3D Printing Hydrogel, Perovskite Technology, and Preparation and Application of Hydrogel Perovskite Composite Materials

Funding: This work was supported by the National Natural Science Foundation of China (52073083) and the Hubei Provincial Natural Science Foundation (2010CDB05805).

ABSTRACT

Flexible electronic materials have received extensive attention and have become a research hotspot in recent years. Three-dimensional (3D) printing technology, with its advantages such as high precision and high efficiency, has become an important choice for manufacturing flexible electronic devices. Through 3D printing technology, flexible materials with complex structures can be manufactured, making them applicable to various fields. Hydrogel–perovskite materials have shown broad prospects in flexible optoelectronic devices and intelligent response systems by combining the flexibility and environmental responsiveness of hydrogels with the efficient photoelectric performance of perovskites. However, their development is confronted with poor interface compatibility, insufficient long-term stability (and difficulties in large-scale preparation), and so on. Current research focuses on the optimization of composite structures, dynamic self-healing mechanisms, and the cross-application of bioenergy. However, how to precisely regulate interfacial chemical bonding to balance flexibility and efficiency, suppress ion migration and toxicity risks, and develop multi-scale in situ characterization techniques remains an unsolved problem. This paper reviews the research progress of 3D-printed hydrogels and 3D-printed perovskite materials technology in recent years, summarizes the preparation of hydrogel–perovskite composites and their applications in optoelectronic devices, sensors, and other fields, and looks forward to the future development of 3D-printed hydrogel–perovskite composites. The aim is to provide insights for the future development and application of 3D-printed hydrogel–perovskite composite technology.

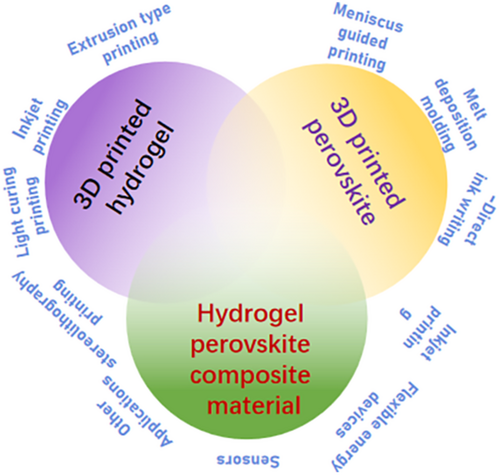

Graphical Abstract

1 Introduction

Flexible electronic devices, characterized by their stretchability, light weight, thinness, and ease of integration [1-4], are gradually transforming the fields of wearable technology, healthcare, and smart textiles [5-7]. With continuous advancements in material science, manufacturing processes, and device integration technologies, the application prospects of flexible electronic devices are becoming increasingly broad. Hydrogels are a class of 3D network materials composed of water and hydrophilic polymer materials. Due to their high water affinity, hydrogels can absorb a large amount of water to form gel-like substances with excellent elasticity and flexibility [8]. As a novel material, hydrogels exhibit significant potential for application in flexible electronic devices, thanks to their superior flexibility, good biocompatibility, intelligent responsiveness, and tunability [9-12], which can enhance device performance and drive the expansion of applications in flexible electronics [13, 14]. 3D printing is a technology that builds 3D objects by adding material layer by layer. 3D printing has shown numerous unique advantages, such as design freedom without assembly, high applicability in various materials including polymers, metals, and composites, and environmental friendliness in terms of materials and processes, which significantly promote its development in the applications of information hiding, soft robotics, sensors and flexible electronics [15]. 3D-printed hydrogels are created by using 3D printing technology to deposit hydrogel materials layer by layer, forming 3D hydrogel structures. This method allows for flexible functional design of hydrogels and combines their flexibility, elasticity, and biocompatibility to precisely produce hydrogels with complex 3D structures and high performance [16, 17].

Perovskite is a material with a specific crystal structure. Its crystal structure is a 3D network formed by a metal cation and two different anions, usually in the ABX3 structure. Here, A represents a larger cation, B is a smaller metal cation, and X is a smaller anion. These components form an interconnected cubic or octahedral network at their vertices [18]. The rich chemical composition and diverse crystal structures of perovskite materials endow them with excellent electrical, optical, and magnetic properties [19-21]. When perovskite thin-film materials are prepared on flexible substrates, they can exhibit outstanding mechanical flexibility and stretchability. Unlike traditional inorganic materials, they do not crack during bending and stretching processes, making them suitable for the fabrication of various flexible electronic devices [22, 23]. Their lightweight nature, high efficiency, adjustable bandgap, and excellent optoelectronic properties have made them highly regarded flexible optoelectronic materials [24-27]. 3D printing offers a manufacturing approach with high design freedom, controllable costs, and strong flexibility and compatibility for the optoelectronic field. For instance, digital light processing (DLP) 3D printing can trigger local photopolymerization by using digital mask projection, thereby manufacturing complex photoelectric material structures and achieving multiple stimulus responses [28, 29]. 3D printing of perovskite materials takes advantage of the unique benefits of additive manufacturing to achieve high degrees of freedom, enabling the production of perovskite thin films with complex shapes and structures that cannot be achieved by traditional manufacturing methods [30]. Combining hydrogels with perovskite materials allows for the utilization of the flexibility of hydrogels and the high-efficiency optoelectronic conversion ability of perovskite to create flexible electronic devices that possess both excellent optoelectronic properties and good mechanical properties and comfort [31]. This combination not only enhances the stability, durability, and versatility of the devices but also opens up new application scenarios. The core advantage of perovskite in hydrogel-based flexible devices lies in the synergistic combination of its outstanding photoelectric properties (such as high light absorption coefficient and adjustable band gap) with the flexibility and environmental responsiveness of hydrogels, which can significantly enhance the efficiency and adaptability of flexible optoelectronic devices (such as wearable sensors and solar cells), while also being compatible with low-cost solution processing techniques. However, its application is limited by the structural damage of perovskite caused by the swelling of hydrogels due to water absorption, microcracks resulting from mechanical mismatch at the interface, the mutual constraints between efficiency and flexibility, as well as the biological toxicity risks of lead-containing perovskite.

This article reviews the research progress of 3D printing hydrogel and perovskite material technologies in recent years, and discusses the advantages and development trends of 3D-printed hydrogel materials and 3D-printed perovskite materials. Meanwhile, it summarizes the preparation of hydrogel–perovskite composite materials in recent years and their applications in the field of flexible optoelectronic devices. The purpose of this review is to provide a foundation for the subsequent preparation of high-performance hydrogel–perovskite flexible optoelectronic devices using 3D printing technology by combining the advantages of 3D printing technology, the characteristics of hydrogels, and the unique optoelectronic properties of perovskite.

2 3D Printing Hydrogel Technology

Compared to traditional processing methods, 3D printing has outstanding advantages such as simple operation procedures, precise structural control, and high cost-effectiveness. It can directly obtain macroscopic 3D structural products from pre-designed 3D digital models [32]. Polymer-based 3D printing structures have the merits of being lightweight, highly flexible, biocompatible, and sensitive to external stimuli, endowing them with shape or property changes over time [15]. By using layer-by-layer printing, it can ingeniously design 3D structural hydrogels for different functional applications separately. So far, 3D-printed hydrogels are expected to approach mainstream adoption [33]. At present, the main 3D printing hydrogel technologies include extrusion-based printing, inkjet printing, photocuring printing, and stereolithography (SLA) printing [34-37].

2.1 Extrusion Type Printing

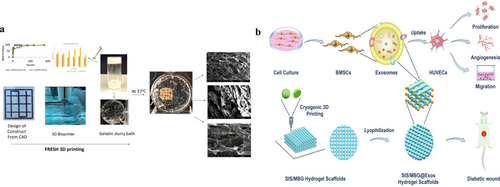

Extrusion molding 3D printing hydrogel technology is an additive manufacturing method that builds 3D structures by precisely controlling the extrusion-curing process of viscoelastic hydrogel precursors. The core principle is based on the shear-thinning characteristics of hydrogel materials. When subjected to shear force in the nozzle, the viscosity decreases, facilitating extrusion. After extrusion, it quickly returns to high viscosity to maintain the structural shape, and in situ curing is achieved through mechanisms such as temperature control and ion cross-linking. It is suitable for high-viscosity hydrogels and can print large-sized and complex structures, and is often used in the manufacture of tissue engineering scaffolds. Wassif et al. [38] employed the freeform reversible embedding of hydrogels (FRESH) printing technology to prepare a composite thermosensitive hydrogel loaded with zoledronic acid. This hydrogel is composed of chitosan, sodium alginate (SA), and hydroxyapatite, and its flow behavior exhibits pseudoplastic flow, following the non-Newtonian fluid flow pattern. The scaffolds with and without hydroxyapatite achieved nearly 100% release of zoledronic acid within 360 and 48 h, respectively, showing good biocompatibility (Figure 1a). Li et al. [39] used amino-terminated Pluronic F127 (AOP127) and oxidized dextran (ODex) as materials to develop a double-crosslinked hydrogel based on dynamic oxime cross-linking and hydrophobic interactions for direct extrusion printing. At a lower temperature (about 16°C), AOP127 and ODex combine with oxime to form a hydrogel. At a higher temperature (37°C), the PPO segments of AOP127 physically bind to form a second cross-linking, toughening the hydrogel. This hydrogel has excellent thermosensitivity and self-healing properties, as well as high toughness and excellent cell compatibility, and can be used as a tough scaffold material. Zhang et al. [40] developed a novel self-healing pre-crosslinked hydrogel microparticle (pcH MPS) using a mixture of chitosan methacrylate (CHMA) and polyvinyl alcohol (PVA) hydrogel as the material and applied it as bio-ink for high-fidelity and biocompatible scaffold extrusion 3D printing. When pcH mu Ps is injected through a syringe, it shows excellent shear thinning and then self-heals into a gel as the shear force is eliminated. A series of bionic structures with high aspect ratios and fine structures were directly printed using pcH-mu-P ink. 3D-printed scaffolds support the growth of bone marrow mesenchymal stem cells (BMSCs) and the formation of cell spheres. Huang et al. [41] utilized bacterial cellulose nanofibers (BCNFs) to enhance the structural resolution and mechanical properties of silk fibroin (SF)/gelatin composite hydrogel scaffolds. SF-based hydrogel scaffolds with stratified pores were fabricated by 3D printing and freeze-drying. Macroporous and microporous scaffolds were fabricated by designing and printing patterns and freeze-drying after extrusion. The 10–20 μm pores inside the printed filaments serve as hosts for cell infiltration, while the 300–600 μm pores surrounded by the printed filaments ensure an adequate supply of nutrients, presenting promising prospects for further tissue engineering applications. Dong et al. [42] used extrusion 3D printing to develop a nanocomposite hydrogel composed of a high-solid-content Laponite suspension and gelatin methacrylamide (GelMA). This hydrogel shows good printability and cell compatibility under mild conditions. The GelMA/Laponite hydrogel significantly promotes the proliferation and osteogenic differentiation of BMSCs, and has good rheological properties, degradation stability, and mechanical strength. Hu et al. [43] used extrusion-based cryogenic 3D printing technology to construct acellular small intestinal submucosa (SIS), combined with mesoporous bioactive glass (MBG) and exosomes to fabricate a 3D hydrogel scaffold bandage (SIS/MBG@Exos). This hydrogel scaffold has a good 3D structure, appropriate porosity, biocompatibility, and hemostatic ability, and can promote the proliferation, migration, and angiogenesis of human umbilical vein endothelial cells (Figure 1b). Li et al. [44] prepared a macroporous hydrogel scaffold using extrusion cryogenic 3D printing technology through horseradish peroxidase (HRP)-mediated cross-linking of SF and tyramine-substituted gelatin (GT). This hydrogel has excellent structural stability, appropriate mechanical properties, and an adjustable degradation rate. By combining 3D printing technology and the cell aggregate seeding strategy, they developed an SF-GT hydrogel scaffold with a macroscopic pore structure for cartilage regeneration. Liu et al. [45] developed a protein-rich gelatin/SA-based hydrogel prepared from gelatin, SA, and soy protein/soy peptide powder. Through 3D printing technology, they prepared a composite hydrogel scaffold with macroscopic pores. The hydrogel scaffold containing soy protein and soy peptide powder can promote cell adhesion, spreading, migration, and proliferation, and this scaffold can promote the growth of new blood vessels within the scaffold. Qiu et al. [46] driven by the attraction function of starch, selected oxidized corn starch (OMS) and used thermal extrusion 3D printing technology (HE-3DP) to construct the corresponding hydrogel (3D-OMS). The formation of a porous structure in the HE-3DP environment contributes to the rapid water absorption and good water retention capacity of 3D-OMS. When the OMS concentration increases from 11% to 19%, 3D-OMS shows good hydration properties, and its maximum water absorption rate and water retention capacity reach 3013.43% (11-OMS) and 93.53% (19-OMS), respectively. In addition, 3D-OMS also exhibits good biodegradability and cell compatibility. Jadhav et al. [47] used UV-assisted semi-solid extrusion 3D printing technology. In the presence of polyethylene glycol diacrylate (PEGDA), they used UV light to photocrosslink the hydrogel matrix to prepare a hydrogel with a high-surface-area network structure. This hydrogel shows good antibacterial activity against both Staphylococcus aureus (S. aureus) and Escherichia coli (E. coli). In vitro drug release experiments show that the drug release kinetics conform to the Korsmeyer–Peppas model, indicating that the drug release mechanism is Fickian diffusion. This hydrogel can not only promote wound healing but also effectively prevent bacterial infections, providing a new solution for wound treatment. Dong et al. [48] used metal supramolecular gel extrusion 3D printing technology to design tough hydrogel soft robots with different response characteristics. Due to the excellent mechanical properties and small diameter of the gel fibers, the printed hydrogel robots have high robustness, fast response, and agile movement under the remote control of dynamic light. They have flexible multi-gait movement and task execution ability under dynamic light stimulation, and also have good mechanical properties.

The advantages of extrusion-based 3D printing of hydrogels lie in their ability to use a variety of biocompatible hydrogel materials, support cell loading, and require no complex post-processing steps, making it suitable for personalized medicine and tissue engineering applications. However, this technology also has some drawbacks. For example, the printing resolution is relatively low, making it difficult to achieve fine structures at the micron scale. The printing speed is slow, especially for high-precision biological scaffolds. In addition, the rheological properties of hydrogels require precise control; otherwise, material clogging or structural deformation may occur during the printing process.

2.2 Inkjet Printing

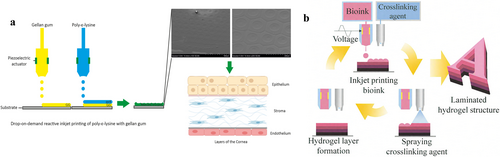

Inkjet printing 3D printing hydrogel technology is a high-precision additive manufacturing method based on micro-droplet jetting. Its core principle is to discretize a hydrogel precursor solution with moderate viscosity into micro-droplets through hot air bubbles or piezoelectric drive and jet them as needed, which then stack layer by layer on the substrate surface to form a 3D structure and fuse with each other. This technology utilizes the shear-thinning characteristics of hydrogels to achieve stable jetting at high shear rates and rapid recovery after deposition, and realizes immediate curing through mechanisms such as temperature-sensitive phase transition, ion cross-linking, or photopolymerization. It can achieve high-precision printing and has low requirements for material viscosity. Duffy et al. [49] used reactive inkjet printing to fabricate polymer hydrogels based on natural polypeptides, poly-ε-lysine, and gellan gum. Based on the ionic bonds that form immediately between polymers with opposite charges, alternating printing of different ink layers can create unique surface patterns presenting a honeycomb-like repeating structure (Figure 2a). The printed hydrogel structure can be modified to contain pores and has 80% transparency, showing good cell compatibility with corneal epithelial cells and endothelial cells. Chen et al. [50] designed conductive SA/graphene/carbon nanotube (SGC) ink and achieved high-resolution, multi-functional 3D graphene hydrogel flexible circuits through inkjet 3D printing technology. The addition of graphene oxide, SWCNTs, and Ca2+ endows SGC with excellent electrical conductivity and flame retardancy. The electrical conductivity of SGC reaches 24.11 S/m, which is three times that of SA hydrogel, and its LOI is above 99.7%. Wei et al. [51] used direct inkjet printing (DIW) technology to integrate fumed silica as a rheological modifier into a crosslinked polyvinyl alcohol/polyacrylamide (PVA/PAAm) network to prepare chemically and physically crosslinked 3D structure hydrogels. The porous structure of the hydrogel provides a conductive network for Ca2+ migration. As the concentration of CaCl2 increases, the electrical conductivity improves. This hydrogel has good electrical conductivity and strain sensitivity. The assembled sensor has cyclic stability and accurate recognition ability in detecting mechanical deformation and human body movements. Wan et al. [52] constructed a fluorescent nanosystem for cell imaging and drug delivery based on polyethyleneimine (PEI) and HAP functionalized with riboflavin sodium phosphate (HE) (HAP-HE@PEI). Printing HAP-HE@PEI as 3D inkjet printing ink together with GelMA hydrogel, this hydrogel composite shows good biocompatibility for 3D cell culture of RAW 264.7 macrophages. Jiao et al. [53] prepared a double-crosslinked ink by optimizing the rheological properties of sodium alginate (NaAlg), NaAlg/transglutaminase (TG), calcium chloride (CaCl2), and gelatin/CaCl2 solutions. They prepared SA/gelatin hydrogels through inkjet printing. By increasing the gelatin content, the compressive modulus of the hydrogel can be adjusted from 19.2 ± 1.2 to 65.9 ± 3.3 kPa. After 7 days of cultivation, fibroblasts infiltrated all the printed hydrogels, and as the gelatin content increased, the cell proliferation rate increased, with the highest cell proliferation rate reaching 497%. Cheng et al. [54] developed a multi-jet method to deliver SA and calcium ions together through separate nozzles to create hydrogel patterns on a gypsum powder bed. To further enhance the mechanical properties, Zr4+ cations were used to produce highly crosslinked alginic acid hydrogels with high viscosity. The printed samples showed the best bending strength, reaching 8.7 MPa. The printed green samples had good wear resistance, with a pencil hardness of 6H and a Shore D hardness of 43.5 HD, exceeding that of ordinary chalk (1H and 30 HD). In addition, the printed samples exhibited excellent water resistance and remained intact without deformation after 4 h of ultrasonic treatment. Yoon et al. [55] developed a novel inkjet spray printing process by combining a high-resolution DOD inkjet printer and a fine mist spray gun. They prepared hydrogel structures of different shapes composed of various materials such as alginate, cellulose nanofibers, and fibrinogen through inkjet printing technology. The results showed that the inkjet printing system can quickly and reliably form cell-laden hydrogel structures with high shape fidelity (Figure 2b). This printing method overcomes the resolution, size, and speed limitations of previous scaffold-free inkjet printing processes and can quickly and reliably form cell-laden hydrogel structures with high shape fidelity. Clark et al. [56] used a piezoelectric-driven inkjet technology to 3D print ropinirole hydrochloride. The produced tablets consisted of a crosslinked PEGDA hydrogel matrix containing the drug, and the cross-linking was carried out by photoinitiation in a low-oxygen environment using an aqueous solution of Irgacure 2959. When the loading amount of ropinirole hydrochloride was 0.41 mg, the drug release in the tablets exhibited a Fickian diffusion mechanism. Raman spectroscopy and infrared spectroscopy indicated a high degree of cross-linking and the formation of an amorphous solid dispersion. Teo et al. [57] utilized micro-reaction inkjet printing technology (MRIJP) to fabricate various two-dimensional and 3D structures of PEDOT:PSS/IL hydrogels through the aerial merging of PEDOT:PSS and ionic liquid (IL). The diameter of a single droplet of PEDOT:PSS/IL hydrogel was approximately 260 μm. Based on MRIJP, PEDOT:PSS/IL has the potential for free-form patterning while maintaining the same performance as that fabricated by the traditional spin-coating method. Through the controlled deposition achieved by MRIJP, PEDOT:PSS/IL can be transformed into different 3D structures without the need for molding.

The advantages of inkjet 3D printing of hydrogels lie in its ability to print rapidly, support a variety of biocompatible materials, and precisely control cell distribution, making it suitable for tissue engineering and drug delivery applications. However, the shortcomings of this technology are that it has strict requirements for the rheological properties of materials. It requires low-viscosity hydrogels to ensure smooth inkjetting, which may limit the range of material selection.

2.3 Light-Curing Printing

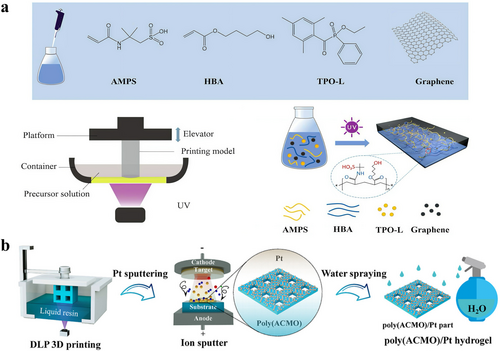

Light-curing 3D printing hydrogel technology is an additive manufacturing method based on photosensitive polymerization. Its core principle is to selectively irradiate the hydrogel precursor solution containing photoinitiators with ultraviolet or visible light, and under the photochemical reaction, initiate the cross-linking polymerization of monomers to achieve the layer-by-layer curing and shaping of the hydrogel structure. This technology utilizes DLP or laser scanning (SLA) systems to slice 3D models into two-dimensional patterns. By controlling the spot path through a photomask or galvanometer, the liquid resin undergoes photo-curing reactions in specific areas, while the unexposed areas remain liquid and can be rinsed away. It has high precision and fast forming speed and can manufacture fine and complex structures. Tang et al. [58] added the photosensitive component PEGDA to the nanocellulose aqueous dispersion system to make the nanocellulose photosensitive and used the additive manufacturing method of photocuring nanocellulose to prepare nanocellulose/PEGDA hydrogels. The prepared nanocellulose/PEGDA hydrogels have a uniform shape and controllable structure. Nanocellulose supports the scaffold structure in the hydrogel. The maximum compressive modulus of the nanocellulose/PEGDA hydrogel is 0.91 MPa, and the photocuring time is 40 s. Yan et al. [59] used DLP 3D printing technology to quickly construct a double-network (DN) ion-conductive hydrogel and designed and printed a fingerprint-like microstructure hydrogel (MH) film to manufacture an ionic pressure sensor. This DN hydrogel forms a covalent cross-linking network composed of acrylamide/acrylic acid and introduces magnesium chloride to form an ionic cross-linking physical network in the hydrogel. The printability (resolution of 150 μm) and the adjustability of the mechanical properties of the DN hydrogel make the manufacture of the sensor very convenient. This ionic pressure sensor not only has high sensitivity (0.06 kPa−1) but also has a large detection range (26 Pa–70 kPa) and good stability (200 pressure loading cycles). Wang et al. [60] prepared printable ion-conductive hydrogels by introducing 2-acrylamido-2-methylpropanesulfonic acid (AMPS), 4-hydroxybutyl acrylate (HBA), and graphene and prepared stretchable, highly conductive, and self-adhesive ionic hydrogels based on LCD photocuring 3D printing technology (Figure 3a). The hydrogel has excellent electrical conductivity (0.0487 S/cm), excellent linear sensitivity (GF = 1.86 at 100% strain), amazing stretchability (1200% strain), and strong adhesion properties to various materials. The flexible wearable device based on this hydrogel can monitor various human movements from the micro scale to the macro scale. Guo et al. [61] designed a conductive and degradable hydrogel for epidermal strain sensors based on DLP 3D printing technology. They developed a three-step strategy of ultraviolet curing, ion sputtering, and water spraying, effectively reducing the complexity and difficulty of preparing electronic-based hydrogels (Figure 3b), and used a monofunctional resin curing system to endow the hydrogel with good degradability. Wong et al. [62] adopted an unconventional but universal triplet-triplet annihilation upconversion (TTA-UC) multi-exciton process for curing opaque hydrogel composites produced by direct ink writing (DIW) 3D printing. TTA-UC converts low-energy red light (λmax = 660 nm) into high-energy blue light, thereby initiating free radical polymerization within opaque objects. The TTA-UC technology achieves uniform curing of opaque hydrogel composites through low-energy red light, solving the limitations of traditional photocuring technology in thick or opaque materials. Han et al. [63] reported a rapid multi-material projection micro-SLA technology that uses the dynamic fluid control of multiple liquid photopolymers in an integrated fluid cell. They printed a multi-responsive hydrogel microstructure using thermoresponsive hydrogels and electroactive hydrogels. This structure can exhibit different swelling-driven modes under various external stimuli and has the ability to quickly and heterogeneously integrate multiple functional materials at the microscale. Shen et al. [64] simply synthesized the CHI-MA precursor by grafting chitosan molecular chains with methacryloyl groups and printed complex 3D hydrogel structures through DIP technology. When using CHI-MA with a high DS (33.6%), a 150-μm-thick hydrogel layer can be cured in a short time, and the printed hydrogel has high resolution, high fidelity, and good biocompatibility. Zhang et al. [65] used photocuring 3D printing technology to print a PEGDA grid scaffold and then filled the PEGDA grid scaffold with a low-concentration GelMA/SA hydrogel containing chondrocytes to obtain a cell-filled hydrogel with excellent biocompatibility. Compared to the scaffold obtained using a single hydrogel, the combination of two different hydrogels can produce a cartilage scaffold with good mechanical properties and strong biocompatibility. Liu et al. [66] used DLP technology and customized liquid crystal LC ink to print an innovative hydrogel scaffold with a liquid crystal state and viscoelasticity similar to bone-like tissue. By using these liquid crystal scaffolds as 3D research models, it was found that the liquid crystal state exposes accessible arginine-glycine-aspartic acid (RGD) motifs by promoting high-density protein aggregation, thereby triggering cell–protein interactions and osteogenic differentiation; while viscoelasticity plays a role through the mechanical transduction pathway. The synergistic effect between the liquid crystal state and viscoelasticity enhances the cell–protein interaction and osteogenic mechanical transduction processes.

The advantages of 3D light-curing printing hydrogel technology lie in its ability to manufacture hydrogel structures with high resolution and fine features, making it suitable for tissue engineering and biomedical applications. In addition, the photocuring technology can achieve rapid printing and improve production efficiency. However, the shortcomings of this technology are that it requires the use of specific photosensitive hydrogel materials, which may be costly and have a limited selection range. Moreover, problems such as light scattering and oxygen inhibition may occur during the photocuring process, affecting the printing quality and accuracy.

2.4 SLA Printing

SLA 3D printing hydrogel technology is a high-precision additive manufacturing method based on photosensitive polymerization. Its core principle is to selectively scan and irradiate the hydrogel precursor solution containing photoinitiators through ultraviolet laser beams or projected light patterns, and trigger the cross-linking and curing of monomers under photochemical reactions, gradually accumulating to form 3D structures layer by layer. This technology employs a top-down or bottom-up optical path system. It uses a galvanometer to control laser focusing scanning (point scanning type) or DLP to project the entire layer pattern (surface projection type), precisely initiating photopolymerization reactions on the surface of liquid resin. The curing thickness of each layer can be precisely regulated to 10–100 μm. The uncured part is separated by the lifting platform and remains in liquid form or is washed away. It has the ability to support complex suspended structures. It can achieve sub-micron resolution and can manufacture complex and fine 3D structures. Zhang et al. [69] utilized the SLA high-resolution 3D printing technology of PEGDA (molecular weight 700) to manufacture diffusion-open and mechanically stable hydrogel constructs as self-sealing chips. The integration of multiple independent and perfusable channel systems with stable structures further allows for the easy combination of different volume materials at precise relative spatial positions. By embedding a highly compliant cell-laden gelatin hydrogel within the defined range of a 3D-printed PEGDA hydrogel chip with intermediate compliance, complex 3D constructs containing a microfluidic perfusion network were fabricated. Muralidharan et al. [67] printed PEGDA structures with specific cross-linking densities through SLA and then filled the printed structures with soft hydrogel materials. By controlling the cross-linking density of PEGDA, the pore size can be adjusted, thereby controlling the diffusion and integration of the soft hydrogel (Figure 4a). Through the SLA technology, the integration area between the two materials can be precisely controlled, reducing the risk of interfacial stress and mechanical failure and solving the problem of material property mismatch in composite materials. Sun et al. [70] used SLA 3D printing to manufacture hydrogels with high mechanical tunability and self-welding properties. First, hard dry gels were printed, and then through post-processing, they were converted into soft hydrogels after hydration and ionic coordination. This method decouples the printability of the hydrogel precursor from the final properties of the hydrogel. By adjusting the chemical composition and ionic source, the printed hydrogels exhibit high mechanical property tunability. Compared to traditional, directly printed hydrogels, the hydrogels printed by this method have ultra-soft 3D structures and show ultra-high stretchability, ion-sensitive gel–sol transitions, and excellent self-welding properties. Taebnia et al. [71] used SLA 3D printing technology to manufacture biocompatible hydrogel substrates with villus-like microcolumn arrays of adjustable sizes. These microcolumn arrays are composed of PEGDAs. The results show that the 3D-printed hydrogel microstructures can support up to 1 month of cultivation and can induce apical-basal polarization of the Caco-2 epithelial cell layer along the villus axis, forming a microenvironment similar to the native intestinal one. Kim et al. [72] used SLA to print cell-compatible hydrogel structures composed of PEGDA, a UV initiator, and a photosensitizer and used them as 3D microfluidic cell culture chips. The culture chip is transparent and can be used for cell culture and observing cell proliferation. This method reduces the manufacturing steps and time, avoids any assembly and bonding, and saves manufacturing costs. Huang et al. [68] used MXene as a multifunctional light-blocking agent in photocuring aqueous inks and manufactured hydrogels with fine geometries through the continuous liquid interface production (CLIP) technology (Figure 4b). The organogels printed by CLIP show potential in atmospheric water collection, and the CLIP-printed hollow organogels show higher efficiency due to their larger surface area. Valentin et al. [73] used noncovalent (ionic) cross-linking SLA technology to print hydrogels, which makes reversible patterning and controllable degradation possible. The combination of SA, a photoacid generator, and various divalent cation salts can be used to regulate the degradation kinetics, pattern fidelity, and mechanical properties of the hydrogels. This light-based 3D printing technology using noncovalent cross-linking enables the production of adaptable and stimulus-responsive biomaterials. Hsiao et al. [74] composed a thermoresponsive ink with poly(dimethylsiloxane) in an aqueous phase of sodium dodecyl sulfate and the cross-linking agent polyethylene glycol dimethacrylate and printed hydrogels through SLA 3D printing. Due to the rapid structural recovery of the nanoemulsion after yielding under large strain and its shear-thinning behavior, the control of the hydrogel microstructure can be achieved.

The advantages of SLA 3D printing hydrogel technology lie in its ability to manufacture hydrogel structures with high resolution and fine features, making it suitable for tissue engineering and biomedical applications. In addition, the SLA technology can achieve rapid printing, improve production efficiency, and is capable of manufacturing structures with complex geometric shapes, such as hollow structures and lattice designs. However, the shortcomings of this technology are that it requires the use of specific photosensitive hydrogel materials, which may be costly and have a limited selection range. Moreover, problems such as light scattering and oxygen inhibition may occur during the photocuring process, affecting the printing quality and accuracy.

3 3D Printing Perovskite Technology

In recent years, remarkable progress has been made in 3D printing perovskite technology, primarily focusing on aspects such as material preparation, printing process optimization, and application expansion. Through 3D printing technology, the structure and morphology of perovskite materials can be precisely controlled, achieving a uniform distribution of perovskite thin. With 3D printing technology, perovskite nanocrystals can be mixed with transparent ultraviolet-curable resin to create a color conversion layer capable of transforming ultraviolet light into various colors [75]. The 3D printing perovskite technologies include meniscus-guided printing technology, fused deposition modeling (FDM), DIW, inkjet printing technology, and so on [76-79].

3.1 Meniscus-Guided Printing

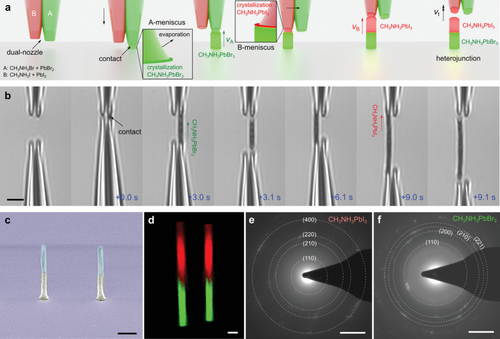

Meniscus-guided printing hinges on the interplay of capillary forces and surface tension, establishing a stable liquid meniscus at the interface between the solution and the substrate. Through meticulous regulation of parameters such as the velocity of the print head, the concentration of the printing solution, and the temperature of the substrate, precise control over the morphology and thickness of the film can be achieved. In recent years, this technique has found applications in the printing of perovskite films and structures, demonstrating substantial potential within the realm of flexible electronic devices. Chen et al. [80] employed a 3D printing approach to fabricate self-standing metal halide perovskite nanowire heterostructures with highly precise shape and composition control. A dual-tube nanopipette was utilized as the printing nozzle. The evaporation-driven perovskite crystallization, guided by the femtoliter-scale precursor meniscus formed on the printing nozzle, enabled the “one-step” fabrication of heterostructures within a matter of seconds. These 3D-printed perovskite nanowire heterojunctions exhibit multiple emission colors and outstanding optical properties, facilitating programmable color mixing and encryption at the single-nanopixel scale (Figure 5). Chen et al. [81] harnessed the femtoliter-sized ink meniscus formed on a nanopipette to direct the evaporation-induced perovskite crystallization in the air, thereby generating self-standing 3D perovskite nanostructures with preferential crystal orientations. By manipulating the stretching of the ink meniscus during the stretching process, the diameter and hollowness of the nanostructures can be modulated, enabling the transition from tubular to solid forms. Through altering the pulling direction, the programmed layer-by-layer stacking of perovskite nanostructures in the designated shape and position was successfully demonstrated. A blade-coating method with precisely controlled stick-slip motion was adopted, where the periodically decomposed lateral 3D meniscus facilitated the uniform and oriented growth of highly crystalline CsPbI3 nanowires without the requirement of a template. Kim et al. [76] accomplished laterally confined oriented nanocrystal growth by controlling the stick-slip motion, resulting in well-ordered nanowire arrays. This method allows for the oriented growth of nanowires without relying on a template, merely through the control of simple processing variables. It offers the advantages of rapid and large-scale synthesis. Chen et al. [82] created a femtoliter-sized ink meniscus via the contact between a pipette and the substrate. Subsequently, the rapid evaporation of the solvent instigated perovskite crystallization, leading to the formation of CH3NH3PbI3 crystals. By adjusting the moving speed of the pipette, the height of the nanopixels can be regulated. The meniscus formed by the femtoliter-sized ink steers the highly confined, vertically oriented crystallization process, yielding 3D perovskite nanopixels. This method can significantly enhance the luminescence brightness by increasing the pixel height without compromising the lateral resolution. Li et al. [83] incorporated siloxanes of varying molecular weights as additives. These siloxanes, upon cross-linking, form a 3D network structure, which effectively immobilizes the solute, thereby reducing solute migration. The silicon within the siloxanes can interact with the metal oxide in the substrate, creating nucleation sites that promote crystallization at the base of the perovskite film. Through the precise control of the meniscus movement speed and the solution evaporation rate, uniform crystallization of the perovskite film was attained, minimizing the number of grain boundaries and enhancing the film's crystallization quality.

3.2 Melt Deposition Molding

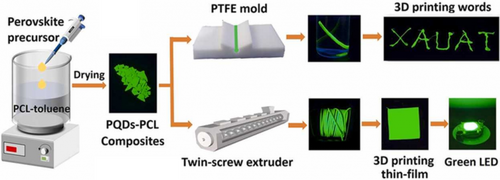

FDM technology creates 3D structures of perovskite composite materials by compounding perovskite with polymers and then extruding the molten composite filaments through a heated nozzle. Tang et al. [84] prepared PQDs-CL composites by in situ formation of perovskite quantum dots (PQDs) in a polycaprolactone (PCL) matrix. The perovskite precursor solution was dropped into the PCL-toluene system to achieve uniform dispersion of PQDs within the PCL matrix. The PQD-CL composite materials were further processed into fluorescent filaments through FDM. By combining the 3D-printed MAPbBr3 PQD-CL film with an ultraviolet LED chip, and by combining the MAPbBr3 PQD-CL film with K2SiF6:Mn4+ phosphor on a blue LED chip, green LED and white LED devices were realized (Figure 6).

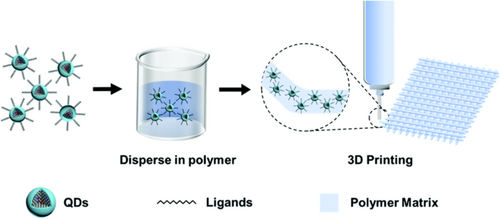

3.3 DIW

DIW 3D printing technology constructs 3D structures by precisely controlling the movement of the nozzle and the extrusion of perovskite ink, depositing materials layer by layer. This technique involves preparing a perovskite precursor solution and adding rheological modifiers to optimize printing performance. A perovskite film is formed through layer-by-layer deposition and drying for solidification, and finally, posttreatment steps such as annealing are carried out to improve the crystallization quality and optoelectronic properties of the material. Xu et al. [85] dispersed PQDs in a polymer gel with optimal viscosity and uniform dispersion (Figure 7). Through DIW 3D printing, the PQD-polymer gel was printed into large-scale one-dimensional, two-dimensional, and hierarchical superstructures. This achieved the stable dispersion of highly luminescent quantum dots in the polymer matrix and the fabrication of its multifunctional 3D-printed framework superstructures, which effectively maintained the inherent properties of the polymer. In the solid polymer superstructure, the photoluminescence of the quantum dots remained stable enough within 2 years with little performance loss. Jeon et al. [86] used an ink composed of pre-fabricated PQDs and hydroxypropyl cellulose (HPC) in dichloromethane (DCM) to directly and efficiently prepare PQD-encapsulated high-performance 3D composite structures (PQD-HPCs) through DIW. By adjusting the ratio of perovskite halides, photoluminescence with different monochromatic peaks was achieved. Optimizing the printing parameters of DIW enabled the precise manufacturing of programmed and complex PQD-PC 3D architectures. Wang et al. [87] formulated an ink composed of polyvinylpyrrolidone and dimethyl sulfoxide, which had effective printability and shape fidelity. By adjusting the viscosity of the ink and using DIW printing technology, continuous and uniform perovskite film printing was realized. The film thickness was increased by repeating the DIW printing and thermal annealing processes. This method enabled the printing of high-quality thick perovskite films, breaking through the performance limitations of traditional polycrystalline perovskite films. Moreover, the TFT-integrated XFPD fabricated by DIW technology exhibited the advantages of high resolution and a low dead-pixel rate in practical digital radiography.

3.4 Inkjet Printing

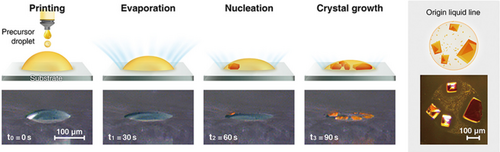

Inkjet printing is a technology that sprays perovskite precursor solutions onto a substrate. Through solvent evaporation and crystal growth, a 3D perovskite structure with specific optoelectronic properties is formed by layer-by-layer deposition. This method combines the high resolution of inkjet printing with the excellent optoelectronic properties of perovskite materials. Schackmar et al. [88] prepared perovskite solar cells based on fully inkjet-printed absorption and extraction layers, achieving scalable and material-efficient deposition. The inkjet-printed PSCs adopt a pi-structure, including a precursor-based nickel oxide hole-transport layer, a high-quality perovskite absorption layer, and a double-layer electron-transport layer. PSCs with such inkjet-printed absorption and charge-carrier extraction layers have achieved an efficiency of over 17% with low hysteresis. Mescher et al. [89] used inkjet printing technology, which is material-efficient, contact-free, and compatible with high-throughput roll-to-roll manufacturing, to prepare triple-cation perovskite films and fabricate X-ray detectors with a pi-structure on flexible substrates. This provides a new manufacturing method for high-performance flexible direct-conversion X-ray detectors through cost-effective digital inkjet printing technology. Peng et al. [90] established a dual-nozzle inkjet printing method to directly mix perovskite precursors and anti-solvents for preparing perovskite single-crystal patterns (Figure 8). An edge-deposition strategy was adopted to minimize the contact area between droplets and effectively control the nucleation position of crystal growth. This not only avoids the coffee-ring effect of perovskite crystals but also enables the direct patterning of single-crystal perovskite. Moreover, this technology can also be used for the preparation of 3D perovskite single crystals. Chen et al. [91] employed a novel electrohydrodynamic (EHD) inkjet printing technology to fabricate 3D perovskite nanocrystal (PeNCs) arrays. By preparing a PeNCs@PS colloidal ink consisting of pre-synthesized PeNCs, the polymer polystyrene (PS), and the nonpolar solvent xylene, this ink enables precise control of the size and shape of the arrays through EHD inkjet printing technology, thus achieving the construction of on-demand micropillar structures. The presence of PS transforms the printed structures from two-dimensional micropillars to 3D ones. Liu et al. [92] mixed PQDs with photocurable precursors to prepare an ink suitable for inkjet printing. Inkjet printing technology combined with in situ photopolymerization was used to manufacture PQD microarrays. By adjusting the UV-curable precursors and the surface-functionalized substrate, the shape of the microarrays can be precisely controlled. The fabricated PQD microarrays exhibit a 3D hemispherical morphology and strong photoluminescence properties.

The 3D printing perovskite technology combines the excellent optoelectronic properties of perovskite materials with the advantages of 3D printing, such as high precision, low cost, and customizability, enabling the manufacturing of high-efficiency and low-energy-consumption flexible electronic devices and optoelectronic devices. Its merits lie in its ability to meet the manufacturing requirements for a variety of complex geometric structures and its scalability for large-area production. The 3D printing perovskite technology is expected to drive the widespread application of next-generation flexible electronics and optoelectronic devices, and contribute to the development of green energy and intelligent technologies. The material stability challenges in perovskite 3D printing primarily stem from environmental factors such as water, oxygen, and temperature. Water molecules induce hydrolysis reactions that degrade the perovskite lattice (e.g., MAPbI3 decomposes into PbI2 and HI), resulting in lead ion leakage and diminished photoelectric performance. Oxygen facilitates the oxidation of iodide ions, forming inactive phases like I2, which exacerbates structural degradation. Additionally, temperature sensitivity poses a significant issue, as high printing temperatures (e.g., during extrusion or annealing) can thermally decompose perovskites. To mitigate these challenges, current strategies encompass material modification (e.g., incorporating hydrophobic additives or antioxidants), process optimization (e.g., printing under inert atmospheres and low-temperature/light-induced crystallization), and structural design (e.g., in situ encapsulation and gradient protective layers). Furthermore, the development of lead-free perovskites is being pursued to enhance environmental robustness.

4 Hydrogel Perovskite Composite Material and Its Application

Hydrogel–perovskite composites integrate the flexibility, stretchability, and biocompatibility of hydrogels with the excellent optoelectronic properties and high optoelectronic conversion efficiency of perovskite materials. This innovative material combines mechanical flexibility with functional characteristics, holding great promise for applications in areas such as flexible optoelectronic devices and sensors [93, 94].

4.1 Flexible Energy Devices

Hydrogel–perovskite composites find extensive applications in the field of flexible optoelectronic devices. Their flexibility and stretchability make them suitable for devices such as flexible solar cells, photodetectors, and wearable displays. The water-retaining property and biocompatibility of hydrogels can significantly enhance the environmental stability of perovskite. Meanwhile, their transparency and self-healing ability support the durability and functionality of the devices. The high optoelectronic conversion efficiency of perovskite materials endows the composites with excellent optoelectronic properties, laying an important foundation for the development of efficient, flexible, and environmentally friendly optoelectronic devices. Chen et al. [95] synthesized modified LaMnO3 (MLMO) perovskite with a porous tubular skeleton structure using the typical sol-gel method and integrated it into a DN hydrogel, enabling the uniform dispersion of MLMO perovskite in the polyacrylamide (PAM)/PVA matrix. The elongation at break of the composite hydrogel exceeded 440%, and the composite hydrogel electrode exhibited excellent capacitive properties, including a high specific capacitance per unit weight (392 F g−1 at 1 A/g) and outstanding cycling stability. Flavell et al. [96] used peptide hydrogels to passivate the defect sites of methylammonium lead iodide and improve its stability. The results showed that peptide hydrogels could enhance the stability and optical properties of MAPI films by passivating defect sites and controlling particle size. Moreover, the addition of peptides improved the power conversion efficiency (PCE) and stability of PSCs. After storage at 35% relative humidity for 480 h, it retained 81% of its optimal efficiency. Xin et al. [97] designed and constructed a biomimetic intelligent photovoltaic window (SPW) by integrating hydrogels, CsPbBr3 semi-transparent perovskite solar cells (ST-PSCs), and transparent polymer films. Through the optimization of the perovskite film and the ultra-thin metal electrode, the highest photovoltaic efficiency (8.35%) and a record-breaking light utilization efficiency (4.43%) were achieved, along with remarkable cycling stability. Meng et al. [98] combined perovskite solar cells and hydrogels to prepare a building-integrated photovoltaic (BIPV) intelligent window with functions of energy modulation, energy generation, and low emissivity. Its average visible light transmittance was 27.3% and 10.4% at temperatures above 20°C and 40°C, respectively, with an energy modulation (T-sol) of 15.7%. Its peak conversion efficiency was 17.5%, and the emissivity was as low as 0.31. Harputlu et al. [99] prepared a ternary composite, LaFeO3/g-C3N4@reduced graphene oxide (GH) 3D nanostructured supercapacitor, using lanthanum ferrite (LaFeO3) perovskite, graphite carbon nitride (g-C3N4), and reduced graphene oxide-based hydrogel (GH). The LaFeO3/g-C3N4@GH electrode achieved a high specific capacitance of 652.12 F/g at a scanning rate of 5 mV/s and only lost 11.8% of its specific capacitance after 2000 cycles, demonstrating excellent cycling stability. Gao et al. [100] prepared Mg-doped BaTiO3 (barium titanate) particles via a hydrothermal method and dispersed them into a gelatin hydrogel elastomer to prepare an electro-responsive material. By controlling the pH value of the synthesis system, Mg-doped BaTiO3 particles with different morphologies were successfully prepared. In the gelatin hydrogel elastomer, the electro-responsive properties of Mg-doped BaTiO3 particles were enhanced with the variation of particle morphologies. Pan et al. [101] regulated the nanosheet network structure and oxygen defects of BiFeO3 through V-doping and electrochemical induction without annealing. A flexible asymmetric micro-supercapacitor using the prepared c-BiFe0.95V0.05O3 as the anode and PPyHG (polypyrrole hydrogel) as the cathode could provide an extremely wide voltage window of 2.3 V and a high areal energy density of 7.33 μWh cm−2 at a power density of 63.7 μW cm−2. Zhao et al. [102] utilized poly-(2-hydroxyethyl methacrylate) (pHEMA) to improve the stability of methylammonium lead iodide (MAPI, CH3NH3PbI3) and prepared perovskite–polymer hydrogel composites. The addition of pHEMA led to the formation of a porous structure in the PbI2 film, which facilitated the penetration of MAI, thereby improving the quality of the MAPI film. Devices based on the pHEMA–MAPI composite exhibited a higher optoelectronic conversion efficiency, reaching up to 17.8%. After aging at 35% relative humidity for 1500 h, they still retained 95.4% of their optimal efficiency.

4.2 Sensors

Sensors prepared from hydrogel–perovskite composites combine the flexibility, self-healing ability, and electrical conductivity of hydrogels with the high sensitivity and excellent optoelectronic properties of perovskite, enabling accurate detection of stress, temperature, light, and chemical signals. Li et al. [103] mixed CsPbBr3@PbBr(OH) with stretchable PAM hydrogel to construct a water-stable luminescent perovskite hydrogel. The introduction of CsPbBr3@PbBr(OH) endows the hydrogel with excellent optical properties, high mechanical strength, and a high tensile breaking rate (740%). It still maintains bright green fluorescence under conditions including water, ultraviolet light, and high stretching (> 700%). Based on this hydrogel, a novel wearable stretch–strain sensor fabric was developed. It has the ability of visual–digital collaborative strain detection and can perceive various human body movements in real time. Yang et al. [104] combined the structurally colored colloidal sol of originally polymer-synthesized perovskite nanosheets with a polymer hydrogel film to prepare a mechanochromic material. The perovskite nanosheets are arranged parallel to the surface of the hydrogel film, with a periodic distance of up to about 300 nm, and the structural color can be adjusted across the full color range. This structurally colored gel has a reversible mechanochromic response, can detect weak stress of 1 kPa, has a fast response time of less than 1 ms, and exhibits high mechanical toughness. Li et al. [94] combined Mn(II) substitution with a CsPb2Cl2 inert shell and an NH2–PEG–OOH coating to design Mn2+-doped CsPbCl3/CsPb2Cl2 core/shell heterogeneous perovskite nanocrystals (PMCP pnc). Then, they embedded PMCP pnc into the hydrogel to prepare a photoluminescent hydrogel biosensor. Benefiting from the dual-enzyme-triggered response characteristics of PMCP PNCs, this hydrogel biosensor has ultra-high sensitivity to chlorpyrifos pesticides at the nanogram-per-milliliter level, enabling on-site monitoring of chlorpyrifos at the nanogram-per-milliliter level.

4.3 Other Applications

As the advantages of hydrogel–perovskite composites become increasingly evident, these composites are being applied in a growing number of fields. For instance, Arshad et al. [105] synthesized a novel two-dimensional MXenes (Ti3C2)—embedded perovskite (LaSr−0.6Co−0.4Fe−0.2O−0.8(3−) & (LSCF)) hydrogel composite, which was applied to solar-driven seawater desalination and evaporation. This composite achieved high-efficiency photothermal conversion and stability of the evaporation rate. Wu et al. [106] combined polydopamine with hybrid organic–inorganic perovskites (HOIPs) to prepare a (HPDA)2PbBr4 (PDA-1) thin film. This film exhibits excellent semiconductor properties and strong adhesion, enabling the formation of a self-adhesive optoelectronic coating on various interfaces. Fan et al. [107] prepared the perovskite La0.5Sr0.5CoO3 (LSC5) via the sol-gel method. They then mixed it with PVA and chitosan (CS) to form an interpenetrating polymer network, thus preparing a dual-functional hydrogel for photothermal–photocatalytic degradation. Subsequently, they fabricated a solar evaporator for applications in sewage treatment and seawater desalination.

The conductivity of hydrogels exhibits a bidirectional regulatory effect on the photoelectric performance of perovskite composites. Specifically, when hydrogels possess optimized mixed ion/electron conductivity (e.g., through doping with conductive polymers or incorporating carbon materials), they can markedly enhance carrier transport efficiency and reduce interfacial resistance, thereby improving the photocurrent density and energy conversion efficiency of the device. Conversely, improper conductivity design (e.g., reliance on high-concentration electrolytes) may accelerate perovskite ion migration (such as halogen ion diffusion), induce phase separation, or increase defect states. Additionally, the introduction of highly polar groups or rigid conductive fillers could exacerbate interfacial stress mismatches and nonradiative recombination, leading to performance degradation. The enzymatic or hydrolytic behavior of hydrogels might also expedite the decomposition of perovskites (especially lead-containing systems), releasing toxic metal ions (e.g., Pb2+). Meanwhile, the light/thermal instability of perovskites could disrupt the hydrogel network, forming a mutually reinforcing degradation cycle. Weak interfacial bonding may further result in the release of nanoscale perovskite fragments, increasing the risk of biological toxicity. From the perspective of biocompatibility, even biofriendly hydrogels (e.g., gelatin- or hyaluronic acid-based) cannot fully prevent heavy metal leakage from perovskites via ion migration or degradation, potentially triggering cytotoxicity or inflammatory responses. Moreover, mismatches between the material surface charge and its hydrophilic/hydrophobic properties may interfere with cellular behavior. During long-term implantation, interactions between dynamic degradation products and the biological microenvironment (e.g., local pH changes and oxidative stress) may exacerbate uncontrollable toxic release. To address these challenges, a multi-pronged strategy is proposed: develop a composite system integrating lead-free perovskites (e.g., bismuth- or tin-based) with degradable hydrogels. Utilize core-shell structures (hydrogel-coated perovskite nanocrystals) combined with chelating groups (e.g., thiol and carboxyl groups) to immobilize metal ions, and design light/enzyme-responsive degradation mechanisms for precise controlled release. Degradation pathways and biosafety were evaluated using in vitro phagocytosis experiments, in vivo metabolic tracking, and animal model systems. Ultimately, this approach establishes a balance among degradation controllability, environmental tolerance, and biofunctional compatibility, paving the way for applications such as biosensing and targeted therapy.

5 Conclusion and Prospect

3D printing technology has been widely applied in the manufacturing of materials with complex structures due to its advantages, such as high freedom, high precision, high efficiency, and high utilization rate. Compared to traditional manufacturing methods, 3D printing technology can be used to fabricate hydrogel structures with high complexity. 3D printing of perovskite combines the excellent optoelectronic properties of perovskite materials with the advantages of high precision and high freedom of 3D printing, enabling fine patterning and complex structures of perovskite. By adopting 3D printing technology, researchers can make informed decisions in terms of material selection, preparation methods, and equipment design. Combining the high flexibility and biocompatibility of hydrogels with the excellent optoelectronic properties of perovskite, as well as the advantages of 3D printing technology, contributes to the development of flexible optoelectronic materials. This article reviews the current development status of 3D printing materials and summarizes the advantages and disadvantages existing in different 3D printing hydrogel technologies. Meanwhile, the article summarizes the development of 3D printing perovskite technology in recent years and the application of hydrogel perovskite composite systems in flexible electronics, sensing energy, and other fields. By integrating the advantages of 3D-printed hydrogel and 3D-printed perovskite technologies, as well as the benefits of the hydrogel perovskite system, this paper provides ideas for the future development and innovation of 3D-printed hydrogel perovskite technology.

However, the research and preparation of 3D-printed hydrogel–perovskite composites face several challenges: (1) Material stability: Although hydrogel–perovskite composites have demonstrated good stability in applications, long-term use in complex environments may lead to changes in material properties. (2) Material uniformity and compatibility: During the synthesis process, it is a major challenge to ensure the stable combination of perovskite and hydrogel, as well as their uniform distribution during the 3D printing process to obtain the desired structure. (3) Functional integration: Integrating 3D-printed hydrogel–perovskite composites with other functional materials or devices to achieve more complex functions and applications is a challenging task.

In the future, the development of 3D-printed hydrogel–perovskite composites will focus on improving the stability, uniformity, and functional integration ability of the materials. By enhancing the stability and environmental adaptability of perovskite, strengthening the mechanical properties of hydrogels, and adopting advanced multi-material printing technologies, other semiconductor materials can be introduced into the composites to construct heterojunctions, effectively improving the optoelectronic properties of hydrogel–perovskite composites. For example, graphene can be introduced into hydrogel–perovskite composites to construct heterojunctions, and the synergy can promote the separation of electron–hole pairs in perovskite. Hydrogel–perovskite composites will find more extensive applications in fields such as soft robots and intelligent medicine. The scalability of 3D-printed hydrogel-integrated perovskite materials faces multiple challenges: material compatibility contradictions, multiscale interface stresses, and the trade-off between printing efficiency and resolution, and so on. Future research on 3D-printed hydrogel perovskites should mainly focus on dynamic cross-linking strategies, multi-material microfluidic collaborative printing, and bionic mineralization design (preset templates guiding the directional growth of perovskites), and combine machine learning to optimize process parameters in real time to improve the yield of finished products. By adopting the combination of roll-to-roll and 3D printing as well as modular functional integration, lead-free systems and closed-loop recycling processes are developed to achieve efficient customized production and sustainable application of flexible optoelectronic devices.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 52073083), the Hubei Provincial Natural Science Foundation (2010CDB05805), and the Hubei University of Technology Doctoral Research Initiation Fund (BSQD12038).

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

No primary research results, software or code have been included, and no new data were generated or analyzed as part of this review.