Ultraviolet-visible-near-infrared light-responsive soft materials: Fabrication, photomechanical deformation and applications

Abstract

In recent years, the advances in light-responsive soft materials with fascinating properties and functions have attracted tremendous attention, which are also enlightening when attempting to achieve the goals of complex deformations, motions, or attractive applications by precise regulation. Attractively, light is not only a clean and inexhaustible energy but also can be controlled remotely, quickly and accurately in a non-contact way. Moreover, light-responsive soft materials are capable of amplifying photo-triggered molecular changes at the microscopic scale into macroscopic deformations, that is, directly converting the input light energy into the output mechanical work, therefore enabling potential applications in the field of actuators and functional devices. To date, some wonderful reviews have reported the progress in photo-driven soft materials. However, the research progress in ultraviolet, visible (Vis) and near-infrared (NIR) light-driven soft materials containing azobenzene or other non-azobenzene moieties has not been reported yet. In this review, we summarize recent progress in light-responsive soft materials in terms of preparation methods, response wavelengths and potential applications. Firstly, the preparation methods of photoresponsive soft materials are introduced. Subsequently, photoinduced macroscopic deformations or motions are summarized, in which Vis and NIR light-responsive behaviors are especially highlighted. Finally, the potential applications of photoresponsive soft materials are classified. To guide the future work for researchers, the existing problems and future development prospects of light-responsive soft materials are proposed.

1 INTRODUCTION

As one kind of stimulus-responsive smart materials, light-responsive soft materials have been greatly developed and attracted tremendous attention in recent years.1-3 Compared with metal and inorganic non-metal smart materials prepared with stiff or fragile matrixes, photoresponsive soft materials obtained via utilizing soft matrixes possess superior properties of light weight and low cost, good processability, and easy functionalization, and thus expanding their application fields. As is known, various external stimuli (such as temperature,4-6 electric and magnetic field,7-10 pH,11 ultrasound12 and light,13-17 etc.) have been applied to trigger the responsiveness of materials. Among these stimuli, light possesses fascinating advantages since it is a kind of clean and inexhaustible energy and allows a remote, contactless, and efficient stimulation which can be manipulated precisely and spatiotemporally.18-20 Moreover, accompanied by the photo-triggered changes of molecular structures or morphologies, macroscopic deformations or motions of photo-driven soft materials can be induced upon light irradiation.21 These excellent characteristics endow photoresponsive soft materials with potential applications in the field of actuators and functional devices.

Generally, azobenzene and its derivatives have been intensively investigated as one of the most attractive photoresponsive molecules.22, 23 An azobenzene molecule isomerizes from a rod-like trans configuration with its molecular length of about 0.9 nm into a bent-shaped cis-form with a molecular length of about 0.55 nm upon ultraviolet (UV) light irradiation; therefore, the materials can be induced to undergo rapid and macroscopic deformations or motions by UV light when combined with azobenzene chromophores.24 Besides, some other UV light-responsive molecules or groups (such as cinnamic groups, chalcone and stilbene, etc.) can also be applied to obtain photo-deformable soft materials.25, 26 However, the above-mentioned materials are all UV light-responsive. Usually, UV light with high energy can accelerate the aging and fading of materials and bring about great harm to organisms, while long-wavelength visible (Vis) and near-infrared (NIR) light with relative low energy can penetrate into deeper tissues and bring less damage to materials or organisms.27, 28 Therefore, it is of great significance to develop visible and NIR light-responsive materials from the perspective of practical applications. In order to obtain Vis or NIR light-deformable soft materials, researchers have made many efforts such as the introduction of photothermal conversion components (PCCs),29, 30 the modification of azobenzene molecular structure,31 the introduction of up-conversion luminescent materials (UCLMs),32 etc. Via the innovative design, photoresponsive behaviors (such as planar contraction,33 bending,34-36 twisting,37 crawling37, 38 and oscillation,39, 40 etc.) can be induced by utilizing photo-deformable soft materials upon light irradiation, enabling the fabrication of various flexible actuators and functional devices. Therefore, the development and applications of light-responsive soft materials have become a hotspot for researchers in the past few years.41, 42

Recently, Yu et al. summarized UV, Vis, and NIR photoinduced deformations of azobenzene-containing cross-linked liquid-crystal polymers.21 Wu and co-workers reviewed UV, Vis, and NIR light-switchable azobenzene-containing macromolecules.43 Both of the reviews focus on azobenzene-containing polymers or chemically cross-linked materials. In this review, we summarize the research status of UV, Vis, and NIR light-responsive soft materials containing azobenzene or other non-azobenzene moieties in the form of bulk film, fiber, blend, and bilayer composites. In the first part of this review, we introduce the preparation method of light-responsive soft materials. Subsequently, UV, Vis, and NIR light-induced deformations or motions of photo-driven soft materials are systematically summarized. Then the potential applications of photo-deformable soft materials are separately described, and finally, the current existing problems and future development prospects of photo-responsive soft materials are proposed.

2 FABRICATION OF LIGHT-RESPONSIVE SOFT MATERIALS

At present, photo-deformable soft materials that have been reported mainly include photo-responsive bulk film, fiber, blend and bilayer composites, etc. In this section, the preparation methods of aforementioned light-responsive soft materials are separately introduced in terms of the structure of materials.

2.1 Bulk film

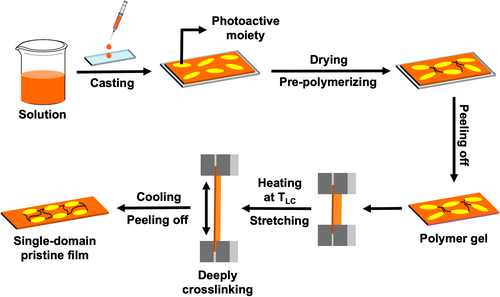

Up to now, there are three main methods for the preparation of bulk films of photo-deformable soft materials, especially for mesogenic materials. The first is the two-step cross-linking method, first proposed by Finkelmann et al.,44-46 and the preparation process is shown in Figure 1. Firstly, the initiator, monomer(s) and cross-linking agent(s) are dissolved in solvent to obtain a homogeneously dispersed solution, which subsequently is cast on a substrate. After volatilization of the solvent, the mixture is pre-polymerized to obtain a lightly cross-linked polymer gel.42 Then the gel is stretched at the liquid crystal (LC) temperature (TLC) under external stress, which undergoes deep cross-linking while retaining the stretched state to obtain a single-domain aligned pristine film.42 When the cross-linking degree of the prepolymer is too low, the polymer precursor is easily broken (poor gel strength) during the stretching process.42 Contrarily, increasing the cross-linking degree of the polymer precursor will increase the difficulty of stretching orientation process, which reduces the orientation degree of the material.42 Although the two-step cross-linking method has been favored by researchers and has made some research progress, the contradiction between the cross-linking degree and the orientation degree limits the practical applications of the method.42

Preparation process of bulk films by the two-step cross-linking method.

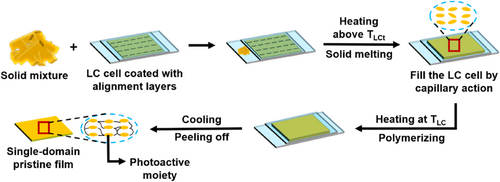

In addition, one-step method, first proposed by Broer et al.,47, 48 can be used to fabricate bulk films of soft materials directly, and the preparation process is shown in Figure 2. Firstly, the initiator, monomer(s) and cross-linking agent(s) are dissolved in solvent to obtain one homogeneously dispersed solution. After volatilization of the solvent, the solid mixture is filled into an LC cell pre-coated with rubbed-polyimide (PI) alignment layers under the function of capillary action above the LC-isotrophic phase-transition temperature (TLCt).42 Upon light or thermally induced free radical polymerization at the TLC to fix the pre-oriented mesogens, a single-domain aligned pristine film can be obtained upon being peeled from the cell. By utilization of the one-step method both parallel or vertical and hybrid alignments of mesogens in films can be conveniently realized without the external stress by controlling the alignment conditions.42 However, only thin film with a smaller size can be produced due to the dimensional constraint of the used LC cells.42 Moreover, some unreacted small molecules may exist in the bulk film, which could influence the final performance of film materials.

Preparation process of pristine films via the one-step method.

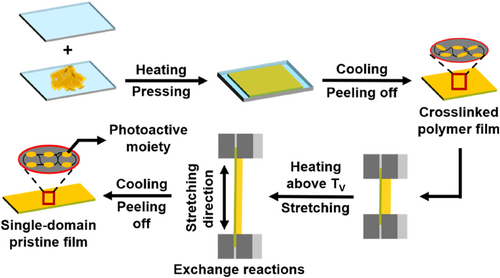

The two-step cross-linking method has a low success rate, and the one-step method can only be used for the preparation of thin film with a smaller size.42 Obviously, the aforementioned two methods also face a significant challenge, that is, it is difficult for them to fabricate actuators with complex and programmable three-dimensional (3D) shapes.42 It is well known that exchangeable dynamic covalent bonds (EDCBs) can be reversibly broken and regenerated upon specific external stimuli and no irreversible side reactions occur during this process.49 Exchange reactions enable the rearrangement of internally cross-linked networks of materials, endowing the materials (especially cross-linked thermosetting materials) with novel functions.50, 51 In recent years, Ji and co-workers have proposed a new method for preparing single-domain pristine films,29, 52 that is, utilizing exchange reactions to completely cross-link materials and then stretching them to achieve a designed orientation, and the preparation process is shown in Figure 3. Firstly, the powdery or nubbly polymer with EDCBs is pressed under the external pressure upon heating to obtain film samples. Then the resultant films are stretched under an external stress upon heating above the topology-freezing transition temperature (Tv), at which the exchange reactions occur quickly.53 After keeping at this temperature for a certain time while maintaining the stretching state, single-domain pristine films are obtained upon cooling the samples to room temperature. This method overcomes the defects of low success rate and limited material size of the above-mentioned two methods.42 Since EDCBs endow the cross-linked networks with processability, the cross-linked materials can be flexibly designed into various 3D shapes, which greatly promotes the development and applications of cross-linked materials.42

Preparation process of pristine films by utilizing exchange reactions.

2.2 Fiber

At present, the main preparation method for fibers is melt spinning, and the preparation process is as follows. Firstly, the powdery or nubbly solid is placed on a glass slide or quartz plate, which is then heated above the melting point of the material until it is completely melted. Subsequently, fibers are obtained via completely immersing the tips of one tweezer into the molten solid and pulling them out at one constant speed. For the photo-actuation, the fibers prepared via this method possess superior orientation and no further orientation treatment is required.54 By this way, both polymer main chains and mesogens can be manipulated easily. The mesogens in the fibers can be aligned parallel or perpendicular to the pulling direction, leading to different photoinduced deformation behaviors. However, the mechanical strength of obtained fibers still needs improvement.

2.3 Blend film

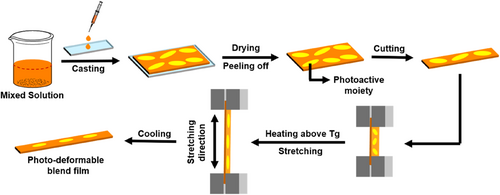

Photo-deformable blend films are usually prepared via one drop-coating or casting film-forming methods, followed by mechanical stretching to induce orientation. In this process the glass transition temperature (Tg) of polymer materials should be above room temperature,55 and the preparation process is shown in Figure 4. Firstly, two or more functional components are dissolved in the same solvent to obtain one homogeneously dispersed solution, which is cast into a mold. After evaporating the solvent and peeling off, the blend film is obtained, which is usually cut into strips for the following mechanical treatment. Upon heating the film above the Tg of polymer, the film strips are stretched under external stress. Accompanied by the orientation of polymer chains along the stretching direction, the doped photoactive components are also aligned along the stretching direction.56 Then, photo-deformable blend films are obtained by cooling to room temperature since the orientation can be frozen by this way.55 The relatively simple drop-coating or casting method can be applied for large-scale preparation of blend films with different functions, and the film thickness can be conveniently controlled by the concentration or dosage of the solution and the stretching condition. Besides, the orientation degree of films can be adjusted by the elongation ratio. However, the heterogeneous distribution of doped components may occur due to the coffee ring effect and the solubility or compatibility difference of the components, etc.,57 which should be considered when using this method.

Preparation process of blend films via the drop-coating or casting method.

2.4 Bilayer film

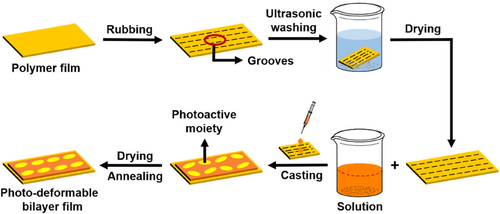

The most common method for fabricating bilayer films is drop-coating a certain solution on the rubbed polymer film, and the preparation process is shown in Figure 5. Firstly, a commercially available flexible polymer film such as PI or polyethylene (PE) films is carefully polished in one direction with a piece of sandpaper, followed by the ultrasonic washing and drying.58 Then the solution containing different functional components is cast on the pre-treated polymer film. Photo-deformable bilayer films are obtained via evaporating the solvent and annealing at an appropriate temperature to eliminate the residual stress. The simple drop-coating method can be utilized for the large-scale preparation of photo-deformable bilayer films; however, the heterogeneous distribution and even shedding of some components may occur because of the bad interaction between the two layers. These should be overcome in the future applications.

Preparation process of bilayer films by the drop-coating method.

3 UV PHOTO-ACTUATION OF SOFT MATERIALS

3.1 UV photothermal actuation

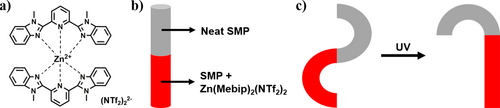

As is known, UV light mainly induces the photochemical response of materials, and its photothermal effect is relatively negligible even for the materials doped with common PCCs such as graphene oxide (GO).59 However, incorporating UV light specified PCCs into thermally responsive materials can produce UV photothermally responsive soft materials. As shown in Figure 6, Hu et al. successfully prepared an UV photothermally responsive composite by utilizing one shape-memory polymer (SMP).60 Firstly, they prepared one SMP pristine strip, and then the SMP prepolymer containing a certain amount of UV-specified photothermal conversion coordination compound Zn(Mebip)2(NTf2)2 (Figure 6a) was cast onto the surface of the lower part of the SMP pristine strip, while the upper part remained unchanged, as shown in Figure 6b. After being completely cured, the SMP composite was deformed upon heating to obtain the bent temporary shape. As shown in Figure 6c, upon irradiation of UV light, the lower part of the SMP composite reverted to its original shape within several seconds due to the strong UV photothermal effect, while the upper part still remained the bent temporary shape because Zn(Mebip)2(NTf2)2 is an efficient UV-specified PCC, enabling the composite to undergo one shape-change process at the elevated temperature.

(a) Molecular structure of the UV photothermal conversion coordination compound Zn(Mebip)2(NTf2)2. (b) Schematic diagram of the SMP composite. (c) The shape recovery of the SMP composite upon exposure to UV light. SMP, shape-memory polymer; UV, ultraviolet.

3.2 UV photochemical actuation

Azobenzene is one of the most commonly used UV light-responsive molecules.61, 62 Upon irradiation of UV light, azobenzene can undergo the trans-cis isomerization.63-66 So incorporating azobenzene moieties into materials often brings about macroscopic deformations.67, 68 Our group successfully fabricated an UV photochemically responsive composite film composed of a commercially available Kapton (PI) film and an azobenzene-containing LC polymer (LCP).69 To enhance the interfacial interaction, hydroxyl groups were introduced into the side chains of the LCP via copolymerization to form supramolecular hydrogen bonding (HB) with the PI nanofibers, providing the composite film with a relatively high elastic modulus and nanohardness. Due to the enhanced mechanical performance and the unique bilayer structure, the composite film exhibited rapid photoinduced oscillation behaviors independent of the irradiation direction of the incident light, which is ascribed to an unconventional deformation mechanism arising from the interactions at the polymer-nanofiber interface. Besides, the flapping frequency and bending angle of the bilayer composite film can be continuously tuned by modifying the pulsed light irradiation.

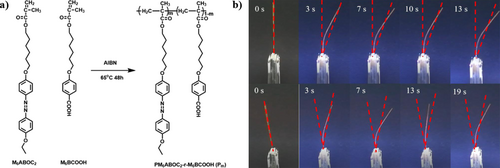

Besides, our group also reported several UV photochemically driven swing actuators composed of one commercial PI film and azobenzene-containing LCPs.70 The PI film with a high elastic modulus is photoinert and functions as the substrate layer. The LCPs act as the photoactive layer, which were synthesized by copolymerization of a benzenecarboxylic acid-containing monomer (M6BCOOH) and an azobenzene-containing monomer (M6ABOC2) with different molar ratios, as shown in Figure 7a. Interestingly, the introduction of M6BCOOH to the copolymer not only accelerated the trans-cis isomerization rate of azobenzene, but also formed supramolecular HBs acting as physical cross-linking sites, enabling the polymer film to work as a whole. As shown in Figure 7b, the bilayer films displayed chaotic swing behaviors upon continuous irradiation of UV light and the swing amplitude of bilayer films was greatly enhanced by the existence of supramolecular HB in LCPs. Obviously, the HB interaction enhanced the driving force for photomechanical deformation of the composite film. In addition, the HB formation in the form of acidic dimers had a spatial confinement effect, extending the timescale of photo-driven swing. The photomechanical self-vibration behaviors of bilayer films can be ascribed to the combination of the photoisomerization of azobenzene with the local photosoftening effect of LCPs.

(a) Synthetic route of the LCPs. (b) Snapshots of the displacements of bilayer films upon UV irradiation. The molar ratios of M6BCOOH were 0 (upper) and 0.29 (lower). Reproduced with permission.70 Copyright 2021, American Chemical Society. LCPs, liquid crystal polymers; UV, ultraviolet.

Other groups have also made some progress in photochemical actuation. Recently, Ikeda et al. successfully prepared an UV light-responsive LC elastomer (LCE) film.71 Upon UV irradiation, the film bent towards incident direction of the light source since the trans-cis isomerization of azobenzene enabled the film surface to change from an LC state to the isotropic phase, resulting in the non-uniform shrinkage of the film. They also deformed the film into a spiral shape, and such a film exhibited the unwinding behavior upon UV irradiation since the trans-cis isomerization of azobenzene on the outer surface of the helix lead to the non-uniform shrinkage of the film. Schenning and co-workers successfully obtained a single-domain LC network (LCN) bilayer film with a spiral shape.72 Upon UV irradiation, when the azobenzene layer is located on the inside, the trans-cis isomerization of azobenzene enabled the azobenzene layer to change from the LC state to the isotropic state, leading to the asymmetric shrinkage of the bilayer film, the spiral further wrapped. Similarly, when the azobenzene layer is located on the outside, the asymmetric shrinkage caused by the trans-cis isomerization of azobenzene enables the bilayer film to exhibit the unwinding behavior.

In addition to azobenzene, other UV light-responsive groups or molecules (such as cinnamic groups and stilbene, etc.) can also be used to fabricate photo-deformable soft materials.26, 73 Ashby et al. successfully synthesized an UV light-responsive SMP with cinnamic groups in the side chains.25 The temporary elongated shape of the SMP film was fixed when irradiated with UV light (>260 nm) since the [2 + 2] cycloaddition reaction of pendant cinnamic groups in the adjacent main chains brought about cross-linking for the material. When irradiated with another UV light (<260 nm), the newly formed temporary cross-links were broken and the film returned to its original shape due to the decrosslinking of pendant cinnamic groups in the adjacent main chains. Zhang et al. successfully prepared a supramolecular HB LCP fiber with poly-4-vinylpyridine as the main chain and stilbene derivative as the side chain.74 Upon UV irradiation, the polymer fiber bent towards the light source since the trans-cis isomerization of surface stilbene led to the non-uniform shrinkage of the fiber. Interestingly, the polymer fiber can be subjected to fixed-point deformations with UV light. They deformed the straight fibers into different letter shapes or complex curved shapes via UV light-induced fixed-point actuation. These indicate that the excellent light-responsiveness of the fiber endows the material with potential applications in the field of intelligent actuators and information encryption.

At present, a large number of photo-deformable soft materials are driven by UV light, which has been greatly restricted in practical applications due to the harmfulness of UV light. Therefore, it is of great significance to develop visible or NIR light-driven soft materials from the perspective of practical applications. Next, we introduce the photo-deformable soft materials driven by visible and NIR light.

4 VISIBLE PHOTO-ACTUATION OF SOFT MATERIALS

4.1 Visible photothermal actuation

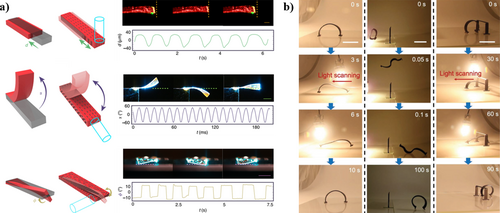

With the development of photo-deformable soft materials, PCCs have also been introduced into these systems as functional additives. Visible photothermally driven soft materials can be obtained via incorporating visible-stimulated PCCs, such as GO, carbon nanotubes (CNTs) and Au nanoparticles (AuNPs), etc., into thermally responsive materials since visible-stimulated PCCs can absorb visible light and convert light energy into heat, thereby inducing macroscopic deformations or motions of the materials. Among the reported photothermally induced deformations of soft materials, there are simple 2D or 3D deformations (such as contraction/expansion, bending, etc.) as well as complex 3D deformations or motions (such as vibration, crawling, etc.). For instance, Jin and co-workers prepared several single-domain LCE/AuNP composite films, and the positions and shapes of AuNPs dispersed in the films were controlled by the reduction reaction.75 Upon irradiation of visible light, the films contracted at different positions due to the photothermal effect of AuNPs, resulting in different complex deformations. As shown in Figure 8a, Priimagi et al. successfully prepared a visible photothermally driven LCN film.76 Three oscillation modes of contraction/expansion, bending, and twisting were, respectively, obtained via controlling the mesogenic orientation or the irradiation position of incident light, which is potentially applicable in the field of micro-robots and optical sensing. Cai and co-workers prepared a single-domain arch-shape LCE/CNT composite film.77 As shown in Figure 8b, the arch-shape composite film exhibited complex motions (crawling, jumping and drilling into a hole) upon visible light irradiation due to the photothermal effect.

(a) Schematic diagram, snapshots and amplitude changes of three oscillation modes of the self-oscillator. Reproduced with permission.76 Copyright 2019, Springer Nature. (b) The arch-shape composite film exhibited three complex motions upon visible light irradiation. Reproduced with permission.77 Copyright 2019, Wiley-VCH.

4.2 Visible photochemical actuation

Modification of azobenzene structures

Most of azobenzene and its derivatives are UV light-responsive. Considering their potential harmfulness to living organisms, the development of visible light-responsive azobenzene derivatives has become a trend. From the viewpoint of molecular orbital transition, it is necessary to change the π–π* absorption of azobenzene from the UV to the visible region, which requires to redesign the structure of azobenzene. To endow azobenzene with visible light responsiveness, Broer et al. synthesized one fluoroazobenzene-containing LCP, which underwent the trans-cis isomerization upon blue or green light irradiation.31 When irradiated with visible light, the polymer film exhibited irregular vibrational behaviors due to the asymmetric contraction caused by the photoisomerization of fluoroazobenzene. In addition, Broer and co-workers also prepared an LCP film containing the azobenzene with a specially designed molecular structure.78 Upon visible light irradiation, the film bent towards the direction of incident light. Zhang et al. synthesized a linear polyurea with bridged-azobenzene moieties in the backbone.79 Upon irradiation with blue light (405 nm), the bridged-azobenzene moieties converted from the stable cis states into their metastable trans ones, and then the trans-cis isomerization of bridged-azobenzene moieties could take place upon further illumination with green light (532 nm). Upon irradiation of blue light, the polymer film bent away from the light source with a bending angle higher than 110° in several seconds, and then the film can recover to its initial state with no attenuation upon irradiation with green light. The photoresponsive behaviors of the polymer film were different from those of the photoresponsive soft materials containing planar azobenzene moieties, which is expected to be promising for smart materials.

Introduction of UCLMs

In addition to modifying the structure of azobenzene, the introduction of UCLMs can also produce visible light-driven behaviors of soft materials. UCLMs can upconvert a long-wavelength visible light into UV light or a short-wavelength visible light,80 and photochemically cause the trans-cis isomerization of azobenzene, thereby resulting in photoinduced macroscopic deformations of the materials. Yu et al. prepared a single-domain LCP bilayer film containing azotolane and an UCLM.32 Upon irradiation of red light (635 nm), the bilayer film bent towards the light source since the UCLM upconverted the red light into blue light (470 nm), which overlapped well with the absorption of azotolane and thus caused the asymmetric contraction of the bilayer film. Surprisingly, when irradiated with red light passing through a piece of pork with 3 mm thickness, the bilayer film still bent towards the light source, indicating the excellent visible-light responsiveness of the bilayer film.

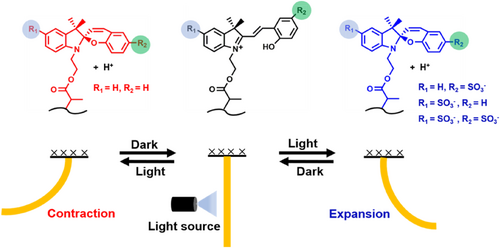

Introduction of non-azobenzene groups

The chemically modified azobenzene chromophore can undergo a considerable trans-cis isomerization upon visible-light irradiation, which is necessary for the preparation of visible light-driven soft materials. However, except for azobenzene, other light-responsive molecules or groups are rarely reported for utilization in visible photochemically driven soft materials. Recently, Li et al. successfully prepared a visible light-responsive rod-like hydrogel with spiropyran groups in the side chains.81 The rod-like hydrogel was treated with acid to transform the spiropyran groups into the merocyanine groups. As shown in Figure 9, upon visible light irradiation, the rod-like hydrogel containing merocyanine groups bent towards the light source due to the volume contraction caused by the transformation of the positively charged hydrophilic merocyanine form into the uncharged spiropyran form, while the rod-like hydrogel containing sulfonated merocyanine groups bent away from the light source due to the volume expansion caused by the light-induced increment of charges. In addition, as the increment of critical solution temperature, the bending degree of the rod-like hydrogel gradually decreased.

Schematic illustration of the bending deformation of the rod-like hydrogel upon visible light irradiation.

5 NIR PHOTO-ACTUATION OF SOFT MATERIALS

5.1 NIR photothermal actuation

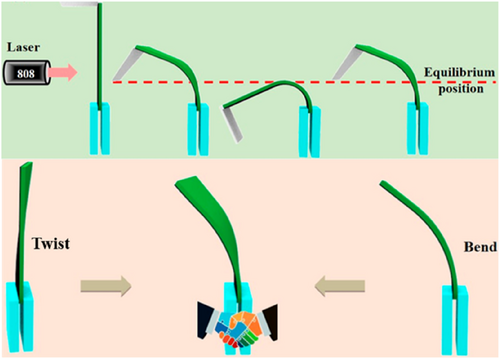

Similar to visible light, NIR photothermally-driven soft materials can also be obtained via doping PCCs (such as GO, CNTs and AuNPs, etc.) into thermally responsive materials. NIR PCCs are capable of converting NIR light into thermal energy, thereby inducing macroscopic deformations or motions of the materials. In 2022, our group reported one GO/LCN composite film, showing a unique NIR light-induced oscillation behavior with amplitude and frequency superposition.82 The composite film was prepared by the one-step polymerization of mesogenic monomers in an LC cell, which favors a splay orientation in the LC cell made by gluing two glass sheets together, one coated with GO and the other coated with one rubbed PI alignment layer. As shown in Figure 10, when the composite film was embedded in a self-shadowing system, upon NIR irradiation, it exhibited an unconventional hybrid oscillation mode, that is, bending and twisting oscillation coupled. Furthermore, when the aspect ratio of the composite film decreased, the twisting oscillation mode was suppressed and the oscillation mode changed from a coupled mode to a single bending mode. The strategy might extend the applications of GO/LCN composite materials and enrich the light-activated oscillation behaviors. Zhao and co-workers successfully prepared a NIR photothermally driven LCP three-layer film, in which the upper layer is the GO layer, the middle layer is the adhesive layer and the lower layer is the thermally responsive LCP film.83 Upon photo irradiation, GO absorbed the NIR light and converted it into heat energy, which gradually conducted to the lower LCP film. When the temperature of the LCP film was higher than TLCt, the LCP film contracted, causing the three-layer film to bend away from the light source. When both ends of the three-layer film were fixed, the protrusion of the film moved back and forth between both ends of the film as NIR light moved. When both ends of the three-layer film were free, the film moved on the flat substrate towards the direction in which NIR light moved. Moreover, the film could not only move on the flat substrate but also on a slope with an angle of 15°. In addition, Zhao and co-workers also prepared one NIR photothermally responsive dye-doped LCN film.84 Upon irradiation of NIR light, the composite film exhibited two different locomotion behaviors, that is, moving in the laser scanning direction and moving in the opposite direction.

Scheme illustration of the photoinduced oscillation process (upper) and deformation process (lower) of the composite film upon near-infrared irradiation. Reproduced with permission.82 Copyright 2022, American Chemical Society.

However, doping PCCs directly into matrix materials will lead to the uneven distribution of PCCs. To solve this problem, PCCs can be directly covalently linked to polymer matrixes in the preparation process. Yang et al. obtained a NIR photothermally responsive LCE film, in which the NIR-specified PCC was covalently connected to the matrix.85 Upon NIR irradiation, the film contracted since the photothermal effect caused the mesogens to change from the LC state to the isotropic state. When NIR light was turned off, the film reverted to its original state due to the decrease in temperature. It is worth noting that upon NIR irradiation, the force generated by the contraction of the film could lift up an object of 5680 times its own weight, indicating that the film possesses ultra-strong mechanical properties, thereby being capable of potential applications in the field of micromechanical devices.

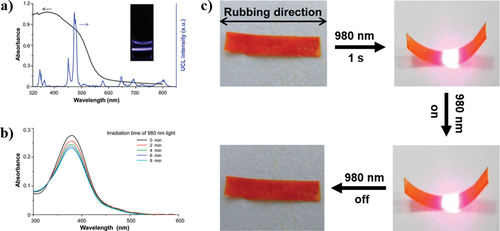

5.2 Introduction of UCLMs

At present, in addition to the introduction of PCCs into thermally responsive materials, incorporating UCLMs into photoresponsive materials (e.g., azobenzene-containing polymer materials) can also produce NIR light-driven soft materials. UCLMs can upconvert long-wavelength NIR light into UV light or short-wavelength visible light86-89 and induce the trans-cis isomerization of azobenzene, thereby resulting in photoinduced macroscopic deformations of the materials. Yu et al. successfully prepared a NIR light-driven LCP film containing azotolane and an UCLM.90 Upon irradiation with NIR light (980 nm), the UCLM upconverted NIR light into blue light, which overlapped well with the absorption of azotolane (Figure 11a) and induced the trans-cis isomerization of the upper azotolane (Figure 11b), thereby leading to the bending of the film towards the light source derived from the asymmetric contraction (Figure 11c).

(a) UV-vis absorption spectrum of azotolane and fluorescence emission spectrum of the UCLM excited by NIR light (980 nm). (b) UV-vis absorption spectra of azotolane upon NIR irradiation for different times in the present of UCLM. (c) NIR light-induced bending deformation of the LCP film containing an UCLM. Reproduced with permission.90 Copyright 2011, American Chemical Society. LCP, liquid crystal polymer; NIR, near-infrared; UCLM, up-conversion luminescent material; UV, ultraviolet.

6 UV-Vis-NIR PHOTO-ACTUATION OF SOFT MATERIALS

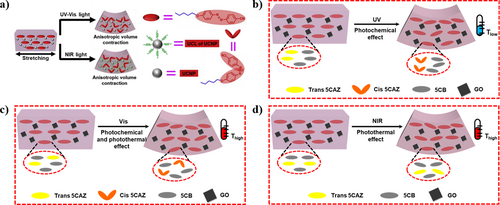

Photo-deformable soft materials described above are only responsive to a specific or one short range of wavelengths, which is far from sufficient for practical applications. As is well known, sunlight mainly consists of UV, Vis, and NIR light. In order to make full use of solar energy and facilitate practical applications, multi-wavelength (especially UV-Vis-NIR) light-driven soft materials are undoubtedly more advantageous and attractive. Our group prepared one UV-Vis-NIR photochemically driven composite film containing cyano-azobenzene and a UCLM.91 As shown in Figure 12a, upon irradiation of UV (365 nm) or green (530 nm) light, the film exhibited bending deformations along the orientation direction due to the asymmetrical contraction caused by the trans-cis isomerization of cyano-azobenzene. When exposed to NIR light (808 nm), the film still exhibited the bending deformation along the orientation direction due to the asymmetrical contraction caused by the upconverting green light-induced trans-cis isomerization of cyano-azobenzene. To further improve the photoresponse performance of the composite film, our group successfully prepared a polymer-dispersed LC composite film containing GO.92 Upon irradiation of UV light (365 nm), the film showed the rapid bending deformation along the orientation direction due to the asymmetrical contraction caused by the photochemically induced LC-isotropic phase transition (Figure 12b). Upon irradiation with visible light (460 nm), the film exhibited the rapid bending deformation along the orientation direction due to the asymmetrical contraction caused by the photochemically and photothermally triggered LC-isotropic phase transition (Figure 12c). When exposed to low-intensity NIR light (808 nm), the film displayed the rapid bending deformation along the orientation direction due to the asymmetrical contraction caused by the photothermally induced LC-isotropic phase transition and partial stress relaxation (Figure 12d). Due to its excellent UV-Vis-NIR light-responsive characteristics, the composite film was capable of potential applications in the field of functional devices.

(a) Schematic illustration of UV-Vis-NIR light-induced bending deformations of the composite film containing an UCLM. Reproduced with permission.91 Copyright 2019, Elsevier. (b–d) Schematic illustration of bending deformations of the composite film containing GO upon irradiation of UV, visible and NIR light, respectively. GO, graphene oxide; NIR, near-infrared; UCLM, up-conversion luminescent material; UV, ultraviolet; Vis, visible.

7 APPLICATIONS OF PHOTO-DEFORMABLE SOFT MATERIALS

7.1 Biomimetic actuators

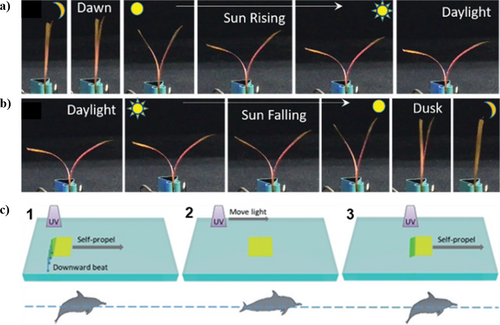

Inspired by varied and amazing natural movements, researchers have developed many attractive biomimetic actuators, and the photoinduced complex macroscopic deformations or motions of photo-deformable soft materials also provide basic conditions for the fabrication of biomimetic actuators. Li et al. successfully simulated the circadian rhythm of an acacia tree using a bilayer film with the azopyridine-containing photoactive layer.93 Two bilayer films were placed face-to-face vertically with the lower end fixed and the upper end free. Upon irradiation of UV light, the two bilayer films bent away from the light source due to the free volume expansion of azopyridine moieties, successfully simulating the unfolding of leaves of an acacia tree during the day (Figure 13a). Turning off the UV light, the two bent films gradually closed towards the middle until they became vertical due to the recovery of the high modulus Kapton films, successfully simulating the closure of leaves of an acacia tree at night (Figure 13b). In addition, Ma et al. successfully simulated the motion of a dolphin via using a bilayer film with an azobenzene-containing photoactive layer.94 The bilayer film floated on the liquid surface when placed on the ethanol/water surface with the Kapton layer facing the liquid surface. When irradiated from the left side with UV light, the bilayer film bent down and beat the liquid, while the reactive force of the liquid pushed the film forward (Figure 13c). Priimagi and co-workers successfully simulated the process of trapping insects of a dionaea muscipula using a photoresponsive LCE film.95 It is interesting that a feedback system was introduced during the process of trapping insects to enable the actuator to spontaneously respond to the changes in the external environment, which greatly promotes the development of biomimetic actuators towards the direction of intelligence and practicality.

(a) Simulate the unfolding of leaves of an acacia tree during the day. (b) Simulate the closure of leaves of an acacia tree at night. (a, b) Reproduced with permission.93 Copyright 2019, The Royal Society of Chemistry. (c) Simulate the motion of a dolphin by using a bilayer film upon UV irradiation. Reproduced with permission.94 Copyright 2019, Wiley-VCH. UV, ultraviolet.

7.2 Micromechanical devices

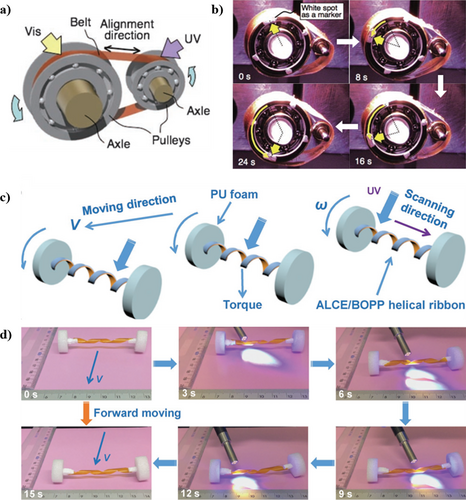

Ikeda et al. fabricated a photo-driven motor device (Figure 14a).96 They placed the belt prepared by connecting both ends of an azobenzene-containing cross-linked LCE/PE laminated film on two homemade pulleys with different sizes to obtain a motor system. As shown in Figure 14b, the motor system rotated in a counterclockwise direction by irradiating the belt using UV light from upper right and visible light from upper left. This may be because the contractile force derived from the UV-induced arrangement change of azobenzene mesogens acted on the right pulley, enabling it to rotate in a counterclockwise direction. Meanwhile, the expansion force generated upon visible-light irradiation also led to the counterclockwise rotation of the left pulley. The rotation of the pulleys exposed new parts of the belt to UV and visible light, driving the motor system to rotate continuously. The reverse rotation of the motor system could be realized by exchanging the irradiation positions of the two light sources. Zhao and co-workers fabricated a light-driven “vehicle” (Figure 14c).97 They deformed the bilayer film into a spiral shape with the azobenzene-containing photoactive layer on the inner side, and then fixed the two ends of the film on two wheels made up of plastic foam. As shown in Figure 14d, upon UV irradiation from right to left, the trans-cis isomerization of azobenzene moieties caused the spiral to wind, and the generating force drove the two wheels forward.

7.3 Flexible robots

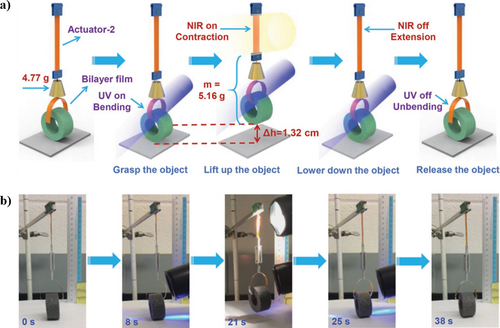

Generally, flexible robots require the materials to be capable of undergoing macroscopical deformations even when the loads are applied, while light-responsive soft materials can produce macroscopical deformations upon light irradiation, exhibiting great potential in the field of flexible robots.98, 99 At present, researchers have fabricated some flexible robots via using light-responsive soft materials. Among them, the flexible robots capable of grasping objects are more welcomed. Zhao et al. fabricated a flexible “crane” that could grab and lift up heavy objects via using azobenzene-containing LCN films (Figure 15a),100 in which the bilayer film with an azobenzene-containing photoactive layer was used as a “hand” and an LCN/AuNPs composite film was used as an “arm.” As shown in Figure 15b, when irradiated with UV light, the bilayer film bent away from the light source due to the asymmetric contraction derived from the trans-cis isomerization of the inner azobenzene layer, “grabbing” a wheel-shaped object. The LCN/AuNPs composite film was then irradiated with NIR light; the film contracted due to the photothermal effect of AuNPs, “lifting up” the heavy object. However, some flexible robots can only grasp the objects with small length/diameter ratios, and can do nothing for the objects with large length/diameter ratios. Hu et al. successfully fabricated an actuator which could “capture” the objects with large length/diameter ratios by using a bilayer film with an azobenzene-containing photoactive layer.37 Upon UV irradiation, the film winded due to the asymmetric contraction derived from the LC-isotropic phase transition induced by the photo-liquefaction, “capturing” the object with a large length/diameter ratio (wooden stick).

(a) Schematic illustration and (b) Snapshots of grasping, lifting up, lowering down and releasing a tube-shaped object of a “crane.” Reproduced with permission.100 Copyright 2018, Wiley-VCH.

7.4 Photoelectric elements

Upon light irradiation, photoresponsive soft materials can produce macroscopic deformations or motions, which can be regarded as a conversion of light energy into mechanical energy.101 This part of mechanical energy can also be transformed into other energies,101 one of which is the conversion of light energy–mechanical energy–electrical energy. Tang et al. successfully fabricated an optical pendulum generator (Figure 16a) by using a bilayer film composed of an azobenzene-containing LCP layer and a photo-inert layer.102 One end of the film was fixed, the other was attached to copper coils, and the whole device was placed in a magnetic field generated by a magnet. Upon UV irradiation, the bilayer film bent towards the light source and drove the coils to move in the magnetic field. The induction voltage was generated when the magnetic flux passing through the coils changed according to the Faraday's law of electromagnetic induction. When the UV light was turned off, the bilayer film unbent and drove the coils to move in the reverse direction. At this time, a reverse induction voltage was generated. To obtain continuous electricity output, the irradiation parameters were adjusted to enable the bilayer film to oscillate and the coils to swing, thereby generating a relatively stable alternating voltage (Figure 16b). In addition, Yang et al. also fabricated a generator device via utilizing the electromagnetic induction.103 When the bilayer film was embedded in a self-shadowing system, upon NIR irradiation, the film oscillated up and down due to the photothermal effect of polydopamine, which enabled the string hanging the coil to swing back and forth, leading to a change of the magnetic field strength passing through the coil. According to Faraday's law of electromagnetic induction, the induced current was generated at this time.

(a) Schematic illustration of the optical pendulum generator. (b) Continuous electricity output upon ultraviolet irradiation on the bilayer film. Reproduced with permission.102 Copyright 2015, American Chemical Society.

8 CONCLUSION AND OUTLOOK

This review summarizes the research status of light-responsive soft materials in terms of preparation methods, response wavelengths, and applications. Compared with other stimulus-responsive materials, photo-deformable soft materials possess unique advantages since light is a kind of clean, safe and inexhaustible energy and allows a remote, contactless, and efficient stimulation which can be manipulated precisely and spatiotemporally, and no by-products are produced in the photoresponsive process. By adjusting the parameters (such as light wavelength and intensity, etc.), macroscopic deformations or motions of light-driven soft materials can be precisely regulated, without the intervention of batteries, motors, and gears, enabling the materials to be easily miniaturized and providing important braking components for micro-robots and micro-mechanical systems. Moreover, from the perspective of energy conversion, photo-deformable soft materials can directly convert light energy into mechanical energy, which is expected to reduce the loss of energy in multiple conversion processes and improve the conversion efficiency of light energy. Although light-responsive soft materials have been greatly developed in the past decades, some problems still exist in the current development of photo-deformable soft materials.

Firstly, although the drop-coating or casting method for the preparation of composite films and the melt spinning method used to prepare fibers are simple, the obtained light-driven soft materials exhibiting relatively simple structures are difficult to produce complex 3D deformations or motions upon light irradiation due to the relatively simple alignments of photoactive mesogens. The methods for the preparation of bulk films can produce photo-responsive soft materials with light-induced complex 3D deformations or motions; however, they are relatively complicated and the success rate is lower than the former. Therefore, light-driven soft materials with simple preparation methods and photoinduced complex 3D deformations or motions will be the future developing direction.

Secondly, photoresponsive molecules or groups used in light-driven soft materials are mainly azobenzene and its derivatives, while other photoresponsive molecules or groups (such as stilbene, cinnamic group and spiropyran, etc.) are rarely used in photo-deformable soft materials. Although currently reported azobenzene-containing photoresponsive soft materials can produce complex 3D deformations or motions and have many potential applications, azobenzene chromophore has a large UV absorption coefficient and it needs higher energy to drive. Besides, azobenzene-containing materials are sometimes toxic and possess poor film-forming properties. Therefore, from the perspective of the long-term development of materials, it is significant to put more energy on photo-deformable soft materials containing other non-azobenzene photoresponsive moieties.

Thirdly, up to now, more than half of photo-deformable soft materials are UV light-responsive. As is known, UV light accounts for a small fraction (about 5%) in sunlight,43 which is more harmful to organisms and materials, while visible and NIR light account for a large proportion in sunlight, which are less harmful to organisms and materials. In order to avoid the harmfulness of UV light and make full use of solar energy, visible and NIR light-driven soft materials should be greatly developed. In addition, most of light-responsive soft materials are single-wavelength responsive. In order to improve the versatility and practicality of photo-deformable soft materials, researches on multi-wavelength, especially UV-Vis-NIR photo-responsive soft materials should be intensified.

Last but not least, the deformations of a large portion of light-responsive soft materials are relatively simple. To endow light-responsive soft materials with considerable practical values, the ability of producing complex deformations or motions is required. Therefore, to achieve this goal, it is necessary to carry out the innovative designs of compositions, structures and preparation methods of materials and innovative assemblies of functional devices.

In summary, gratifying achievements have been made in preparation methods, driving wavelengths and modes and potential applications of light-responsive soft materials. However, to achieve practical applications of photo-deformable soft materials, there is still a long way to go. Therefore, in order to enable light-responsive soft materials to occupy a place in the future development of materials, the unremitting efforts of researchers are also required.

AUTHOR CONTRIBUTIONS

Haifeng Yu: Funding acquisition (lead); investigation (lead); supervision (lead); writing – review & editing (equal). Guojie Wang: Investigation (equal); writing – review & editing (equal). Peng Zhang: Data curation (lead); formal analysis (lead); software (lead); writing – original draft (lead).

ACKNOWLEDGMENTS

This work was supported by the National Natural Science Foundation of China (Nos. 51921002, 52173066, 51773002, and 51373025).

CONFLICT OF INTEREST STATEMENT

The authors declare no conflicts of interests.

Biographies

Peng Zhang received his PhD in Materials Science and Engineering from University of Science and Technology Beijing in 2022. He is currently a lecturer in the college of Chemistry and Chemical Engineering at Dezhou University. His research is focused on photoresponsive azobenzene-containing soft materials and magnetic materials.

Guo-Jie Wang received his PhD in Polymer Chemistry and Physics from Jilin University in 2000. Then he worked as a post-doctor at Tsinghua University. In 2002, he joined the Institute of Chemistry, Chinese Academy of Sciences as an associate professor. In 2005, he joined the Georgia Institute of Technology. In 2006, he moved to the Katholieke Universiteit Leuven. In 2008, he joined the School of Materials Science and Engineering at the University of Science and Technology Beijing. In 2011, he was awarded as New Century Excellent Talents in Universities in China. Prof. Wang's research interest is focused on photoswitches, luminescent materials and functional nanomaterials.

Hai-Feng Yu received his PhD from Tsinghua University in 2003. Then he worked as a researcher at JST-CREST, and then as a postdoc at JSPS at Tokyo Institute of Technology and Kyodo University. In 2008, he started his independent research as Associate Professor by special appointment at Nagaoka University of Technology. In 2012, he joined Peking University as a research professor as the “2011 National Thousand Young Talents Program” recipient. In 2013, he obtained the “NSFC Award” for Excellent Young Scholar. In 2023, he was selected as one of the National high-level leading talents. His research interests focus on photoresponsive soft matter, supramolecular self-assembled materials and organic/inorganic hybrid materials.