Coupling the benefits of grassland crops and green biorefining to produce protein, materials and services for the green transition

An earlier version of this article was a keynote presentation at the 29th General Meeting of the European Grassland Federation hosted by France in 2022 (www.europeangrassland.org/)

Funding information: European Commission; gudp; Innovationsfonden; Horizon 2020 Research and Innovation programme, Grant/Award Number: 862674; Interreg Øresund-Kattegat-Skagerak, Grant/Award Number: 20201847; Innovation Fund Denmark, Grant/Award Number: 0224-00091B; Ministry of Food, Agriculture and Fisheries of Denmark

Abstract

Compared with annual grain and seed crops, perennial grassland has significantly lower losses of nutrients and low pesticide requirements, whilst also supporting soil carbon build-up. Until now grassland crops have almost exclusively been fed to ruminants and horses. Our experiments on biorefining forages have produced protein of a quality equal to soybean meal. Forage crops can deliver high yields of biomass as well as protein with a well-balanced amino acid profile. In grass crops from unfertilised permanent grassland, focus has to be on the fibre part of the grass due to a low protein yield. With current techniques we have recovered up to 40% of the forage protein into a protein concentrate with around 50% protein. In addition, a fibre fraction containing 15%–18% protein of dry matter can be produced and used as ruminant feed, bioenergy, or further biorefined into chemical building blocks or bio-materials. Our feeding experiments have shown that biorefined grassland protein can provide a substitute for soybean meal for poultry and pigs without negative effects on animal performance. The first industrial scale biorefineries on green biomass for feed and bioenergy are now established in Denmark, although more research is needed in order to evaluate protein quality for both feed and food applications. In addition, a full EFSA approval has to be obtained for the application for food. The green biorefinery concept opens new markets for grassland and opportunities for increasing the grassland area to obtain associated ecosystem services.

1 INTRODUCTION

A fully developed bioeconomy will require a complete utilisation of agricultural biomass for not only food and feed but also for chemicals, materials and bioenergy. This will require both a larger total biomass production and higher utilisation of residues. However, in Europe it may be difficult to increase productivity in existing cropping systems without also increasing environmental impacts, and the concept of ‘sustainable intensification (more with less)’ is contested in much recent literature. van Grinsven et al. (2015) proposed to focus on ‘sustainable extensification (less with less)’ in Europe. In contrast, Jørgensen and Lærke (2016) proposed a change in cropping systems for North-western Europe from annual crop rotations into grassland, which holds the potential for increasing biomass yield, reducing environmental impact, and a European production of protein to substitute the high current imports of soy. This would support the EU Protein Strategy that otherwise has a focus on increased protein seed (legumes) production (EU Commission, 2018).

The idea of utilising leaf-protein concentrates as a protein source for animal or human consumption is not new; it dates back to early 20th century where pioneering efforts led to significant amounts of research and pilot-scale development (Pirie, 1942). Throughout the 20th century and well into the 21st there have been multiple attempts and supporting research to facilitate commercial success of green biorefineries in Denmark (Pedersen et al., 1979) and internationally (Chiesa & Gnansounou, 2011; Houseman & Connell, 1976; Näsi & Kiiskinen, 1985; Pirie, 1978; Pisulewska et al., 1991). However, these early evaluations did not value the environmental benefits by changing cropping systems, utilising surplus grasslands, and substituting imports of soy products from other continents with high carbon footprints. Such environmental effects have attained much higher political focus over the last decades, and national and EU legislation such as the Water Framework Directive, Nitrate Directive and recent climate policies stipulate the needs for improvements.

The combination of the techno-economic and environmental potential of producing high carbon capture in grasslands with the recent developments in biorefinery techniques is the novelty of the concept of ‘Green Biorefinery’. Our aim is to develop and document win-win solutions with positive business economy, environmental benefits, no or negative iLUC, bioenergy provision, and improved self-sufficiency of protein concentrates, as a novel opportunity to solve several of our grand challenges in a sustainable way. So far, two commercial plants have been established in this context; see, e.g. www.biorefine.dk.

The development of new crop production systems combined with green biorefineries is not just about technical development of the production circle. It is also important to discuss the total land-use in relation to societal demands for environment, climate, recreation and biodiversity. This discussion has been supported by several land-use and technology scenarios, including Gylling et al. (2016), Larsen et al. (2017) and Mortensen and Jørgensen (2022). Here we show that the bioeconomy may contribute significantly to additional reductions in nitrate leaching and greenhouse gas emissions but the scale of reductions depends a lot on the way agriculture is combined with the biobased energy and material sector. The development of the land-use towards either sustainable intensification or extensification and a higher share of nature, was shown to be important determinants for the potential size of the bioeconomy and for emission reductions. The aim of the present paper is to describe in a cross disciplinary way the research-driven development of a new biobased industry from sustainable grassland crops in Denmark as a case study with the aim of producing sustainable feed and food protein, materials and services for the green transition.

2 MATERIAL AND METHODS

2.1 Platform for sustainable intensification of crop production

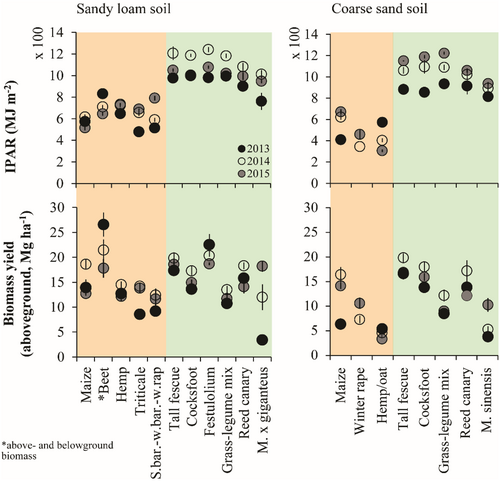

Aarhus University (AU) has a long history of agricultural crop research dating back to former research within the Danish Institute of Agricultural Sciences and Danish Institute of Plant and Soil Science (Christensen et al., 2022). In 2012 an experiment was established at two locations in Denmark to compare very different cropping systems (a range of grassland crops and double cropping systems) with the purpose of investigating potential productivity, whilst also measuring nutrient balances, input demands and greenhouse gas balances. For comparison, a common crop rotation in Denmark of spring barley, winter barley, rapeseed and winter wheat, and also monocultures of maize and triticale were included in the experiment (Manevski et al., 2017), which is intended for long-term continuation to investigate long-term crop productivity, soil carbon and microbiome impacts of the systems.

The experiment was established with 4 replicates in an incomplete block design. Crops are most often harvested with a plot-scale crop harvester (Haldrup), and analysed for dry matter content, mineral contents etc. (for details see Solati et al., 2018). Radiation interception was calculated from measured canopy near-infrared reflection (Manevski et al., 2017), and nitrate leaching was calculated from measured nitrate concentrations in soil water extracted with suction cups installed at 1 m depth in the experimental plots (Manevski et al., 2018). Soil carbon concentrations were measured in soil samples excavated to 1 m depth and separated into 0–20, 20–50 and 50–100 cm after 5 years of the experiment (Chen et al., 2022). New samples were taken after 10 years and are still under analysis.

In addition to experiments on university experimental farms, research is also performed on farmers' fields; e.g. to analyse crop productivity and protein content, and greenhouse gas balance on lowland organic soils (Kandel et al., 2013, 2016; Nielsen, Elsgaard, et al., 2021, Nielsen, Stødkilde, et al., 2021).

2.2 Platform for extraction of protein and other products from green, leafy biomass

The technological R&D of the green biorefinery concept at AU was initiated at a laboratory scale (1 kg input) by a lab-scale twin screw press (Angelia 8500 S, Angel) in 2013 (Methods described in Damborg et al., 2020) and further developed at a pilot scale (1 ton input) from 2015 to 2018 based on individually operating unit operations (methods described in Stødkilde et al., 2021). In 2019 we established a fully automated demonstration platform with an input capacity of 10 t fresh biomass per hour with a flexible process design appropriate for test, optimization and data collection at an industrially relevant scale. The process and equipment is described in more detail below. The platform has currently been running for three seasons and produced results, experience and products for more than 15 R&D projects.

The purpose of the platform is to accelerate development and implementation of sustainable production of feed and food proteins, biochemicals, biomaterials and bioenergy from green biomasses such as grasses and legumes. We test, optimise and integrate physical, biological and chemical biomass conversion technologies, and collaborate in an interdisciplinary network on circular bioeconomy with partners within universities, industry and public organisations.

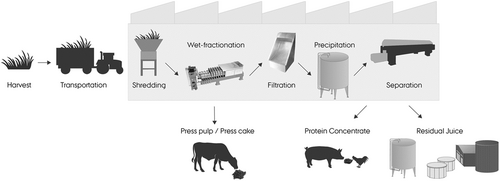

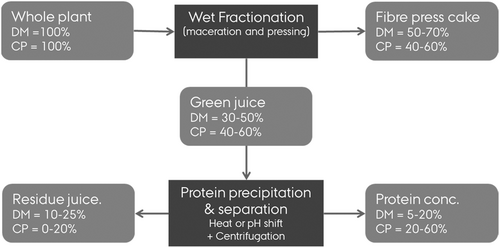

Several unit operations and steps are involved in the processing of fresh green biomass, before the desired protein concentrate can be separated. The major steps involved are harvest, transport, shredding/maceration, fractionation, precipitation and separation. An overview of these process steps and the protein separation platform is presented in Figure 1.

All biomasses are sourced from the agricultural research facility at AU Foulum, Denmark. Many different types of biomass, cutting strategies and harvest equipment are tested on the platform. The biomass is always processed directly after harvest to extract the fresh juice; thus, wilting is avoided. When it is necessary to have the biomass delivered without chopping in the field, we use a GrassTech GT140 (Future Grass Technology Ltd., IE). When it is necessary to have the biomass chopped in the field, we use a swather (Kuhn FC 10030D with a front mounted FC 3525 F) and a chopper (CLAAS Jaguar 990–930) with theoretical cutting length of 10-15 mm. The green biomasses are transported from the field to the demonstration platform and fed through the input system within an hour of cutting to ensure minimal protein degradation. Exceptions to this are those experiments in which the purpose is to explore and evaluate the effect of time between harvesting and processing, and how biological and chemical processes in different plants influences the processing, yields and product quality.

The core processes on the platform include:

2.2.1 Mechanical maceration and wet fractionation

The harvested biomass is initially shredded in a stationary cutter (custom made at AU) to a theoretical length of 4–5 cm. An extra maceration step was coupled in some of the experiments. After maceration, the crushed biomass is conveyed to a P25 Twin-screw press (rotation speed of 10–18 rpm. 45 kW motor, Cir-Tech A/S, Kogsvej 62, 6780 Skærbæk, DK) where the mechanical separation of the fibre pulp and green juice is carried out. The green juice is filtrated in a 50 μm-filter bow screen to remove larger particles.

2.2.2 Protein precipitation

Heat precipitation is the method most often used. In this case, green juice is pumped through a two-step heat exchanger. The first step heats the juice to around 65 °C by recovering the heat from the residual brown juice. The second step adds additional heat to the green juice to achieve a temperature of 85 °C. In specific experiments the protein is precipitated through acidification by either addition of hydrochloric acid to achieve a pH of 4.0, or by lowering the pH by lactic acid fermenting bacteria naturally present in the juice.

2.2.3 Separation and drying

The precipitated protein is separated from the pre-treated juice in a decanter centrifuge (GEA Westfalia Separator CF 4000) producing the protein concentrate and a liquid residue referred to as brown juice. The dry matter content of protein concentrate paste is about 30%–50% and is further dried in a vacuum dryer to reach a dry matter (DM) content of around 95%.

2.2.4 Anaerobic digestion

When not used for other specific experiments considering alternative applications, the brown juice and the fibre pulp are used for producing bioenergy and fertiliser through anaerobic digestion at the farm scale R&D biogas plant at AU Foulum.

- Process evaluation and optimization

- Valorization of all process streams

- Technology integration

- Techno-economic assessment

- Analysis and improvement of process sustainability impact

- Scale-up and implementation

2.3 Platform for animal testing of new feed products

Feeding experiments and evaluation of the nutritional value and feeding value of new feed sources has been an integrated part of Department of Animal and Veterinary Sciences at Aarhus University for many years. The experimental facilities and knowledge comprise both monogastrics (pigs, poultry and rats) as well as ruminants (cattle and sheep), where feeding experiments are performed with fistulated animals for sequential digestive tract digestibility determinations, intact animals for whole tract digestibility determinations, feed utilisation, palatability and health performance studies, as well as in-vitro techniques and well equipped laboratories for determination of chemical composition and in-vitro determination of digestibility (www.anivet.au.dk/en/research/facilities).

3 RESULTS AND DISCUSSION

3.1 Grassland crops are the most sustainable agricultural crops although they have a limited market

Compared with annual grain and seed crops, using land for the production of perennial grassland crops reduces significantly the losses of nutrients, with reduced need for pesticides, and it further supports soil carbon build-up (Cadoux et al., 2014; Chen et al., 2022; Manevski et al., 2018; Pugesgaard et al., 2015). Even though water quality will be improved under perennial cropping systems with longer growing seasons, water quantity (surplus for ground water and river discharge) may be reduced due to a higher annual evapotranspiration than from annual crops. However, there is an increased water infiltration capacity in perennial compared with annual crops due to more soil macropores (Basche & DeLonge, 2019), which can reduce the losses caused by water run-off. The potential for securing a water supply for a long growing period is highest in humid Northwestern Europe. Here, grasses and legumes can capture solar radiation more efficiently than annual grain and seed crops, as these require a considerable part of the growing season to be used for crop ripening, harvest, soil tillage and sowing (Cadoux et al., 2014; Dohleman & Long, 2009; Pugesgaard et al., 2015). Accordingly, we measured an interception of almost double the amount of Photosynthetically Active Radiation in the perennial grassland crops compared with in the annual monocultures or crop rotations (Manevski et al., 2017), which in most cases translated into higher crop harvest in the grasses (Figure 2). However, especially beetroot but also maize had higher Radiation Use Efficiencies (RUE - calculated for harvested crop) than other crops and therefore had similar yields as the best grasses. The grass-legume mixture, which was not fertilised with nitrogen, had significantly lower RUE than the other grasses and therefore gave the lowest yields (apart from also miscanthus in the first years of its establishment). Tall fescue and festulolium gave the best yields of the grassland species, and it seems that, in general, these species are the most productive forage grasses at North-western European latitudes (Becker et al., 2020; Cougnon et al., 2017).

It is not new knowledge that grasslands are considered to be generally environmentally benign. However, there has been a problem, first, that these ecosystem benefits of grasslands are not economically valorized, and secondly, that market outlets for increased grassland areas have been limited almost entirely to the ruminant sector. There is some use of grass for biogas production (Pehme et al., 2017) but to avoid severe indirect land-use change effects there is also a need for envisaging new food products from grasslands in order to ensure better delivery of the ecosystem services associated with them. The extraction of protein to feed monogastric animals or for use in food products for direct human consumption will open a market for more grassland, which may enable increased carbon sequestration per land unit and lower environmental impacts.

3.2 Perennial grass and legume crops on intensive arable land

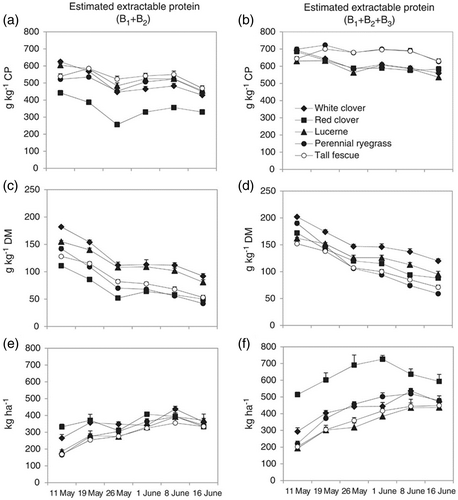

Intensive grass production on arable land can be managed to optimise protein concentration and quality for extraction in a biorefinery. Numerous factors influence protein content, extractability and yield per ha. Some of the most important are plant species, harvest time, fertilisation, and leaf/stem ratio. We have investigated the quality of protein with regard to its availability to animals using the Cornell Net Carbohydrate and Protein System (CNCPS) as a proxy for its extractability in a biorefinery (Solati et al., 2017; Thers et al., 2021). With regards to plant species, total protein recovery into concentrate was highest for the legumes (Thers et al., 2021) but this may depend on grass fertilisation optimization. Solati et al. (2017) found, when extracting protein from five species, that the estimated fraction of total protein extracted in the easily available fractions B1 + B2 was significantly lowest for red clover (Figure 3a). However, when including the more cell wall attached protein fraction B3, all legumes showed similar protein fraction extracted, whilst the two grass species showed higher relative extraction at most harvest times (Figure 3b). Doing the calculation for extractable protein content (g/kg DM), the sum of the easily available protein fractions B1 + B2, was significantly highest in white clover and alfalfa (Figure 3c). However, if in addition the more cell wall attached protein fraction B3 can be extracted, white clover had the highest extractable protein content among all species (Figure 3d). Due to the higher biomass productivity of red clover, it was the species that showed the highest productivity of B1 + B2 + B3 protein fractions per ha (Figure 3f), whilst this difference was less clear for B1 + B2 and depended on harvest time (Figure 3e).

The chemical composition, and in particular the protein content, depends on N fertilisation. In grass-clover mixtures, N fertilisation does not influence total protein yield by much, whilst the yield of protein in pure ryegrass increases significantly with increased N-fertilisation (Jørgensen et al., 2021). Thus, the protein to carbohydrate ratio is high in grasses that are cut frequently and supplemented with N fertiliser, whereas protein content in grass-clover varies only a little depending on N fertilisation.

3.3 Perennial grassland in an extensive production system

If long-term grasslands are not fertilised, only very moderate DM yields can be expected after a few years of harvest; in Denmark this would typically be 2–4 t/ha/year (Nielsen, 2012; Nielsen et al., 2013). In addition, grass from unfertilised meadows usually has low nitrogen and protein concentrations and is therefore not suitable for protein extraction. Alternatively, the use of the grass biomass for biogas production can be considered, and this may present positive LCA-results, assuming there is no alternative use of the grassland, e.g. for animal grazing (Pehme et al., 2017). Another option available for supporting the bioeconomy is the use of fibres from grasses with low protein content, for instance in making paper, packaging, animal bedding, biochar, etc. (Hôller et al., 2021; www.go-grass.eu).

The attainable yield of permanent grassland on organic soils depends on type of species and cultivars, sward age, annual harvest frequency and fertilisation rates (Jørgensen et al., 2021). On well-drained areas, fertilised permanent grassland is expected to produce the same yield as grass in rotation for several years after establishment. However, if not well-drained, the typical DM production is estimated to be between 70% and 80% of grass in rotation (Nielsen, 2012). The cultivation of flood-tolerant species, e.g. reed canary grass, festulolium and tall fescue on wet or temporarily flooded organic soils, also known as paludiculture, has documented high annual yields of up to 10–19 t DM/ha (Jørgensen et al., 2021; Kandel et al., 2013, 2016; Nielsen, Stødkilde, et al., 2021). This is comparable to the productivity of grass in rotation on drained soils under similar fertilisation rates of 160–240 kg N/ha per year.

For biorefining, the protein content in grass biomass depends on nitrogen availability, frequency and timing of cutting, similar to the systems on intensive arable land. Recent research found crude protein contents of up to 2.9–3.4 t/ha/year, and precipitated protein concentrates of up to 1.2–2.2 t/ha/year, for reed canary grass and tall fescue, cultivated on wet organic soils (Nielsen, Stødkilde, et al., 2021). Optimal timing of harvest seems to remain the most critical factor for biomass and protein yields.

3.4 Green biorefining and its main products

Green Biorefining is a fundamental concept that ‘represents the sustainable processing of green biomass into a spectrum of marketable products and energy’ (McEniry & O'Kiely, 2014). In other words, Green Biorefining is a technology platform that integrates a variety of different sustainable solutions in order to produce everything from food and feed to biomaterials, biofuels and bioenergy. Green Biorefining has an inherent focus on products containing proteins or amino acids, which is due to the high protein productivity of green crops.

The yields and mass distribution between the different processing streams depends on a long list of parameters and can vary to a large extent. Figure 4 shows the typical ranges of DM and crude protein yields following a Green Biorefining separation process like the one in Figure 1. Depending on the processing conditions, the extractability of the protein in the green biomass and the efficiency at the biorefinery, 30–50% of the biomass DM and up to 40%–60% of protein will be pressed out in the juice fraction.

From the juice fraction, 5%–20% of the original DM and 20–60% of the original protein can be precipitated and remain in the precipitated protein-rich fraction, and the rest goes to the residual juice (Damborg et al., 2020; and unpublished results from L. Stødkilde). These ranges of mass and protein distribution are not ultimate, but they illustrate the possibilities for optimization of the process according to what the desired outcome is with respect to protein yield and process cost.

The development in Denmark during recent years has focused around the processing of fresh green biomass, as opposed to processing of ensiled grass. The main products in focus have been a protein-rich concentrate that can provide a substitute for soybean meal in feed mixtures for monogastric animals, a press cake fibre-rich product for ruminant feed and/or biogas production, and a residual juice for biogas and nutrient recycling.

3.5 The protein product

The protein fraction is considered the most valuable of the three main products, and there has been much focus on increasing the amount of protein and on the concentration and nutritional quality of this protein. Protein concentration in the green protein concentrates produced at pilot scale were initially around 35% of DM, and this concentration has now been improved further in the demonstration platform to protein concentrates containing between 50% and 60% crude protein, and the nutritional quality of the protein has increased concurrently (Stødkilde et al., 2022). Table 1 shows the chemical composition of green protein concentrates with 46% and 56% protein in the DM (Stødkilde et al., 2021).

| On DM basis | Protein, 46% | Protein, 56% | Soybean meal |

|---|---|---|---|

| DM, % | 97.4 | 92.32 | 87.2 |

| Crude protein, % | 45.8 | 56.2 | 52.4 |

| Lipids, % | 10.6 | 13.8 | 2.9 |

| Ash, % | 12.1 | 8.30 | 8.14 |

| Total Dietary fibre, % | 29.7 | Nab | Nab |

| Amino acids, g/16 g N | |||

| Lysine | 5.76 | 5.75 | 6.29 |

| Methionine | 2.27 | 2.03 | 1.36 |

| Methionine + Cysteine | 2.73 | 2.72 | 2.79 |

| Threonine | 5.02 | 4.60 | 4.06 |

| Tryptophan | 2.42 | 2.21 | 1.38 |

| EDOMia, % | 67.9 | 72.8 | 77.8 |

- a EDOMi: Enzyme digestibility of organic matter at the ileum.

- b Not analysed.

The amino acid composition in both of the green protein batches in Table 1 are similar to the amino acid composition in soybean meal, whilst the lipid content is highest in the green protein. It is worth noting that roughly 50% of the fatty acids in the green protein consist of alpha-linolenic acid (C18:13n3). In addition, the fibre content is high in the green protein. In agreement with previous studies with rats, where it was shown that the protein digestibility increased with increasing protein content in the green protein (Stødkilde et al., 2019), the in-vitro digestibility (EDOMi) was higher in the green protein with the highest protein content, but still lower than in soybean meal (Table 1).

3.6 Nutritional value of the protein as feed for pigs and poultry

The first Danish feeding experiment was performed with organic broilers fed with a relatively low crude protein diet containing concentrate with only 36% CP. With this protein concentrate it was possible to substitute 8% of the diet, primarily soy press cake, (13% of the CP) with protein concentrate extracted from an organic grass-clover crop without affecting growth performance (Stødkilde et al., 2020). However, larger inclusions challenged feed intakes and growth rates due to the low protein content and the correspondingly high content of insoluble dietary fibres in the protein extract, which to a large extent are indigestible.

In addition, we performed two feeding experiments with growing-finishing pigs with a protein concentrate containing 46% and 56% protein (Table 1), respectively. Both protein concentrates showed a well-balanced amino acid composition. The lysine content was slightly lower than soybean but the content of most other essential amino acids was higher. With these concentrates, pigs performed equally, irrespective of inclusion rate (Stødkilde et al., 2021). The highest inclusion rate of 15% of the traditional feed (up to 41% of the crude protein) with grass-clover protein still secured similar levels of feed intake, growth and feed utilisation to a control group with soybean meal as the dominant protein source. In both experiments, daily weight gains above 1000 g were achieved.

In the broiler experiments the n3 fatty acids increased from 6.7% to 11.8% of the total fatty acids in breast meat, and in the pig experiment the increase was from 1.17% to 3.12% of total fatty acids in Longissimus dorsi (Stødkilde et al., 2020, 2021). In a recent study (Stødkilde et al., 2022) where soybean meal was substituted 1:1 with green protein (9% of total diet) a professional taste panel was not able to detect significant differences in odour, texture, taste and flavour of M. longissimus lumborum roasts from female pigs.

3.7 Possibilities for using the protein in human food

A recent review concluded that high quality leaf protein may be incorporated into food for humans (Møller et al., 2021). RuBisCO and alfalfa protein show the most promising functional properties with respect to solubility and foaming properties, making it a potential substitute for animal protein ingredients. Thus far, when considering leaf protein for food the focus has been on proteins from alfalfa and sugar beet leaves. However, the RuBisCO protein is very well preserved amongst different plant species in terms of protein sequence and structure, which is why RuBisCO obtained from leafy plants, such as grasses and clovers, may have similar functional properties. At the same time, RuBisCO shows relatively low allergenicity, so a purified RuBisCO product may serve as a potential source for highly challenged multiallergenic consumers. However, it is unclear whether there are other proteins, in addition to RuBisCO, present in different types of green biomass that may have allergenic properties, and this needs to be resolved. Today, alfalfa protein is approved in food applications, but only based on a limited daily intake. There is still a way to go to describe the full matrix both for alfalfa and other green biomass. Different anti-nutritional factors are present in different plant species and they need to be quantified in each specific case as they may concentrate in the protein fraction and affect nutrient bioavailability. Any new protein product produced from alfalfa, clover or grass needs an EFSA approval before the protein can be used in food products in the EU (Møller et al., 2021).

3.8 Fibre press cake

Around half of the plant crude protein will distribute to the fibre press cake (pulp), and the composition of amino acids in this fraction is similar to the composition in the whole plant (Damborg et al., 2018). As a considerable proportion of the protein retained in the pulp is fibre-associated, the pulp is expected to be suitable for ruminants. Chemical analysis of the pulp revealed a fraction with a higher DM concentration than in the whole crop (plant), similar crude protein concentration, and lower crude ash concentration (Table 2). In vitro rumen digestibility tended to be lower for the pulp, as expected due to a large proportion of soluble organic matter removed upon juice extraction. When expressed as digestible organic matter (DOM) as a proportion of DM, the difference disappeared for white clover and perennial ryegrass because the ash content is also reduced during the extraction step.

| Plant species | Fraction | DM, % | Crude protein, % of DM | Crude ash, % of DM | In-vitro OM digestibility, % | DOMa, % |

|---|---|---|---|---|---|---|

| Red clover | Plant | 16.6 | 20.5 | 9.06 | 65.4 | 59.4 |

| Pulp | 43.5 | 19.8 | 6.63 | 57.9 | 54.0 | |

| Perennial ryegrass | Plant | 19.9 | 16.7 | 8.63 | 74.4 | 67.9 |

| Pulp | 41.4 | 16.4 | 5.11 | 69.9 | 66.3 | |

| Alfalfa | Plant | 19.6 | 20.5 | 8.86 | 61.9 | 56.4 |

| Pulp | 39.9 | 19.8 | 5.80 | 56.6 | 53.2 | |

| White clover | Plant | 15.8 | 26.7 | 10.4 | 77.4 | 69.4 |

| Pulp | 41.2 | 26.8 | 7.23 | 74.3 | 68.9 | |

| p-Value | <0.001 | 0.44 | <0.001 | 0.046 | 0.21 |

- Note: All values are mean of three harvests (Nov 2013, Jun 2014, Sep 2014).

- a DOM = In-vitro Digestible Organic Matter in % of total Dry Matter.

3.9 Nutritional value of the pulp as feed for ruminants

Hitherto only the results from a few feeding experiment with cows have been published (Damborg et al., 2019; Savonen et al., 2020; Sousa et al., 2022). In these studies substitution of whole plant silages with pulp of the fractionated whole plant or whole plant silage, has led to different results. Damborg et al. (2019) showed increased milk production in dairy cows, whereas in the experiment of Savonen et al. (2020) milk production tended to decrease, and in the experiment of Sousa et al. (2022) milk production decreased. Furthermore, dry matter intake was either not affected (Damborg et al., 2019; Sousa et al., 2022) or increased at medium inclusion rate (Savonen et al., 2020), when cows were fed silage pulp compared to the corresponding whole plant silage. Several ensiling experiments have been performed with the pulp. Despite the low residual sugar in the pulp, it generally ensiles very well, probably because the buffer capacity is also low due to the relatively low mineral content (Hansen et al., 2020). Contrary to the in vitro and in situ digestibility analyses of the pulp by Damborg et al. (2018), the in vivo digestibility of CP and NDF was greater for pulp silage diets compared with grass-clover silage diets. This observation can likely be explained by the physical processing of the pulp in the screw-press during biorefining, which disintegrates the fibres and increases the accessibility for the rumen microbes, thus increasing the degradability of the fibre and fibre-bound nutrients. This higher feed utilisation was reflected in a higher energy-corrected milk yield from cows fed pulp silage compared to grass clover silage (Table 3). The results imply that extraction of protein from grassland plants can increase the digestibility of the fibre part of grassland plants. In the Finnish study by Savonen et al. (2020) investigating the effects of including pulp made from silage up to a 50% substitution of the grass silage, no effect on milk yield (37 kg ECM) was detected.

| Feed | Pulp silage | Grass clover silage |

|---|---|---|

| DM, % | 28 | 52 |

| Crude Protein, % | 18 | 16 |

| Ash, % | 9.3 | 9.4 |

| NDF, % | 45 | 39 |

| In-vitro digestible OM, % | 70 | 72 |

| DM intake, kg/day | 23.0 | 22.7b |

| ECMa, kg/day | 37.0 | 33.5b |

| In-vivo digestibility | ||

| OM, % | 73 | 70b |

| NDF, % | 63 | 54b |

| Protein, % | 66 | 60b |

- a ECM = Energy Corrected Milk yield.

- b Significantly different from pulp silage.

3.10 Alternative uses of the fibre pulp

The fibre pulp has numerous alternative applications to its use as ruminant feed and there are many possibilities for adding further biorefining technologies. Examples include bioenergy production through anaerobic digestion to biogas, cellulosic bioethanol production, pyrolysis to synthesise gas, bio-oil and biochar, or hydrothermal liquefaction to bio-crude oil, or materials production through fibre processing for biomaterials and biological and chemical processing into biochemicals. In the project Grass Biochar (Danish funded GUDP project), we investigate how green biorefining can be integrated with pyrolysis of the fibre pulp. The pyrolysis will produce renewable energy in the form of combustible gas to supply the heat for protein precipitation and drying of the protein concentrate, as well as biochar to be used as feed additives. Large-scale production of biochar from the grass fibre will open significant potential for creating Bioenergy with Carbon Capture and Storage (BECCS) solutions in combination with green biorefineries (Elsgaard et al., 2022).

Using the fibre pulp for fibre-based biomaterials is another valuable application. This approach is in fact the main aim for all of the existing Green Biorefineries that process silage instead of fresh green biomass. Biowert in Brensbach, Germany (www.biowert.de) produces grass-based insulation material and grass fibre enforced bio-plastic, a biocomposite material suitable for injection moulding or extrusion applications. Newfoss in Uden in The Netherlands (www.newfoss.com) produces insulation materials and fibres for paper and packaging. The project SinProPack in Denmark (Project—Grass fibre-based paper for sustainable ‘to-go’ packaging products—Projects—Danish Technological Institute (www.dti.dk)) has recently started the investigations and development of producing biobased packaging for the takeaway market out of the fibre pulp from green biorefineries, and another project, Høsttek, has started developing sustainable fibreboards of the fibre pulp (Ny høstteknologi til klimavenlig dyrkning af lavbundsjord—Grønt Udviklings- og Demonstrationsprogram (www.lbst.dk)).

In both fibre pulp utilisation for bioenergy, or for biomaterials, it is advantageous if the fibre is depleted of its protein content. Thus, efficient extraction of protein at the green biorefineries poses no negative impact on these applications. However, for the application where the fibre pulp is utilised for ruminant animal feed, there is a lower limit of how little protein should be left in the pulp.

3.11 Residual juice fraction

The residual juice remaining after the protein precipitation from the green juice is characterized by a low DM content (5%–8%), a variable but high content of soluble carbohydrates and minerals, whilst the crude protein (10%–20% of DM) contains only half the amount expressed as true protein, the other half being various non-protein nitrogen compounds (NPN) (Damborg et al., 2020). The specific composition of the residual juice depends on a number of factors including both the processing steps involved in the Green Biorefining separation platform, especially the precipitation method, as well as type, maturity- and growth conditions of the green biomass input.

3.12 Anaerobic digestion of residual juice

The application for anaerobic digestion of the residual juice is a straightforward opportunity, especially in Denmark, which has a significant biogas industry. Many of the biogas plants in Denmark could benefit from an extra substrate with a low, but easily digested, solids concentration in order to co-digest with fibrous agricultural residues such as deep litter, cow manure and straw from cereal grain or grass-seed production. This is, for example, the case at Ausumgaard, the first commercial green biorefinery in Denmark (www.ausumgaard.dk/baeredygtig-energi/graesprotein), which has a large biogas facility where both the residual juice and the fibrous pulp from the biorefinery can be digested. The use of residual juice for anaerobic digestion has been evaluated in terms of technical, economic and environmental sustainability (Corona et al., 2018; Djomo et al., 2020; Feng et al., 2021; Jensen & Gylling, 2018; Santamaria-Fernández et al., 2018). If the residual juice cannot be co-digested in an existing anaerobic digestion plant, it is a much cheaper and more efficient solution to instal a packed bed reactor, as shown by Feng et al. (2021). Here residual juice was efficiently digested as a sole substrate at low retention time (5.5 days) and therefore a much smaller reactor size and capital investment is needed.

An obvious advantage for anaerobic digestion of the residual juice from green biorefineries is that the inorganic nutrients will be utilised directly into existing systems for recirculation of nutrients. As occurs already in the current system, the digestate from anaerobic digestion is spread on agricultural land as fertiliser.

3.13 Biochemicals from the residual juice

The residual juice could potentially be used for much more than bioenergy, before nutrients are recirculated to support crop production. Historically, use of the valuable products from residual juice/brown juice from green biomass processing has focused around its amino acids and lactic acid. Several studies and commercial activities have looked into the production of amino acid concentrates (Ecker et al., 2012) or specific amino acids such as L-Lysine (Andersen & Kiel, 2000; Thomsen & Kiel, 2008).

In the few existing green biorefineries that are processing silage grass, the juice is used for bioenergy through biogas production (Biowert) or its amino acid, organic acids, and inorganic nutrient content used primarily in fertiliser products, which is concentrated through membrane filtration technology.

When processed in the Danish base case setup (Figure 4) the residual juice will be high in carbohydrates and inorganic nutrients. This combination has high potential as a substrate for fermentation applications in the biotech industry as a substrate for precision fermentation, for instance producing building block biochemicals, single cell protein or high value secondary metabolites. In order to achieve a good fermentation substrate, it is advantageous to reduce the volume and increase the concentration of the carbohydrates as well as other macronutrients present in the residual juice. This is experimented in the current biorefinery demonstration platform by membrane filtration. Thus the potential for further valorization of the residual juice is large and might be regarded as a ‘low hanging fruit’ in order to improve overall economic sustainability of the green biorefinery.

4 FUTURE PERSPECTIVES

- Plant breeding for optimal protein extractability and quality

- Studies on the differences in protein solubility between forage species and cultivars

- Development of efficient harvest planning and logistics to enable continuous delivery of good quality green biomass to the biorefineries

- Process development and optimization at the biorefineries to achieve constant high yields of protein concentrates with constant high digestibility and nutritional value

- Value creation of the fibre pulp and the residual juice to achieve a better overall business case for the green biorefinery

- Technology integration for cascade utilisation of side streams and residues

- Development of flexible biorefinery solutions, where input biomass and output products can change according to seasonal variation and market conditions, in order to achieve efficient use of production facilities all year round

- Storage options for green biomass to be utilised in the biorefinery during winter

- Valorization of the benefits from grassland production in terms of climate (net greenhouse gas reduction) and other environmental benefits.

ACKNOWLEDGEMENT

This work has been supported by several projects over the last 10 years, and currently GO-GRASS (Horizon 2020 Research and Innovation programme, grant agreement N° 862674), Green Valleys (Interreg Øresund-Kattegat-Skagerak, project No 20201847), GrassTools (Innovation Fund Denmark, project No 0224-00091B), and various Green Development and Demonstration projects under the Ministry of Food, Agriculture and Fisheries of Denmark, Grass Biochar, SinProPack, SuperGrassPork, AlfaMaxBioraf are amongst the main contributors.

Open Research

DATA AVAILABILITY STATEMENT

Data sharing is not applicable to this article as no new data were created or analyzed in this study.