Modification of dietary rumen degradable starch content by chemical processing of feed ingredients: A meta-analysis

Abstract

The efficiency of starch utilization in ruminant feed can be enhanced by reducing the degradation of starch in the rumen. Chemical processing of feed ingredients may modify such ruminal starch degradation. This study aimed to evaluate the chemical processing of ruminant feed ingredients on rumen degradable starch (RDS) and starch degradation kinetics in the rumen. A database was constructed from a total of 34 articles, consisted of 100 observations. The articles were searched and identified from the Scopus platform. Data were analyzed by using the fixed effect model. The types of chemical processing in this study included sodium hydroxide, ammonia, potassium aluminum, urea, formaldehyde, and organic acid. Results indicated that chemical processing significantly reduced the RDS content (p < 0.001) and the immediately soluble fraction (p < 0.001) and increased the value of slowly degradable fraction (p < 0.001) and starch absorption in the small intestine (p < 0.01). Formaldehyde was particularly effective to decrease the RDS (p < 0.05). The RDS contents in corn and wheat were reduced by the chemical processing (p < 0.05), but not with that of barley. It can be concluded that chemical processing is effective in reducing starch degradation of ruminant feeds and may enhance its utilization by ruminants.

1 INTRODUCTION

Generally, the provision of energy source in feed for ruminants with high production is concentrate. Grains as the main constituents in concentrate have one of the nutrients that are important in providing energy, that is, starch or non-fiber carbohydrates. Feeding ruminants with starch in large quantities, however, may have negative effects on rumen health and ruminants productivity. This is because starch present in feed ingredients is easily fermented in the rumen and is associated with the accumulation of large amounts of fermentative acids and, consequently, leads to a low rumen pH (Pilachai et al., 2017). The degradation of starch in the rumen depends on a number of factors such as physical morphology of the grain, nutrient content, grain pericarp, kernel, amylose, and amylopectin proportion (Srakaewa et al., 2021). The strong pericarp, for instance, might prevent the rumen microbes from degrading too much starch.

Efforts to reduce the negative effects of easily digestible starch in the rumen have been carried out by a number of measures, that is, physical processing (Guney, 2019; Trotta et al., 2021), chemical processing (Palacios-Fonseca et al., 2013; Shen, Ran, et al., 2019), and combination between both physical and chemical processing (Gruber et al., 2017; Metzler-Zebeli et al., 2015). Nowadays, chemical processing methods such as alkaline and acid treatments are more attractive for practitioners because they are cheaper and easier to be carried out than other processing methods (Deckardt et al., 2013).

Although studies on effectiveness of modified starch with chemical processing have been repeatedly reported, however, the results obtained so far have been inconsistent and it remains unclear to conclude the actual effect of chemical processing on starch digestibility in the rumen. Several studies reported that the modification feed ingredients with chemical processing increased the quality of the nutrient content (Bradshaw et al., 1996; Gruber et al., 2017), but several others reported no effect on the rumen degradable starch (RDS) (Dehghan-Banadaky et al., 2008; Ghoorchi et al., 2013; Naseroleslami et al., 2018). In contrast to physical processing that has been summarized quantitatively by Rafiee and Darabighane (2021), there is no study to date that attempts to summarize quantitatively the RDS modification by using chemical processing methods. Therefore, this study aimed to evaluate the chemical processing of ruminant feed ingredients on nutrient content and in situ starch degradation in the rumen from various scientific literatures by using a meta-analysis approach.

2 MATERIALS AND METHODS

2.1 Database development

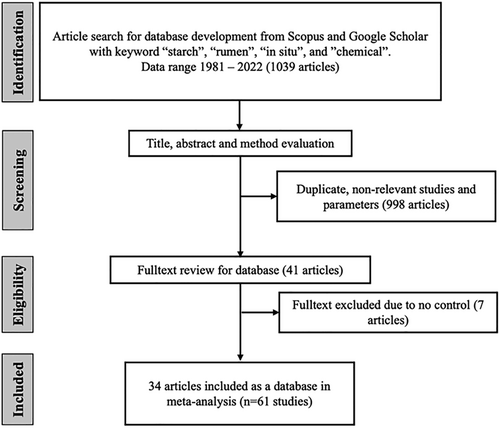

A database was developed from various articles reporting chemical treatments to modulate rumen degradation of ruminant feed ingredients, particularly on nutrient contents and in situ starch degradation parameters. Searching of the articles used a number of keywords, that is, “starch,” “rumen,” “in situ,” and “chemical,” on Scopus and Google Scholar platforms. The literature selection process is shown in Figure 1. In this study, the articles were published from 1981 to 2022. The number of articles that fulfill the inclusion criteria was 34 (Table 1), in which the process was based on the Preferred Reporting Items for Systematic Reviews and Meta-Analyses or PRISMA protocol (Liberati et al., 2009). The criteria for articles to be included in the database were (1) articles were published in English, (2) there was a chemical treatment for processing a ruminant feed ingredient, (3) there were treatment and control groups in pairs, and (4) articles reported the nutrient contents of the treated feed ingredients and/or data on starch degradation parameters in situ. The in situ method employed fistulated animals, that is, beef cattle and dairy cows. Starch degradation was measured by the loss of substrate from the synthetic fiber bag. The articles reported different chemical types to modify RDS such as ammonia, sodium hydroxide, urea, potassium aluminum, formaldehyde, and organic acid. The feed ingredients used in the database were corn, barley, wheat, and cassava.

| No. | Reference | Feed ingredient | Chemical used | Level (%) |

|---|---|---|---|---|

| 1 | Laksesvela (1981) | Barley | Ammonia | 0–3 |

| 2 | Laksesvela and Slagsvold (1980) | Barley | Ammonia | 0–3 |

| 3 | Rode et al. (1986) | Barley | Urea, ammonia | 0–6 |

| 4 | van Ramshorst and Thomas (1988) | Barley | Formaldehyde | 0–4.1 |

| 5 | Robinson and Kenelly (1988) | Barley | Ammonia | 0–6.5 |

| 6 | Mandell et al. (1988) | Barley | Ammonia | 0–5 |

| 7 | Fluharty and Loerch (1989) | Corn | Formaldehyde | 0–2 |

| 8 | Oke et al. (1991) | Corn | Formaldehyde | 0–3.7 |

| 9 | McAllister et al. (1992) | Barley | Formaldehyde | 0–3.7 |

| 10 | Pauly et al. (1992) | Oats | Sodium hydroxide | 0–4.5 |

| 11 | McNiven et al. (1995) | Barley | Sodium hydroxide | 0–4 |

| 12 | Bradshaw et al. (1996) | Barley | Ammonia | 0–3 |

| 13 | Michalet-Doreau et al. (1997) | Corn, wheat | Formaldehyde | 0–5 |

| 14 | Goonewardene et al. (1998) | Barley | Ammonia | NA |

| 15 | Ortega-Cerrilla et al. (1999) | Barley | Formaldehyde | 0–3 |

| 16 | Schmidt et al. (2006) | Wheat | Sodium hydroxide, formaldehyde | 0–2 |

| 17 | De Campeneere et al. (2006) | Wheat | Sodium hydroxide | 0–3 |

| 18 | Dehghan-Banadaky et al. (2008) | Barley | Sodium hydroxide, formaldehyde, urea | 0–4 |

| 19 | Iqbal et al. (2009) | Barley | Organic acid | 0–0.5 |

| 20 | Iqbal et al. (2010) | Barley | Organic acid | 0–0.5 |

| 21 | Iqbal et al. (2012) | Barley | Organic acid | 0–1 |

| 22 | Ghoorchi et al. (2013) | Wheat | Sodium hydroxide | 0–3 |

| 23 | Deckardt et al. (2014) | Barley | Organic acid | 0–5 |

| 24 | Metzler-Zebeli et al. (2015) | Barley | Organic acid | 0–1 |

| 25 | Khol-Parisini et al. (2015) | Barley | Organic acid | 0–1 |

| 26 | Humer et al. (2015) | Barley | Organic acid | 0–1 |

| 27 | McDonnell et al. (2017) | Wheat | Sodium hydroxide | 0–3 |

| 28 | Gruber et al. (2017) | Barley | Organic acid | 0–1 |

| 29 | Naseroleslami et al. (2018) | Barley | Ammonia, sodium hydroxide, potassium aluminum | 0–5 |

| 30 | Shen, Ran, et al. (2019) | Corn | Organic acid | 0–1 |

| 31 | Shen, Ding, et al. (2019) | Corn | Organic acid | 0–0.5 |

| 32 | Naghadeh et al. (2020) | Barley | Organic acid | 0–1 |

| 33 | Srakaewa et al. (2021) | Corn, cassava | Sodium hydroxide | 0–3.5 |

| 34 | Gonzalez-Rivas et al. (2021) | Wheat | Sodium hydroxide | 0–3 |

- Abbreviation: NA, not available.

Chemicals used from the articles were reported at different levels, ranged from 0.5% to 5% of the dry matter (DM) content. Some articles also reported different units of measurements for specific parameters. In such case, the data obtained from each parameter were uniformed by converting it into a pre-determined unit. Parameters included in the database were DM (%), crude protein (CP; %), ether extract (EE; %), neutral detergent fiber (NDF; %), acid detergent fiber (ADF; %), starch (%), organic matter (OM; %), metabolizable energy (ME; MJ/kg), a or immediately soluble fraction (%), b or insoluble fraction (%), c or rate b is degraded (%/h), RDS (%), starch absorption in small intestine (%), and total tract digestion of starch (%).

2.2 Data analysis

3 RESULTS

The meta-database was extracted from 34 articles that composed of 100 observations with 39 control groups and 61 chemical processing groups (Table 1). Chemical treatment of feed ingredients decreased the nutrient contents of EE (p < 0.05) and DM (p < 0.001) and increased the ADF content (p < 0.001) (Table 2). However, the other parameters, such as CP, ash, NDF, starch, OM, and EM, were not significantly affected by the chemical processing. The application of chemical processing significantly affected the in situ starch degradation parameters. Accordingly, the RDS (p < 0.001) and immediately soluble fraction (a) (p < 0.001) decreased by the chemical processing, whereas it significantly decreased the degradation rate (c) (p < 0.01). Furthermore, chemical processing significantly increased the value of insoluble fraction (b) (p < 0.001) and starch absorption in small intestine (p < 0.01). Modification of starch by chemical processing did not significantly affect the total tract digestion of starch. A forest plot of RDS from different chemical processing and starch source (Figure 2) revealed that types of chemical processing (p < 0.01) and starch source (p < 0.001) significantly decreased the cumulative effect size of dietary RDS on in situ degradation. However, among several types of chemical treatments, only formaldehyde significantly lowered the RDS proportion (p < 0.05). Based on the starch source, chemical processing lowered the RDS proportions of corn and wheat (p < 0.05), but it did not modify that of barley.

| Variable | Unit | NC | Estimate | Lower | Upper | Std. error | p-value | Q | Het. p-value |

|---|---|---|---|---|---|---|---|---|---|

| Nutrient content | |||||||||

| DM | % | 38 | −0.568 | −0.892 | −0.244 | 0.165 | <0.001 | 111.2 | <0.001 |

| CP | % | 25 | −0.216 | −0.578 | 0.145 | 0.184 | 0.241 | 59.60 | <0.001 |

| Ash | % | 18 | 0.213 | −0.329 | 0.755 | 0.277 | 0.442 | 52.32 | <0.001 |

| EE | % | 9 | −0.890 | −1.645 | −0.135 | 0.385 | 0.021 | 20.70 | 0.008 |

| NDF | % | 30 | −0.085 | −0.406 | 0.235 | 0.163 | 0.602 | 36.35 | 0.164 |

| ADF | % | 31 | 0.562 | 0.230 | 0.893 | 0.169 | <0.001 | 37.61 | 0.160 |

| Starch | % | 29 | −0.196 | −0.455 | 0.064 | 0.132 | 0.139 | 12.04 | 0.996 |

| OM | % | 16 | −0.024 | −0.424 | 0.377 | 0.204 | 0.908 | 0.202 | 1.000 |

| ME | MJ/kg | 7 | 0.096 | −0.414 | 0.606 | 0.260 | 0.712 | 9.800 | 0.133 |

| In situ starch degradation | |||||||||

| a | % | 14 | −1.680 | −2.103 | −1.258 | 0.216 | <0.001 | 135.0 | <0.001 |

| b | % | 14 | 1.430 | 1.043 | 1.816 | 0.197 | <0.001 | 109.7 | <0.001 |

| c | %/h | 14 | −0.495 | −0.815 | −0.174 | 0.164 | 0.003 | 60.13 | <0.001 |

| RDS | % | 24 | −0.487 | −0.755 | −0.220 | 0.136 | <0.001 | 157.6 | <0.001 |

| Absorption in small intestine | % | 7 | 0.844 | 0.221 | 1.467 | 0.318 | 0.008 | 13.66 | 0.034 |

| Total tract digestion of starch | % | 6 | −0.645 | −1.316 | 0.027 | 0.5343 | 0.060 | 12.32 | 0.031 |

- Abbreviations: a, immediately soluble fraction; ADF, acid detergent fiber; b, insoluble fraction; c, rate b is degraded; CP, crude protein; DM, dry matter; EE, ether extract; ME, metabolizable energy; NC, number of comparison; NDF, neutral detergent fiber; OM, organic matter; Q, study homogeneity; RDS, rumen degradable starch.

4 DISCUSSION

4.1 Effects of chemical processing on nutrient contents

The nutrient contents of feed ingredients may be altered by chemical processing. In this study, the chemical processing decreased the DM and EE contents. In agreement with the present study, Srakaewa et al. (2021) reported that the NaOH treatment on cassava and corn reduced the contents of EE and DM. McNiven et al. (1995) also reported similar results where NaOH treatment decreased barley DM and EE contents, followed by a decrease in ADF and NDF contents. Alteration of nutrient contents due to chemical treatment is possible because the treatment may affect the composition of grain kernels, such as lipids, protein, and starch. Differences in the ruminal starch digestion of feed components are mostly caused by the protein matrix around the starch granules. However, this study concluded that, quantitatively, the decrease was only found in EE and DM. Different results were obtained by Busanello et al. (2018) through a meta-analysis study that there is no effect of DM from physical processing on the nutrient content of feed ingredients. The DM loss in large quantities will have a negative impact on the nutrient content in available for absorption by ruminants. This is because DM consists of all nutrients (Al-Arif et al., 2017). Actually, the decrease in DM from this study is still in the low range of −0.568 and has not had a negative effect on the quality of feed ingredients.

On the other hand, the increase in ADF content by chemical processing is thought to be due to high polymer decomposition due to alkaline treatment of damaging hemicellulose and cellulose (Zhao et al., 2016). It is complicated to simplify how the chemical processing affects NDF, ADF, and soluble carbohydrates and then impacts to starch degradation. However, several hypotheses can be discussed. Naseroleslami et al. (2018) reported the relationship between β-glucans and fiber fraction with viscosity, where increasing the fiber fraction led to an increase in the viscosity of feed ingredients, thereby slowing down the starch degradation. These results clarify that soaked treatment or adding chemical processes to ruminant feed ingredients as a source of starch is more effective in modulating rumen starch degradation.

4.2 Effects of chemical processing on starch degradation

The chemical processing affects some parameters in situ starch degradation. The decrease in the immediately soluble fraction of starch indicated that the chemical treatment modified ruminant feedstuff to bypass starch (Dehghan-Banadaky et al., 2008). This result is equivalent to the result of indigestible rumen fraction or b value that increased by chemical processing, where the following effect can be seen from the degradation of nutrients in the rumen.

The decrease in RDS value due to chemical processing caused several physicochemical changes, such as the swelling of starch granules (Gunun, 2013), as well as the release of amylose and amylopectin from the structure. The released amylose and amylopectin molecules form a continuous gel matrix, which surrounds the broken starch granule residues. This condition illustrates that chemical treatment can affect the rheological properties of starch (Roberts & Cameron, 2002), so the starch is not easily degraded in the rumen. This result is expected because it indicates that the amount of starch that will be digested in the post-ruminal digestive tract will increase without affecting the total digestibility.

This study showed that chemical processing increases not only the quality of the ruminant feed but also the efficiency of starch utilization in ruminants. This efficiency is obtained because the value of starch absorption in small intestine significantly increases without affecting the total digestibility of starch. Shen, Ran, et al. (2019) reported that transferring some of the starch digestion from rumen to the small intestine is more efficient because of more supply net glucose to the liver. Decreased RDS also supports efficiency by reducing heat from fermentation and metabolic heat loss (Gonzalez-Rivas et al., 2021). In addition, achieving a more optimal integration efficiency can be applied by considering the ratio balance of digested starch in the rumen and post-rumen. This is related to limited starch digestion in the small intestine of ruminants due to the limited availability of pancreatic α-amylase (Deckardt et al., 2013) and the number of glucose transporters that play a role in supporting glucose absorption (Lohrenz et al., 2011).

All types of chemical processing can reduce the RDS (Figure 2). This result is related to the ability of chemical to cross-linkage in starch. The effect of reducing starch degradation is an indirect effect of reducing degradable protein. The decreased degradability of the protein matrix of the endosperm inhibited microbial access to embedded starch granules, thereby reducing the availability of starch to rumen microbes. Dehghan-Banadaky et al. (2008) further stated that the degree of connection is influenced by how deeply starch granules are ingested into the protein. The chemical processing that is significantly effective in reducing RDS is formaldehyde. The processing is a traditional method that is corrosive and requires special equipment. Its use in large quantities and for an extended period can negatively impact the health of livestock and humans who consume livestock products. As science develops so that this processing technology can be adopted by industry and farmers, chemical processing is expected to start using safer organic acids that are proven effective in reducing RDS.

The type of starch source also affects the results of starch modification. Based on degradability ratings in the rumen reported in the National Research Council (NRC, 2001), wheat has a greater starch degradation value than barley and corn. The results of this meta-analysis study showed that chemical processing is more effective in reducing degradation in corn and wheat than barley. This is because barley has a high degree of hydrolysis both amylopectin and amylose (Naguleswaran et al., 2014). The increased RDS value is due to the hydrolysis of starch with alkaline and acids, causing shorter amylose hydrolysates to form with polymers of <10 glucose units. This condition can inhibit starch retrogradation so that starch is more easily degraded in the rumen. According to Schmiedl et al. (2000), the optimal chain length to make the starch more resistant is α-(1–4)-d-glucan between 10 and 40. In addition, Michalet-Doreau et al. (1997) also obtained the same results that chemical processing of corn was more effective in reducing starch degradation in the rumen than wheat. It might be because of the different rates of protein matrix degradation around the starch granules.

The results of the present study suggest that chemical processing methods effectively reduce the RDS proportion and soluble fiber fraction and enhance the value of the slowly degradable fraction. In terms of nutrient contents, chemical processing methods reduce the contents of DM and EE and increase that of ADF. Based on the RDS value, formaldehyde is particularly effective in modulating the RDS. Modification of RDS is, in turn, expected to enhance net utilization of starch by ruminants.

ACKNOWLEDGMENTS

This study was financially supported by the Directorate General of Higher Education, Ministry of Education, Culture, Research, and Technology (Kementerian Pendidikan, Kebudayaan, Riset, dan Teknologi), Republic of Indonesia, through the PMDSU scheme, Year 2022, grant number 3874/IT3.LI/PT.01.03/P/B/2022.

CONFLICT OF INTEREST STATEMENT

All authors declare that there is no conflict of interest.