Switchable Power Generation in Triboelectric Nanogenerator Toward Chip-Less Wearable Power Module Applications

Abstract

A conceptual shift toward next-generation wearable electronics is driving research into self-powered electronics technologies that can be independently operated without plugging into the grid for external power feeding. Triboelectric nanogenerators (TENGs) are emerging as a key component of self-powered electronics, but a power type mismatch between supply and demand limits their direct implementation into wearable self-powered electronics. Here, a TENG with switchable power mode capability is reported where the charge flow direction is modulated over the course of slow and random mechanical stimuli, with exceptional rectification capabilities as high as ≈133, stable outputs over the cycles, and design flexibility in different platforms. Importantly, the remarkable switchable power generation with fabric counter materials illuminates a new path for the smooth integration of flexible TENGs into wearable self-powered electronics.

1 Introduction

With the overwhelming demands of modern, efficient, and high standards of living, one major development in electronics has been the conceptual shift away from stationary electronics toward wearable and implantable electronics, which are emerging as a key building block of a smart city. The wearable devices have enriched our daily lives by exchanging information without needing human intervention,[1-3] thereby requiring the devices to be continuously powered.4 Although state-of-the-art energy storage technologies such as lithium-ion batteries and supercapacitors are mature and can provide a stable power supply for wearable electronics,[5-9] they still require regular recharging. Recently, a new paradigm of “self-powering” devices (SPD) is emerging to address the aforementioned issues. These SPDs feature integrated energy harvesters with energy storage that allow a stable power supply. The energy harvesting technologies for SPDs need to be independent, sustainable, and maintenance-free.10 Moreover, for wearable devices, energy harvesting is limited to the body surface, such as body heat, body movement, and light. In this regard, triboelectric nanogenerators (TENGs) have attracted considerable attention due in large part to their lightweight, simple fabrication, diversity in material selection, and high energy conversion efficiency.[11-16]

TENGs are mechanical energy harvesting devices based on the mechanism of contact electrification and electrostatic induction.17 The transient electron flows generated from contact and release are determined by electrostatic induction and relaxation so that their directions inevitably oppose each other, yielding an alternative current (AC) output. The power output of TENGs has dramatically advanced in the past years, and state-of-the-art TENGs can now yield an improved power output of several hundred volts and micro amperes.[15, 16, 18-26] However, the TENGs still suffer from a power mismatch between supply and demand,27 including but not limited to the voltage mismatch, unstable output, and alternating power peak. In particular, the AC output needs to be rectified with the help of rigid electrical circuit components in order to serve as a power module in SPDs, limiting the direct incorporation of flexible TENGs into wearable SPDs. Furthermore, the internal resistance of the circuit components leads to energy loss. Although these components exhibit low energy losses between 5% and 30%, such power drops are especially significant for the low power output of TENGs. To take advantage of TENGs as wearable energy harvesters, output power management is urgently required for compact and efficient integration. Various progress related to the rectifier-free TENGs has been achieved using the Schottky nanocontact,[28-40] phasing coupling,[41-46] and electrostatic breakdown.[47-55] However, a continuous rectified output has been realized only using the fast and periodic sliding working mode, which is likely not suitable for wearable applications. Although the electrostatic breakdown mechanism facilitates achieving high outputs in terms of voltage and current, it has yet to be demonstrated in a flexible platform. Herein, we report the TENGs with a convertible rectification feature, in which the direction of the charge flow generated by TENGs is systematically controlled by electrostatic breakdown over the course of slow and random mechanical stimuli, benefiting the integration into wearable electronics. The switchable TENG consists of a triboelectrification layer and an electrode, connected through a patterned SU-8 mold in which the air gaps between triboelectrification and electrode enable on-demand charge flow control. Without any circuit component, the switchable TENG exhibits remarkable rectification capabilities and a high switchability in power mode, together with stable outputs over the cycles and design flexibility in different platforms. Triboelectrification test with fabric counter materials potentially renders our s-TENGs a versatile power module for wearable electronics.

2 Results and Discussion

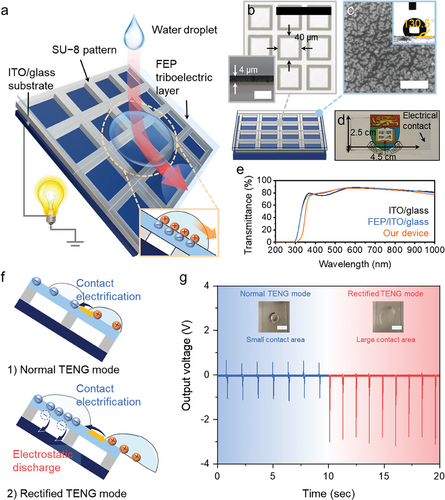

2.1 Switchable Triboelectric Nanogenerator Design

The structure of switchable triboelectric nanogenerators (s-TENGs) is schematically illustrated in Figure 1a. The s-TENGs was based on an elastic SU-8 mold patterned on an indium tin oxide-coated glass (ITO/glass) substrate, covered with a fluorinated ethylene propylene (FEP) film as a triboelectrification layer, thereby forming an array of air gaps for electrostatic breakdown. We chose to use water droplets as a counter triboelectrification material as the water droplet is easily controllable counter material in terms of contact area and contact speed, and the droplets impinged onto the s-TENGs donate the electrons to the FEP film while sliding down throughout the device. In order to fabricate the s-TENGs, a 4-µm-thick SU-8 photoresist mold, with a patterned square pore of 40 µm side and 50 µm pitch, was defined on the ITO/glass substrate by photolithography (Figure 1b). The morphology of the FEP adhesive film attached on top of the SU-8 mold was treated by a simple reactive-ion etching (RIE) process optimized for nanostructure fabrication (Carbon tetrafluoride (CF4), Argon (Ar), and Oxygen (O2), 100 W, 30 min conditions in Figure 1c). The inset image in Figure 1c indicates that the treated FEP surface became more hydrophobic (contact angle = ≈ 130.5°) compared to the pristine film (contact angle = ≈ 102°), which facilitates not only contact electrification but also the rolling-off of water droplets over the FEP surface. The transparent s-TENG with a dimension of 25 × 45 mm2 was obtained (Figure 1d), and the transmittance in the visible range (380−750 nm) of our s-TENGs was ≈85% (Figure 1e), suggesting that our s-TENGs can be potentially mounted on top of any surface without disturbing aesthetics.

2.2 Working Principle

Impinging droplets onto the s-TENGs surface results in contact electrification, negatively charging the surface of the FEP triboelectrification layer. A schematic illustration of charge distributions over the s-TENGs surface in two different working modes is shown in Figure 1f. After the water droplet rolls off the s-TENGs surface, the charge amount transferred onto the FEP layer relies on the droplet size sliding down due to the contact area difference. The electrostatic field developed by surface charge induces the transient electron flow from the device electrode to the electron reservoir (Figure S1a-ii, Supporting Information), and the induced positive charges still remain on the surface of the electrode while waiting for the second droplet due to the surface charge of FEP (Figure S1a-iii, Supporting Information). These electrons return back to the device electrode when the surface charges are screened by the next water droplets (normal TENG mode; Figure S1a-iv, Supporting Information), yielding the negative and positive output signals, respectively (left signals in Figures 1g; S2, Supporting Information). If the electrostatic field developed by surface charge exceeds the dielectric strength of the air, the partial ionization in the air gap gives rise to the electrons on the FEP bottom surface to discharge through the air, eliminating the surface charge on the FEP layer (Figure S1b-iii, Supporting Information). As the induced positive charges in the electrode are already discharged by electrostatic breakdown when the next water droplets touch the FEP surface, only a single direction of electron flow is found over the course of water dropping and sliding cycles (rectified TENG mode; Figure S1b-iv, Supporting Information), demonstrating the rectified electrical outputs (right signals in Figures 1g; S2, Supporting Information). As the surface charge is almost removed after every cycle and the new droplet keeps donating the electrons to the FEP surface, we can observe the stable rectified electrical signal from the very first droplet (Figure S1b-i, Supporting Information). In our s-TENGs, it is worth noting that the controllable charge distribution determines the strength of the electrostatic field developed on the FEP surface, facilitating to dictate of the electron flow direction on our demand.

2.3 Switchable Power Generation in TENGs

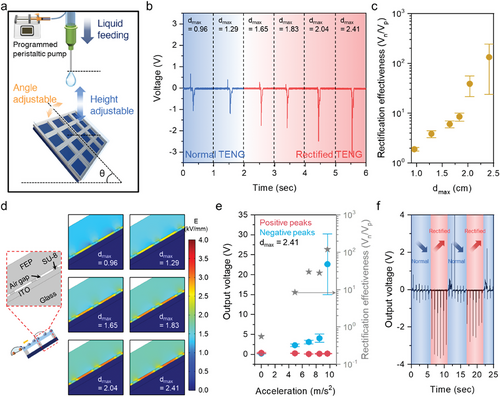

Two factors were critical to switchable power generation. The droplet size impinging onto the s-TENG surface determines the spatial charge distribution whereas the temporal charge distribution over the surface is governed by the droplet movement. The switchable power generation in TENGs was thoroughly evaluated using a custom measurement setup (Figure 2a), in which the altitude and sliding angle of droplets being fed by a programmed peristaltic pump were adjusted to systematically regulate spatial and temporal charge distributions. As a maximum spreading diameter of the droplets on the s-TENG surface can be approximated by where We, ρ, v, d0, and σ denote the Weber number, water density, impinging velocity, droplet diameter before impingement, and surface energy density of the water, respectively,[56-60] we first varied the altitude of the feeding nozzle to manage the impinging speed (v2∝h). The s-TENGs were anchored to the custom measurement setup with a tilt angle of 45° and analyzed to investigate the maximum spreading area. A low altitude (2.5 cm fall distance) resulted in the lowest spreading area of 72.2 mm2, and this value increased up to 457.07 mm2 for a higher altitude (25 cm fall distance) (Figure S3a–f, Supporting Information). The maximum diameters were accordingly determined by assuming that the droplet is the circle, demonstrating that we successfully modulated the maximum spreading diameter by controlling the nozzle altitude (Figure S3g, Supporting Information).

The electrical outputs of s-TENGs given altitudes were further investigated using an oscilloscope equipped with a current preamplifier. Notably, the positive peaks in output voltage and current were found to be disappeared with increasing the maximum spreading diameter (Figure 2b; Figure S4, Supporting Information), which we attribute to the greater spatial charge distribution over the s-TENG surface, surpassing the threshold electrostatic field for dielectric breakdown. The results indicated a negative voltage peak with an increasing spreading diameter up to the highest value of 3.2 V for a maximum spreading diameter of 2.41 cm. We have compared the outcomes of single-electrode triboelectric nanogenerators (seTENGs) that are activated by water droplets.[61-66] To account for varying device sizes in the literature, we normalize the peak voltage based on the size of each device. As shown in Figure S5 (Supporting Information), our s-TENG outperforms the most of single-electrode TENGs reported to date in terms of the normalized peak voltage. It is important to note that our device achieved the rectified outputs in the absence of an external circuit, whereas other single-electrode TENGs yield alternating current outputs. An average charge of 0.45, 0.51, 0.50, and 0.61 nC was generated from a single dropping and sliding of the water cycle at the spreading diameters of 1.65, 1.83, 2.04, and 2.41 cm, respectively (Figure S6, Supporting Information). In contrast, the charge accumulation in the capacitor charged by the normal-TENGs mode is substantially lower (0.27 and 0.22 nC at the spreading diameters of 0.96 and 1.29 cm, respectively) likely due to the instantaneous discharge while the droplet strikes the surface. Our device stores the elastic potential energy in the triboelectrification layer while the droplet impinges onto the device, and then which is converted into electrical energy. The elastic potential energy and the electrical energy generated from a single droplet can be approximated by Eelastic = 0.5×σ2 E and Eelectric = Q V, respectively, where σ is stress and E is Young's modulus of triboelectrification layer (344.7 MPa).67 The Q and V are charge and voltage generated from the single droplet, respectively. We accordingly estimated the energy conversion efficiency using the relation, η = Eelectric/Eelastic. The detailed explanation is described in Supporting information, and the calculation result is presented in Table 1. The energy conversion efficiencies of varying spreading diameters were determined to be in the range of 13.4 to 26%, which is comparable to the value reported.68 In addition, the rectification effectiveness of differing the spreading diameters was extracted from voltage signals using the ratio of negative to positive peaks (Figure 2c), and the effectiveness has been shown to increase with increasing the maximum spreading diameter. Moreover, we found that rectification effectiveness increases with opening size while the decreased gap size improves the rectification effectiveness (Figure S7, Supporting Information), which we attributed to the enhanced strength of the electric field in the gaps. These results imply that the systematic design of the device structure determines the threshold of power mode on demand. To gain further insight into the electron flow in the s-TENGs, we sought to simulate the electrostatic field within the air gap upon introducing the water droplets using COMSOL Multiphysics, as shown as a function of spreading diameter (Figure 2d), in which the amount of surface charge developed by the single droplet was extracted from the TENGs in the absence of an air gap to fully reflect the surface charge developed (Figure S8, Supporting Information). The electric field exhibits exceed the dielectric strength of air (3 kV mm−1[69, 70]) when the water droplets larger than 1.29 cm touch and roll off (Figure S9, Supporting Information), affording the air gap the occurrence of dielectric breakdown. These results are also consistent with the electrical output data, which indicated that the broader contact electrification facilitates the rectification of the electron flow in the device.

| Devices | Spreading diameter [cm] | Eelastic [nJ] | Eelectric [nJ] | η [%] |

|---|---|---|---|---|

| s-TENG | 0.96 | 1.89 | 0.29 | 15.3 |

| 1.29 | 1.90 | 0.33 | 17.2 | |

| 1.65 | 2.59 | 0.48 | 18.4 | |

| 1.83 | 3.76 | 0.50 | 13.4 | |

| 2.04 | 4.24 | 0.68 | 15.9 | |

| 2.41 | 3.32 | 0.86 | 26.0 | |

| FEP/ITO without gap | 2.41 | 3.32 | 0.61 | 18.3 |

| FEP/SU-8/ITO without gap | 2.41 | 3.32 | 0.20 | 6.2 |

Next, the strategy for alteration in temporal charge distribution was demonstrated by sloping the s-TENGs, assisting in ruling the droplet acceleration on the device surface. We chose the slop angles of 0, 30, 45, 60, and 80°, and the droplet acceleration is found to be primarily angle-dependent (a = g sin θ where g and θ are gravitational acceleration and slope angle, respectively), as seen in Figure S10 (Supporting Information). When increased the droplet acceleration on the surface of s-TENGs, the negative voltage peak of the devices exhibited a significant elevation up to ≈23 V while the positive peak remained similar less than ≈0.1 V, boosting the rectification effectiveness up to ≈119 (Figure 2e). This remarkable performance is attributed to the faster temporal charge distribution, which in turn provides a uniform and localized electric field in the vicinity of the FEP layer with minimal charge loss. The rectification performance remains reasonably stable over 20 cycles at two working modes carried out at the repeated spreading dimeters of 0.96 and 2.41 cm (Figure 2f), indicating the power generation is switchable upon the control of spatial and temporal charge distribution over the surface of s-TENGs. Furthermore, Figure S11 (Supporting Information) revealed that the rectification feature is operational even in the stimuli with both non-periodicity as well as low frequencies ranging from 0.8 to 2.5 Hz, suggesting that the s-TENGs are suitable for applications in human-interactive mechanical stimuli (0 to 20 Hz).71 Ultimately, the power mode switchability with low or even non-periodic frequency excitation renders our s-TENGs a promising candidate power module for wearable electronics.

2.4 Power Management in s-TENGs

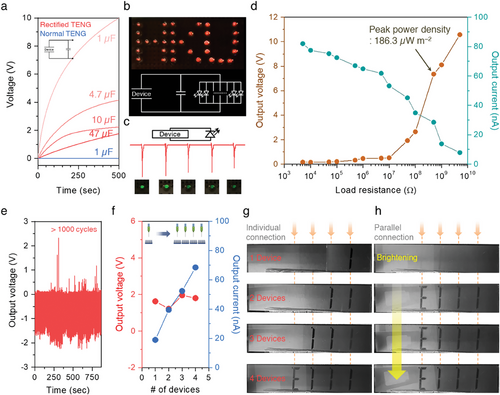

We employed the capacitors to analyze the power output rectification of the s-TENGs. Remarkably, the capacitors of 1, 4.7, 10, and 47 µF were stably charged up to 10, 4.2, 2.2, and 1.8 V, respectively, within 500 s using the rectified TENG mode (Figure 3a). For comparison, we also evaluated the capacitor charging with normal TENG mode, and the capacitor remained uncharged due to the alternating power output generated from the normal TENG mode. It is noteworthy that energy delivery of the rectified TENG mode is stable even in the absence of additional rectifiers, which is markedly advantageous given that the rigidity and complexity of conventional rectifiers restrict their direct integration into flexible TENGs. We successfully lit up the light-emitting diodes (LEDs) with character patterns of “HKU” using the capacitor being fully charged with the rectified TENG mode (Figure 3b; Movie S1, Supporting Information). In addition, the rectified electrical output from s-TENGs provided the direct lighting of the single LED without any electrical circuit components, including the rectifier and capacitor (Figure 3c). Both lightings reveal that our s-TENGs hold promise as an efficient power source for portable and wearable electronics. The maximum peak power of s-TENGs under rectified mode was investigated using differing resistors, with a value of 186.3 µW m−2 at a load resistance of 0.5 GΩ (Figure 3d), which offers sufficient energy for data transfer using low-power wireless technologies, such as Bluetooth and Wi-Fi.[72, 73] The long-term stability was tested for the rectified s-TENG mode under the repetitive water drops. Even after 1000 cycles as shown in Figure 3e, the rectification of voltage appeared to be stable, demonstrating the outstanding durability and robustness of our device. After the stability test, we disassembled our device and sought to observe any damages in the airgaps. The optical microscope images of the top and cross-section before and after the stability test display no significant changes in airgap structure (Figure S12, Supporting Information), indicating that our device is durable and sustainable even under electric breakdown and arc formation. To enhance the output performance of the s-TENG, we connected the single double, triple, and quadruple s-TENGs in parallel configuration (Figure 3f). The output current increased with a greater number of devices, including the highest value of ≈ 68 nA with quadruple devices while the voltage remained similar, demonstrating we successfully tuned the output power of s-TENGs by changing the number of devices. We can manage the power outputs by wiring the individual s-TENGs to a liquid crystal display (LCD), demonstrating successful lighting up each digit in the LCD panel by increasing the number of connected s-TENGs (Figure 3g; Movie S2, Supporting Information). Further, the brightness of the LCD panel could also be tuned by the number of s-TENGs in parallel connection configuration (Figure 3h; Movie S3, Supporting Information). As such, we have confirmed that the power output level of s-TENGs is readily manageable given both serial and parallel configurations, potentially providing sufficient power for microelectronic devices.

2.5 Flexible s-TENGs Fabrication

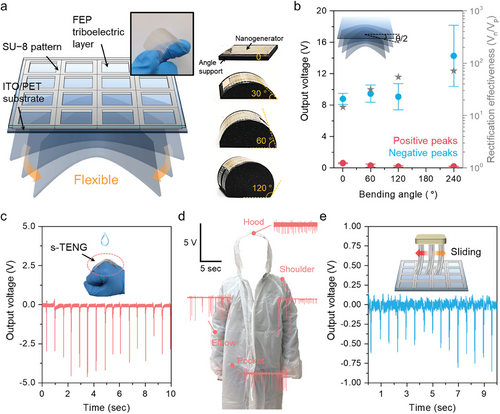

Beyond the rigid s-TENGs, the switchable outputs must be demonstrated in the flexible platform to ensure the applications to wearable electronics. A flexible s-TENG was implemented on an ITO-coated polyethylene terephthalate substrate (Figure 4a), and a photograph presented in the inset of Figure 4a suggests the high flexibility of the fabricated s-TENG. In order to investigate the rectification capability of power outputs upon bending stimuli, the flexible device was deformed by virtue of the 3-D printed variable angle supports (0, 60, 120, and 240°) in which the bending angles were determined to be tangential to the support edge with respect to the undeformed device. For all bending angles, the values of positive and negative peaks were extracted from the voltage outputs at the spreading dimeters of 2.41 cm (Figure 4b). The negative peaks were found to increase with the bending angle, reaching up to 14.3 V for the bending angle of 240°, while the positive peaks persisted in being low values of below 0.6 V. Resultingly, the rectification effectiveness was shown to achieve up to ≈ 71 for the bending angle of 240°. The exceptional rectified outputs of bent s-TENG are likely attributed to the fast acceleration of droplet sliding over the s-TENG surface in tandem with the reduced airgap distance while deformed, which together maximize the electrostatic field in the airgap. As shown in Movie S4 (Supporting Information), the LED lighting was successfully demonstrated in direct connection with deformed s-TENG.

We demonstrated a practical performance of flexible s-TENGs as a power module for wearable electronics applications. The s-TENG was readily mounted on the back of the hands in the light of high flexibility, and its electric outputs were characterized upon dropping the water with the spreading dimeter of 2.41 cm while clenching the fist (i.e., deformed device) (Insest of Figure 4c). We successfully acquired a rectified output voltage and current of up to ≈ 4.6 V and ≈150 nA, respectively (Figure 4c; Figure S13; Movie S5, Supporting Information), suggesting that such a device holds promise for portable or wearable energy harvesting where the device can be exposed to the scattered water, especially. For instance, the s-TENGs can be integrated at any location of the raincoat‒including the hood, shoulder, elbow, and pocket‒ to harvest the hydropower of raindrops (Figure 4d). The s-TENGs provided well-rectified electrical outputs of up to 5 V through manual spraying of the water onto the device surface, and the single s-TENG yielded almost continuous rectified electricity when exposed to the continuous raindrops (Figure S14, Supporting Information), offering a simple route to wearable rectified energy harvesting system for broadband raindrops no matter the heaviness. Since the working mechanism underlying the rectification involves the soft impingement and sliding of counter materials for triboelectrification, not limited to water droplets, we verified the rectification competency of s-TENG through manual rubbing with a variety of fabric counter materials to confirm the versatility. Indeed, the well-rectified output voltage was found in s-TENGs in which the nylon fibers were slid over the device surface (Figure 4e), and the level of output voltage can be modified using other fabric counter materials, being well-matched with the trend of the triboelectric series (Figure S15, Supporting Information).[74, 75] Eventually, no limitation of choice in counter materials benefits potential wearable applications of our s-TENGs into broad research fields such as military, robotics, and smart healthcare as long as the airgap is not destroyed by strong pressure (62 MPa in our dimension, see Figure S16, Supporting Information). Indeed, the air gaps have been found to be stably maintained even at harsh bending conditions as shown in Figure S17 (Supporting Information).

3 Conclusion

We have reported a switchable triboelectric nanogenerator, s-TENG, that exhibits outstanding switchability in power generation modes through control over the electron flow direction with the help of spatial and temporal charge distribution over the device. The s-TENGs yielded electrical outputs with switchable rectification effectiveness up to ≈133 upon applying even slow and random mechanical stimuli. The switchability of power mode was successfully demonstrated in both rigid and flexible platforms when activated by counter materials, including not limited to water droplets, fabric, and human fingers, suggesting the versatile s-TENG can be applicable to universal portable and wearable electronics. Moreover, the power outputs of s-TENG can be further improved with the help of device optimization, including but not limited to micro-patterned electrode and nano-patterned triboelectrification layer (Figure S18, Supporting Information). To our knowledge, our work is the first report to date for TENGs with convertible power mode as well as flexible rectifier-free TENGs. We believe this new class of fully flexible s-TENGs will pave the path for the development of chip-less nanogenerators, and will speed up the incorporation of nanogenerators into wearable self-powered electronics in the near future. We envision that the self-powered wearable devices will play an important role in many aspects of our daily lives, including wearable electronic payments, wearable healthcare services, smart airports, smart community healthcare, and smart hospital services.

4 Experimental Section

Fabrication of a Switchable Triboelectric Nanogenerator

The basic structure of the switchable triboelectric nanogenerator comprises a defined elastic SU-8 sandwiched by an indium tin oxide-coated glass (ITO/glass) or polyethylene terephthalate (ITO/PET) substrates and fluorinated ethylene propylene (FEP) film. The ITO-coated substrates (200 nm-thick-ITO) purchased from Luoyang Guluo Glass Co., Ltd were subsequently cleaned with acetone, isopropanol, and deionized water in an ultrasonic cleaner, followed by oxygen plasma (15 sccm, 200 W, 130 s) to enhance the wettability of the surface. The negative SU-8 photoresist (GM1060, Gersteltec Co., Ltd.) mold with a 4-µm-thick was added on the ITO-coated substrates by photolithography, with a defined square pore of 40 µm side and 50 µm pitch. The adhesive FEP film (Taizhou Chenguang Plastic Industry Co., Ltd) was attached on top of the SU-8 mold, and the FEP surface was etched by reactive ion etching (RIE) treatment with CF4, Ar, and O2 gases at flow rates of 30, 15, and 10 sccm, respectively, for 30 min under a power of 100 W to improve the surface roughness.

Characterizations

The periodic water droplets fed through a grounded metal needle were applied to the s-TENGs by using a programmed peristaltic pump (Runze Fluid Tech. BT100-2J). Output voltage and current were recorded using an oscilloscope (Agilent DSO-X-2012A) equipped with a preamplifier (SRS SR-570) throughout this research. The digital multimeter (Keithley 6514) was employed to further analyze the charge generated. The angle supports for the bending test were designed to be a fixed bottom area of 30 × 60 mm2 with the arc of differing angles with respect to the bottom plane, and printed by a 3D printer (PRUSA Original Prusa i3 MK3S+). Transmittance spectra were collected on a UV–Vis–NIR spectrophotometer (Agilent Cary 5000). The wettability and surface morphology of the FEP film were investigated using a Kruss DSA20E Easy Drop Contact Angle Measurement and a field-emission scanning electron microscope (Hitachi S4800), respectively. The LCD screen was taken from a commercial digitalized table clock, and a proper connection was selected to display the number “1” of each digit on the front panel. the LCD screen to the nanogenerator through the silver-pasted wires was connected. The LCD screen was directly connected to either individual or parallelly combined nanogenerators without any external electrical devices.

Numerical Simulation via COMSOL

To compute the electric field within airgaps, 2D models of s-TENG featuring FEP and ITO layers separated by a SU-8 pattern were built in COMSOL Multiphysics. The thickness of FEP and ITO layers were set to be 50 and 10 µm, respectively. The SU-8 layer consists of an array comprising the patterns with a width of 10 µm, and thickness of 4 µm and an airgap width of 5 µm. An initial charge density of ‒23.33 µC m−2 was prescribed to the FEP surface to reflect charge accumulated through previous triboelectrification between the FEP and water droplets. To investigate the effect of the height of water droplets on the electric field, transferred chargesof ‒3.97, ‒6.64, ‒9.88, ‒11.37, ‒12.31, and ‒12.92 nC from water droplets which were obtained from the experiments was added to the FEP surface for water dropped from the height of 2.5, 5, 10, 15, 20, and 25 cm respectively. The ITO was grounded as the zero potential reference. For the calculation of pressure that requires to make the contact between FEP and ITO electrode, 3D models comprising a FEP layer stacked on SU-8 pattern consists of a 9 × 9 array were built in COMSOL Multiphysics. By fixing the SU-8 patterns, pressures from 1 to 100 MPa in a step of 1 MPa were applied on the top surface of FEP and the maximum displacement of the bottom surface of FEP was probed. When the displacement reached up to 4 µm, the FEP and ITO electrode were supposed to start contact since this value was the distance between FEP and ITO.

Acknowledgements

The authors acknowledge the financial support of the Early Career Scheme of the Research Grants Council of the Hong Kong Special Administrative Region, China, under Award Number 27202920.

Conflict of Interest

The authors declare the following conflict of interests: the University of Hong Kong has applied for a patent (US application no. 18/126,026) on some of the technology discussed herein, on which J.Z., X.M., J.G., E.K., and D.-M. S. are listed as co-inventors.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.