Comparison of the Effects of Two Screw Insertion Patterns on Bone Fragment Translocation in a 3.5 mm Dynamic Compression Plate and a 3.5 mm Limited-Contact Dynamic Compression Plate

Presented in part as a poster at the ACVS Veterinary Symposium, Seattle, WA, October 21–23, 2010.

Abstract

Objective

To compare the effects of screw insertion pattern, plate type, application of bone reduction forceps, and additional load screw insertion in an 8-hole 3.5 mm dynamic compression plate (DCP) and limited-contact dynamic compression plate (LC-DCP) on bone fragment translocation (BFT) in a fracture gap model.

Study Design

In vitro mechanical study.

Methods

Two screw insertion patterns were tested in the DCP and newly redesigned LC-DCP using gap model synthetic bone constructs. In Pattern 1, screws were first inserted into the holes at each end of the plate, then screws were inserted into the holes adjacent to the fracture gap. In Pattern 2, screws were only inserted into the holes adjacent to the fracture gap. The effects of tight or loose bone forceps securing the plate, loosening a neutral screw in Pattern 1, and inserting up to 4 additional load screws with each pattern were tested. Changes in the fracture gap were measured after insertion of all neutral screws and after each load screw.

Results

Pattern 2 BFT was significantly greater than Pattern 1 BFT when bone forceps were loose with both plates (P < .001). In the DCP, the BFT was significantly increased by loosening the bone forceps with Pattern 2 (P < .001) and by loosening 1 neutral screw in Pattern 1 (P < .001). The BFT for each additional load screw inserted was significantly less than 1.0 mm.

Conclusions

A tight neutral screw in the same bone fragment as the load screw or bone clamps that tightly secure the plate to the bone can limit BFT.

The dynamic compression plate (DCP) is one of the most reliable means of internal fixation for transverse and short oblique diaphyseal fractures. The holes in the DCP and the limited-contact dynamic compression plate (LC-DCP) were designed to eliminate small gaps between fracture ends and to create static axial compression between reduced fracture fragments.1-5 This permits direct load transfer from 1 fracture fragment to the other and diminishes the load assumed by the fixation device.2 Axial compression, which causes increased friction between the fracture fragments, combined with friction between the plate and the underlying bone increases the stability of fracture fixation.4 Eccentric insertion of a screw in a DCP or LC-DCP hole causes the screw head to slide down the glide slope of the plate hole, resulting in translocation of the bone fragment as the screw is tightened.1-7 Compression results if the fractured surfaces of the bone fragments are in contact with each other when the load screw is inserted.1, 5, 7, 8 If there is a gap between the fracture ends the insertion of a load screw will close the gap distance. The reported translocation for a load screw in a 3.5 mm DCP or LC-DCP is 1.0 mm and for a neutral screw is 0.1 mm.1-5 The order in which screw holes are filled and the position of the screws in the holes must be considered for proper application of a DCP or LC-DCP.

Different load screw insertion patterns have been described for the DCP and LC-DCP.1-5, 7-9 Additionally, bone reduction forceps are commonly used to stabilize bone plates to reduced fracture fragments during plate and screw application. Most studies involving the DCP and LC-DCP have tested the compressive force generated, the mechanical stability of the plates, and the holding strength of inserted bone screws.1, 5, 9-11 The effects of screw insertion pattern and bone forcep application on bone fragment translocation (BFT) with a 3.5 mm DCP or LC-DCP have not been documented. It is reported that a maximum of 2 load screws can be inserted on each side of a fracture before BFT is limited by contact between the screw heads and the walls of the DCP or LC-DCP holes. To our knowledge, the individual effect of these additional load screws has not been described.1-4, 8

We used a fracture gap model to measure BFT from screw insertion in a standard 8-hole 3.5 mm DCP and the newly redesigned LC-DCP. Our objectives were to evaluate (1) the BFT from 2 common screw insertion patterns with both plates; (2) the effect of using bone reduction forceps to stabilize plate-bone constructs during load screw insertion with both screw insertion patterns; (3) the effect on BFT when using the same screw insertion pattern in 2 types of plates; and (4) the amount of BFT caused by insertion of additional load screws. We hypothesized that BFT would be affected by the different screw insertion patterns, by tight or loose bone reduction forceps, and by plate type. We also hypothesized that inserting additional load screws would cause BFT; however, the amount of BFT would progressively decrease with each screw inserted.

MATERIALS AND METHODS

At the 1996 AO-Vet meeting in Davos, Switzerland, one of the authors (MO) surveyed AO faculty members regarding their preferred technique for applying a standard 8-hole 3.5 mm DCP to a transverse mid-diaphyseal fracture. Of the 16 anonymous surveys returned, 12 different compression screw insertion patterns were provided. The 2 most commonly preferred screw insertion patterns reported (Fig 1) in this survey were a pattern with 3 neutral screws and 1 load screw (Pattern 1) and a pattern with 1 neutral screw and 1 load screw (Pattern 2). The current study tests these 2 patterns using a standard 8-hole 3.5 mm DCP (Synthes.vet, Monument, CO) and the newly redesigned 8-hole, 3.5 mm LC-DCP (Synthes.vet) on a fracture gap synthetic bone (Synbone®, #0066 Generic bone cut model, Synbone AG, Malans, Switzerland) model.

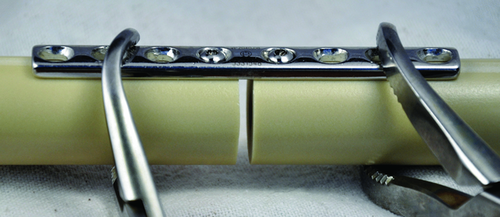

One investigator (AC) created each fracture construct by securing the DCP or LC-DCP parallel to the long axis of 2 Synbone® cylinders using serrated bone reduction forceps (Synthes.vet) placed at the second to last hole from each end of the plate (Fig 2). The plates and cylinders were visually aligned using a straight edged ruler. The bone forceps were hand tightened by the same author (AC) until they could no longer be tightened. The speed lock on the forceps was hand tightened until it could no longer be tightened. The center portion of the plate was placed over a gap (range 4–6 mm) between the Synbone® cylinders. One construct was created for each trial. Ten trials were performed for each test pattern.

For each trial the end of 1 Synbone® cylinder was secured in a vise. A single mark was made on the gap end of each cylinder using an ultra fine-point Sharpie® permanent marker (Sanford, L.P., Oak Brook, IL) with a tip diameter of 0.5 mm. The marks were immediately adjacent to the plate and directly across the fracture gap from each other. The initial gap distance between the 2 cylinders was measured in millimeters using a digital caliper with a resolution of 0.01 mm and accuracy of 0.03 mm (Traceable, Model no. 62379-531, Control Company, Friendswood, TX) centered on the marks at the end of each cylinder. This initial gap distance was recorded for each construct. Screw holes were drilled perpendicular to the longitudinal axis of the plates and through both sides of the cylinders using a 2.5 mm drill bit driven by an electric drill. The AO load or neutral drill guide (Synthes.vet) was used with the DCP, and the universal drill guide (Synthes.vet) was used with the LC-DCP according to the standard Arbeitsgemeinschaft fur Oseosynthesefragen (AO) and Association for the Study of Internal Fixation (ASIF) technique.1, 2, 5 Drilled holes were tapped with a 3.5 mm tap driven by an electric drill. The 3.5 mm cortical bone screws were inserted into each plate hole and hand tightened with a screw driver according to AO/ASIF principles by 1 author (AC).1, 2 All screws were bicortical. The gap distance was measured using the digital caliper and recorded at the same initial marks between the cylinders after insertion of the neutral screw(s) and each load screw in every trial. The BFT was determined by calculating the change in gap distance caused by insertion of neutral and load screws. The sum of the BFT from the neutral screw(s) and the BFT from the load screw in each pattern was the total pattern BFT.

The DCP was tested using Pattern 1 and Pattern 2 (Fig 1), each with the bone reduction forceps tight in 1 trial set and loose in another. To loosen the forceps, the speed lock was released, allowing the plate to move on the cylinders without restriction. The newly redesigned LC-DCP has a single round hole at one end of the plate. This plate was tested with Pattern 1, using the round hole at the end of the plate, with a modification of Pattern 1, using the oval hole adjacent to the round hole, and with Pattern 2. Bone forceps were loose in all LC-DCP tests. Additionally, a test using Pattern 1 in both the DCP and LC-DCP was performed in which the neutral screw in the same fragment as the load screw was loosened by one half of a turn before tightening the load screw while bone forceps were loose. After the initial load screw in each of these patterns was placed, 4 additional load screws were inserted with each pattern. Implants were randomly reused for all trials and replaced when they showed any visible wear.

Data Analysis

Mean ± SD BFT was calculated for each combination of plate, screw insertion pattern, and tight or loose bone forceps tested. Data evaluation was performed using Student's t-tests. Statistical significance was set at P < .05.

RESULTS

Pattern Testing (Tables 1 and 2)

Mean total pattern BFT from Pattern 2 was significantly greater than BFT from Pattern 1 with the DCP when bone forceps were tight and loose as well as with loose forceps on the LC-DCP. Pattern 2 BFT with the DCP increased significantly when bone forceps were loosened during load screw insertion as compared to when they remained tight. Mean BFT increased when the bone forceps were loosened with Pattern 1 in the DCP, but the difference was not statistically significant. When bone forceps were loose with Pattern 2 in the DCP and LC-DCP, the underlying bone fragment deviated from the long axis of the plate as the load screw was inserted. This deviation was not observed when the bone forceps remained tight with Pattern 2 or with tight or loose forceps with Pattern 1 regardless of plate type.

| Pattern 1 | Pattern 2 | ||||

|---|---|---|---|---|---|

| BFT (mm) | Tight Forceps (a) | Loose Forceps (b) | Neutral Screw Loosened (c) | Tight Forceps (d) | Loose Forceps (e) |

| Neutral screw* | 0.383 ± 0.08 | 0.425 ± 0.27 | 0.403 ± 0.09 | 0.136 ± 0.11 | 0.121 ± 0.06 |

| (Pa-b = .724) | (Pb-c = .900) | (Pb-d < .001) | (Pb-e = .003, Pd-e = .704) | ||

| Load screw* | 0.403 ± 0.12 | 0.523 ± 0.15 | 1.102 ± 0.10 | 1.105 ± 0.13 | 1.414 ± 0.21 |

| (Pa-b = .041) | (Pb-c < .001) | (Pb-d < .001) | (Pb-e < .001, Pd-e < .001) | ||

| Total patterna | 0.786 ± 0.15 | 0.938 ± 0.26 | 1.505 ± 0.14 | 1.241 ± 0.15 | 1.535 ± 0.18 |

| (Pa-b = .122) | (Pb-c < .001) | (Pb-d < .001) | (Pb-e < .001, Pc-d = .686, Pd-e < .001) | ||

- a Reported data are the mean ± SD (mm) BFT measured after insertion of the neutral screw(s), load screw, and all screws (total) in each pattern. For Pattern 1, the reported values reflect the total BFT for all 3 neutral screws inserted in the pattern. P-values in bold indicate statistical significance.

| BFT (mm) | Pattern 1 (a) | Modified Pattern 1 (b) | Neutral Screw Loosened Pattern 1 (c) | Pattern 2 (d) |

|---|---|---|---|---|

| Neutral screwa | 0.483 ± 0.25 | 0.57 ± 0.33 | 0.298 ± 0.07 | 0.008 ± 0.06 |

| (Pa-b = .516) | (Pa-c = .040) | (Pa-d < .001) | ||

| Load screwa | 0.384 ± 0.10 | 0.556 ± 0.20 | 0.298 ± 0.17 | 1.298 ± 0.18 |

| (Pa-b = .026) | (Pa-c = .188) | (Pa-d < .001) | ||

| Total patterna | 0.867 ± 0.29 | 1.126 ± 0.34 | 0.596 ± 0.21 | 1.306 ± 0.18 |

| (Pa-b = .083) | (Pa-c = .026) | (Pa-d <.001, Pc-d < .001) |

- a Reported data are the mean ± SD (mm) BFT measured after insertion of the neutral screw(s), load screw, and all screws (total) in each pattern. For Pattern 1, the reported values reflect the total BFT for all 3 neutral screws inserted in the pattern. P-values in bold indicate statistical significance.

Loosening the neutral screw in the same fragment as the load screw before tightening the load screw in Pattern 1, while bone forceps were loose significantly, increased the BFT with the DCP compared with loosening the bone forceps alone. In addition, the BFT from DCP Pattern 1 with the loosened neutral screw was not significantly different than the BFT from DCP Pattern 2 with loose bone forceps. Loosening the neutral screw in the same fragment as the load screw before tightening the load screw in Pattern 1 with the LC-DCP caused a small but significant decrease in the BFT. The BFT from Pattern 2 in the LC-DCP was still significantly greater than the BFT from Pattern 1 with the neutral screw loosened. Slight deviation of the underlying bone fragment from the long axis of the plate was observed once the neutral screw in Pattern 1 was loosened, and when the load screw was tightened while bone forceps were loose with both the DCP and the LC-DCP.

Pattern 2 BFT with bone forceps loose was significantly greater with the DCP as compared to the LC-DCP (P = .015). There was no statistically significant difference in BFT from Pattern 1 with bone forceps loose between the DCP and LC-DCP. There was no significant difference in BFT and no visible deviation of the underlying bone fragments when Pattern 1 and Modified Pattern 1 were compared in the LC-DCP.

The BFT from the load screw in Pattern 1 with the DCP was significantly less than the reported 1.0 mm with both tight and loose forceps (P < .001). Load screw BFT was also significantly less than 1.0 mm (P < .001) for the load screw in the LC-DCP with Pattern 1, Modified Pattern 1, and Pattern 1 with the neutral screw loosened. However, load screw BFT was significantly greater than 1.0 mm for the following patterns: DCP Pattern 2 with bone forceps tight (P = .018) and forceps loose (P < .001), DCP Pattern 1 with the neutral screw loosened (P = .005), and LC-DCP Pattern 2 (P < .001).

Additional Load Screw Testing (Table 3)

Insertion of additional load screws, beyond the initial load screw in each pattern, resulted in BFT that was significantly less than 1.0 mm with both plates and all patterns (P < .001). The BFT from the initial load screw in each pattern was significantly greater than the BFT from the first additional load screw inserted in each pattern. The BFT from the initial load screw in each pattern was also significantly greater than the total combined BFT from all additional load screws inserted with 3 of the 4 patterns tested: LC-DCP Modified Pattern 1, DCP Pattern 2, and LC-DCP Pattern 2. The total combined BFT from all the additional load screws inserted in DCP Pattern 1 was not significantly different from the initial load screw BFT from this pattern. There was no significant difference in BFT when comparing the 1st and 2nd or the 3rd and 4th additional load screws inserted with both plates and all patterns. BFT from the second additional load screw was significantly greater than the BFT from the 3rd additional load screw with Pattern 2 in both plates.

| Load screw | DCP Pattern 1* | LC-DCP Modified Pattern 1* | DCP Pattern 2* | LC-DCP Pattern 2* |

|---|---|---|---|---|

| Initial (a) | 0.523 ± 0.15 | 0.556 ± 0.20 | 1.414 ± 0.205 | 1.298 ± 0.18 |

| 1st additional (b) | 0.175 ± 0.19 | 0.105 ± 0.04 | 0.340 ± 0.09 | 0.296 ± 0.12 |

| (Pa-b < .001) | (Pa-b < .001) | (Pa-b < .001) | (Pa-b < .001) | |

| 2nd additional (c) | 0.193 ± 0.10 | 0.146 ± 0.08 | 0.285 ± 0.15 | 0.373 ± 0.19 |

| (Pb-c = .790) | (Pb-c = .157) | (Pb-c = .328) | (Pb-c = .301) | |

| 3rd additional (d) | 0.122 ± 0.06 | 0.133 ± 0.08 | 0.127 ± 0.05 | 0.145 ± 0.03 |

| (Pc-d = .701) | (Pc-d = .717) | (Pc-d = .005) | (Pc-d = .002) | |

| 4th additional (e) | 0.091 ± 0.04 | N/A | 0.131 ± 0.04 | 0.153 ± 0.08 |

| (Pd-e = .187) | (Pd-e = .839) | (Pd-e = .773) | ||

| Total additional (f) | 0.581 ± 0.22 | 0.384 ± 0.091 | 0.883 ± 0.26 | 0.967 ± 0.23 |

| (Pa-f = .500) | (Pa-f = .025) | (Pa-f < .001) | (Pa-f = .002) |

- Bone reduction forceps were loosened before load screw insertion for all tests.

- *The reported data are the mean ± SD (mm) BFT measured after insertion of the neutral screw(s), load screw, and all screws (total) in each pattern. Modified pattern 1 was used with the LC-DCP to avoid potential effects of using the round plate hole but this limited the test to 3 additional load screws instead of 4. P-values in bold indicate statistical significance.

- DCP, dynamic compression plate; LC-DCP, limited-contact dynamic compression plate; BFT, bone fragment translocation.

DISCUSSION

We identified several factors that can influence BFT in a standard 3.5 mm DCP or LC-DCP. In Pattern 1, a neutral screw was first inserted into the hole furthest from the fracture gap on both ends of the plate. Then a neutral and a load screw were inserted into the closest hole on both sides of the fracture gap to stabilize the fracture in alignment and to produce BFT. In Pattern 2, only the closest hole on both sides of the fracture gap was used to insert first a neutral and then a load screw to stabilize the fracture in alignment and to produce BFT. The BFT from Pattern 2, which had only 1 tight neutral screw, was significantly greater than the BFT from Pattern 1, which had 3 tight neutral screws, when the applied bone forceps were tight or loosened. Loosening the neutral screw in the same bone fragment as the load screw in Pattern 1 while bone forceps were loose caused a significant change in BFT with both the DCP and the LC-DCP. Interestingly, the BFT from DCP Pattern 1 with the neutral screw loosened was not significantly different than the BFT from DCP Pattern 2 with loosened bone forceps. This indicates that the tight neutral screw in the same fragment as the load screw in Pattern 1 limited the BFT for Pattern 1 as compared to Pattern 2 when bone forceps were loose. These findings are consistent with previous reports that suggest loosening a screw previously inserted in the same fragment as a load screw to allow additional compression from the load screw.1-5 The tight neutral screw in the same fragment as the load screw in this study most likely restricts BFT because of friction between the plate, the neutral screw head, and the bone, which prevents full movement of the load screw down the glide slope. In addition, there may be some deformation of the screw or plate hole as the screw engages the plate that limits BFT.5

A similar BFT-limiting effect was observed when tests with tight and loose bone reduction forceps were compared. Bone reduction forceps were initially applied to all constructs in order to secure the plate to the aligned bone cylinders until screws were inserted. The significant increase in BFT observed with Pattern 2 in the DCP when bone forceps were loosened demonstrated that the tight forceps limited BFT. With Pattern 1 in the DCP there was an increase in BFT observed when the bone forceps were loosened but it was not statistically significant. However, when bone forceps were loose there was no significant difference in BFT between Pattern 1 with the loosened neutral screw and Pattern 2 in the DCP. We suspect that the BFT from Pattern 1 in the DCP was not significantly increased by loosening the bone forceps alone because BFT was already significantly limited by the tight neutral screw inserted in the same bone fragment as the load screw. These results demonstrate that factors such as the tightness of the bone reduction forceps and/or tight neutral screw(s) in the same fragment as the load screw during compression plate application can limit BFT. In general, when these factors were not applied to the plates or were adjusted (eg, loosening a neutral screw), there was a resulting increase in BFT. We believe the effects of these factors on BFT may have been caused by changes in friction between the plate and the underlying bone fragments.

Although we did not directly measure deviation of the bone fragments from the long axis of the plate, this was observed while the load screw was tightened after loosening the neutral screw in Pattern 1 and when the bone forceps were loose in Pattern 2. Visible displacement of the fragments indicative of measurable rotational or other directional movement was not observed once the screws were completely tightened in these tests. Pattern 2 with loose bone forceps had only one point of fixation in each bone fragment while the load screw was being tightened. This could have allowed the underlying bone fragment to be displaced off the long axis of the plate with little effort because of the torque of the screw rotating the fragment until the load screw was completely tightened. Since Pattern 1 with loose bone forceps had two points of fixation in each fragment as the load screw was tightened, deviation from the long axis of the plate was controlled. When one point of fixation was removed by loosening the neutral screw in Pattern 1, the underlying fragment became susceptible to the torque from the load screw and a minor amount of displacement was observed. We suspect that the same factors that restricted movement of the load screw in the glide hole and limited BFT also prevented deviation of the underlying bone fragment along the long axis of the plate.

A confounding finding in the study was that loosening the neutral screw in Pattern 1 with loose bone forceps caused a decrease in BFT with the LC-DCP but an increase in BFT with the DCP. We suspect 2 possible causes for this seemingly conflicting result, both related to the slight incongruity between the LC-DCP hole, the universal guide, and the head of an inserted screw. First, loosening the neutral screw could have allowed the underlying bone fragment to deviate from the long axis of the plate and change where and how the head of the load screw interacted with the LC-DCP hole. This could cause either less interaction between the glide slope and the load screw head or a subtle malalignment between the bone cylinders at the point of fracture gap measurement, which may have decreased BFT. In addition, we observed better congruity between the AO drill guide and DCP plate than between the universal guide and LC-DCP hole. Slight incongruence between the universal guide and the LC-DCP hole may have allowed slight variation in positioning of inserted screws within the LC-DCP holes. This ultimately could have changed the interaction between the screw heads and the glide slope of the holes, or resulted in subtle malalignment that would have decreased BFT as previously discussed. The argument that there is greater variability in the interaction between the LC-DCP hole and inserted screws is supported by the generally higher standard deviations reported for the LC-DCP tests compared to the DCP tests.

Use of the round plate hole in the newly redesigned LC-DCP did not affect BFT in this study. With Pattern 1, a neutral screw was inserted in the round plate hole and the load screw was inserted on the opposite side of the fracture gap. It is possible that BFT could have been restricted if the load screw had been inserted in the same fragment as the neutral screw in the round hole. Also, the geometry of the round hole makes it unlikely that loosening a neutral screw inserted in the round hole would have increased BFT from a load screw inserted in the same fragment.1 An additional set of trials would be needed to test this hypothesis.

Load screw BFT was less than the reported 1.0 mm in 60% (5 of 9) and significantly >1.0 mm in 40% (4 of 9) of the tests performed in this study. All tests with a load screw BFT of less than 1.0 mm were variations of Pattern 1. The AO eccentric load guide and the inner sleeve of the universal guide are designed to place a screw hole 1.0 mm up the glide slope of a 3.5 mm DCP or LC-DCP hole. As an inserted load screw moves this distance down the glide slope, it is expected to cause the reported 1.0 mm of displacement along the long axis of the plate.1-5, 7 It is possible that the factors that limited total pattern BFT in this study could have caused the BFT from the load screws to be less than 1.0 mm by limiting the movement of the load screws. Notably, the load screws in all Pattern 2 tests had greater BFT than the load screws in Pattern 1 tests. In one of the Pattern 2 tests, load screw BFT was significantly limited by tight bone forceps. This suggests that without the influence of limiting factors the BFT for a load screw inserted in a 3.5 mm standard DCP or LC-DCP may be greater than 1.0 mm.

The initial load screws in each pattern resulted in significantly more BFT than any single additional load screw inserted. This result is in agreement with previous reports that BFT from additional load screws is limited by previously inserted screws, which increase friction between the plate and the bone, and by contact between the heads of the inserted screws and walls of the DCP or LC-DCP holes.1-5 All additional load screws did cause BFT, but all the BFT values from these screws were significantly less than 1.0 mm. Contrary to our hypothesis, BFT did not progressively decrease with each additional load screw inserted regardless of pattern or plate. It is worth noting that the additional load screws inserted with Pattern 2 caused significantly more BFT than the load screws inserted with Pattern 1. This is consistent with our finding that a tight screw(s) in the same fragment as a load screw limits BFT. The significant decrease in BFT between the second and third additional load screws inserted with Pattern 2 is consistent with the literature that suggests that maximum BFT is achieved after insertion of 3 or 4 total load screws (up to 2 screws on either side of the fracture gap).1-4, 7 Though it has been reported that sequentially inserting these load screws on alternating sides of the fracture gap can result in 4 mm BFT, this amount of BFT was not achieved with any pattern in our study.5 One possible explanation is that previously inserted screws in the same fragments as additional load screws were not loosened slightly before tightening the additional load screws. The literature is unclear as to whether loosening previously placed screws would improve BFT from additional load screws and, if so, how many of the previously placed screws in the same fragment would need to be loosened.1-5 Additional trials would be needed to determine if loosening a previously placed screw in the same fragment as additional load screws were inserted would result in 4 mm BFT, and if this is the maximum amount of BFT that can be achieved.

Application of more than 1 neutral screw before load screw insertion is a method of stabilizing the plate to the bone to prevent malalignment during compression plate application. Based on our study, factors that controlled deviation of the bone fragments from the long axis of the plate resulted in decreased BFT. Clinically, even a minor amount of deviation of the bone fragments during DCP application, as seen with Pattern 2 when bone clamps were loosened, could increase the difficulty of maintaining fracture alignment or allow malalignment of the plate on the bone. The surgeon should weigh the risk of possible malalignment versus increased BFT when considering screw insertion patterns and application of bone forceps.

Limitations of this study are those inherent with benchtop research with synthetic bone models and human variance in application of bone plates and screws. Synbone was used instead of living or cadaveric canine bone and the uniform nature of Synbone allowed for greater contact between the plates and the bone than occurs clinically. Though a single author (AC) created all of the constructs and drilled, tapped, and inserted all of the screws with strict attention to AO/ASIF guidelines and technique, visual alignment was used for plate application and screw insertion, which may have contributed variability to the study. The consistency of this author's hand strength was assumed and, therefore, so was the uniform tightness of the bone forceps and screws. Arguably, a torque screwdriver could have been used to eliminate screw tightness as a variable; however, torque screwdrivers can have up to ±6% variance in accuracy according to the specifications from 2 manufacturers (CDI TORQUE products, City of Industry, CA, and Futek Inc., Irvine, CA). The same author performed all the gap distance measurements and used the marks on the cylinders as visual markers for any displacement of the fracture fragments off of the longitudinal axis of the plate. Though horizontal displacement was not observed, the distance between these marks and the plate could have been measured and recorded to provide more objective data. Multiple trials were performed by a single author to minimize this potential human variance. Although we found statistical significance in our study the BFT measurements represented very small increments of measurement (tenths of a millimeter). These differences may have minimal effect in a clinical setting, particularly when near anatomic reduction has been achieved before insertion of the load screw.

This study demonstrates several factors that influence BFT, which should be considered when applying a DCP. The results support the conclusions that BFT is limited by a neutral screw inserted tightly in the same bone fragment as the load screw, by bone forceps that tightly secure the plate to the underlying bone fragments, and by screws placed in the plate before additional load screw insertion. We suspect that any factor that increases friction between the plate and the underlying bone will limit BFT. Our results also suggest that BFT for the first load screw inserted in a standard 3.5 mm DCP or LC-DCP may be >1.0 mm and that any additional load screws will be <1.0 mm. This study confirms the previous recommendation that insertion of >4 load screws will result in a negligible effect on BFT.

ACKNOWLEDGMENT

We thank Synthes.vet for the generous donation of materials.