Advances in high-temperature operatable triboelectric nanogenerator

Abstract

The triboelectric nanogenerator (TENG) offers a novel approach to harness mechanical energy continuously and sustainably. It has emerged as a leading technology for converting mechanical energy into electricity. The demand for self-powered wearable microelectronics and energy generation in extreme conditions underscores the need for efficient high-temperature operatable TENGs (HTO-TENGs). However, the operating environment temperature not only affects the storage and dissipation of electrons during triboelectrification, leading to decreased output performance of TENG and instability at high temperatures, but also damage to the mechanical stability and effective defects in most tribo-materials, resulting in a further reduction in TENG's effective output power. Moreover, the unstable material properties of the triboelectric layer at high temperatures also restrict the use of the TENG in harsh environments. Therefore, it is imperative to consider the structural durability and electrical output stability of TENG when applying it in challenging working environments. This review aims to bridge this gap by providing a comprehensive overview of the current state and research advancements in HTO-TENG for the first time. Finally, this review presents insights into future research prospects and proposes design strategies to facilitate the rapid development of the field.

1 INTRODUCTION

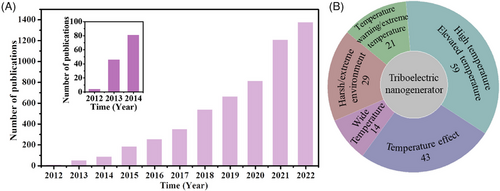

As concerns about the depletion of fossil fuels and their impact on the environment continue to grow, researchers have been exploring renewable energy sources more fervently than ever before.1-3 Finding sustainable energy sources from the surrounding environment to reduce carbon emissions, ensure long-term energy supply, and diminish dependence on fossil fuels has become an essential condition for the sustainable development of human civilization.4-7 Fortunately, the invention of triboelectric nanogenerator (TENG) in 2012, as an eco-friendly, enduring and self-sufficient power source, has opened up new possibilities for effective use of various forms of mechanical energy.8-10 Since invention, the number of TENG publications per year has significantly increased according to the analysis of published literature from the Web of Science database (Figure 1A). As a novel branch of energy conversion technology, TENG can efficiently convert the ubiquitous mechanical energy from the environment, including wind, vibration, water waves, biological energy, and human motion, into electrical energy through the coupling effect of contact electrification (CE) and electrostatic induction.11, 12 Unlike traditional power sources, TENG boasts several unique advantages, including a simple structure (basically two contact materials and electrodes), ease of manufacturing, lightweight, flexibility, low cost, high efficiency even at low operation frequency, sustainability, and unrestricted material selection.13-17 As a result, TENG has the potential to revolutionize the way we power various devices and systems, including human motion monitoring, athletic big data analytics, biochemical detection, and wearable electronics.9, 18-22 It is regarded as one of the most promising technologies to harvest electricity from mechanical kinetic energy, which will facilitate our transition toward a more sustainable future.

Currently, the majority of research in the field of TENG predominantly focuses on designing power supply systems or self-powered sensors within room temperature range.4, 23-26 However, due to increasing demand for self-powered wearable microelectronics in scientific missions and energy production under extreme environments such as automotive engines, oil exploration, geothermal wells, industrial plants, military, wildfires, and aerospace electronics systems,27, 28 efficient collection of triboelectric energy at high temperatures has become a crucial research area.29, 30 Relevant research in this area is gradually emerging, as evidenced by the data extracted from Web of Science (Figure 1B). Nevertheless, the output performance of TENG is substantially influenced by ambient temperature, presenting new challenges.31-34 Ensuring efficient and steady operation of TENG in a constantly changing environment is an urgent problem that needs to be addressed.

It is widely understood that the electron is the dominant CE transferred charge identity.24, 35, 36 The total surface charge output of TENG can be reasonably interpreted as the direct result of the coupling of the electron thermionic emission rate, the CE charge transfer rate, and the change in contact area between the two tribo-materials.24, 37, 38 Currently, TENG has been predominantly used to study CE at relatively low temperatures.4, 23, 39, 40 However, at high temperatures, the electrostatic charge on the TENG surface can be released via electron thermionic emission and/or photon excitation.23, 25, 38, 41 Consequently, the temperature of tribo-materials will affect the storage and dissipation of electrons in the process of triboelectrification, resulting in a decrease in the output performance of TENG and an inability to maintain a stable electrical output at high temperatures.42-44 Relevant studies have also further confirmed that increasing the tribo-layer's temperature will increase its electron thermionic emission rate, thereby reducing the charge storage capacity of the tribo-layer and deteriorating TENG's output.27, 44 Thermionic emission plays a critical role in explaining electron-dominated CE, where heating tribo-materials allows electrons to acquire sufficient thermal energy to overcome the work function and then emit from the tribo-materials.24, 42, 45 As there are limited studies on how to prevent or suppress this effect (thermionic emission), it is essential to further investigate its relationship with the operating environment temperature, as well as TENG output performance, in order to facilitate the development and application of high-temperature operatable TENG (HTO-TENG) devices.

TENG is a highly effective technology for generating electricity from mechanical energy.33, 46-48 Despite its many advantages, TENG's output can be negatively impacted by several factors. As mentioned above, the electron thermion emission rate of the tribo-layer increases as its temperature rises, which, in turn, reduces the charge storage capacity of the tribo-layer, ultimately leading to a decline in TENG's output.42-44 In addition to this issue, unstable material properties such as bandgap energy, interatomic bonding, breakdown field, carrier mobility, crystal structures, mechanical properties, and existing defects can also restrict the use of TENG in harsh environments.49, 50 Moreover, exposure to high temperatures can cause damage to the mechanical stability and effective defects in most tribo-materials, resulting in a further reduction in TENG's effective output power.42, 51 Therefore, it is essential to consider structural durability and electrical output stability when applying TENG technology in challenging working environments.4, 45 To address these challenges, researchers are exploring new ways to enhance TENG's durability and expand its application fields.

As mentioned previously, in order to the efficient, stable, and continuous operation of tribo-materials in an environment with constantly changing conditions, it is necessary to prevent or suppress the electron thermionic emission effect and enhance structural stability at high temperatures. It is crucial for developing HTO-TENG and expanding its application fields. Despite being a thriving field, research progress on similar topics elsewhere has not been reviewed. This review aims to fill this gap by providing a comprehensive overview of the research progress and current situation in the field of HTO-TENG for the first time. The outline of this review is structured as follows: (1) Basic aspects of HTO-TENG are expounded, including the device's working mode, working mechanism, and temperature effect. (2) Recent advances in HTO-TENG are discussed from five different perspectives: device structure design, polymer-based tribo-materials structure design, gel-based TENG, carbon-based TENG, and metal–organic framework (MOF)-based TENG. (3) Prospects for future research are explored and some recommended design strategies are proposed to facilitate the rapid advancement of this field.

2 BASIC THEORY AND WORKING MECHANISM OF TENG

TENG efficiently converts ubiquitous mechanical energy in the environment into electricity through the coupling effect of CE and electrostatic induction.52 This section will delve into the fundamental theory, basic working mechanism and working modes, as well as the temperature effect of TENG.

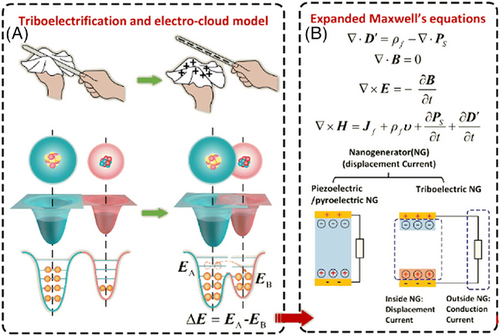

2.1 Contact electrification

The CE effect, also known as triboelectrification, is a fundamental phenomenon in electricity that involves the charge transfer between two dissimilar materials (Figure 2A), which is typically described as the ability of both materials to become charged during contact and separation.52-54 The emergence and rapid advancement of TENG technology have catalyzed fundamental research on CE. Prof. Wang put forward an electron-cloud overlap model that can explain the common occurrence of the CE effect in solid–solid and liquid–solid interfaces.23, 55 Additionally, by utilizing the Kelvin probe force microscope system, Wang's team has investigated the fundamental mechanism of CE and concluded that electron transfer is the primary mechanism between solid–solid pairs.36, 56-58 Specifically, the contact surfaces of two dissimilar materials generate equal electrostatic charges with opposite polarity, and the separation of the two surfaces under an external force facilitates the contact-induced triboelectric charges to generate a protential drop, thereby driving electrons to flow between the two electrodes assembled on the top and bottom surfaces of the two materials.59

2.2 Maxwell's displacement current

Maxwell's equations, ranked among the top 10 equations in physics, hold immense significance in modern fundamental science and technologies.54 To gain a deeper comprehension of TENG's working mechanism, Prof. Wang has proposed the formulation of Maxwell's displacement current for the TENG and its corresponding extended Maxwell's equations.55, 59, 60 In general, Wang's team has derived the differential form of the extended Maxwell's equations for a moving medium as a translational rigid object from the original differential form of Maxwell's equations for a fixed volume and boundary medium. Maxwell's equations for the moving charged medium (also known as the extended Maxwell's equations) are depicted in Figure 2B, where D′ represents the displacement field, ρf represents the free electric charge density, B represents the magnetic field, E represents the electric field, H represents the magnetizing field, Ps represents the added term due to the presence of surface/volume electrostatic charges with the variation time in boundary shapes (independent of E), υ represents the movement velocity of the medium, and Jf represents the free electric current density. Considering the presence of surface electrostatic charges resulting from CE, the invariant expressions of the modified equations under the action of displacement current are proposed. The extended Maxwell's equations make a significant contribution to the fundamental theory of TENG.60, 61 To conclude, TENG utilizes the displacement current generated by external forces through the CE effect as a driving force to convert mechanical energy into electrical energy.

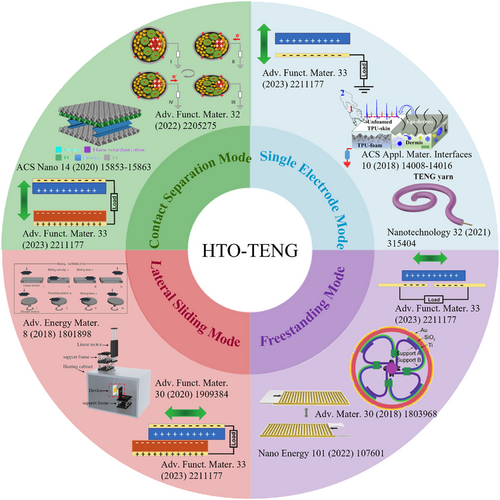

2.3 Basic working modes of the TENG

Based on the coupling of two common phenomena, namely, CE and electrostatic induction, the basic working modes of TENG can be categorized into four modes (Figure 3): contact separation mode,44, 51, 62 single electrode mode,62-64 free-standing mode,25, 65 and lateral sliding mode.24, 66 Furthermore, TENGs can be categorized as contact and sliding mode based on the friction mode,67-70 as well as single or double dielectric-layered TENG depending on the number of dielectric layers.71, 72 The four working modes of TENG demonstrate distinct application scenarios due to variations in its structure and electrode arrangement.73 In all instances, CE results in the generation of triboelectric charges with opposite polarities on the surface of materials. Subsequently, electrostatic induction produces a driving force that converts mechanical stimuli into electrical energy during relative motion.

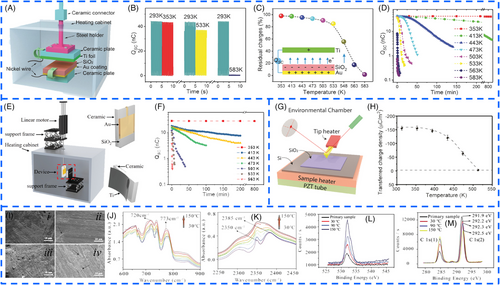

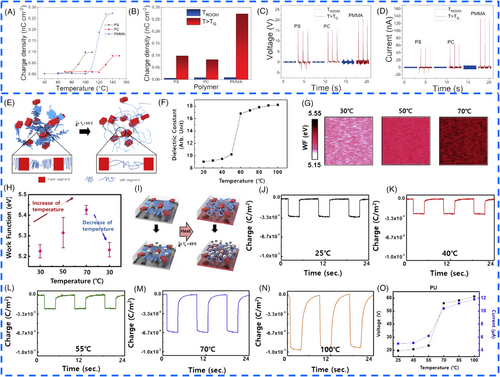

2.4 Temperature effect on performance of TENG

As previously mentioned, TENG is a novel energy conversion technology that utilizes the coupling effect of CE and electrostatic induction to convert mechanical energy into electrical energy.11, 12 First, from the point of view of the tribo-charges, electron thermionic emission is the crucial factor that influences the fundamental mechanism of CE and is an inevitable effect in almost all tribo-materials.23, 37 Electrons serve as the primary charge carriers in CE,23, 24, 37 which exhibits a strong temperature dependence (Figure 4A–F).25 Specifically, electron thermionic emission poses a significant challenge at elevated temperatures (Figure 4G,H).25 The overall surface charge output of the TENG can be attributed to the interplay between the electron thermionic emission rate, CE charge transfer rate, and the changing rate in contact area between the two materials.24 Due to the electron thermionic emission effect, electrons transferred to the surface of the tribo-layer are released into the vacuum after CE,27, 42 resulting in a reduction in surface charge density of the tribo-materials. Consequently, TENG cannot maintain effective output under high-temperature conditions. Second, from the perspective of the material, the intrinsic property of tribo-materials plays a crucial role in determining the output of TENGs.31 High temperatures not only induce changes in the dielectric constant of tribo-materials, which are closely linked to TENG's output performance,31, 74 but also have the potential to cause structural and mechanical instability as well as material defects in most tribo-materials.75, 76 As presented Figure 4I–M, exposure to elevated temperatures can result in unstable material properties, compromised mechanical durability and effective defects of most tribo-materials,4, 31, 42, 49-51 thereby further diminishing the TENG's power output efficiency. In conclusion, the impact of high temperature on the output performance of TENGs needs to take into account multiple factors, including the surface charge density of tribo-materials, storage, and dissipation mechanisms for tribocharges, dielectric constant, structural stability, mechanical stability, and wear resistance.

3 RECENT ADVANCES IN HTO-TENG

3.1 Structural design of TENG devices

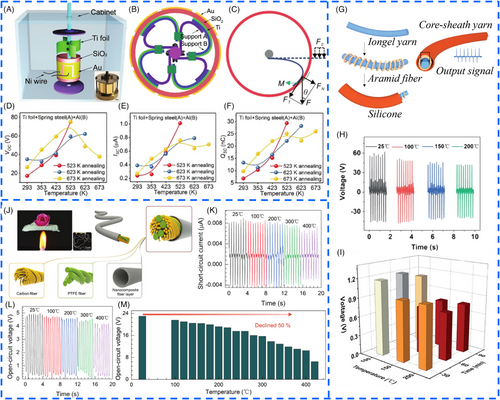

The strong temperature dependence of CE has been widely acknowledged, with electron thermionic emission being the main limiting factor of CE at high temperatures.24, 25, 42, 45 A detailed investigation by Wen et al. examined the effect of temperature on TENG and confirmed that it could operate successfully at 500 K despite experiencing a significant drop in voltage due to thermionic emission.43 To further broaden the operating temperature range of TENG devices, Xu et al. developed a polymer-free rotating self-standing mode TENG (R-TENG) with a double support structure made of spring steel and Al from a device structure design perspective, as shown in Figure 5A,B.25 By optimizing this device structure, the R-TENG with double supports achieved maximum output at 523 K, as displayed Figure 5D–F. Additionally, the working temperature of the R-TENG was increased to 673 K by suppressing thermionic emission through direct physical contact of the two support materials after preannealing, as shown in Figure 5D–F. The working mode, triboelectric materials, electrode, operating temperature, output performance, and output efficiency of this work and all below-mentioned works are listed in Table 1. This study successfully designed and constructed an R-TENG that was capable of operating up to 673 K, potentially broadening the temperature range of TENG applications to various extreme environments of planets, outer space, and even extrasolar planets.

| Section of this article | Working mode | Triboelectric materials | Electrode | Operating temperature | Voc/Isc | χ (%) | Ref. |

|---|---|---|---|---|---|---|---|

| 3.1 | Rotating free-standing mode with double supports | Ti and SiO2 | Au | 523 K | 286 V | 414 | 25 |

| 3.1 | Single electrode mode | Aramid fiber and Silicone | Double-network ionogel | 200°C | 48 V | 70 | 76 |

| 3.1 | Single electrode mode | Silica aerogel/PI nanocomposite and PTFE | Carbon fiber | 100°C | 21.6 V | 93.5 | 51 |

| 200°C | 19.2 V | 83.1 | |||||

| 300°C | 15.7 V | 66.2 | |||||

| 400°C | 10.6 V | 45.9 | |||||

| 3.2.1 | Flutter-driven single electrode mode | 1% BaTiO3-doped 6FDA-TFDB | Al | 200°C | 0.7 µA | 32 | 42 |

| 3.2.2 | Single electrode mode | md-PI_95 | Al | 60°C | 157 V | 224 | 106 |

| 70°C | 127 V | 181 | |||||

| 3.2.2 | Contact separation mode | Cu/hc-PI | Cu | 60°C | 61 V | 244 | 105 |

| 70°C | 58 V | 232 | |||||

| 3.2.3 | Contact separation mode | PVA/PPA-PEI and PVDF | Al | 100°C | 10.6 V | 54.3 | 115 |

| 3.2.3 | Single electrode mode | 1AFE-25 and FEP | 6AFE-26 | 200°C | 27.3 V | 120 | 116 |

| 250°C | 28.2 V | 124 | |||||

| 3.2.3 | Single electrode mode | EFM | Conductive elastic fabric | 70°C | 110 V | 100 | 120 |

| 3.2.3 | Single electrode mode | PH-SA film | Cu | 60°C | 117.8 V | 285.3 | 121 |

| 90°C | 87.7 V | 256.0 | |||||

| 100°C | 81.0 V | 231.4 | |||||

| 3.2.3 | Single electrode mode | Flame-retardant wood | Cu | 200°C | – | 82.0 | 18 |

| 250°C | – | 60.5 | |||||

| 3.2.3 | Single electrode mode | CNF-BP-PA | CNF-BP-PA/AgNWs | 80°C | 129 V | 131.6 | 142 |

| 110°C | 93 V | 94.9 | |||||

| 3.3 | Free-standing mode | Cu and PU | Cu | 40°C | 20.8 V | 105 | 149 |

| 55°C | 23.8 V | 120 | |||||

| 70°C | 56.1 V | 282 | |||||

| 85°C | 58.6 V | 294 | |||||

| 100°C | 61.4 V | 309 | |||||

| 3.4 | Contact separation mode | Cotton fibers and PTFE | Al | 60°C | 204 V | 93.6 | 154 |

| 3.4 | Contact separation mode | Flame-retardant conductive fabric and PTFE-coated fabric | Flame-retardant conductive fabric | 100°C | 75.2 V | 73.0 | 44 |

| 160°C | 51. V | 50.4 | |||||

| 200°C | 39.8 V | 38.9 | |||||

| 220°C | 35.8 V | 34.5 | |||||

| 3.4 | Contact separation mode | Cu and PINF | Cu | 100°C | 49.3 V | 80.8 | 45 |

| 150°C | 40.4 V | 65.0 | |||||

| 200°C | 29.7 V | 47.4 | |||||

| 250°C | 16.0 V | 26.2 | |||||

| 3.5.1 | Contact separation mode | Hydrogel and FEP | Ag NWs | 40°C | 10 V | 100 | 165 |

| 3.5.1 | Single electrode mode | Silicone rubber | Hydrogel | 60°C | 275 V | 95.8 | 166 |

| 3.5.1 | Single electrode mode | VHB | CPH | 60°C | 41 V | 100 | 167 |

| 3.5.1 | Single electrode mode | Commercial PU tape | MMCOHs | 60°C | 56.3 V | 96.7 | 169 |

| 3.5.1 | Single electrode mode | PAZ | PAAm-clay-KI organohydrogel | 80°C | 136 V | 105 | 170 |

| 3.5.1 | Single electrode mode | IU-PDMS | Paam-clay organohydrogel | 80°C | 154 V | 100 | 171 |

| 3.5.1 | Single electrode mode | SR | AVN organohydrogel | 100°C | 141 V | 98.4 | 172 |

| 3.5.1 | Single electrode mode | NSO | CSO | 80°C | 30 V | 214 | 173 |

| 3.5.2 | Single electrode mode | PDMS | Ionogel | 60°C | 4.35 µA | 106 | 184 |

| 3.5.2 | Single electrode mode | Electrospun PVDF/PU | ICL | 80°C | 179 V | 100 | 114 |

| 3.5.2 | Single electrode mode | PDMS | Ionogel | 100°C | 111 V | 100 | 186 |

| 3.5.2 | Single electrode mode | RD-PDMS | TEOA-PTA@LiTFSI | 60°C | 82 V | 115 | 188 |

| 3.5.3 | Contact separation mode | SFS e-textile and PTFE fabric | Cu | 150°C | 1.98 V | 53.1 | 194 |

| 250°C | 1.48 V | 47.7 | |||||

| 3.5.3 | Contact separation mode | PEO and PBO | ITO | 350°C | 32 V | 100 | 195 |

- Note: χ: Output efficiency:

- Abbreviations: CNF, cellulose nanofiber; CPH, cellulose/ polyvinyl alcohol hydrogel; EFM, electro-spun fiber membrane; NSO, nonconductive self-healable organohydrogels; PA, phytic acid; PBO, poly(p-phenylene benzobisoxazole); PINF, polyimide nanofiber; PTFE, polytetrafluoroethylene.

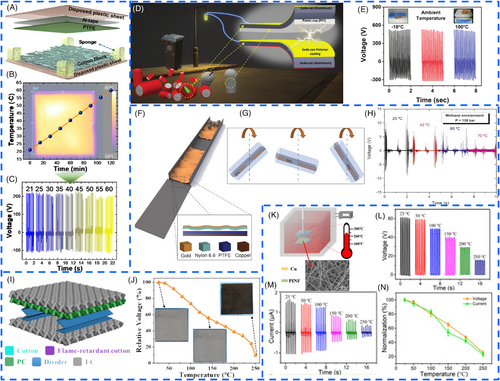

In addition to the aforementioned support structure, the researchers have also developed a range of core-sheath TENGs capable of operating within a broad temperature range.51, 76-79 Zhong et al. created an innovative flexible, heat-resistant, and self-powered ionogel-based TENG (I-TENG) sensor featuring a core-sheath configuration, as depicted in Figure 5G.76 The I-TENG comprises a double-network ionogel with excellent tensile and electrical conductivity as its electrode, aramid fibers serving as the tribo-positive layer, and a 3D-printed silicone sheath functioning as the tribo-negative layer. As exhibited in Figure 5H, the Voc of I-TENG decreases with increasing temperature, resulting in a signal intensity reduction of approximately 30% at 200°C. Nonetheless, as illustrated in Figure 5I, although the maximum output signal of the I-TENG sensor initially decreases with increasing processing temperature and time, it eventually stabilizes. These results imply that although high temperature does affect voltage reduction to some extent, the stable output demonstrates that the sensor can still function efficiently even at 200°C. This is due not only to the superior thermal stability and triboelectric properties of the chosen tribo-materials (double-network ionogel, aramid fibers, and silicone) but also to its unique core-sheath structure design. Xing et al. developed a highly flexible and long-lasting all yarns-based TENGs (Y-TENGs) with exceptional resistance to high temperatures.51 They accomplished this by utilizing a straightforward two-step doubling process that involved electrospinning and ancient twisting methods to incorporate silica aerogel into the polyimide (PI) nano-covered layer. The resulting multiply and stabilized triboelectric yarns were endowed with flame retardancy, heat insulation, and high-temperature resistance. As displayed in Figure 5J, the single triboelectric yarn possessed excellent flexibility and fineness and was wrapped around conductive spiral fiber bundles through a nano-covered electrospinning to form a tightly packed core-sheath structure. The produced triboelectric yarn was subjected to different temperatures on an electromagnetic heating plate, and the corresponding electrical output performance of Y-TENG is depicted in Figure 5K–M. From the figures, it can be observed that the electrical output performance of Y-TENG decreased slowly at the initial stage of heating but significantly worsened when the temperature surpassed 400°C. This indicates that the triboelectric yarn maintained good electrical output within the operating temperature range of 25–400°C, and the upper limit temperature was considerably raised when using prepared triboelectric yarns for fabricating Y-TENGs. This significant breakthrough in organic tribo-materials’ temperature upper limit has the potential to improve the working temperature of textile-based TENG devices, thereby holding enormous application prospects for energy generation and motion detection in high-temperature and other high-risk environments.

3.2 Structural design of TENG PTMs

TENG is an innovative energy harvesting technique that combines CE and electrostatic induction effect to offer several advantages, including low-cost, high-power output, and superior energy conversion efficiency.80-82 Typically, at least one of the triboelectric surfaces used in TENG is composed of a polymer material,83, 84 such as polyvinylidene fluoride (PVDF),85, 86 PI,13, 87 nylon,88, 89 polyacrylonitrile,90, 91 and polytetrafluoroethylene.92, 93 Compared to classical metal and inorganic tribo-materials, polymer tribo-materials (PTMs) possess various functional groups (–F, –CN, –COOH, and –CONH), which can facilitate charge transfer and capture during the CE process through their unique hybrid orbital configurations.8, 94, 95 Furthermore, PTMs also offer numerous advantages, including diverse material selection, excellent flexibility, processability, extensibility, ductility, and lightweight, making them the fundamental building blocks of TENG technology.8, 96

3.2.1 Chemical structure design of PTMs

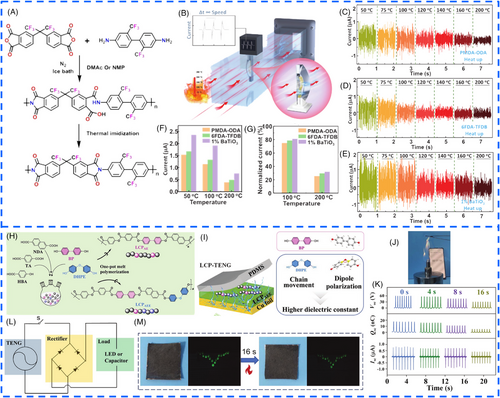

Thermionic emission plays a crucial role in the basic mechanism of CE, and it is an inevitable phenomenon for nearly all tribo-materials.23, 37, 42 During the CE process, electrons transferred to the tribo-surface can be thermally excited and escape into vacuum, thereby hindering the generation of tribo-charges and the energy output from TENG.97 It is widely recognized that the thermionic emission effect imposes a significant restriction on high-temperature TENG, with tribo-charges typically being dismissed above 200°C.25, 27, 37 Consequently, the TENG cannot maintain effective electrical output in high-temperature environments. To address this issue and achieve high thermal charge stability, Tao et al. designed fluorinated PI (F-PI) films with exceptional charge thermal stability and high charge density by introducing strong electron-absorbing groups such as trifluoromethyl (–CF3) and sulfone (–SO2–) into the polymer backbone using chemical structure design techniques for PTMs themselves (Figure 6A).42 These F-PI films contain robust electron-absorbing groups in their backbone, which can provide a significant highest occupied molecular orbital and the lowest unoccupied molecular orbital and numerous surface states for charge transfer. The F-PI film, characterized by a large band gap, exhibits a remarkable tribo-charge density of 170 µC m−2, which is four times higher than that of ordinary Kapton film.98, 99 Additionally, the incorporation of BaTiO3 nanofillers into the F-PI matrix can induce interfacial polarizations and electron deep traps, further enhancing the tribo-charge density (200 µC m−2) and thermal charge stability of the tribo-polymer.43, 100 Based on this BaTiO3-doped F-PI film, Tao et al. developed a flutter-driven TENG (FD-TENG, Figure 6B) for wind energy harvesting and high-temperature wind speed detection. The FD-TENG demonstrated exceptional thermal charge stability, maintaining 32% output performance at 200°C compared with room temperature (Figure 6C–G). This represents the highest reported thermal charge stability for the triboelectric polymer at the time; however, there still remains a concern regarding performance degradation in frictional electric output under elevated temperatures. This BaTiO3-doped F-PI has great potential for application in self-powered sensors operating in hot air tunnels and other harsh environments, while also providing a viable strategy for harvesting environment energy under high-temperature conditions.

The emergence of TENG provides a secure approach to acquire eco-friendly energy and convert it into electrical power. Polymer-based TENGs, in particular, have shown great potential for powering flexible electronic devices without the need for external power sources. However, the majority of polymer materials utilized in TENG manufacturing are flammable and susceptible to melting and dripping when exposed to temperatures up to 220°C. This not only severely restricts the application of TENG under extreme conditions but also poses a significant risk to human health and safety.44, 101, 102 Advancements in design principles of material structure have significantly influenced the development of high-performance materials for future applications.20 To address these challenges, researchers have explored new approaches to designing high-performance TENG materials with enhanced flame-retardant properties. For example, Guan et al. have ingeniously crafted a flame-retardant TENG by means of a one-pot melt polycondensation reaction, utilizing the all-aromatic liquid crystal poly(aryl ether ester) (LCPAEE) as their base material (Figure 6H,I).20 The high rigidity main chain of LCPAEE not only endows the LCP-TENG with outstanding anti-dripping and temperature-resistance properties but also helps improve its fire-resistance characteristics.103, 104 Moreover, the synthesized LCP-TENG demonstrates exceptional electrical output performance thanks to the high dielectric constant of LCPAEE (ε′ = 4.8) and fibrous-structured morphology (Figure 6I). Even under extreme conditions, such as combustion at ≈520°C for 16 s (Figure 6J,K), the LCP-TENG device exhibits remarkable resilience by maintaining an open-circuit voltage of over 65%. Furthermore, when connected to a bridge rectifier (Figure 6L), the LCP-TENG (2 × 2 cm2) can power LED bulbs adorned with seabird patterns in a vivid green hue. Impressively, this light remains visible even after 16 s of combustion, demonstrating that LCPAEE is capable of delivering stable electrical output performance under extreme environments (Figure 6M). These results suggest that the LCP-TENG holds immense potential in the realm of personal protective equipment, encompassing fire-resistant energy harvesters and rescue systems for use in extreme environments such as firefighting.

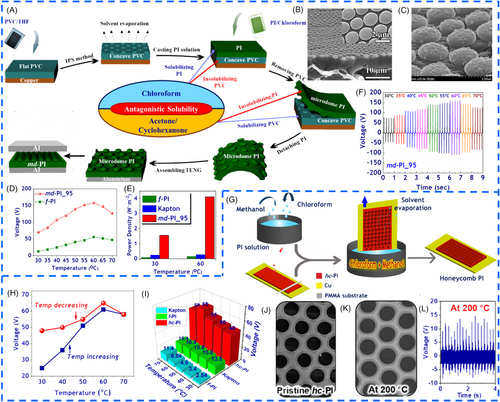

3.2.2 Physical structure design of PTMs

Polymer materials have a reputation for being vulnerable in harsh environments, particularly under high-temperature conditions.41, 105 This is especially relevant when it comes to dielectric materials used in the production of typical TENG, as they are often made up of polymer films.83, 84 In addition to the chemical structure design of PTMs mentioned above, the special physical structure design of tribo-materials can also enhance their heat resistance and high-temperature electrical output performance to some extent. As depicted in Figure 7, Bui's team has developed highly efficient PI tribo-surfaces with customizable non-close packed microdome arrays (md-PI) and customizable honeycomb patterns (hc-PI) respectively.105, 106

Specifically, as illustrated in Figure 7A–C, Bui et al. developed an improved phase separation (IPS) method to imprint microdome pattern arrays on the surface of PI.106 This results in the construction of a microdome-patterned PI (md-PI) with customizable non-close packed microbead arrays, which enhances the effective contact surface area and contact stress while taking advantage of the high thermal and mechanical stability of PI. The md-PI-based TENG (md-TENG) can effectively collect windmill energy and vibration from the engine even in hot air and high humidity environments, with excellent durability of over 16 000 contact-separation cycles and better electrical outputs at elevated temperatures. As revealed in Figure 7D–F, the output voltage of the device exhibits a significant increase with rising ambient temperature, reaching a maximum value of about 158 V at 60°C. In addition, the output voltage of f-TENG (flat PI-based TENG) is much lower than that of md-TENG at each temperature point due to a significantly smaller surface area before tribo-surface patterning. Notably, the power density of commercial Kapton, f-PI (flat PI), and md-PI_95 (the md-PI prepared with THF/MeOH of 95/5) also increases with temperature, consistent with previous studies.4, 27, 31, 43 However, there is an optimal temperature point for obtaining the highest output due to the electron-driving-related factors and material-related factors.42, 43, 107 The study identifies 60°C as the ideal operating temperature for obtaining the optimal electrical output.

In sequence, Bui et al. proposed a triboelectric that can mitigate the typical defects of TENGs by utilizing a surface-patterned high-temperature-resistant thermoplastic.105 Specifically, the customizable honeycomb-patterned PI (hc-PI, Figure 7G) was fabricated through a simple and scalable IPS method. The excellent heat-resistant flexible thermoplastic property of PI, along with the dead-end pore honeycomb pattern array, optimized the electrification efficiency of hc-TENG (hc-PI-based TENG, Figure 7H,I). The fabricated hc-TENG demonstrated an exceptional output power of 1.05 W m−2, which is 22 times higher than the TENG assembled with normal flat PI. Notably, hc-PI could withstand temperatures up to 200°C without causing damage to the hexagonal honeycomb hole arrays while maintaining high uniformity (Figure 7J,K). As a result of this dimensional and structural stability, hc-TENG can operate stably at 200°C (Figure 7L), implying that it can be used at extreme temperatures up to 200°C or even higher. The above results demonstrate that the optimization of surface physical structures in PTMs serves as an effective strategy for enhancing their triboelectric output in high-temperature environments.

3.2.3 Polymer composite tribo-materials

3.2.3.1 Synthetic polymer composite tribo-materials

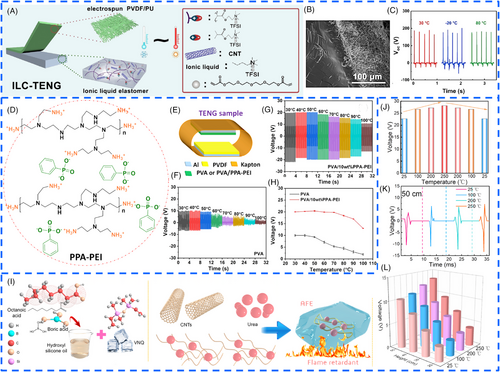

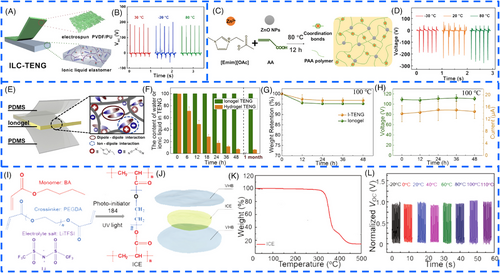

Theoretical research on TENG devices reveals that tribo-materials not only serve as friction materials but also as storage mediums for friction charges.108-110 As such, the output performance of TENG devices is heavily reliant on the properties of the utilized tribo-materials. To achieve more specific and superior properties, researchers have developed triboelectric composites by doping and combining other component characteristics with those of the original tribo-materials.111-113 Remarkably, this strategy has demonstrated its value in producing high-output performance TENG devices. For instance, Cheng et al. created an efficient ionic liquid (IL) elastomer-based TENG (ILC-TENG, Figure 8A,B) that is flexible, stretchable, self-healing, environmentally stable, and durable by utilizing carbon nanotubes (CNTs)-doped ILC as the conductive electrode and electrospun PVDF/polyurethane (PVDF/PU) nanofibrous membrane as the tribo-layer.114 The PVDF/PU was autonomously adhered onto the surface of ILC electrode. After storing the assembled ILC-TENG device at −20, 30, and 80°C for 12 h, respectively, the relevant triboelectric output performance test results (Figure 8C) demonstrated Voc values of 177.44, 182.90, and 179.18 V at each temperature point respectively, indicating excellent environmental thermal stability of the device.

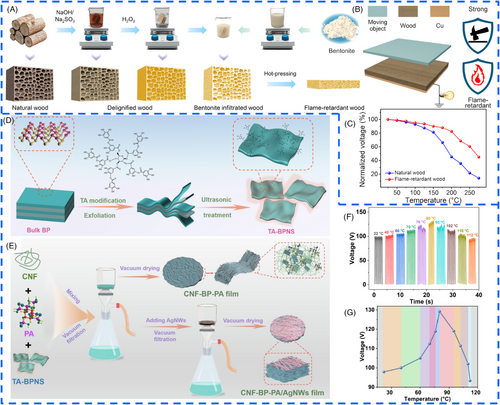

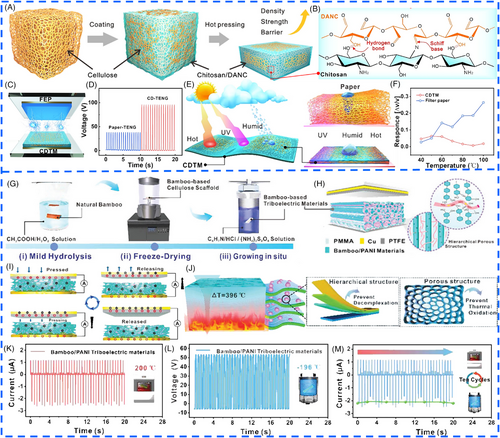

As previously mentioned, polymers are currently the primary alternatives utilized in various TENG applications due to their inherent advantages such as flexibility, lightweight, and ease of large-scale preparation.83, 84, 117 However, the use of most polymer alternatives is limited by their flammability and melt-dripping issues, which can result in not only shutdown of electronic equipment but also dangerous fires. Therefore, it is crucial to develop flame-retardant tribo-materials, particularly in aerospace, transportation, fire protection, and other demanding applications. To address this issue, Chen et al. proposed a facile, robust, and cost-effective solution-casting method for preparing flame-retardant triboelectric polymer based on PVA doped with PPA-PEI polyelectrolyte (Figure 8D).115 The PVA/PPA-PEI film, containing 10 wt.% PPA-PEI, not only self-extinguished immediately after the burner was moved away but also improved its triboelectric properties (Figure 8F–H). Furthermore, PVA/10 wt.% PPA-PEI-based TENG (Figure 8E) could still maintain stable electrical output within a wide temperature range (≤70°C), making it suitable for harsh environments. This study proposes a feasible approach to enhance the electrical and flame-retardant properties of conventional TENGs (c-TENGs), as well as broaden their application in harsh environments through the incorporation of appropriate polyelectrolytes as flame-retardant additives. Similarly, Luo et al. reported a robust and flame-retardant wood-based TENG (FW-TENG), which was prepared using a three-step process involving delignification, infiltration with bentonite nanosheets, and hot-pressing, for self-powered building fire protection.18 The FW-TENG demonstrated consistent electrical output from room temperature to 150°C, indicating its exceptional heat resistance.

Due to the susceptibility of TENG devices to high ambient temperature,118, 119 researchers are compelled to develop a new type of TENG with stable electrical performance. Thereinto, Chen et al. crafted an AFE-based TENG (AFE-TENG) with energy harvesting, protection, and fire alarm capabilities by integrating 6AFE-25 (containing 25% urea) and 1AFE-25 (containing 25% urea).116 Additionally, the incorporation of CNTs and urea into 6AFE-25 has resulted in exceptional flame retardancy (Figure 8I). Figure 8J illustrates the temperature-dependent triboelectric effect of AFE-TENG within a range of 25–250°C. The enhanced electron transfer rate resulting from elevated temperatures leads to an increase in output voltage from the initial value of 22.70–28.13 V,31 thereby enabling it to function as a wearable power source to activate electronics. Additionally, the AFE-TENG could also serve as a self-powered sensor to generate output electrical signals during collisions (Figure 8K,L). From Figure 8K, it can be observed that the peak voltage of AFE-TENG increased from 10.42 to 13.33 V as the temperature rose from 25 to 250°C and when the descent height reached 50 cm, indicating a positive correlation between electrical output and temperature. Furthermore, Figure 8L demonstrates the voltage and temperature-dependent electric properties of AFE-TENG, providing further evidence that the device maintains stable mechanical–electrical–thermal coupling performance under various extreme conditions. Besides, Wen et al. employed micro-nanocomposites to construct a robust freestanding and single-electrode mode harsh-environmental TENG (heTENG) with wear resistance, high-temperature endurance, and high hardness, enabling it to efficiently collect sliding/vibration energy and self-powered vibration sensing.66 Remarkably, the heTENG device can operate within a wide temperature range of −30 to 550°C. However, the impact of temperature on the output performance of heTENG was not investigated in this particular study.

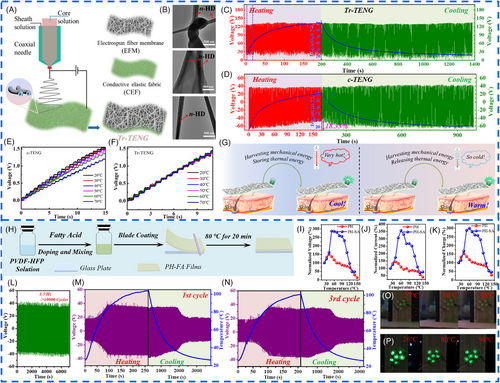

Moreover, our group has conducted relevant and significant research in this field.120, 121 Our efforts culminated in the design of a groundbreaking thermo-regulating TENG (Tr-TENG) that leverages phase change materials (PCMs) to mitigate the thermal negative impact of PTMs and maintain high-temperature steady electrical performance, as depicted in Figure 9A,B.120 The Tr-TENG is composed of a sheath/core electro-spun fiber membrane and conductive elastic fabric, enabling the simultaneous harvesting of both mechanical and thermal energy. By integrating PCMs and triboelectric materials, as illustrated in Figure 9G, the wasted mechanical and heat energy generated by friction and thermal stresses in the environment could be effectively recycled and utilized. Results from Figure 9C,D clearly indicate that the Tr-TENG could uphold a steady output performance without any deterioration resulting from the introduction of PCMs, even during continuous heating and natural cooling, whereas the output performance of c-TENG deteriorated by 18.33%. Figure 9E,F presents the charging performance of the c-TENG and Tr-TENG, which once again confirms that the fabricated Tr-TENG is capable of maintaining a stable electrical output within a wide temperature range, effectively suppressing the negative effect of the heat energy generated by friction and the environmental thermal energy on the output performance of the TENG. More importantly, the Tr-TENG exhibits high-efficiency thermal management ability, as shown in Figure 9F, resulting in improved durability, reliability, and thermal comfort.

Additionally, recent studies have revealed that the incorporation of appropriate liquid lubrication not only confers superlative wear resistance to TENGs by inhibiting the wear and transfer of PTMs but also enhances their electrical outputs.83, 122-125 In light of this, our group employed blade coating technology to fabricate a series of fatty acid (FA)-doped PVDF-HFP (PH-FA) PTM films with optimized ratios, as depicted in Figure 9H.121 Here, the FA was utilized to enhance the electronegativity of PVDF-HFP PTM and simultaneously employed as lubrication additive to improve the wear resistance. As shown in Figure 9I–K, the PH-SA PTM exhibited exceptional electrical output characteristics with VT/VRoom, IT/IRoom, and QT/QRoom (output efficiency) values at 100°C reaching unprecedented levels of 231.10%, 251.46%, and 234.01% respectively, which have not been reported in previous studies related to PTM-TENG.4, 25, 42-44, 120, 121, 126, 127 Furthermore, the PH-SA-based TENG exhibits exceptional stability, durability, and repeatability as evidenced by its consistent output performance during continuous heating and cooling thermal cycles, even after three such cycles, and in high-temperature environments up to 100°C (Figure 9L–N). Moreover, in comparison to PH, the PH-SA-based TENG could still illuminate six LEDs in a high-temperature operating environment of approximately 100°C, with no significant change in brightness (Figure 9O,P). Our research not only opens up new possibilities for developing advanced multifunctional TENGs with desirable characteristics but also greatly promotes the application of TENG electronic devices in harsh or extreme temperature environments.

3.2.3.2 Natural polymer composite tribo-materials

Most synthetic polymer materials are associated with complex fabrication processes. While their widespread use in energy engineering,128-130 these materials present a challenge to environmental sustainability due to their origin from nonrenewable and hard-to-degrade petrochemicals in the natural environment.131, 132 Conversely, biomass-derived natural polymer materials offer an inexhaustible and sustainable resource, presenting significant advantages in the exploitation of high-performance materials due to their unique hierarchical and porous structure.133, 134 Therefore, these natural polymer materials present an appealing alternative to synthetic materials, as they offer a more environmentally friendly and sustainable option for the development of advanced materials.135-137

Cellulose, which is widely found in green plants and other biomass, is an abundant and sustainable natural polymer material with a unique multidimensional structure, controllable surface chemistry, and excellent thermal and chemical properties.138-140 It can exhibit particular tolerability, compared to other dielectric materials, by reasonable physical and chemical regulation while maintaining remarkable stability performance even under extreme environmental conditions such as high temperature and humidity.139, 141 Therefore, the multi-scale engineering optimization and further development of cellulosic triboelectric materials with a wide range of temperature resistance can pave the way for superior feasibility in applying TENGs under adverse temperature environmental conditions.

Recently, Luo et al. developed a wood-based TENG using natural linden wood that underwent chemical pretreatment and hot-pressing to remove lignin and hemicellulose while retaining cellulose in a simple and effective three-step strategy (Figure 10A,B). The as-synthesized TENG maintained 60.5% of its original power output even at high temperatures of up to 250°C, as depicted in Figure 10C.18 In a similar vein, Wang et al. created a flame-retardant cellulose-based TENG (FR-TENG) by incorporating BP and PA as flame retardants, as illustrated in Figure 10D.142 The CNF-BP-PA/AgNWs composite film exhibited a layered structure of tannic acid-modified black phosphorus nanosheet that acted as a physical barrier (Figure 10E), whereas PA facilitated dehydration and coking of the composite material, thereby synergistically achieving excellent fire resistance and flame retardancy, resulting in a stable electric output performance of FR-TENG, as demonstrated in Figure 10F,G.

In addition, as described in Figure 11A, Gao et al. utilized a combination of casting and hot-pressing strategy to fabricate a novel chitosan/di-aldehyde nanocrystalline cellulose (DANC)-based triboelectric material (CDTM) that was used for energy harvesting in severe atmospheric conditions.129 The stable Schiff base structure (Figure 11B) formed between the amino group of chitosan and the aldehyde group of DANC enhanced the internal binding of CDTM, ensuring its stability under harsh conditions.143 Meanwhile, the active amino group of chitosan improved the electron-donating ability of the CDTM,144 thereby improving the triboelectric output performance of CD-TENG (Figure 11C,D). Importantly, the CD-TENG demonstrated resistance to various environmental factors such as temperature, humidity, and UV radiation (Figure 11E). Experimental results (Figure 11F) showed that the Voc change rate of the constructed CD-TENG was significantly lower than that of a regular paper matrix at 99 RH% and only 2% at 100°C, demonstrating excellent environmental interference resistance. Zhao et al. presented a three-step strategy (mild hydrolysis, freeze-drying, and in situ growing, Figure 11G) for large-scale production of bamboo/polyaniline triboelectric material (BPTM) with unique nanostructures.130 Figure 11H,I illustrates the hierarchical porous structure of BPTM and the underlying working mechanism of BPTM-based TENG, respectively. Due to the unique hierarchical porous structure of the fabricated BPTM, the BPTM-based TENG retained 85% of its triboelectric output characteristic even under extreme temperatures (200 and −196°C) and continuous thermal impacts (ΔT = 396°C), as demonstrated in Figure 11J–M. These studies significantly expand the application scope of cellulosic triboelectric material-based TENGs, offering novel insights for developing next-generation self-powered smart devices that can operate in extreme temperature environments.

3.3 PTMs-based HTO-TENG with enhanced electrical output

The mechanisms of triboelectrification in polymers have been the subject of intense debate in recent years due to their critical role in mechanical energy harvesting by TENG devices,145 prevention of electric discharge from accumulated surface charge and protection of electric devices,146 as well as enhancement of particle separation in filters.147 The focus of this debate has centered on electron transfer and covalent bond breaking as potential dominant mechanisms for polymer triboelectrification. The latter mechanisms, heterolytic covalent bond cleavage (heterolysis or heterolytic fission) has been gaining recognition as a credible mechanism for polymer triboelectrification. In fact, Šutka et al. demonstrated for the first time that the dramatic increase in triboelectrification of glassy polymers upon transitioning to a rubbery state,145 as well as CE, can be modulated by intramolecular forces within the polymer bulk and adhesive forces at the contact interface. This confirms the breakage of covalent bond as a mechanism for triboelectrification in polymer insulators, without requiring chemical interaction between different polymers.148 As presented in Figure 12A,B, the net surface charge for all studied polymers exhibited a significant increase by more than one order of magnitude when the temperature reaches the glass transition point. For instance, the surface charge of polycarbonate only increased from 0.006 to 0.011 nC cm−2 as the temperature rises from room temperature to 110°C. Notely, the qualitative measures of electrical output for TENG devices, such as Voc and Isc, are also increased, as demonstrated in Figure 12C,D. This research provides theoretical guidance for the construction of TENG devices that can efficiently collect high-temperature mechanical energy.

Meanwhile, recent studies on PU, a glassy polymer, as a triboelectric material have confirmed the aforementioned conclusion: When the temperature exceeds the glass transition temperature (Tg) of the glassy polymer, there is a significant increase in electrical output for the relevant TENG devices.149 Sohn et al. introduced a glassy polymer-based PU as a tribo-layer to improve output performance of TENG and proposed a new method for making TENG devices operate stably and efficiently at elevated temperatures through friction.149 Figure 12E illustrates the PU structure consisting of hard and soft segments, with the soft segment typically being a polyether block that can be formed a reversible phase due to molecular motion.150, 151 Above Tg, PU undergoes a glass transition from a glassy state to a rubbery state. From Figure 12F,H, the dielectric constant and work function of the PU tribo-layer initially increased slightly with temperature, followed by a sudden increase near Tg, which is in contrast to the general trend of decreasing dielectric constants for conventional polymers as temperature increases. As displayed in Figure 12G,H, the work function of PU increased by 0.2 eV as sample temperature rose from 30 to 70°C. It is well known that the triboelectric output performance is directly affected by the number of transferred triboelectric charges.152, 153 From Figure 12I–N, the transferred charge density of PU was almost constant while the sample temperature increased from 25 to 55°C, indicating that PU is in a glassy state. However, after undergoing a glass transition, the transferred charge density drastically increased, indicating the rubbery state. Therefore, PU in rubbery state can store more charges than in glassy state, leading to enhanced output performance of TENG (Figure 12O) due to higher dielectric constant, work function, and trap sites. This finding not only suggests an intriguing approach to increase the output performance of TENG by reusing abandoned heat energy but also offers a new perspective on selecting appropriate polymers as a triboelectric layer.

3.4 Other PTMs-based HTO-TENG

In Figure 13A, Graham et al. demonstrated the utilization of plastics extracted from the waste stream and electronic waste commonly found in households to fabricate a smart-home-applicable TENG (SHA-TENG) capable of harvesting mechanical energy generated by everyday human activities.154 The electrical output was measured after 15-min intervals while incubating the SHA-TENG under varying temperature conditions. Voc measurements were taken at regular intervals, as shown in Figure 13B,C. The results indicated that the output performance of the SHA-TENG remained stable even when subjected to harsh environmental conditions, highlighting its potential as a lightweight and durable device for smart homes. Similarly, to address the issues of waste pollution and efficient energy generation, Chougale et al. proposed a unique approach utilizing discarded soda cans and plastic cups through a simple function change (Funchange) TENG, which offers the added benefit of avoiding chemical processing (Figure 13D).30 As displayed in Figure 13E, the Funchange TENG device exhibited exceptional output performance. The effect of temperature on the tribolayers of the Funchange TENG device was also tested at various temperature conditions, with results indicating minimal impact on its output performance. Such methods of utilizing waste materials in high-performance TENG devices provide a valuable reference for sustainable, convenient, clean, and environment-friendly energy collection.

Additionally, as displayed in Figure 13F–N, Rodrigues, Cheng, and Shi et al. also constructed a series of PTM-based TENG devices.44, 45, 121 The research findings indicate that these devices could effectively harvest mechanical energy at high temperatures of 70, 220, and 250°C respectively, showcasing their potential for high-temperature operation. Nevertheless, the electrical output performance of the corresponding TENG devices shows considerable attenuation under such elevated temperatures, presenting challenges for the practical applications.

3.5 Gel-based HTO-TENG

TENG represents an emerging technology in energy harvesting, medical treatment, and information technology.156 As stretchable and multifunctional electronics continue to advance, there is a growing demand for TENGs that have comparable stretchability and functionality.157 Unfortunately, although there are many candidate materials for flexible tribo-layers,158 options for flexible and bionic-skin electrode materials are still quite limited. Traditional flexible conductive materials like silver paste, silver nanowires, CNTs, and graphene are not ideal for mass production due to their ultrahigh cost or complicated preparation processes.159-161 Therefore, it is urgent to explore and develop high-performance flexible bionic-skin electrode materials for TENGs used in electronics.

3.5.1 Hydrogels/organohydrogels-based HTO-TENG

Distinguished from conventional flexible conductive materials, hydrogels in solid form consist of hydrophilic polymer networks that are swollen with water or ionic aqueous solution and directly embed the conductive phase within the polymer micro-networks.157, 162 This unique feature ensures the continuity of the conductive phase throughout deformation processes, resulting in exceptional electrical conductivity, stretchability, and adhesion.162, 163 Meanwhile, the 3D network architecture of hydrogels endows them with outstanding mechanical properties,164, 165 such as high flexibility, softness, and elasticity, rendering them an ideal material for realizing flexible and stretchable TENGs.

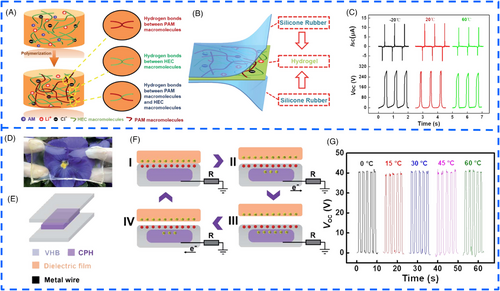

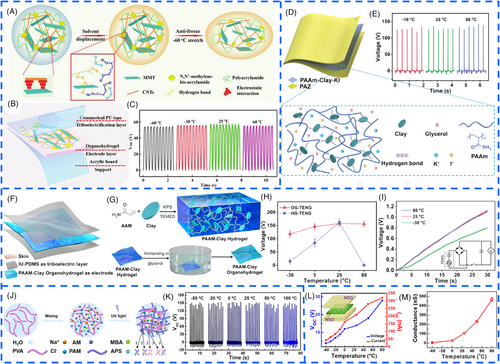

Various efforts have been made to design and develop flexible TENG devices capable of stable operation in extreme environments due to the remarkable properties of the aforementioned hydrogels.165-168 Chen et al. fabricated a thin hydrogel membrane using a solution replacement treatment method.165 The double-network ionic hydrogel membrane serves as both the flexible electrode and triboelectric layer in the constructed EHTS device, demonstrating excellent stretchability and a wide application temperature range (−10 to 40°C). The output signals of the EHTS are generated around a peak voltage of about 10 V without noticeable variations over a wide temperature range from −10 to 40°C. Bao et al. synthesized an anti-freezing hydrogel via one-step radical polymerization of acrylamide monomer in hydroxyethyl cellulose aqueous solution (Figure 14A),166 which improved mechanical properties and provided water retention. As depicted in Figure 14B, a single-electrode mode AH-TENG with a sandwiched structure was constructed, with the AH serving as the conductive electrode and silicone rubber thin layers employed as triboelectric layers at both top and bottom. Analysis of the electrical output of AH-TENG under different temperatures revealed that the Voc and Isc at −20 and 20°C exhibited only a small difference (Figure 14C). Furthermore, the AH-TENG could operate at a temperature of 60°C, but there was an obvious attenuation in electrical output at 60°C compared to that at 20°C due to the competing effect between thermal fluctuation and mechanical properties.43 Wang et al. fabricated an ionic conductive CPH through a facile and environment-friendly strategy with zero wastage, as displayed Figure 14D.167 The Voc value of CPH-based TENG exhibited no significant variation in the range of 0–60°C (Figure 14E–G), indicating that the CPH-based TENG for energy harvesting showed resistance to temperature change, further expanding the applicability of self-powered wearable electronic devices.

Hydrogels possess excellent properties such as electrical conductivity, flexibility, stretchability, and biocompatibility,174, 175 but their mechanical properties are highly unstable due to water loss or absorption caused by environmental factors during applications.174, 176-178 To address this issue, researchers have developed organohydrogels that replace water molecules with organic solvent molecules to enhance antifreeze and water retention capabilities.174-176 The resulting conductive organohydrogels, including MMCOHs (Figure 15A–C),169 PAAm-Clay-KI organohydrogel (Figure 15D,E),170 PAAM-clay organohydrogel (Figure 15F–I),171 and AVN organohydrogel (Figure 15J,K),172 displayed superior temperature resistance and stretchability, making them ideal electrodes for TENG devices. These devices maintain stable electrical output performance in a range of temperatures (−60 to 60, −20 to 80, −30 to 80, and −50 to 100°C) due to the HTO characteristics of the organohydrogels. Furthermore, Khan et al. created fully self-healing TENG devices utilizing highly stretchable and anti-freezing conductive self-healable organohydrogels (CSOs) as electrode and nonconductive self-healable organohydrogels (NSOs) as triboelectric materials. As-fabricated CSO-TENG displayed increasing electrical outputs with rising temperature (Figure 15L),173 which can be attributed to the increased conductivity resulting from the free movement of ions within the conductive organohydrogel at elevated temperatures (Figure 15M). Conversely, lower outputs were observed at subzero temperatures due to the ice coating formed on the surface of the tribo-layer reducing the active area.

3.5.2 Ionogels/ionic elastomer-based HTO-TENG

Ionogels, which are polymer networks saturated with ILs,178, 179 have garnered significant interest from researchers because of their exceptional ionic conductivity, robust thermal and chemical stability, non-volatility, and nonflammability.180, 181 Ionic elastomers, on the other hand, consist entirely of a network of cross-linked polyelectrolytes and associated counter-ions without any liquid component,182, 183 which makes them naturally resistant to leakage or evaporation. Consequently, both ionogels and ionic elastomers demonstrate remarkable environmental tolerance.

Recently, Liao,184 Li,185 Sun,186 and Zhang et al.,126 respectively, constructed TENG devices with a sandwich structure utilizing four different ionogels as electrodes, as depicted in Figure 16C,D and E–L. The ionogels possess excellent chemical and thermal stability, enabling the abovementioned TENG devices to maintain relatively stable electrical outputs across various temperature ranges: −20 to 40, −30 to 80, −20 to 100, and −20 to 110°C, respectively. Additionally, Cheng et al. developed an ionic elastomer-based TENG (ILC-TENG) with CNT-doped ILC as the electrode and PVDF/PU nanofibrous membrane as the tribo-layer (Figure 16A,B).114 The TENG devices produced peak-to-peak Voc of 177.44, 182.90, and 179.18 V at −20, 30, and 80°C, respectively, indicating that the ILC-TENG also maintains stable electrical output characteristic over a wide temperature range.

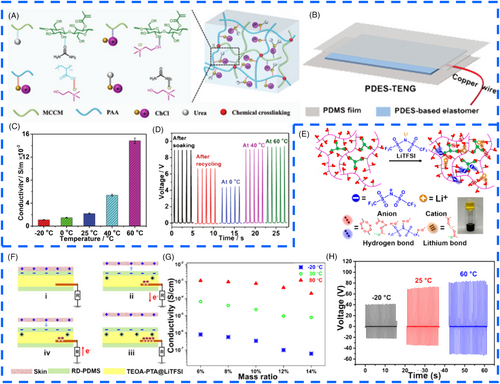

More significantly, Lu and Zhang et al.187, 188 independently developed ionic conductive elastomer-based TENG devices utilizing liquid-free cellulose-derived ionic conductive elastomer (ChCl/urea-MCCM3%-AA, Figure 17A,B) and solvent-free elastomeric ionic conductor (TEOA-PTA@LiTFSI, Figure 17E,F) as electrodes. As is widely recognized, the ability of triboelectric devices to maintain their electric output characteristics under extreme conditions is a crucial factor for TENG devices. Notably, as depicted in Figure 17D,H, the electrical outputs of the PDES-TENG and sustainable TENG devices displayed a noticeable increasing trend with rising temperature up to 60°C, which may be attributed to a decrease in internal resistance (i.e., an increase in ionic conductivity, Figure 17C,G) of the ChCl/urea-MCCM3%-AA and TEOA-PTA@LiTFSI ionic elastomers at high temperatures.

3.5.3 Aerogels-based HTO-TENG

Aerogel is a remarkable ultra-lightweight porous material that replaces the liquid component of gel with gas,189, 190 which is a typical bulk material with nanostructured solid skeletons and open pores, offering excellent physical and chemical properties such as ultra-low density, high porosity, ultrahigh specific surface area, ultra-strong adsorption capacity, and adjustable surface chemistry.191, 192 These exceptional characteristics make aerogel an ideal material for various applications, offering broad prospects for its use.189, 190 Recently, the feasibility of aerogel has been widely explored in different fields, showcasing its potential for diverse applications.193

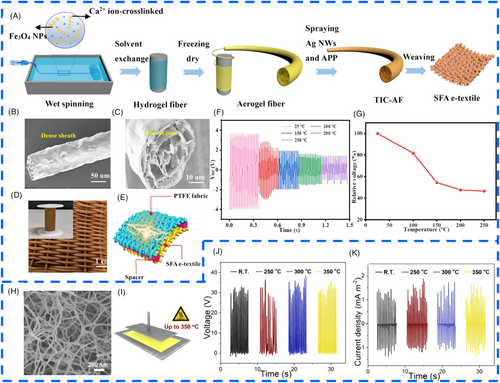

He et al. utilized a combination of traditional wet spinning technology and emerging triboelectric technology to create an SFA e-textile (Figure 18A) that is based on thermal-induced conductive aerogel fiber (TIC-AF, Figure 18B–D).194 By incorporating Fe3O4 nanoparticles and Ag NWs into calcium alginate-based AFs, the researchers were able to achieve repeatable and highly sensitive temperature monitoring as well as energy harvesting for the SFA e-textile (Figure 18F). The resulting SFA e-textile was then integrated into firefighting protective clothing to provide wide-range temperature sensing and repeatable fire warning capabilities, demonstrating its potential for enhancing the safety of firefighters in high-risk environments. Although the Voc of the TENG decreased as the temperature increased from 25 to 250°C (Figure 18G), it still retained 47.7% of its initial electrical output at 250°C, indicating its high-temperature operability and effective functionality across a wide range of temperature environments.

Flame-retardant electronegative aerogel materials are highly suitable for TENGs operating in extreme environments such as thermal power plants and aerospace.196 However, the existing electronegative aerogel materials are predominantly polymeric materials that require further enhancement in high-temperature stability and flame resistance. Recently, a series of research explorations have been conducted in this field. For instance, Qian et al. fabricated poly(p-phenylene benzobisoxazole) aerogels (PBOAs) (Figure 18H) from poly(p-phenylene benzobisoxazole) fibers and used it utilized them as the electronegative tribo-materials.195 Subsequently, the as-fabricated PBOA was paired with Al foil to construct PBOA/Al TENGs (Figure 18I). As demonstrated in Figure 18J,K, the electrical output performance of the as-constructed PBOA/Al TENGs remained almost unaffected within the temperature range of room temperature to 350°C. Moreover, these PBOA/Al TENGs exhibited a Voc of 32 V, and a Jsc of 1.2 mA m−2 even at high temperatures up to 350°C, demonstrating the potential for application of triboelectrical devices in high-temperature environments.

3.6 Metal–organic frameworks (MOF)-based HTO-TENG

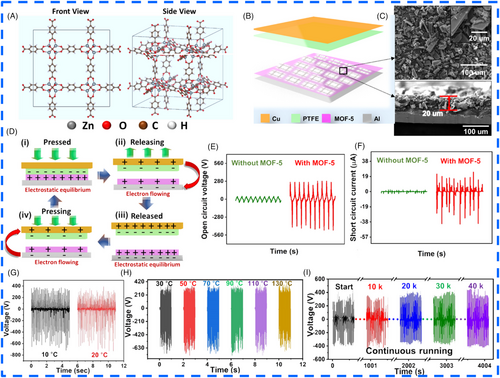

MOFs are a type of crystalline porous materials consisting of metal ions (or clusters) with multifunctional organic ligands.197-199 Due to their porous feature, highly ordered structure, and ability to be rationally designed and assembled for desired versatility, they have been widely used in energy conversion and storage applications.200-202 Among different types of MOFs, isoreticular MOFs (IRMOFs), a subfamily of MOFs with exceptional thermal and chemical stability, tunable porosity, and high surface area,32, 203 hold great potential for fabricating ultra-durable triboelectric and piezoelectric nanogenerators with superior environmental stability. In a recent study by Shaukat et al., an MOF (MOF-5 or IRMOF-1) was used for the first time to fabricate a TENG for energy harvesting, as illustrated in Figure 19A–D.32 The TENG based on MOF-5 demonstrated excellent electrical outputs (Figure 19E,F) including Voc of 484 V, Isc of 40 µA, and maximum instantaneous power of 3174 µW. Furthermore, the as-constructed TENG exhibited stable output performances under untoward environmental conditions such as temperature variations ranging from −10 to 130°C (Figure 19G–I), demonstrating its robustness under challenging operational environmental. These findings suggest that MOF-5 is a highly promising alternative for constructing ultra-robust TENGs that can operate at high temperatures.

4 CONCLUSIONS AND OUTLOOK

- (1)

The continuous improvement of TENG's output performance serves as a driving force for sustainable development. First, high-temperature environments pose higher demands on material performance, necessitating the use of materials that maintain stability and performance under high temperatures for TENGs. Second, under such conditions, enhanced electron thermionic emission effects may interfere with normal charge collection. Effectively suppressing or overcoming this effect is one of the challenges in the design of TENGs. Furthermore, the mechanical stability of these generators is also challenged at high temperatures, requiring device design to maintain structural integrity under extreme conditions. Lastly, increased temperature may result in unstable energy output which is unacceptable in certain applications. In subsequent research, it is anticipated that a manufacturing technique for HTO-TENG devices can be developed to significantly enhance power output, particularly in terms of current and power density, by comprehensively considering the aforementioned four aspects.

- (2)

As the demand for self-powered wearable electronic devices continues to increase, there is a growing need to manufacture HTO-TENG devices with improved wear resistance, higher temperature limits, and diversified functions such as softness, permeability, biocompatibility, flame retardancy, self-healing capabilities, and thermal management abilities. These improvements will contribute to the rapid advancement of this field and broaden its application scope.

- (3)

The operating mechanism of HTO-TENGs is currently unclear. To provide guidance for exploring new manufacturing strategies, more comprehensive research should be conducted on the intrinsic operating mechanism of HTO-TENGs in subsequent studies. Additionally, it is also necessary to develop an evaluation standard for the triboelectric performance of HTO-TENGs.

- (4)

The future large-scale practical application of self-powered electronic devices in extreme environments necessitates the large-scale production and industrialization of HTO-TENGs with exceptional performance.

In summary, there is an urgent need to develop more advanced manufacturing strategies for the production of HTO-TENGs with enhanced performance and multifunctional integration. Exploring effective mechanisms to suppress or overcome the inherent electron thermionic emission effect will provide valuable theoretical guidance for future research on efficient and multifunctional HTO-TENGs, further promoting the rapid development and practical application of this field. Further, overcoming the challenges in high-temperature environments will enable triboelectric devices to demonstrate broad prospects for applications in various fields, thereby bringing new possibilities for self-powering technology and energy conversion.

ACKNOWLEDGMENTS

This work was supported by the National Natural Science Foundation of China (No. 52003074, 52125205, U20A20166, 52192614, 52003073, and 62174049), the Project funded by China Postdoctoral Science Foundation (No. 2020M680097), the Postdoctoral Fellowship Program of CPSF (No. GZC20230681), the Natural Science Foundation of Henan Province (No. 202300410058), the National Science Fund for Excellent Young Scholars of Henan Province (No. 222300420033), National key R&D program of China (2021YFB3200302 and 2021YFB3200304), Natural Science Foundation of Beijing Municipality (Z180011 and 2222088), Shenzhen Science and Technology Program (grant number KQTD20170810105439418), and the Fundamental Research Funds for the Central Universities.

CONFLICT OF INTEREST STATEMENT

The authors declare no conflict of interest.

Biographies

Ruirui Cao is currently an associate Professor in the School of Future Technology and Henan Key Laboratory of Photovoltaic Materials at Henan University. She received her Ph.D. from School of Material Science and Engineering of Tiangong University in 2019 and then joined the Henan Key Laboratory of Photovoltaic Materials, Henan University. Her research focuses on energy conversion and storage, self-powered sensing, and flexible electronic devices.

Chong Chen is now a senior research fellow at Hefei Institute of Physical Science (HIPS), Chinese Academy of Sciences (CAS). He received his Ph.D. degree from Institute of Plasma Physics, CAS in 2009. Subsequently he moved to Korea Advanced Institute of Science and Technology (South Korea) and South Dakota State University (SA), as a postdoctoral fellow, respectively. From 2012 to 2022, he worked as a distinguished professor at Henan University. He has been a senior research fellow at HIPS under the CAS since 2023 and is leading a group that mainly studies photovoltaic materials and thin film solar cells.

Caofeng Pan received his B.S. degree (2005) and his Ph.D. (2010) in Materials Science and Engineering from Tsinghua University, China. He then joined the Georgia Institute of Technology as a postdoctoral fellow. He is currently a professor and a group leader at Beijing Institute of Nanoenergy and Nanosystems, Chinese Academy of Sciences since 2013. His main research interests focus on the fields of low dimensional materials for fabricating smart electronic and optoelectronic devices for tactile sensing.