effect of biopolymer film drying on apples based on content of flavor. Biofilm drying method has shown that an effective drying performance on the samples. In addition, this method preserves flavor of apples more effective manner than other methods which include air-drying methods.

Kurnia et al. (2013) studied the effects of air jet velocity, intermittency, and pulsation numerically on the performance of air jet drying. For energy saving potential, it was concluded that pulsating or intermittent air jet drying showed better performance than perpetual air drying on basis of consuming heat energy. Defraeye et al. (2013) conducted a numerical study to evaluate the effect of flow conditions with turbulence and boundary layer on spherical shaped foodstuffs. The computational model with small cell sized was required according to the study. Gulati and Datta (2015) developed a poromechanics model validated with experiments that predicts temperature, density, porosity, and shrinkage changes of potatoes during dehydration process. Caccavale et al. (2016) proposed a model in which the most limiting parameter, the CTCs, was evaluated. The model was solved analytically and compared with the present literature. Defraeye and Verboven (2017a) introduced moisture permeability modeling for fruit drying processes. The model enables better quantitative comprehension in terms of moisture transport characteristics of fruit tissue. Also, the study showed that drying process with low permeability of the tissues has not significant impact on CTC. Defraeye (2014) also studied computational modeling for dehydration of foodstuffs extensively based on multiphysics, multiscale, and multiphase. Selimefendigil et al. (2022) performed a comparative study to evaluate drying characteristics of porous medium with impinging jet and channel flow forms. For impinging jet configuration, increasing Re number improves convective drying performance and increasing hot air inlet temperature enhances drying performance as well. Ben Mabrouk et al. (2012) investigated drying characteristics of apple slices both numerically and experimentally. The study was performed to examine forced convection characteristics and intermittent method for dehydration process of the apple tissues at different flow conditions. An inverse interaction between drying time and temperature was determined from the obtained results. Pandiselvam et al. (2022) scrutinized the changes in bioactive compound content and antioxidant capacity resulting from the application of recent osmotic dehydration (OD) techniques. Emphasis is placed on elucidating the mechanisms behind alterations in phenolic compounds, vitamins, and other bioactive constituents that contribute to the antioxidant potential of the treated foodstuff. Defraeye and Verboven (2017b) analyzed the effects of using barriers to control dehydration rate between foodstuff and its environment. Hygrothermal continuum model was used to understand the barrier effect. It was determined that using the barriers decreased drying time considerably.

Gupta et al. (2022) examined the integration of a semitransparent photovoltaic module into a solar drying system for its potential to enhance both energy and exergy performance. The results of this investigation indicate that the system has achieved enhanced performance compared to other solar dryer studies reported in the literature. McMinn and Magee (1999) reviewed the convective drying methods with basis of classification and applications. Ateeque et al. (2014) developed a numerical model to estimate the content of moisture for foodstuffs. The model was solved in a computational fluent dynamics software with turbulent flow condition and the results validated with experimental data. Increasing air velocity has led to an increase in heat transfer coefficient. Ceylan et al. (2007) designed a heat pump dryer with PID controlled for foodstuffs to analyze the effects of air temperature on drying time. Zlatanović et al. (2013) investigated the parameters that affect drying process in order to reduce the deviation between experimental data and numerical model results. Velocity, moisture content, temperature, and tissue size of apple was examined in this study. Henderson-Pabis model was found to be the best agree with the experimental data. Defraeye et al. (2016) and Defraeye (2017) studied drying duration quantitatively in order to get better product quality and reduce energy consumption. The research provides data to determine the duration of drying processes. Defraeye and Radu (2018) also investigated drying kinetics and moisture distribution of apple tissues as regard to coupled model of the process. This coupled model analysis gives an insight into optimizing drying time, product quality and energy efficiency.

Vijayavenkataraman et al. (2012) studied the effect of solar drying method on agricultural products in terms of performance and design. Lu et al. (2015) established a mathematical model based on Fick's diffusion and Fourier's heat conduction equations to determine heat and mass transfer of a porous medium. Van Boekel (2008) researched kinetic modeling to evaluate quality of foodstuffs, Xiao and Mujumdar (2014) viewed impingement drying methods, Zheng et al. (2021) interpreted air-impingement jet drying kinetics, Santos and Silva (2008) reviewed drying processes in respect to retention of vitamin C.

As a novel drying technique, electrohydrodynamic drying (EHD) is rooted in the interaction between electric fields and liquid substances, offering a unique pathway for controlled moisture removal (Y. Wang & Ding, 2023). By applying high voltage to a liquid, the resulting electric field induces surface tension gradients, leading to the generation of electrically induced flows that facilitate enhanced drying (Iranshahi et al., 2023; Martynenko & Zheng, 2016). Recent developments in EHD technology have expanded its applicability and improved its efficiency. Integration of advanced materials, optimization of electrode configurations, and the incorporation of intelligent control systems have been pivotal in refining the EHD process. Soraiyay Zafar et al. (2023) conducted an investigation into the application of electrohydrodynamic technology as an alternative drying method for the dehydration of egg white. In comparison to samples subjected to spray-drying and freeze-drying methods, notable distinctions were observed in the electrohydrodynamic samples, particularly those treated with electrohydrodynamic, exhibiting complete denaturation. Han et al. (2023) studied the effects of EHD on characterization of garlic. Pusty et al. (2023) undertook an assessment to gauge the efficacy of selected hydrocolloids in preserving bioactive compounds extracted from red cabbage. Additionally, they appraised specific phytochemicals and examined the thermodynamic storage stability of the encapsulated bioactive compounds.

In addition to existing literature, this article offers a comprehensive overview of convective drying methods, elucidating their underlying principles. It further explores mathematical models that provide insights into heat and mass transfer mechanisms during the drying process, with a specific focus on their application to food products. The study delves into the practical applications of dehydration processes, highlighting recent innovations in drying technologies. Additionally, the paper identifies potential avenues for future research in this field. Moreover, beyond the broader scope of drying methods, the investigation continues to scrutinize contemporary trends in fruit drying technology, placing particular emphasis on the complexities of energy-efficient drying methodologies and sustainable approaches to food drying. By encompassing these various facets, the paper contributes to a nuanced understanding of the multifaceted landscape of drying technologies and their implications for the broader field of food science and technology.

2 DRYING METHODS

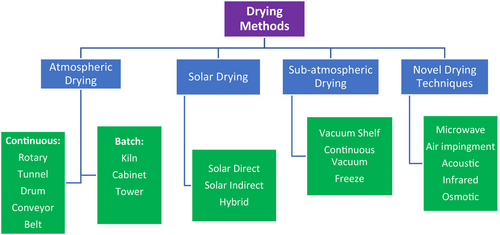

Drying process is mainly based on the principle of removing water from a porous medium. Therefore, drying systems differ in respect to the nutritional values, moisture contents and shelf life of the foodstuffs as well as operation method of convection and heat supply. A generalized classification of drying methods can be presented as in Figure 1.

2.1 Atmospheric drying

The most common convective drying methods such as rotary, tunnel, conveyor, cabinet, tower, and kiln dryer methods are classified under this branch for industrial scale and the literature. These methods provide advantages in terms of high production capacities, low-cost initial setup, and cost-effective operating conditions. The conventional setup of rotary dryer consists of an inclined drum, able to rotate on its own axis horizontally, being internally integrated with fins. The sliced foodstuffs are transported along the drum and lifted by the fins and dried by the airflow as the drum rotates (Silva et al., 2016). A conventional and roto-aerated drum dryers showed in Figure 2 were experimentally studied by Silva et al. (2016) to investigate the effects of process parameters on bioactive compounds.

Tunnel dryers are mostly preferred to dehydrate fruits and vegetables in tropical and subtropical regions (Mewa et al., 2019). A typical application of tunnel dryer integrated with solar collector is shown in Figure 3. Solar collector can be integrated at one side of the tunnel. Heated air flows through tunnel and dehydrates water from products and leaves from another side of the tunnel. This application is used not only for drying a wide range of fruits and vegetables but also meat products. A typical application of tunnel dryer integrated with solar collector is shown in Figure 3.

Drum dryers are consisting of hollow cylindrical rollers which horizontally rotating while hot steam passes through the rollers for drying process (Pua et al., 2010). Galaz et al. (2017) investigated drying kinetics of pomegranate peel in a double drum dryer for different temperatures to evaluate physicochemical properties, antioxidant reaction and polyphenol content of the pomegranate peel.

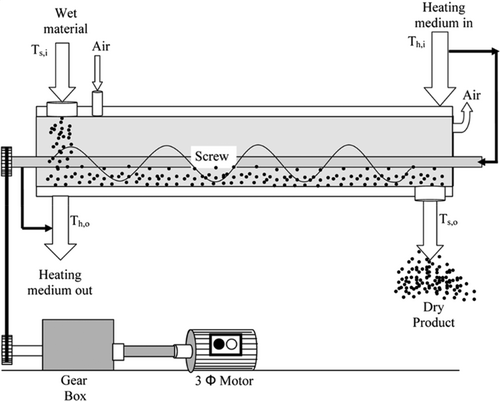

Belt dryers are an effective method developed for drying foodstuffs in liquid and fluidic forms with the help of vacuum pump (Burmester et al., 2011). Screw, belt, chain, and vibratory are the most used types among approximately 80 different types of conveyor dryers. The most used types in practice are screw and belt conveyors due to the ability to controlled discharge of the product. Screw conveyors are particularly useful for processing fine powders or dusty materials. Screw conveyors are usually more operable than belt conveyors due to occupying less volume, cost-effective operation, and simple installation. Furthermore, screw conveyor type can be applied not only for food industry but also for pharmacy, mining, and chemical industries as well. An experimental study was performed by Waje et al. (2007) to evaluate the process and design parameters on screw conveyor type dryer. A schematic view of the experimental setup is shown in Figure 4.

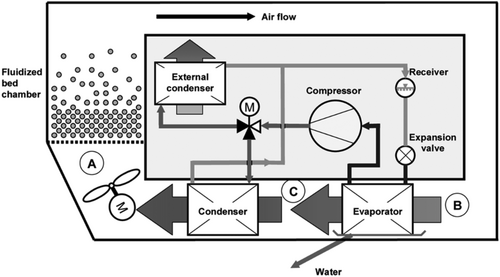

Heat pump dryer as a convective drying method also have advantages compared to subatmospheric drying methods such as vacuum dryer and vacuum freeze dryers. These advantages can be expressed as energy saving, control of drying temperature and air humidity. Heat pump dryers (Figure 5) are more suitable for drying solid products than fluidic or semi-fluidic products (Claussen et al., 2007). This environmentally friendly method provides a wide range of drying conditions to obtain high quality products.

2.2 Solar drying

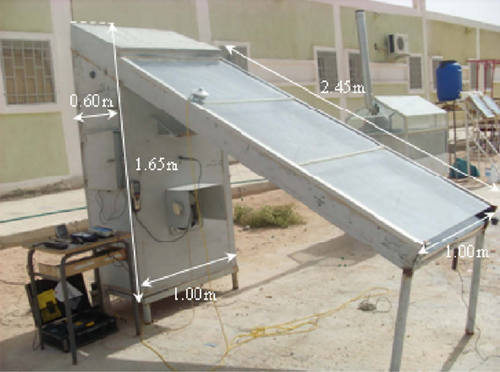

Traditional sun drying technique has been used for a long time in order to remove moisture from agricultural foodstuffs. This method exposes agriculture crops to direct sunlight that has many disadvantages for food quality and health. These drawbacks have led to the development of solar dryers. Solar dryer method is particularly useful for drying agricultural products such as rice, tea, tobacco, and cocoa beans (Luna et al., 2009). The most influential advantage of solar dryers over other methods is energy saving. It plays a crucial role as a drying method in which greenhouse gas effects are minimized. Solar dryers in different designs have been studied in the literature in respect to the diversity of the applications. Solar dryers can be categorized into three main groups as solar direct, solar indirect and hybrid systems. Murthy (2009) reviewed different applications for drying foodstuffs and evaluated the performance characteristics of solar dryers. Sharma et al. (1995) performed an experimental study to evaluate the effects of both natural and forced convection on drying performance of three types of solar dryers. Cabinet type of solar dryers were determined as well suited for household scale; solar type for farm scale and indirect type shelf dryer for industrial scale. Luna et al. (2009) designed a solar dryer showed in Figure 6 integrated with two fans to evacuate the air between timber stacks.

Solar dryers integrated with collector have been used for drying process through natural convection for many applications (Reuss et al., 1997). Direct type solar dryers are used as a good solution for small scale foodstuff production in non-electrified regions. Gbaha et al. (2007) developed a solar direct natural convection fruit dryer by using local materials in order to investigate drying kinetics and drying behavior. Unlike direct type solar dryers, indirect type solar dryers are convenient for producing dried fruits and vegetables of the desired quality even in autumn and winter seasons. Walke (2015) investigated new types of indirect solar dryers for different applications. In order to extend the utilizing drying process, Esakkimuthu et al. (2013) constructed an indirect solar dryer integrated with inorganic salt-based phase change material (PCM; Figure 7) for storing thermal energy. In the period of no sunlight during the day or after sunset, stored thermal energy can be used through PCM by changing its phase from liquid to solid state. In addition, the type of PCM can lead convenient conditions according to its thermophysical properties for certain type of foodstuffs.

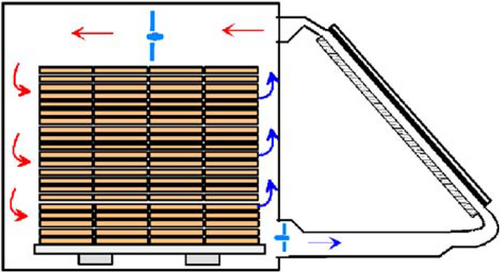

Boughali et al. (2009) constructed a new type of indirect hybrid solar dryer (Figure 8) to analyze the quality of agricultural foodstuffs in terms of energy consumption versus airflow rate. The performance of the indirect solar dryer was evaluated according to different flow rates and different fluid inlet temperatures. It was evaluated that drying temperature is more important parameter on the drying performance than the airflow rate.

2.3 Subatmospheric drying

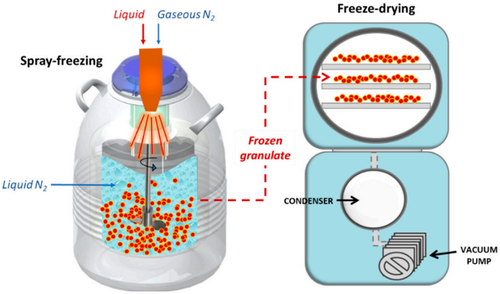

Subatmospheric drying methods are preferred in most cases where product quality of highly valued foodstuffs is important. High operating costs especially energy consumption is the major disadvantage of this method. Marques et al. (2006) studied freeze-drying characteristics of tropical fruits to optimize structural and nutritional quality. Freeze dried products have presented high porosity values and conserved their taste and color. Schematic diagram of conventional freeze-drying process is shown in Figure 9 (Bhatta et al., 2020).

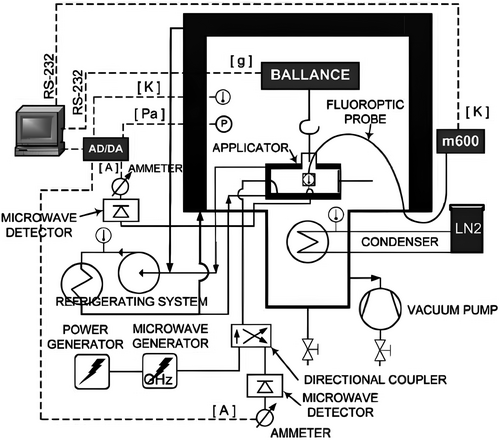

Freeze-drying assisted with microwave has higher energy efficiency potential compared to conventional freeze dryer types. Microwave freeze-drying (MFD) method is growing interest by allowing fast dehydration from foodstuffs. The MFD method, which is becoming more and more widely used for small scales, allows obtaining higher quality products in a shorter time compared to conventional freeze dryers (Cohen & Yang, 1995; Duan et al., 2007, 2008, 2010; Sochanski et al., 1990). MFD processes tend to be retention of higher volatile level than conventional processes. This tendency can be determined by rehydration capacity of the dried products (Duan et al., 2010). MFD method is convenient for a wide range of foodstuffs such as vegetable drying (L. L. Huang et al., 2009), beef and royal jelly drying (Duan et al., 2010), and seafoods drying (Duan et al., 2008), and this method also has a sterilization effect notably. Schematic diagram of vacuum freeze dryer assisted by microwave is shown in Figure 10 (Fan et al., 2019).

Despite its superiorities such as improving product quality, reducing drying time and saving energy, MFD also has some drawbacks. Plasma discharge causes burnings on product surfaces as well as energy losses in industrial scales. During the drying process, it is difficult to measure temperature values accurately due to the negative effect of microwave on electrical signals. Control of temperature of the process is vital in this method to keep product quality.

2.4 Novel drying techniques

Drying foodstuffs to preserve its nutritional value is one of the oldest known primitive methods. In order to product healthier and higher nutritional valued dried foodstuffs, researchers investigate to improve existing drying techniques and lead to develop new techniques in the food industry. Recent developments have led to reveal novel drying approaches such as air impingement drying, ultrasonic drying, IR drying, and osmotic drying so that reduce drying time and energy consumption, increase quality and keep nutritional values of foodstuffs.

2.4.1 Air impingement drying

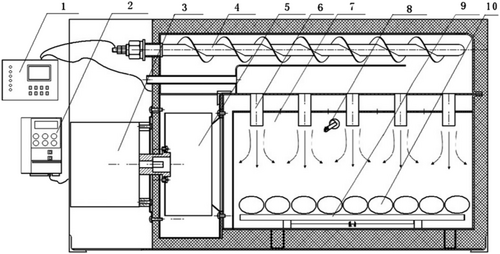

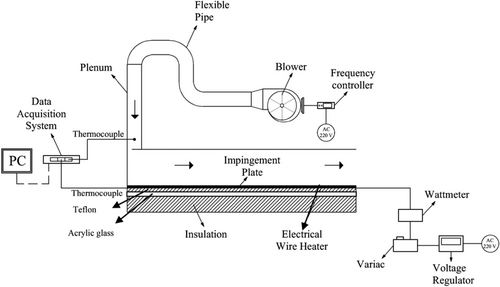

Conventional drying methods often come with significant challenges, including prolonged drying times, excessive energy consumption, and potential loss of product quality and nutritional value. Air impingement drying offers a promising solution to these challenges, and it is rapidly gaining recognition as a novel method in the field. In the process of air impingement, high-velocity air is directed onto the product's surface. This action effectively eliminates thermal boundary layers and significantly augments the heat transfer rate. The resulting heat transfer coefficient is approximately five times greater compared to that of cross-circulation dryers, leading to a remarkable acceleration in the drying rate and a substantial reduction in drying time. A schematic diagram of a typical air impingement dryer is illustrated in Figure 11.

Air impingement technique is currently used in heat exchangers to achieve highly uniform temperature profiles, ensuring consistent product quality (Çalişir et al., 2017). These heat exchangers are designed to transfer heat efficiently between a high-velocity air stream and a solid surface, such as a plate or a material to be heated or cooled. Their operation relies on the principle of forced convection, where air is directed with precision onto the surface to maximize heat exchange. Kilic et al. (2017) conducted both experimental and numerical investigations (shown in Figure 12) to examine the heat transfer phenomenon occurring from a heated flat plate positioned within a rectangular channel subjected to an impinging air jet. The effects of heat transfer were investigated by employing both air impingement and jet impingement methods in conjunction with nanofluids, taking into account the intense turbulence generated in the process (Kiliç & Özcan, 2018; Ullah et al., 2023).

The incorporation of superheated steam in impingement drying processes can be viewed to enhance the texture of food products. The introduction of steam during drying has the potential to alter the product's texture, resulting in a final product that exhibits a crispier texture when fried, as opposed to products dried solely with air (Moreira, 2001).

2.4.2 Supercritical CO2 drying

Supercritical carbon dioxide (ScCO2) has demonstrated its ability to effectively eliminate bacteria in food even when operating at low temperatures (Garcia-Gonzalez et al., 2007). In ScCO2 drying, the moisture removal process differs from traditional methods, as it involves the dissolution of water in ScCO2 rather than relying on evaporation or sublimation. This unique approach essentially transforms ScCO2 drying into a solvent extraction process, harnessing the power of carbon dioxide. One of the distinctive advantages of ScCO2 drying is its remarkable ability to operate in the supercritical state, where the conventional boundaries between gas and liquid blur. This absence of a distinct interface mitigates the capillary forces often encountered in other drying methods, ultimately safeguarding the delicate microstructure of food products (Cappelletti et al., 2014). However, it is worth noting that the use of ScCO2 in drying processes does come with certain limitations. The equipment required for ScCO2 drying can be relatively expensive, and the relatively low solubility of water in ScCO2 can lead to extended drying durations. Despite these challenges, the unique benefits of ScCO2 drying make it an intriguing and promising approach in the realm of food preservation (Wang, Zhang, et al., 2023).

2.4.3 Radio frequency drying

Radio frequency (RF) drying relies on the principle of heating food through RF energy. RF heating operates by utilizing the polar molecules and charged ions within the food to transform electromagnetic energy into heat, a mechanism akin to microwave drying, also known as dielectric drying. In comparison to microwaves, RF energy can penetrate more profoundly, thanks to its lower frequency. In foodstuff industry, RF technology is typically integrated with conventional drying methods, like RF-assisted hot air drying. This integration serves to enhance energy efficiency, optimize thermal performance, ensure uniform drying, and elevate the overall quality of food products.

2.4.4 IR drying

IR radiation constitutes a segment of the electromagnetic spectrum, characterized by wavelengths ranging from 0.78 to 1000 μm. Depending on the length of the wavelength, it can be categorized into near-IR, mid-IR, or far-IR regions (Riadh et al., 2015). IR radiation, often referred to as thermal radiation, possesses the capacity to be absorbed by objects and transformed into thermal energy. The ability of IR radiation to propagate is contingent upon the moisture content of the materials it encounters (Abukhalifeh et al., 2005). In the context of IR radiation, it is important to note that shorter IR wavelengths can penetrate moisture, while longer wavelengths are absorbed by surfaces. Consequently, far-IR radiation exhibits higher heating efficiency when applied to thin-layered food products. This efficiency factor has contributed to the widespread adoption of far-IR radiation technology in the food industry today (Krishnamurthy et al., 2008). In the food industry, IR drying, recognized for its elevated drying efficiency, has emerged as a viable alternative to conventional drying techniques. An advantage of IR drying is its lack of ionizing radiation emissions, which mitigates environmental pollution concerns. Instead, its primary impact on living organisms is thermal in nature. Consequently, IR drying stands out as a relatively environmentally friendly and safe drying method (Bisht et al., 2021).

2.4.5 Ultrasonic drying

Enhancing the quality of dried products can be achieved through the reduction of drying temperature or duration. As a result, vacuum drying has gained extensive favor as a preferred alternative to conventional oven or convective drying methods. Furthermore, various pretreatment techniques are employed to expedite the drying process, with ultrasound treatment being a prominent choice. Ultrasound treatment effectively disrupts membrane continuity, leading to an accelerated mass transfer rate between the cell and its surrounding extracellular environment (Nowacka et al., 2012). Ultrasound treatment is intimately linked with the drying process and serves as a preliminary treatment that brings about favorable outcomes. It has a dual impact, enhancing the quality of dried products and concurrently curtailing energy consumption during the drying phase (Lima & Sastry, 1990). The versatility of ultrasound extends to improving the convective heat transfer coefficient, expediting freezing rates when processing items like potatoes, and augmenting mass transfer in various applications, including the brining of meat and cheese (B. Li & Sun, 2002). While ultrasound treatment finds its utility in hastening numerous drying processes, it has not yet been closely associated with vacuum drying, presenting a potential avenue for exploration and innovation in this context (Muralidhara et al., 1985).

2.4.6 Electrohydrodynamic drying

The EHD method is an innovative approach to drying that makes use of the transfer of electric field energy (Y. Wang & Ding, 2023). It is characterized by material non-heating (Paul & Martynenko, 2022), energy conservation, economical equipment (Dalvand et al., 2014), and is especially well-suited for drying heat-sensitive materials (Dalvi-Isfahan et al., 2016). A considerable part of the researches were dedicated to examining the quality of the final product (including sensory appeal and nutritional content), drying kinetics, and electrode configuration, fine-tuning electrical process parameters, and environmental factors (Iranshahi et al., 2023). Among the recent studies, commonly employed electrode configurations include multiple wire-to-plate, wire-to-mesh, and needle-to-plate setups (Iranshahi et al., n.d.; Defraeye & Martynenko, 2019; Martynenko et al., 2022; Taghian Dinani et al., 2015).

2.4.7 Electrospray drying

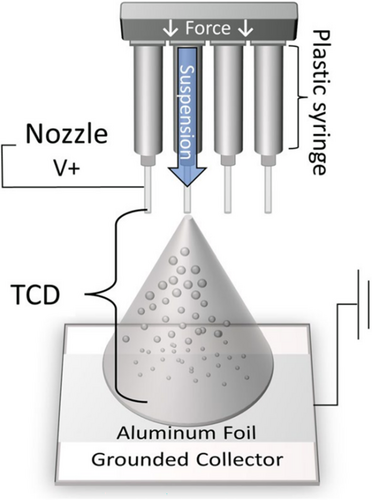

The electrospray drying (ESD) technique comprises four primary steps that transform a natural polymer-based solution into a dried fiber at room temperature. The drying process unfolds as follows: an electrostatic force disperses a conductive liquid stream into fine charged droplets. Subsequently, electrostatic energy generates charged droplets by propelling a solution through a high-electric voltage needle; these droplets condense through solvent evaporation before the deposition of particles onto the substrate. This is succeeded by the disintegration of the droplets into dry particles, which are then collected on the charge plate (collector) at the conclusion of the process. Simultaneously, the distance between the needle (nozzle) and the collector plate must be precisely adjusted to ensure the complete evaporation of the solvent (Fathi et al., 2022). Khosroshahi et al. (2023) conducted a study to explore the impact of mixed lactic acid fermentation on the stabilization of wheat germ (WG). They examined the physical properties of the fermented WG (FWG), including surface tension, conductivity, and viscosity. Additionally, the researchers assessed the electrospray ability of FWG containing probiotic cultures. The ultimate goal of their investigation was to develop a novel nondairy probiotic product in powder form, designed to have an extended shelf life (Khosroshahi et al., 2023). In ESD, the application of voltage induces the movement of charge carriers from a positive source to a grounded collector, generating an “electric wind” that imparts the necessary stress to disrupt liquid surface tension. This applied current, maintained at a constant feed rate (Q), influences the spray mode as dictated by the electric field, leading to the immediate formation of the spray after the needle tip, as depicted in Figure 13 (Sanders et al., 2023).

The ESD method has been employed with variable high voltage in the study. He et al. (2011) demonstrated the viability of ESD in the production of drug nanoparticles. The utilization of the ESD technique, exploring its application domains and its impact on thermophysical properties, particularly within the food sector have been reviewed by Drosou et al. (2017). Employing these technologies for encapsulating food bioactive compounds intends to enhance their stability and facilitate controlled release properties.

2.4.8 Electrospinning drying

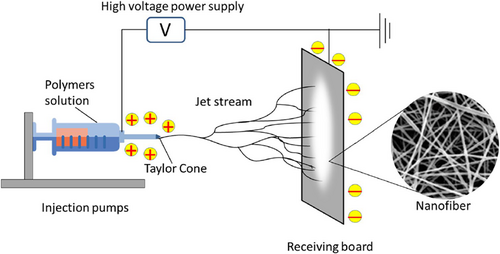

Electrospinning is a voltage-driven technique that arises from the electrohydrodynamic phenomenon induced by high voltage. This method was innovated for the purpose of creating fibers ranging in thickness from nanometers to a few micrometers, with lengths spanning from nanometers to kilometers. These fibers are generated from a liquid medium through the electrospinning process (Fathi et al., 2022). In the review study by Gagaoua et al. (2022), the electrospinning drying technology has been scrutinized in terms of characterization, processing, formulation, and the presently developed types of electrospun fibers. Electrospinning emerges as a promising and efficient methodology in meat packaging, whereby the attributes of electrospun fibers may impart antioxidant and antimicrobial effects, contingent upon their inherent characteristics. The fundamental configuration of an electrospinning apparatus comprises three primary components: a spinneret section, a high-voltage power source, and a metal collector. Within the spinneret section, there is a feed storage (housing the blending solution), a spinneret (a syringe with a conductive needle), and an injection pump that ensures a controlled flow rate of the solution. The high-voltage power supply may be either direct current or alternating current, linked to the metal needle to charge the droplets at the needle's tip, generating a Coulombic repulsive force (Y. Li et al., 2021; Wang, Khan, et al., 2023). A schematic illustration of electrospinning is shown in Figure 14.

da Cruz et al. (2023) aimed to encapsulate red onion skin extract within ultrafine fibers derived from starches sourced from two distinct sweet potato cultivars, employing the electrospinning methodology. Electrospinning method (Ngasotter et al., 2022) can be used for extracting chitin from crustacean shell waste through depolymerization and demineralization processes.

2.4.9 Osmotic drying

OD is a mass transfer process characterized by a counter-current flow mechanism. In this process, solutes migrate into the food product, while moisture is concurrently removed from the food's interior and transported into the hypertonic solution. It is worth noting that due to the semipermeable nature of cell membranes, solutes like organic acids, minerals, fragrances, and colorants also migrate from the food materials into the hypertonic solution. Although the quantitative extent of this transfer may be minimal, it holds significant importance in shaping the overall composition of the end product (Ahmed et al., 2016; Phisut, 2012). Typically, OD is a gradual process, predominantly influenced by the permeability of cell membranes and the structural arrangement of cells within the biological material. The osmotic pressure disparity between the food material and the hypertonic solution serves as the driving force, compelling the removal of water from the food into the osmo-active solution. The intricate cellular structure of biological materials introduces obstacles that impede the diffusion of water, contributing to the overall slowness of the process (Amami et al., 2007; Fernandes et al., 2009). When food materials are immersed in a highly concentrated osmotic solution, a multifaceted transfer process unfolds. Within this process, the solution traverses the biological tissues, giving rise to a combination of drying, leaching, and impregnation processes. Initially, moisture loss from the product occurs at a relatively rapid pace within the first few hours. Subsequently, this rate gradually diminishes over the following hours (up to 6 h) and ultimately levels off. Remarkably, during the initial stages of osmotic treatment, the diffusion of solute into the material remains relatively insignificant. However, as the dewatering rate subsides, there is a concurrent increase in the rate at which solute penetrates the food material (Raoult-Wack, 1994). Several variables exert a notable influence on the kinetics of mass transfer during OD. These variables encompass factors such as its degree of maturity, the variety of the food material, the material's geometry, any pretreatment applied, the temperature, concentration of the osmotic agent, the ratio of food pieces to osmotic solution, the incorporation of additives, and the physicochemical properties and structural characteristics of the food material. Each of these factors plays a significant role in shaping the dynamics of mass transfer during the OD process.

The alteration in color during OD can be notably pronounced. The color parameters of the fruits are assessed both before and after the processing (Osorio et al., 2007). Elevated temperatures contribute to heightened browning in osmodehydrated fruits. The reduction in water activity during the osmotic process promotes chemical reactions, leading to the formation of browning pigments. Additionally, higher temperatures can enhance browning through chemical and enzymatic reactions, facilitating the oxidation of phenolic compounds and the initiation of the Maillard reaction, involving the presence of reducing sugars and amino acids (Atares et al., 2011). Utilizing OD as a pretreatment enables the acquisition of dehydrated fruits with a more authentic color profile. Numerous studies have documented a safeguarding impact on the color of fruits and vegetables when subjected to osmotic pretreatment. This effect has been observed in various instances, including air-dried carrot, lyophilized strawberry, frozen mango, and mango chips (Landim et al., 2016).

Texture stands as a primary qualitative criterion intertwined with the rheological and structural properties of food, assessable through various mechanical parameters such as firmness, adhesiveness, cohesiveness, gumminess, and viscosity (Nieto et al., 2013). The decline in firmness is connected to the breakdown of pectin and insoluble protopectin, as these components play a crucial role in maintaining the structural rigidity of the fruit. The activity of pectinase enzymes, particularly polygalacturonase and polymethylesterase in ripe fruits, leads to the solubilization of pectic substances. A decrease in the respiration rate of fruits diminishes enzyme activity, resulting in a lesser impact on the texture of the food (Ferrari et al., 2013). Diverse alterations in process parameters, including temperature, solution composition, and fruit characteristics, lead to distinct mass transfer kinetics during OD, influencing the composition of plant tissue in various manners. These effects give rise to uneven physicochemical transformations in osmodehydrated products (Jacob & Paliyath, 2012). In the literature, various drying techniques are studied, and their utilization extends to industrial and large-scale facilities. A summary overview is presented in Table 1, outlining the studies from the literature along with the parameters investigated.

| Authors | Study | Parameters | Results |

|---|---|---|---|

| (Fletcher & Langrish, 2009) | Numerical | Inlet swirl angle, turbulence model | The SAS approach captures a significantly greater portion of the turbulence structure in the study. In the case of a 25° inlet swirl, notable turbulence structures are generated at the location where the jet begins to disintegrate. |

| (Harvie et al., 2001) | Numerical | Radial and horizontal inlet angles | By changing the angle of the incoming air streams into the dryer, it is possible to substantially modify the flow characteristics within the dryer. |

| (Duan et al., 2008) | Experimental | Effect of nanoscale silver coating, MDF characteristics of sea cucumber | Microwave freeze-drying (MFD) method can reduce the drying time of conventional freeze-drying (FD) by approximately 50%. |

| Treatment with a nanoscale silver coating had no impact on the quality of dehydrated sea cucumber and could maintain a high level of sterilization even at relatively low microwave power levels. | |||

| (Pua et al., 2010) | Numerical | Steam pressure, drum rotation speed | The ideal drum drying conditions for producing jackfruit powder with desired properties were determined to be a combination of 336 kPa steam pressure and a rotation speed of 1.2 rpm, with a fixed drum clearance of 0.01 inch and a pool level of 10 cm. |

| (Kurnia et al., 2013) | Computational | Slab thickness, slab geometries, jet velocity | In the scenario analyzed in this study involving thin slabs of 0.5 and 5 mm thickness, the findings indicate that an impinging jet with pulsating and intermittent flow provides drying kinetics similar to that of a steady jet but with reduced energy consumption. |

| (Silva et al., 2016) | Experimental | Effect of pretreatment with ethanol | The quality of the product has been assessed by measuring the concentration of bioactive compounds. The results demonstrate that the new dryer proves to be a viable alternative for drying acerola residue, primarily due to its high drying rate and the excellent quality of the product post-drying. |

| (Chapchaimoh et al., 2016) | Experimental | Airflow, nitrogen flow | The heater contributed 62.93% and 65.60% of the total input energy to the refrigerant cycle, whereas the heat gained at the external condenser accounted for 37.92 and 28.79% of the output energy for air and nitrogen drying, respectively. |

| (Laurienzo et al., 2010) | Experimental | Different types of dehydrating films | The innovative bio-films, as proposed, do not exhibit the drawbacks of freeze-drying. They enable the attainment of high free sugar content, preservation of volatile components, maintenance of pH value (similar to fresh apple), and cost-effective treatment. |

| (Zlatanović et al., 2013) | Experimental | Temperature, relative humidity, velocity, material size | The duration required to achieve equilibrium moisture content, starting from the initial moisture level, extends with the rise in drying air temperature and velocity, while it decreases with a reduction in relative humidity and the size of the material sample. |

| (Defraeye, 2017) | Numerical | Drying temperature, ambient environment | The study offers a more precise quantitative understanding of when fruit drying should be terminated, considering specific drying conditions. This approach aims to reduce energy consumption (less rehydration), shorten processing time, and enhance product quality. |

| (Sturm et al., 2014) | Experimental | Air temperature, product temperature, dew point temperature, air velocity | Regulating the product temperature resulted in reduced drying durations and, in general, minimized color alterations. It was observed that the product temperature follows a distinct pattern, characterized by two stages and a clearly defined transition period. |

| (Defraeye, 2016) | Numerical | Tempering time, total cycle time, ambient humidity | Intermittent drying decreases the time that the fruit stays in the dryer by 20% in the study. This enhances both energy efficiency and throughput. Extended tempering times substantially decreased the residence time, primarily because of the prolonged moisture relaxation. |

| (Defraeye, Blocken, Derome, et al., 2012) | Numerical | Different modeling approaches | Conjugate modeling can, therefore, serve as a valuable tool for the analysis of drying processes, enabling a more precise identification of heterogeneous heat and moisture gradients within the porous material. |

| (Defraeye & Radu, 2018) | Numerical | Applying different model approaches | The study provides a comprehensive understanding of fruit drying kinetics, examining the influence of various modeling assumptions and analyzing the impact of the peel on the drying behavior. |

| (Van Boekel, 2008) | Review | Color, nutrient content, safety | This article delves into the quantitative study of critical food quality aspects, including color, nutrient content, and safety, using mathematical models. It emphasizes the challenges in applying chemical kinetics to complex food systems, highlighting the need for improved modeling and quality control in food science. |

| (Surasani et al., 2008) | Numerical | Isothermal and non-isothermal modeling | The research revealed that in scenarios with low temperature gradients, condensation rates were minimal, and errors were negligible. The authors are committed to refining their model for broader applications, particularly in cases with substantial and opposing temperature gradients, while also seeking to boost the algorithm's efficiency for simulating three-dimensional networks in drying processes. |

| (Luo et al., 2021) | Experimental | Hot air drying (HAD), vacuum freeze-drying (VFD), air impingement drying (AID) | AID showed promise in enhancing flavor by increasing volatile sulfides and sweet and umami amino acids. It also offered competitive shrinkage and rehydration rates compared to VFD. Despite some compromises in soluble sugar content and color due to Maillard reactions and heat degradation, AID outperformed both HAD and VFD in terms of drying efficiency, making it a promising technology for dehydrated mushrooms, balancing overall quality and efficiency. |

| (Defraeye et al., 2016) | Experimental | Airflow temperature, air speed, and incident radiation | The study successfully employed quantitative neutron imaging to monitor moisture distribution during convective drying of fruits, revealing the impact of process conditions and the connection between anisotropic shrinkage and non-uniform dehydration due to peel presence. |

| (Nowacka et al., 2012) | Experimental | The effect of ultrasound | Ultrasound pretreatment substantially reduced the drying time of apple cubes by 31–40% and induced increased shrinkage, altered density, and porosity compared to untreated samples. Scanning electron microscopy analysis confirmed notable distinctions in the microstructure of treated and untreated dried apples. |

| (Cappelletti et al., 2014) | Experimental | The effect of SC-CO2 alone and SC-CO2 + HPU treatment on coconut water | The study highlighted the synergistic impact of combining SC-CO2 and HPU processes for the inactivation of specific microorganisms in the sample. The efficiency of this combined approach was influenced by temperature and the microorganism type, resulting in shorter required process times for inactivation compared to using SC-CO2 alone. |

In the food industry, the drying process is characterized by a high energy consumption density. Therefore, the selection of an appropriate drying method is crucial for mitigating environmental impacts. Researchers are actively engaged in endeavors aimed at reducing energy consumption and subsequently enhancing the speed of the drying process. The overarching objective in improving drying processes is to eliminate the maximum amount of moisture with the least energy input. In a proficient drying method, minimizing the reduction in nutritional value of the product while employing the least amount of energy constitutes a pivotal factor (Khaing Hnin et al., 2019). Concerning the future utilization of dried goods, it is important to take into account the application of pretreatment and dehydration parameters. Ongoing research is exploring various methods, including pretreatments, aimed at enhancing the process of food drying (Waghmare et al., 2023). Life cycle assessment stands as a widely employed method for gauging the environmental impact of both processes and products over their entire lifespan. While there has been a substantial growth in the life cycle assessment of food items in recent years, research on ultrasonic-assisted foods appears to be scarce, to the best of our knowledge. Applying life cycle assessment to emerging products and early-stage food processes is challenging due to a dearth of accurate data. Another hindrance is the utilization of unauthenticated laboratory data in some studies, often without accounting for scale-ups (Aghbashlo et al., 2020).

Dried foodstuffs gain widespread popularity as a food product globally. Assessing their quality is a crucial step in preparing them for commercial markets (Richter Reis et al., 2022). Over the recent years, numerous scientific reports have conducted various quality analyses in this regard. Additionally, a variety of drying methods have been employed in these research investigations. In this context, Table 2 presents a summary of the advantages and disadvantages of different drying methods based on various analysis types.

| Authors | Procedure | Product type | Analyze type | Pros | Cons |

|---|---|---|---|---|---|

| (Ge et al., 2020) | Hot air drying | Pepper | Volatile flavor compounds | Optimal preservation of flavor | Significant loss of volatile compounds |

| (J. Wang et al., 2019) | Ultrasound drying | Kiwi | Microstructure observation and color evaluation | High drying rate | Significant reduction in both ascorbic acid and solid content |

| (Ge et al., 2020b) | Vacuum drying | Kiwi | Color inspection and rehydration rate | Preserving the original shape and high bioactive retention | High energy-consuming and long drying period |

| (Geng et al., 2023) | Hot air drying | Sea buckthorn berries | Total phenols, ascorbic acid, and microstructure | High heat transfer coefficient for convection | Rapid reduction in size during the initial drying phase |

| (Z. Zhang et al., 2018) | Hot air drying | Potatoes and carrot | Microstructure | Retained high α-carotene | Significant degradation of β-carotene |

| (Çetin & Sağlam, 2023) | Microwave | Apple | Biochemical analysis | Short drying time | High ash content |

| (Hernández et al., 2020) | Osmotic drying | Apple | Texture and microstructure | Short drying period and high porosity | Pale hue |

| (Çetin & Sağlam, 2023) | Freeze-drying | Apple | Color measurement | Lowest color change | Long drying time |

| (Ozkan et al., 2023) | Hot air drying | Grape | Sensory | Low cohesiveness values | High hardness value |

| (Bozkir, 2020) | Vacuum drying | Orange | Color and density | Effective diffusion, high quality products | High energy-consumption and low overall quality |

3 MACHINE LEARNING IN PRESERVATION OF FOODS

Machine learning (ML) is increasingly being applied in various domains, and food preservation is no exception. ML techniques can enhance the efficiency, accuracy, and quality of food preservation processes. ML algorithms exhibit exceptional capability in managing vast amounts of data and forecasting distinct trends and patterns. Within the array of ML approaches, prominent methods include regression, classification, clustering, ensemble methods, transfer learning, reinforcement learning, natural language processing, and deep learning algorithms, extensively employed in the field of engineering (Khan et al., 2022). In the realm of food drying research, supervised learning methods, particularly deep learning neural networks, are extensively employed owing to their distinct advantages in addressing intricate food drying problems.

Artificial neural networks (ANNs) can be described as mathematical representations of human brain activities, capable of managing numerous linear or nonlinear processing elements, commonly referred to as nodes (Khan et al., 2022). Besides the application of ANN in food drying, recommendations have also been made for the utilization of Fuzzy logic and other computer expert systems (Sun et al., 2019). Fuzzy logic represents a contemporary computer-based approach for predicting data based on degrees of truth, departing from the conventional true or false (1 or 0) Boolean logic. Its remarkable capacity lies in its ability to characterize and manage a specific problem, especially when the model is unknown or ill-defined (Mohd Adnan et al., 2015). Jiang et al. (2023) evaluated frozen food quality through nondestructive testing by utilizing ML performing hierarchical clustering analysis and principal component analysis.

3.1 Quality control and maintenance

Quality control and inspection in the food industry benefit from ML in various ways. Image recognition algorithms play a crucial role in identifying defects, spoilage, and contaminants in food products, ensuring that only high-quality items are delivered to consumers. Additionally, ML models can utilize spectral analysis to detect signs of spoilage or contamination that may be imperceptible to the human eye. Techniques such as hyperspectral imaging contribute to identifying chemical changes in food, enhancing the overall quality control process (Chakravartula et al., 2023; S. Sharma et al., 2023).

Predictive maintenance in food preservation involves the use of ML algorithms to anticipate potential failures in equipment, like refrigeration systems. By predicting these issues in advance, proactive maintenance measures can be implemented, minimizing downtime and preventing spoilage of perishable goods (Peddi et al., 2023). Supply chain optimization benefits from ML algorithms as well, which analyze both historical data and real-time information to enhance various processes. These algorithms predict demand, optimize inventory levels, and refine distribution routes, ensuring the efficient and timely delivery of food products while maintaining optimal conditions throughout the supply chain (W. Huang et al., 2023).

3.2 Packaging and chain management

Cold chain management for perishable goods, ML models play a vital role by analyzing sensor data from temperature and humidity monitoring devices. This analysis enables the prediction and prevention of conditions that could potentially lead to spoilage. This proactive approach is essential for maintaining the quality and integrity of perishable items throughout the supply chain (Chakravartula et al., 2023). In the study conducted by Chakravartula et al., a convective dryer equipped with a computer vision (CV) system and load cell was employed for the continuous monitoring of both unblanched and blanched carrot slices. The investigation involved testing a prototype dryer with smart-enabled features, showcasing the potential for automation and the integration of proactive quality strategies.

ML is also utilized in smart refrigeration systems (Jiang et al., 2023), traceability and recall management (L. Zhang et al., 2024), quality prediction models, optimizing packaging (Gim et al., 2023), and dynamic pricing (Ben Slama & Mahmoud, 2023).

In recent scientific investigations, the ML approach has been integrated with gas sensors for the characterization of tarragon aroma and essential oil (Karami et al., 2024; J. Wang et al., 2024). Additionally, machine-learning-enabled paper chromogenic arrays have been employed for the assessment of food quality, particularly in conjunction with chemometric methods to evaluate the aroma produced (Jia et al., 2024; Liu et al., 2024).

4 MATHEMATICAL MODELING

Typically, biological porous media exhibit an initially high moisture content and possess a complex, porous internal structure. Throughout the drying process, the solid framework of the porous medium experiences noticeable volume contraction and deformation, coinciding with a decrease in moisture content (Lu et al., 2015). In analyzing heat and mass transfer of a porous media, the flow of liquid and vapor within a rigid porous medium is taken into account by considering solid, liquid and gas phases.

4.1 Governing equations

The governing equations for heat transfer and fluid flow have been simplified for a scenario involving steady, two-dimensional, laminar, incompressible fluid flow by assuming constant fluid properties, with no heat generation or deformation occurring within the object. Furthermore, the analysis disregards body forces, viscous dissipation, and heat radiation, primarily due to the relatively mild temperature gradients present in the fluid flow.

Studying drying processes requires understanding how moisture content and temperature change over both space and time (Whitaker, 1977).

Mass conservation equation (Lu et al., 2015):

Drawing from the principles of Fickian diffusion theory and the continuity equation, and considering the impact of porous solid frame deformation throughout the drying process, a mass transfer model can be derived that characterizes the dry basis moisture content within biological porous media as follows:

Momentum equations (Alnak & Karabulut, 2019):

Energy conservation equation:

The significance of physical interpretation of Equation (6) expresses the rise in energy per unit volume per unit time within the porous medium, restraining the bound water (depicted on the left-hand side of the equation), equals the energy linked to nearby heat conduction (represented by the first term on the right-hand side of the equation), along with the energy related to the diffusion of liquid water (illustrated by the second term on the right-hand side of the equation), subtracted by the energy connected to solid displacement (captured in the third term on the right-hand side of the equation).

5 COMPUTATIONAL FLUID DYNAMICS MODELING OF HEAT AND MASS TRANSFER

In numerous applications, the computational fluid dynamics (CFD) approach finds extensive use in numerically modeling food drying processes. Among the commonly employed software for such simulations, ANSYS Fluent and ANSYS CFX take the lead. Despite the extensive research aimed at rigorously validating CFD simulations, concerns about the absolute accuracy of CFD models continue to be raised within the drying community. Some argue that these models have limitations for practical use (Defraeye, 2014; Jamaleddine & Ray, 2010). However, it is important to note that such criticism and skepticism toward CFD, and modeling techniques in general, are not always warranted. Additionally, for issues related to identifying irregularities in flow fields, quantitative accuracy may be of less significance. In many cases, a qualitative comparison of flow fields, such as in different dryer designs, can be adequate to support decision-making processes.

5.1 Turbulence flow models

The demand for enhanced precision in predicting flow-field characteristics, particularly turbulence, has driven researchers in the field of drying toward the adoption of more advanced turbulence modeling techniques. These include the scale-adaptive simulation approach, large eddy simulation (LES), and hybrid Reynolds-averaged Navier–Stokes (RANS)-LES techniques (Fletcher & Langrish, 2009; Harvie et al., 2001; Jongsma et al., 2013). These methods offer improved accuracy by explicitly resolving a portion of the turbulence, as opposed to relying on complete turbulence modeling (LES, DES), or by considering turbulence length scales in a more realistic manner than traditional RANS modeling.

In drying modeling, CTCs are frequently employed to anticipate the convective exchange of heat and mass between macroscopic porous materials or microscopic particles/droplets and their surroundings at the air-material interface, facilitated by the boundary layer. Employing simplified CTCs essentially sidesteps the need to consider the nuanced, case-specific aspects of transport within the boundary layer. While this simplification streamlines a crucial aspect of complex drying process modeling, it also carries the risk of significantly compromising the accuracy of predictions related to air-side convective heat and mass transfer (Defraeye, Blocken, & Carmeliet, 2012; Defraeye, Blocken, Derome, et al., 2012).

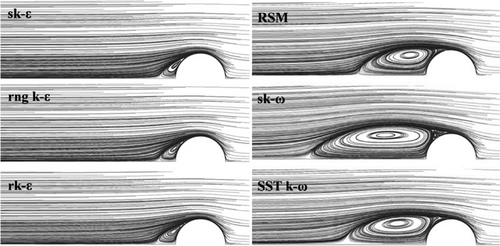

In turbulence modeling, Defraeye et al. (2013) studied different Reynolds turbulence models for spherical foodstuffs which represents wide range of foods with its shape. A comparison between empirical flow parameters and those acquired through CFD using various RANS turbulence models in conjunction with LRNM was conducted as a function of the Reynolds number. Streamlines around a sphere generated from CFD simulations using various RANS turbulence models are shown in Figure 15.

Among all the turbulence models, the SST k–ω model stands out for its excellent performance. Its remarkable agreement with empirical data, typically within less than 5% error, is especially noteworthy in the context of RANS simulations. The outcomes of this CFD validation study suggest that the (LRNM) SST k–ω model can offer a satisfactory level of accuracy for predicting flow and scalar transfer in the case of a single sphere, particularly within a relevant airspeed range (Reynolds number) pertinent to food processing studies.

The performance of the SST k–ω model is presumed to be similarly effective for food products with a spherical shape, such as an apple. Furthermore, for more intricate configurations, such as stacks where the sphere serves as the basic component, the SST k–ω model's performance is expected to excel compared to other turbulence models. Nonetheless, additional verification is warranted in these complex scenarios.

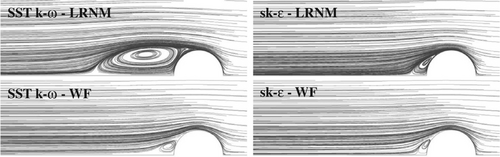

5.2 Boundary-layer models

Defraeye et al. (2013) conducted a comparison between empirical flow parameters and CFD results achieved through diverse boundary-layer modeling techniques, considering variations in the Reynolds number. In this comparison, the SST k–ω model and the standard k–ε model are assessed with both LRNM and WF. The SST k–ω model is included due to its superior performance among all turbulence models, while the standard k–ε model is included because it remains one of the most widely utilized models in CFD engineering Ahmed et al. (2023). To facilitate the comparison of flow fields across different models, streamline visualizations for all models are depicted within the center plane of the sphere. Streamlines surrounding a sphere derived from CFD simulations employing various boundary-layer modeling techniques at a Reynolds number of 10,000 are given in Figure 16.

The conjugate modeling approach has gained prominence in recent studies. Using the conjugate approach at the boundary layer interface can provide convenience in solving complex flow problems in heat and mass transfer, as opposed to the CTC approach. Some studies that have employed the conjugate approach are presented in Table 3.

| Author(s) | Porous material | Fluid flow modeling | Dimension | CFD modeling software |

|---|---|---|---|---|

| (Kaya et al., 2006) | Rectangular moist object | Navier–Stokes equation | 2D | ANSYS Fluent |

| (Defraeye & Radu, 2017) | Different fruit tissue | Navier–Stokes equation | 3D | COMSOL Multiphysics 5.0 |

| (Defraeye & Verboven, 2017a) | Different fruit tissue | Turbulent airflow | 2D | COMSOL Multiphysics 5.2 |

| (Reuss et al., 1997) | Wood tissue | Turbulent airflow | TRANSYS Software | |

| (Ateeque et al., 2014) | Rectangular moist object | Navier–Stokes equation | 3D | ANSYS ICEM CFD |

| (Defraeye, 2017) | Apple slices | CTCs | 3D | COMSOL Multiphysics 5.0 |

| (Defraeye & Radu, 2018) | Apple | Navier–Stokes equation | 3D | COMSOL Multiphysics 5.2 |

| (Defraeye, 2016) | Apple slices | CTCs | 3D | COMSOL Multiphysics 5.2 |

| (Tzempelikos et al., 2015) | Cylindrical quince slices | Turbulent airflow | 2D | COMSOL |

| (Sabarez, 2012) | Prunes | CTCs | 2D | COMSOL Multiphysics 5.2 |

| (W. A. Aregawi et al., 2014) | Apple | Finite Element Method (FEM) | 2D | COMSOL Multiphysics 4.2 |

| (Lemus-Mondaca et al., 2017) | Papaya | CTCs | 3D | FORTRAN |

| (Vahidhosseini et al., 2016) | Quince | Green's function method (GFM) | 2D | Maple 17.02 |

| (W. A. Aregawi et al., 2014) | Apple tissue | Multiscale | 2D | COMSOL Multiphysics 3.5a |

5.3 Mass transport and convective transport in gas and liquid phases

In this gas phase, diffusion equation γ denotes the gas phase, DD gas phase dispersion tensor. The issue of establishing the gas phase velocity can be approached in two ways (Whitaker, 1977). The first method involves anticipating the principles of mechanics and utilizing either the continuity equation or the diffusion equation to ascertain the velocity. This necessitates imposing a constraint on either the pressure field or the velocity field. An illustrative instance of this analytical approach is found in laminar boundary layer theory. In this scenario, one establishes one velocity component through an equation of motion and subsequently restricts the pressure to a constant value, enabling the use of the continuity equation to determine the other component of the velocity vector. It is crucial to emphasize that this approach is capable of determining only one velocity component, given that the continuity equation is a scalar equation. In drying processes, where the gas phase pressure tends to remain relatively constant, employing the continuity equation along with a suitable constraint becomes an appealing option. However, a notable limitation is that this method is applicable primarily to one-dimensional processes. Importantly, the absence of an appropriate constraint on the velocity field is a significant drawback.

In boundary layer analysis, the continuity equation specifies the velocity component along a single coordinate axis, while in the Stefan diffusion tube process, the entire velocity field of one of the species is specified (Whitaker, 1977). Another method, which enables the disregarding of mechanical laws, involves a straightforward assumption: considering that all convective transport, encompassing not only the dispersive part but the entirety of it, can be effectively represented by a diffusive mechanism (Berger & Pei, 1973).

6 CONCLUSION AND FUTURE RESEARCH

In this review, drying methods of fruits has been researched and compiled extensively, encompassing various aspects of the methods, application techniques, their respective advantages and limitations, and the numerical methods employed in drying processes. Drying technology has evolved with the emergence of innovative approaches aimed at minimizing energy consumption and operational expenses. In this context, it holds significant importance to select the suitable drying method based on the specific food product and to execute this method under the relevant operating conditions. This investigation offers a comprehensive overview of drying methods, delving into the engineering aspects and the specific conditions suitable for drying various kinds of fruits and vegetables.

- The advancement of the air jet drying technique is crucial for conserving energy and achieving a uniform temperature distribution.

- Several novel drying methods such as microwave drying, IR drying, and EHD have demonstrated microbiologically passive efficacy. In comparison to conventional methods, these techniques have exhibited superior outcomes and effective drying performance for specific product categories, thereby showcasing high-quality results.

- The ability to precisely represent drying processes through numerical methods holds particular significance, especially within the industrial context.

- In the context of food subjected to pretreatment in drying methods, the utilization of ML offers significant advantages for the optimization of pretreatment processes and the determination of parameters influencing the quality of dried foods. ANN systems, in this regard, provide flexibility concerning applicability and demonstrate high efficiency in the exploration of relevant parameters.

- Intermittent drying proves to be an efficacious approach for accelerating drying rates, elevating product quality, and mitigating energy consumption per unit mass of moisture removal.

- One of the most significant risks to human health in the drying of foods is pesticide residues. The reduction of pesticides currently attracts the attention of researchers and holds promise for future perspectives. Prior to the drying process, foods undergo certain pretreatments to mitigate pesticide residues. Particularly, it has been observed that IR, ultraviolet, and ultrasonic-assisted applications substantially reduce pesticide residues. Further research in this area would be beneficial for enhancing the quality of foods and mitigating potential adverse effects on human health arising from pesticide residues.

- Further research into the rehydration properties of biofilm drying can lead to the achievement of preservation of volatile components, higher free sugar content, stable pH values, and cost-effective treatment methods.

- The utilization of nanoparticles constitutes a viable solution for preservation applications in food. Nano-sized particles, in comparison to their microscale counterparts, demonstrate enhanced performance in the preservation of compounds even at the cellular level.

- Supercritical CO2 drying, as a relatively modern drying approach, results in enhanced product appearance and reduced shrinkage of dried goods.

- IR heating is particularly appealing for applications that require surface heating. To realize the optimal energy efficiency and practical effectiveness of IR heating in the food processing sector, there is significant promise in integrating IR heating with microwave technology and other conventional conductive and convective heating methods.

ACKNOWLEDGMENTS

All authors are thankful to Adana Alparslan Turkes Science and Technology University, Turkey, Pakistan Institute of Engineering and Applied Sciences, Pakistan and University of Alberta, Canada for their support for the preparation of this manuscript.

FUNDING INFORMATION

No funding for this review article was received.

CONFLICT OF INTEREST STATEMENT

None of the authors have a conflict of interest to disclose.

Open Research

DATA AVAILABILITY STATEMENT

The data that support the findings of this study are available from the corresponding author upon reasonable request.