Effects of slatted frame placed in compost pile on enhancing heat generation and organic matter degradation during high-moisture cow manure composting

Abstract

Excess moisture content in cow manure inhibits the process of composting. This study examined the effects of introducing a slatted frame on temperature development, organic matter degradation, and moisture content during high-moisture composting. Twelve tons of cow manure was piled individually, and an iron slatted frame with a pipe and a plain frame filled inside with styrofoam was introduced in the treatment and control piles, respectively. Two hours after the start, running leachate via the pipe in the treatment pile was observed, but not in the control pile. The maximum temperatures as well as durations of the temperatures above 55°C of the treatment piles at all seven positions were higher than those of the control piles. In particular, four of the seven positions in the treatment pile exhibited more than twice the duration. Installing the slatted frame improved the organic matter degradation; the values of organic matter loss in the control and treatment were 48.0% and 58.4%, respectively. The final moisture content in the treated compost was 5% lower than that in the control. Overall, the introduction of a slatted frame generated higher temperatures and produced relatively dried and well-degraded compost.

1 INTRODUCTION

As a result of intensive dairy farming, large volumes of dairy manure are often applied to fields that are relatively close to animal barns. However, this land application has resulted in fields with excessively high nutrient levels. A reduction in volume, weight, and moisture allows dairy farmers to transport organic nutrients farther away from the cow barn. Composting is a controlled aerobic process that converts animal waste into nutrient-rich organic fertilizers. The final product is compost, which has a reduced volume, is dried, and is free from offensive odors. Moreover, the thermogenic process during composting enhances the inactivation of weed seeds and the elimination of pathogens compared with raw manure. Well-stabilized compost can be stored in compost sheds until land application and/or sold as a marketable organic fertilizer.

Multiple factors affect organic matter degradation during composting, and these factors are typically controlled by varying the ingredient material mix ratios, aeration, and turning frequency (Ahn et al., 2007). Cow manure usually contains over 85% moisture and reducing it to the preferred levels requires a large amount of bulking agent, which increases operational costs. Moreover, farmers in Japan face chronic problems owing to a shortage of bulking agents for compost production; hence, dairy farmers inevitably perform composting poorly. Very high moisture triggers anaerobic conditions because the pore spaces of solid matrices are filled with water rather than air (Das & Keener, 1997) and the excess water in high-moisture compost is discharged from the bottom of the pile as a brown-colored leachate.

In general, two common aeration methods are pile turning and forced air supply for heaps. The disadvantage of the former is intensive labor, and that of the latter is a relatively high capital investment. Forced aeration is a technologically advanced system that supplies oxygen to microorganisms and enhances the drying mass via water evaporation. Generally, forced air is supplied using perforated pipes that are laid on the floor, with perforations facing upward. Stacked dairy manure with high moisture content had low air permeability (Chang et al., 2023), and the accumulated water at the bottom of the pile causes pressure loss and increased aeration cost during composting. Therefore, when up-flow forced aeration is applicable for treating high-moisture compost material, adjustment of moisture content of mass is highly recommended prior to aeration. Horizontal perforated pipes at the bottoms of compost piles have also been used to enhance passive aeration (Mathur et al., 1990). Sartaj et al. (1997) compared three aeration methods, namely, natural, passive, and forced aeration, and reported passive aeration for poultry manure slurry amended with peat maintained high temperatures for a longer time than the other two methods. Ogunwande and Osunade (2011) investigated horizontal and vertical pipe orientations, showing that a vertical pipe effectively distributed uniform air in the pile. The vertical pipe system was an improvement over the horizontal pipe system as it improved air delivery into the composting pile, minimized temperature variations within the pile, and resulted in high composting rates (Sylla et al., 2006). Except for the use of perforated pipes, Tanaka (1998) reported the effectiveness of polyester non-woven cloth draining sheet for supporting passive aeration and showed the temperature in the passively aerated pile was higher than that in the non-aerated pile during the initial phase of composting. Although passive aeration is a simple and low-cost technology, few studies treat compost materials with high moisture content (>78%). In the case of high-moisture cow manure composting, the bottom of the pile is a specific location where a large amount of leachate accumulates and is highly compacted by the piled compost weight. The physical conditions at the bottom of the piles hinder passive aeration and induce undesirable anaerobic conditions during composting. To remove the anaerobic area that developed at the bottom of the pile, this study attempted to form a rectangular cavity that supports the discharge of excess water and gas convection. The objective of this study was to clarify the effects of introducing a slatted frame with a pipe on temperature development, organic matter degradation, and moisture content during high-moisture composting.

2 MATERIALS AND METHODS

2.1 Composting trial

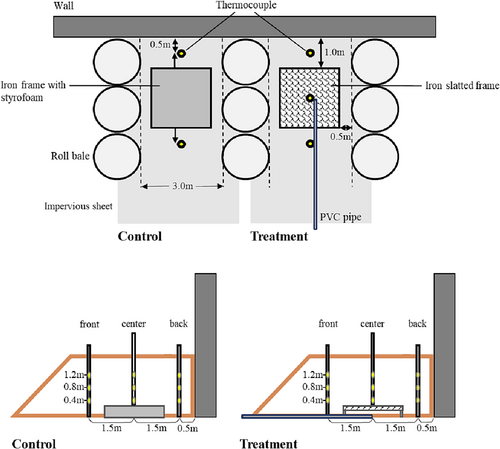

Dairy cattle manure was collected from a free-stall barn at the Hokkaido Agricultural Research Center (HARC). The cattle were fed roughage and concentrated feed, and low-quality hay used as bedding material was mixed with manure. Composting trials were conducted at the compost barn in the HARC using roll bales as the partition of each pile (Figure 1), and a leakage isolation sheet was laid on the floor. The compost materials were piled in a rectangular shape with a slope at the front end. The treatment pile was installed an iron slatted frame (2.0 × 2.0 × 0.3 m) inside the pile (Figure S1). An iron frame with a plain plate was installed in the control pile, and the internal cavity was filled with styrofoam. A polyvinyl chloride (PVC) pipe (75 mm internal diameter, 3.0 m length) was inserted under the slatted frame of the treatment pile to allow gas exchange and leachate discharge. A total of 12,020 and 12,100 kg of manure (wet weight) were piled for the control and treatment, respectively. The composting trial lasted from October 14 to December 2 (7 weeks), and the average ambient temperature during this period was 7.1 ± 4.7°C. The compost mass was turned for each treatment after 3 and 5 weeks using a front-wheel loader. The turning operation was done as follows: a wheel loader with a fork carefully removed the compost mass above the slatted frame. The slatted frame was lifted with a wheel loader, and the removed and remaining compost mass were mixed well. The mass was piled again after placing the slatted frame and PVC pipe on the floor. At the turning event, the mixed composts were piled again by initially decreasing the depth and height because of the reduction in the volume of the compost mass due to microbial degradation. The weight of the compost was measured at each turning point using a truck scale. Thermocouple probes were inserted 40, 80, and 120 cm from the bottom at the back, center, and front of the compost piles (Figure 1). The compost temperature was monitored every 30 min using a recorder (midi LOGGER GL200A; GRAPHTEC). The compost samples near the thermocouples (approximately 15 cm) were collected before turning and subjected to subsequent analyses.

2.2 Analyses

The moisture content was determined by drying the samples for 24 h at 105°C. Volatile solids were determined from the weight loss at 600°C for 1 h. Organic matter losses were calculated from the initial and final ash contents according to the following equation (Paredes et al., 2000): Organic matter loss (%) = 100 − 100[X1(100 − X2)]/[X2(100 − X1)], where X1 and X2 are the initial and final ash concentrations, respectively. The biochemical oxygen demand (BOD) of the initial and final compost samples was measured using a BOD Trak II (Hach Company) according to the manufacturer's instructions. BOD measurements were performed in duplicate. To determine the volatile fatty acids (VFAs), the compost samples (15 g) were homogenized in 75 mL of deionized water using a Stomacher 400 circulator (Seward). Homogenized compost suspensions were centrifuged (1500 ×g, 20 min), and the supernatants were filtered through 0.22-μm filters. The filtrates were mixed with 24% metaphosphoric acid in 3N-H2SO4 in a 5:1 ratio (v:v). The mixture was vortexed and centrifuged at 12,000 ×g for 10 min, and then 1.0 mL of the supernatant was collected. The quantity of VFAs (C2–C5) was determined using a gas chromatograph (GC-4000; GL Sciences Inc., Tokyo, Japan) equipped with a flame-ionization detector. The presence of Escherichia coli was tested by plating serial dilutions (1:9) of compost in duplicate on chromocult coliform agar ES (Merck, Darmstadt, Germany) and incubating them at 37°C for 24 h.

3 RESULTS

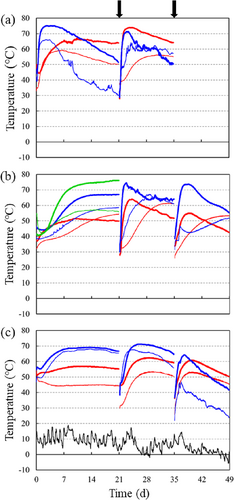

The initial size of the compost pile was approximately 3.0 m in width, 4.5 m in depth, and 1.7 m in height (Figure 1) and the initial moisture content of raw compost material was 78.3% (Table 1). By installing the slatted frame, the discharge of running leachate from the pile or along the pipe was enhanced in the treatment pile, whereas no leachate was observed in the control 2 h after the start (Figure S2). After 22 h, the running leachate was discharged from the control pile (data not shown). The changes in compost temperature at 40, 80, and 120 cm from the bottom at the back, center, and front of the piles are shown in Figure 2. Generally, the temperatures of the treatment pile were higher than those of the control pile, except at 40 cm from the bottom at the center position. On 21 days of composting (3 weeks), the height of both compost piles decreased to less than 120 cm at the back and front positions of the piles, thus the temperature data of these positions are omitted from Figure 2. As the depths of the piles were reduced owing to the decreased volume of the compost mass, the temperatures at the front parts of the piles were not shown after Day 35 (Figure 2a). The differences between the temporal changes in compost temperatures were clearly represented as a duration of the temperatures above 55°C as well as the maximum temperature (Table 2). The maximum temperatures of the treatment piles at all positions were higher than those of the control piles. The durations of the high temperature of the treatment piles were also longer than those of the control. In particular, the positions 80 cm from the bottom at the front (T-F80), 80 cm from the bottom at the center (T-C80), 40 cm from the bottom at the front (T-F40), and 40 cm from the bottom at the back (T-B40) of the piles were two times longer than those of the control. Significant temperature differences between the control and treatment at 80 cm from the bottom at the center and 40 and 80 cm from the bottom at the back of the piles were observed after 2nd-turning (Table 2). Maximum temperatures of these locations in the control pile did not reach 55°C but reached within a range of 60.9–73.8°C in the treatment pile.

| Final samplesb | ||

|---|---|---|

| Initial samplesa | Control | Treatment |

| Moisture content (%) | ||

| 78.3 ± 1.8 | 78.0 ± 0.8 | 73.1 ± 1.6 |

| Total volatile fatty acids concentration (mg/g-DM compost) | ||

| 36.6 ± 8.06 | 0.2 ± 0.13 | n.d. |

| Biochemical oxygen demand (mg-O2/g-DM compost) | ||

| 771.7 ± 208.1 | 133.2 ± 41.6 | 97.1 ± 49.3 |

| Organic matter loss (%) | ||

| 0 | 48.0 ± 2.31 | 58.4 ± 7.60 |

- Abbreviation: n.d., not detected.

- a Average and standard deviation of the three raw manure samples are shown.

- b Average and standard deviation of the final compost samples obtained from five different locations are shown.

| Maximum temperature (°C) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Front | Center | Back | ||||||||||||

| Period (days) | C-F40 | T-F40 | C-F80 | T-F80 | C-C40 | T-C40 | C-C80 | T-C80 | C-C120 | T-C120 | C-B40 | T-B40 | C-B80 | T-B80 |

| 0–21 | 59.2 | 67.1 | 66.2 | 75.2 | 54.5 | 51.4 | 58.6 | 67 | 57.3 | 76.1 | 54.9 | 56.9 | 68.1 | 69.3 |

| 21–35 | 56.2 | 73.9 | 64.2 | 71.4 | 61.4 | 64.0 | 67.1 | 74.6 | n/a | n/a | 53.6 | 62.5 | 67.7 | 71.2 |

| 35–49 | n/a | n/a | n/a | n/a | 53.4 | 55.1 | 51.7 | 73.8 | n/a | n/a | 53.4 | 60.9 | 46.9 | 64.3 |

| Total (0–49) | 59.2 | 73.9 | 66.2 | 75.2 | 61.4 | 64.0 | 67.1 | 74.6 | 57.3 | 76.1 | 54.9 | 62.5 | 68.1 | 71.2 |

| Duration above 55°C (h) | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Front | Center | Back | ||||||||||||

| Period (days) | C-F40 | T-F40 | C-F80 | T-F80 | C-C40 | T-C40 | C-C80 | T-C80 | C-C120 | T-C120 | C-B40 | T-B40 | C-B80 | T-B80 |

| 0–21 | 248 | 437 | 145 | 458 | 0 | 0 | 205 | 346 | 281 | 396.5 | 0 | 369.5 | 435 | 500 |

| 21–35 | 166.5 | 317 | 289 | 243.5 | 163.5 | 221.5 | 262.5 | 318.5 | n/a | n/a | 0 | 270.5 | 312 | 299 |

| 35–49 | n/a | n/a | n/a | n/a | 0 | 1.5 | 0 | 312.5 | n/a | n/a | 0 | 195.5 | 0 | 134.5 |

| Total (0–49) | 414.5 | 835.5 | 434 | 933.5 | 163.5 | 223 | 467.5 | 977 | 281 | 396.5 | 0 | 835.5 | 747 | 933.5 |

- Note: C and T represent control and treated samples, respectively. B40, B80, C40, C80, C120, F40, and F80 represent the compost samples at 40, 80, and 120 cm from the bottom at the back, center, and front of the pile, respectively.

- Abbreviation: n/a, not applicable.

The changes in compost weight are listed in Table S1. The total weights of the control and treatment piles were reduced by 3690 and 4240 kg within the first 35 days of composting. Introducing the slatted frame successfully reduced the total mass at every sampling time, and the differences in compost weight ranged from 250 to 470 kg. The final percentages of the initial weights of the control and treatment were 47.5% and 44.6%, respectively. The changes in compost properties are shown in Figure 3, and the properties of the final compost sample are shown in Table 1. The moisture content of the treatment pile decreased remarkably during the first 35 days of composting, whereas that of the control pile was almost stable and was higher than 78%. Finally, the moisture content of the treated compost was 5% lower than that of the control. Organic matter loss of the treatment pile drastically increased immediately after composting started, and the loss of the treatment was two times higher than that of the control at Day 35. Finally, the organic matter loss of the treated compost was 10% higher than that of the control. The BOD of the compost was determined to evaluate the remaining easily digestible organic matter. The average BOD value of the final treated compost samples was 27.1% lower than that of the control (Table 1). With regard to VFAs, the changes in concentrations were quite similar between piles, and the concentration of the treated compost was below the detection limit at the end of composting. The number of E. coli in the raw manure compost was 1.3 × 106 CFU/g. The E. coli counts decreased remarkably at the first turning and finally decreased below the detection limit (<102 CFU/g) in all treated compost samples (Table S2). The number of E. coli in the control compost also decreased below the detection limit, except in one sample.

4 DISCUSSION

Dairy production tends to be more intensive in Japan, and in some regions, cows generate more manure-derived nutrients than those required by nearby agricultural fields. Cow manure is a high-moisture material with a low nutrient density, making it costly to transport and apply to fields located far from the cow barn. Forced aeration is a common method that uses perforated pipes at the bottom of the compost piles to enhance aeration and produce dried and well-decomposed compost. However, the bottom of the pile is filled with a large amount of accumulated leachate and highly compacted with its own weight. The physical conditions in this area hinder forced/passive aeration and thereafter tend to induce undesirable anaerobic conditions during composting. Therefore, in this study, the introduction of a slatted frame was examined to enhance the discharge of excess water and gas convection during composting of high-moisture cow manure.

The moisture content of the raw compost mixture was 78.3%, which was beyond the recommended moisture content range of 50%–60% (Epstein, 1997). By the installation of the slatted frame, gravity-dependent “natural” dehydration was accelerated, and leachate was discharged from or along with the pipe in the treatment pile while no leachate discharge was observed after 2 h from the start. The running leachate spread over the floor; hence, the leachate volume was not quantified. However, the total weight of the treatment pile at 1st-turning was approximately 400 kg lower than that of the control pile. Moreover, the moisture content of the treatment pile at 1st-turning was more than 3% lower than that of the control compost. Maximum temperatures and durations above 55°C in the treated pile were much higher than those of the control pile. This implies that higher volumes of evaporation occurred in this period. Thus, the enhanced leachate discharge and evaporation could have contributed to the reduction in the moisture content of the treatment pile. In contrast, the moisture content of control changed a little before and after composting. The presence of moisture in compost comes from both the initial water contained and the metabolic water produced by the activities of microorganisms. A certain amount of water is released as leachate and vapor during the process, while the compost mass that can hold water is also reduced by microbial decomposition. Higher moisture content observed in the final control compost was attributed to the lower volume of released leachate and/or vapor against the volume of remaining compost mass. Finally, the difference in the moisture content increased by approximately 5% (Table 1).

By installing the slatted frame, not only a reduced moisture content of the compost mass but also remarkable heat generation at various positions of the treatment pile was observed. With regards to the maximum temperature, the temperature of 5 of 14 positions in the treatment pile was above 70°C, while no position in the control pile (Table 2). These high temperatures were mainly observed at 80 cm from the floor. Thermogenic composting greatly reduces microbial pathogens and the risk of contamination of vegetable crops and is effective in reducing plant diseases (Gurtler et al., 2018; Noble & Roberts, 2004). The regulatory requirements for composting to be classified as a process to further reduce pathogens (PFRPs) mandate that the minimum operating temperatures must be maintained at 55°C or above for 3 days (USEPA, 1994). Nishida et al. (1999) conducted to determine the length of exposure to heat necessary to kill 10 upland weed species and reported all seeds of each species were killed by exposure to heat at 55°C for 72 h. In this study, therefore, duration above 55°C at the same location of each pile was compared. A longer duration was observed in all locations of the treatment pile; in particular, four of the seven locations showed more than twice the duration of the control pile. Although the temperature in the control pile reached a high temperature (>55°C) long enough (163.5 h in minimum) for weed seed elimination, a longer duration of high temperature is expected to ensure pathogen/weed seed destruction in larger parts in the pile. Tanaka (1998) reported that using a porous layer at the bottom of a compost pile enhanced passive aeration and resulted in higher heat generation, especially in the initial phase of composting. Similarly, in this study, a cavity was formed at the bottom of the heap and PVC pipe, which enabled the introduction of fresh air to enhance passive aeration. Interestingly, the temperature of the treatment at 40 cm from the bottom at the center of the pile, just above the slatted frame, was lower or similar to that of the control (Table 2, Figure 2). In contrast, the temperature of the treatment 80 cm from the bottom at the center, front, and back was higher than that of the control. This phenomenon was caused by a “chimney effect” (Andersen et al., 2010; Hellmann et al., 1997) to draw cool air and oxygen into the pile as the warm air is released. The temperature of control at the 40 cm from the bottom at the back did not reach 55°C over the experiment period. This area is close to the floor and surrounded by the back and both sidewalls. Hence, it is assumed that this area is more likely to develop anaerobic conditions in the pile. However, the temperature generation in this area was significantly improved by the introduction of a slatted frame. Remarkable temperature differences between the control and treatment at 80 cm from the bottom at the center and 40 and 80 cm from the bottom at the back of the piles were observed for the last 2 weeks (Table 2). Although the average ambient temperature in this period was very low (1.7 ± 2.4°C), thermogenic composting successfully occurred in the treatment pile. Finally, the organic matter degradation was improved by installing a slatted frame, as indicated by the organic matter losses of the control and treatment, which were 48.0% and 58.4%, respectively. Organic matter loss in each compost pile was in accordance with the BOD data (Table 1).

The effect of introducing the slatted frame on E. coli elimination was evaluated using compost samples collected near each thermocouple. The number of E. coli in all the compost samples from the treatment pile decreased below the detection limit (<102 CFU/g), and those of the control samples decreased below the detection limit, except for one sample. Finally, all compost samples met the standard requirements of the BSI PAS:100 (<103 CFU/g) (British Standards Institution, 2018). Although the compost temperatures of the control pile were lower than those of the treatment pile, the temperatures of the control pile increased above 55°C in most parts of the pile; therefore, it successfully reduced the number of E. coli. Moreover, the turning events could help expose E. coli to high temperatures entirely even if low-temperature areas (e.g., 40 cm from the bottom at the center and/or back) existed in a heap. The total VFAs concentration, an indicator of odorous substances, was also determined. The VFAs concentration varied in the positions of the compost samples, and the trends of the changes in concentration of the control and treatment were similar, finally decreasing to nearly the detection limit level at Day 49.

In conclusion, the slatted frame successfully enhanced the discharge of accumulated water in the pile via or along the pipe. Compost leachate can migrate into and pollute underlying soils and groundwater and flow as runoff into ditches, ponds, and streams. The resulting leachate is strongly recommended to be stored in a pit facilitated beside a compost barn and spread over agricultural fields and/or pasture as liquid fertilizer. The pipe also functions as a tunnel to draw cool air and oxygen into the pile when warm air is released. Heat generation in the area above the slatted frame was highly enhanced by the supplied oxygen, resulting in a longer duration of high temperatures, which ensured pathogen and weed seed elimination. Although the slatted frame in the pile becomes an obstacle during the turning operation with a front-wheel roader, this system has the potential to reduce the turning frequency by inducing air diffusion and convection in the pile. In the practical use of this method, a floor structure with a cavity just under the pile could be a possible solution. Cavity under concrete provides a flat working surface that does not interfere with the wheel loader or requires regular operator intervention. This composting method is expected to be effective for treating high-moisture materials and producing relatively dry and well-degraded final products without high operational costs.

ACKNOWLEDGMENTS

This study was partially supported by JSPS KAKENHI (grant number: JP21K05880).

CONFLICT OF INTEREST STATEMENT

The author declares no conflict of interest for this article.