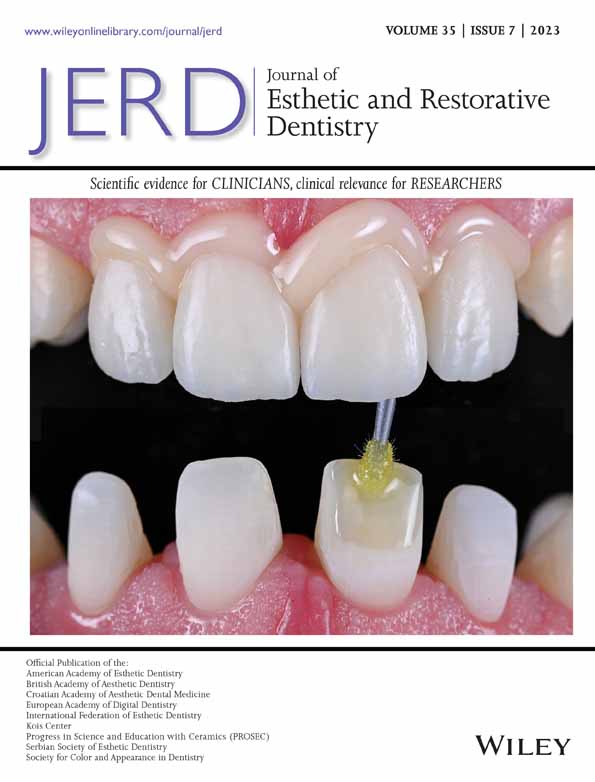

The clinical use of computer aided designed/computer aided manufactured titanium nitride coated implant abutments: Surgical and prosthetic considerations—A case series

Abstract

Objective

To describe the clinical use of nitride-coated titanium CAD/CAM implant abutments in the maxillary esthetic zone in two patients with high esthetic and functional demands and, to highlight the advantages of nitride-coated milled titanium abutments when compared to stock/custom titanium, one-piece monolithic zirconia, and hybrid metal-zirconia implant abutments.

Clinical Considerations

Due to the inherent mechanical and esthetic clinical challenges, single implant-supported reconstructions in the maxillary esthetic zone are a complex restorative treatment. While CAD/CAM technology has been suggested to enhance and ease implant abutment design and manufacturing, implant abutment material selection remains as a critical decision affecting restoration's long-term clinical outcomes. To date, considering the esthetic disadvantages of conventional titanium implant abutments, the mechanical limitations of one-piece zirconia abutments and the manufacturing time and costs associated with hybrid metal-zirconia abutments, no abutment material can be considered “ideal” for all clinical scenarios.

Due to their biocompatibility, biomechanical characteristics (hardness and wear resistance), optical properties (yellow color), and peri-implant soft tissue esthetic integration, the use of CAD/CAM titanium nitride-coated implant abutments has been suggested as a predictable implant abutment material in mechanically challenging but esthetically demanding clinical situations, as the maxillary esthetic zone.

Conclusions

Two patients requiring a combined tooth-implant restorative treatment in the maxillary esthetic zone were treated using CAD/CAM nitride coated titanium implant abutments. The principal advantages of TiN coated abutments include comparable clinical outcomes to stock abutments, optimal biocompatibility, adequate fracture, wear, and corrosion resistance, reduced bacterial adhesion, and excellent esthetic integration with adjacent soft tissues.

Clinical Significance

Clinical reports and short term mechanical, biological and esthetic clinical outcomes indicate that CAD/CAM nitride coated titanium implant abutments can represent a predictable restorative alternative to stock/custom and metal/zirconia implant abutments and be considered a clinical relevant option in mechanically challenging but esthetically demanding situations, as often found in the maxillary esthetic zone.

Open Research

DATA AVAILABILITY STATEMENT

Data sharing not applicable to this article as no datasets were generated or analysed during the current study.