Exploring the polymorphic behavior of a β-nucleated propylene-ethylene random copolymer under shear flow

Funding information: National Natural Science Foundation of China, Grant/Award Number: U1510207; Key Program for Coal-based Science and Technology of Shanxi Province, Grant/Award Number: MH-2014-08; National Outstanding Youth Science Fund Project of National Natural Science Foundation of China, Grant/Award Number: 21922308

Abstract

Shear flow strongly affects the polymorphism and crystallization kinetics of semi-crystalline polymers. In the present work, the crystallization behavior of a β-nucleated propylene-ethylene (P-E) random copolymer was studied both under quiescent and shear flow by using in-situ wide-angle X-ray diffraction. It was observed that shear flow could shorten the induction time, fasten the crystallization rate and increase the degree of crystallinity. The populations of different crystal modifications varied significantly upon shearing. Especially the β crystals fraction decreased with shear strain. When the shear strain was higher than 100 with a fixed shear rate of 5 s−1, the β crystals almost disappeared. Meanwhile, both the fractions and the crystallization rates of α and γ crystals were enhanced by shear flow. The complicated polymorphic behavior can be interpreted by the nucleation kinetics.

1 INTRODUCTION

Crystallization of semi-crystalline polymers proceeds under various flow conditions during processing. Numerous studies1-10 are devoted to clarifying the influence of shear flow on the crystallization rate, morphology, and physical properties of polymers. However, the understanding of the mechanism of shear-induced crystallization is still elusive. In general, shear flow reduces the nucleation barrier and increases the density of nuclei.11-14 For example, in isotactic polypropylene (iPP),14, 15 the density of nuclei increases from 1010 m−3 to 1016 m−3 under shear. When the flow is sufficiently strong, anisotropic morphology may be observed, for example, shish-kebab or fibril-like structure.1, 2, 4-8 Scenarios of a critical shear rate,6, 7 strain,2, 16 shear stress,17 or specific work18 have been proposed for shish-kebab formation.

Besides crystallization kinetics and morphology, the crystal form of iPP can be altered by shear flow. It has been found that shear could induce the β crystals in iPP, which is less stable than the α crystals and is generally not observed under the quiescent condition.19, 20 The mechanism of favored formation of a metastable phase (β crystals) is still unclear. The β nuclei induced by α-β cross nucleation or α-β bifurcation from shear-induced α-row nuclei has been widely elucidated.21-23 The formation of the β crystals in unnucleated iPP has been explained by the higher growth rate than that of the α crystals in the temperature range of 100°C-140°C.24, 25 In this temperature range, the rate-limiting step of forming β crystals is the nucleation. Therefore, β-nucleating agents (β-NAs) can promote the abundant formation of β crystals.25-29 Surprisingly, although both shear flow and β-NA can promote β crystals, a combination of the two factors seems to be detrimental to the formation of β crystals.30-32 Li et al.31 proposed that shear could induce more α nuclei in the β-nucleated iPP.

When studying the effect of shear on the crystallization of β-nucleated iPP, it is generally difficult to distinguish whether the β crystallites are originated from the β nuclei induced by β-NA or α-β cross nucleation induced by shear.30-32 It has been known that the relative growth rate of the α and β crystals in a β-nucleated polypropylene random copolymer turns to be different from that of iPP.33 Varga22 found that no β crystals developed in a propylene-ethylene (P-E) random copolymer under shear generated by fiber pulling, which was interpreted by the lower growth rate of β crystals as compared to the α crystals. Therefore, the addition of β-NAs becomes the only way to induce β crystals in a P-E random copolymer.33-35 In addition to α and β crystals, γ crystals can be observed in the β-nucleated P-E random copolymer because of the constitutional defects with the introduction of the ethylene comonomers.36 Therefore, P-E random copolymer is an appealing system to study the competition of different crystal modifications under shear flow.

In this study, the crystallization behavior of a β-nucleated P-E random copolymer with a ethylene content of 5.6 mol% under quiescent and shear conditions was investigated by in situ wide-angle X-ray diffraction (WAXD). Interesting shear-dependent polymorphic behavior was observed. The crystallization rate and fraction of the α and γ crystals were greatly enhanced by shear while the formation of β crystals was suppressed. The crystallization kinetics of different crystal modifications was analyzed by considering both primary and secondary crystallization. A thermodynamic diagram was proposed to explain complicated polymorphic behavior.

2 EXPERIMENTAL

2.1 Materials

P-E random copolymer (prepared via Ziegler-Natta catalyst) with a melt flow rate of 1.8 g/10 min (230°C/2.16 kg) was supplied by SINOPEC Beijing Yanshan Company. The weight-average molecular weight (Mw) is 5.77 × 105 g mol–1, and the number-average molecular weight (Mn) is 1.63 × 105 g mol–1. The content of ethylene units is ~5.6 mol%, as measured by 13C-NMR. Calcium pimelate (Ca-Pim), an efficient β-NA for P-E random copolymer,33, 37, 38 was synthesized by neutralization reaction between Ca(OH)2 and pimelate acid.

2.2 Sample preparation

The P-E random copolymer, Ca-Pim, and an antioxidant (Irganox B215, Ciba-Geigy) powders were melt mixed in an internal mixer (HAAKE Rheomix OS) at 200°C for 6 min. The weight fraction of Ca-Pim and antioxidant were both 0.1 wt%. The obtained mixture was compressed into films of 200 ~ 300 μm thick at 200°C. Samples in the shape of a ring (i.d. = 10 mm, o.d. = 20 mm) were cut from the pressed films for the WAXD measurements. The melting temperatures (Tm) of the β and α crystals in the β-nucleated P-E random copolymer are 129.9°C and 146.4°C, respectively.

2.3 In situ WAXD measurement

The in situ WAXD measurement was performed at the beamline 1W2A in the Beijing Synchrotron Radiation Facility (BSRF). All diffraction patterns were captured by a MAR CCD (MAR-USA) detector with a resolution of 2048 × 2048 pixels (pixel size: 79 × 79 μm2). The two-dimensional (2D) WAXD patterns were converted to one-dimensional (1D) intensity profiles after background correction by a home-written code using Python.

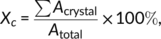

(1)

(1) (2)

(2) (3)

(3)

(4)

(4) (5)

(5) (6)

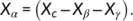

(6)A Linkam CSS-450 high-temperature shearing stage (Linkam Scientific Instruments, Ltd.) was used to control the shear flow and temperature. The samples were positioned between two metal plates coated by Kapton films. A hole was left for the X-ray to pass through. The hole has a diameter of 2.8 mm, located at a radius of 7.5 mm to the center of the rotation axis. Schematics of the temperature and shear protocols are shown in Figure 2: (A) heated the sample to 200°C at 30°C min−1 and held for 3 min and (B) cooled down to 125°C at 30°C min−1. A steady shear with rate = 5 s−1 was immediately applied to the sample with different shear time (0, 2, 4, 6, 10, and 20 s) as soon as the temperature reached 125°C. Correspondingly, the shear strains were 0, 10, 20, 30, 50, and 100, respectively. The relatively weak shear rate was chosen to avoid melt fracture considering the high viscosity of the polymer used in this study.

2.4 Scanning electron microscopy

The etched samples were observed on a scanning electron microscopy (SEM) (JSM-6700F, JEOL), operated with an accelerating voltage of 5 kV. All the samples were sputter-coated with platinum to avoid charging. The selective permanganic etching method proposed by Olley and Bassett42 was used to show the crystalline morphology. The samples were crystallized at 125°C for 40 min, then cooled to room temperature at a rate of 30°C min–1. The etching solution was prepared by dissolving 25 mg potassium permanganate (KMnO4) in 50 mL concentrated orthophosphoric acid. After etching for 70 min, the samples were sequentially washed with a mixture of concentrated sulfuric acid and distilled water (volume ratio = 2:7), hydrogen peroxide, and acetone.

3 RESULTS AND DISCUSSION

3.1 2D WAXD results

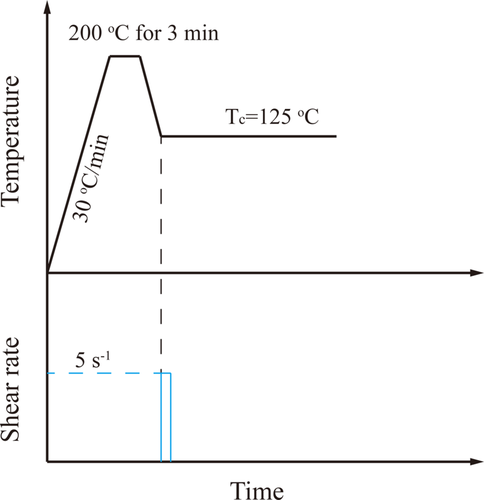

The selected 2D WAXD patterns of the β-nucleated P-E random copolymer isothermally crystallized at 125°C under quiescent and shear conditions are shown in Figure 3. The patterns in the first row exhibit a diffuse halo, corresponding to the amorphous polymer melt. With isothermal time increasing, two isotropic reflections appear in the quiescent polymer which can be indexed as the (110)β and (111)β of β crystals. Upon shearing, the reflections appear earlier as compared to the quiescent condition. The intensity of (110)β decreases with shear strain. When the shear strain exceeds 50, the reflections of β crystals are rather weak. Meanwhile, signals from α and γ crystals are more obvious. These reflections of α and γ crystals are slightly anisotropic, indicating a certain degree of orientation. The diffraction features are discussed in more detail below.

3.2 Crystal orientation

The orientation behaviors of different crystal forms can be expressed by the azimuthal intensity distributions of characteristic diffraction rings, as shown in Figure 4. The (110)β is always uniform under different shear strains, indicating that the orientation of β crystals is independent of shear. Li et al.43 found that relaxation of oriented molecular chains was beneficial to the formation of β crystals and the oriented β lamellae can be obtained by epitaxial growth on the needle-like β-NA. In our case, the Ca-Pim particles are nearly spherical, thus the β crystals are always isotropic under shear flow. The (110)α/(111)γ reflection becomes more anisotropic with increasing shear strain. This indicates that the oriented chains induced by shear flow tend to form oriented α nuclei.22, 23 Subsequently, it is probable that the γ crystals epitaxially grow onto the oriented α crystallites.44-46 According to the literature,47, 48 the c-axis in mother lamellae of the α crystals is parallel to the shear direction, while the daughter lamellae keep a constant 80° angle with the mother lamellae. As shown in Figure 4, the (110)α/(111)γ reflection has an arc at 0° indicating that the α and γ crystals exhibit a certain degree of orientation upon shear.

3.3 Crystallinity and polymorphism

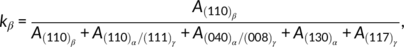

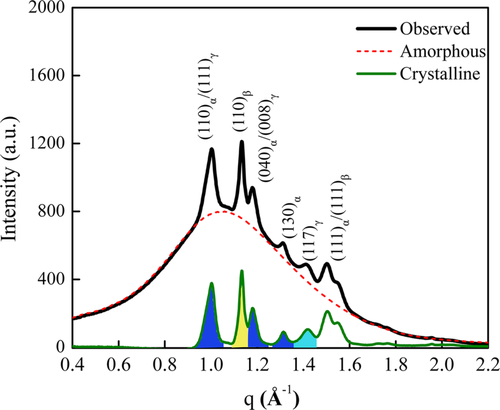

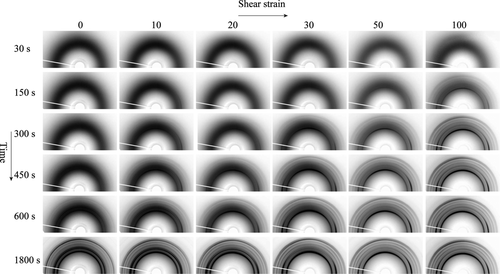

To characterize the evolution of different crystal forms in the β-nucleated P-E random copolymer, the 1D WAXD intensity profiles are shown in Figure 5. Under the quiescent condition, the β crystals and α crystals appear almost simultaneously. When the shear strain = 10, 30, and 50, the (110)β reflection appears later and its intensity becomes weaker as compared to the quiescent condition. When the shear strain further increased to 100, no β crystals can be observed. Hence, the formation of β crystals is suppressed by shear flow. On the other hand, the induction time of α and γ crystals decreases from 450 to 120 s as the shear strain increased from 0 to 100.

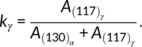

(7)

(7) (8)

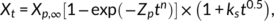

(8)Under the quiescent condition, the final Xc is ~18.2% and the t0.5 is ~950 s. With a mild shear (shear strain = 10 and 20), the Xcs are a little higher than the static condition and the t0.5 decreases to ~800 s. When a relatively intense shear (shear strain = 100) is applied to the β-nucleated P-E random copolymer, the final Xc increases to 20.8%, and the t0.5 further decreases to ~250 s. The enhancement of the crystallization rate of polymers by shear flow has been known. However, the Xc is generally not affected by shear in iPP homopolymer and its mixture with β-NA.3, 50, 51 Enhanced crystallinity was observed in a propylene-1-butylene random copolymer under shear condition.3 This may be a general feature for random copolymers.

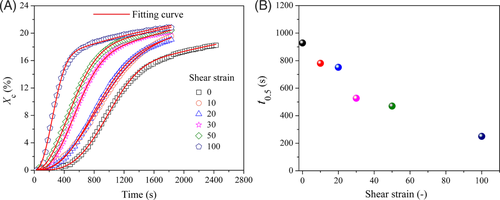

The fractions of the α, β, and γ crystals as a function of time are shown in Figure 7A-C. The formation of α and γ crystals is enhanced both in the overall content and the kinetics. On the other hand, the formation of β crystals is greatly hindered. Remarkably, when the shear strain reaches 100, the β crystals vanish completely, which is never seen in previous studies on β-nucleated iPP under shear. As shown in Figure 7D, under the quiescent condition, the value of Xβ is ~7.5%. When shear strain = 20, the Xβ decreases to 3.5%. As shear strain further increased to 100, the value of Xβ is nearly 0, while the Xα and Xγ reach the highest values. Under shear conditions, the γ crystals become predominate in the β-nucleated P-E random copolymer.

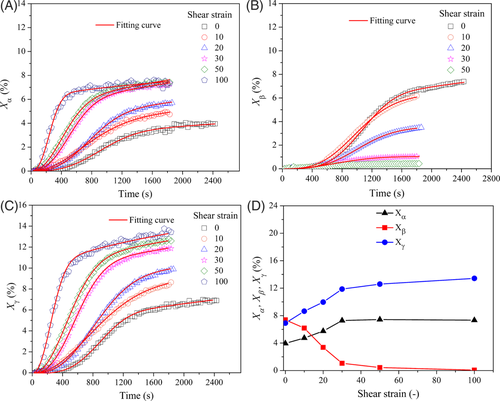

Figure 8A displays the t0.5 of the α, β, and γ crystals as a function of shear strain. The t0.5 of the β crystals is always longer than that of the α and γ crystals. On the other hand, the t0.5 of the α and γ crystals are comparable with each other and both decrease with shear strain. Thus, it is probable that the kinetics of γ crystals is similar to that of α crystals. To further reveal the relationship between α and γ crystals, the kγ is plotted as a function of time. As shown in Figure 8B, it is interesting to find the kγ is almost independent of the shear strain and crystallization time. These results provide strong evidence of the correlation between α and γ crystals and support the existence of epitaxy.

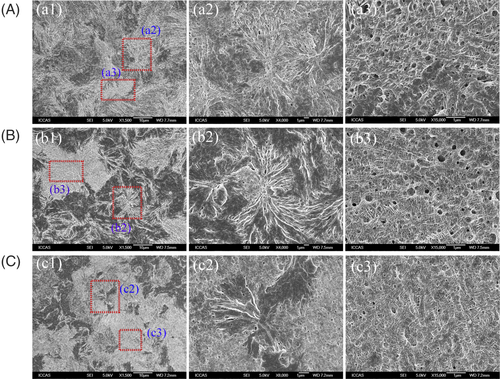

3.4 Crystalline morphology

The effects of shear flow on the polymorphism can also be confirmed by morphology. It is known that β crystals exhibit a bundled structure,25, 37, 52 while a cross-hatched structure forms in α and γ crystals.53, 54 Unfortunately, the epitaxial relationship between α and γ crystals makes it difficult to distinguish them by morphology.55 As shown in Figure 9A1-A3, the bundled-like β crystallites predominate under quiescent crystallization, and its content decreases with the shear strain. On the other hand, the fractions of cross-hatched lamellae increase with the shear strain (shown in Figure 9B,C). It should be mentioned that a small number of bundled-like structures (β crystals) are also seen in Figure 9C which is probably formed during cooling instead of during isothermal crystallization. These results are in line with the WAXD results.

3.5 Mechanism of the suppression of β crystals by shear flow

The suppression effect of shear flow on the formation of β crystals in the β-nucleated iPP samples has been reported.30, 31, 56 However, the combination of shear-induced β nuclei and β-NA induced nucleation makes it difficult to reveal the effects of shear flow on the nucleation and growth of β crystals. On the other hand, the shear-induced β nucleation was eliminated in the β-nucleated P-E random copolymer (Supporting Information, Figure S1), which makes the situation simpler.

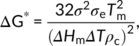

(9)

(9)

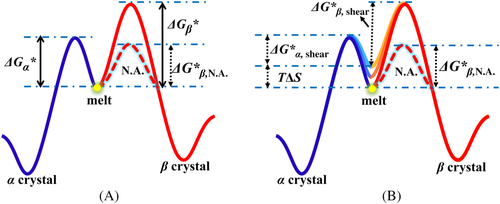

As shown in Figure 10A, under the quiescent condition, the free energy barrier for the β nucleus (ΔGβ*) is higher than that of the α nucleus (ΔGa*). Therefore, no β crystals are formed in the P-E random copolymer (Supporting information Figure S1). By adding β-NA, the free energy barrier of the β nucleus (ΔG*β, N.A) is dramatically decreased because of the lower surface free energy (σ or σe) in proximity to the surface of the β-NA. The ΔG*β, N.A should be comparable to ΔGa*, which can be inferred from the fact that both the α and β crystals are formed in a large number in the sample.

As shown in Figure 10B, under the shear condition, the free energy of the oriented melt increased by T*ΔS because of the decreased conformational entropy of polymer melt. Therefore, the nucleation barriers for the two crystal modifications (ΔG*α, shear and ΔG*β, shear) decrease simultaneously. Following this concept, in principle, both the nucleation of the α and β crystals will be enhanced if the crystallization occurs from the same melt state. Now the key question is: whether the effect of shear and β-NA can add up to promote the crystallization of the β crystals. Experimentally, the answer is no. Whether their effects can be added up depends on the influence of the Ca-Pim particle on the melt flow. The Ca-Pim particles are of micrometer size. According to the literature,58 the existence of the particles will hinder the chain alignment under flow. For poly(lactic acid) and iPP, inorganic nucleating agents have no effect on the strain-induced crystallization when the strain rate is sufficiently high.59, 60 If the two paths could not add up, suppose that the ΔG*β, shear > ΔG*β, N.A., the lowest nucleation barrier for the β crystals is still ΔG*β, N.A., while the ΔG*α, shear decreases dramatically with the shear strain. Under this condition, the nucleation of β crystals will be greatly suppressed.

The above illustration agrees with experiments very well. As shown in Figure 7B, the induction time of the β crystals is basically unaffected by the shear strain. On the other hand, the crystallization kinetics of the α and γ crystals is significantly accelerated by shear. Under intense shear, before the formation of β crystals, the polymer melt is already consumed by the α and γ crystals. Therefore, the polymorphism of the P-E copolymers is effectively controlled by the nucleation kinetics. The γ crystals closely related to the α crystals are not shown in Figure 10. It is known that a decrease of the regular isotactic sequences, the introduction of comonomers and isothermal crystallization are favorable to the formation of γ crystals.61-64 It is possible that shear flow makes more chain segments containing ethylene comonomers crystallize into the γ crystals. This explains why the fraction of γ crystals and the overall crystallinity increase with the shear strain.

4 CONCLUSIONS

The understanding of flow-induced crystallization is of great importance to polymer processing. Yet there are still many unsolved issues. This work focused on the effect of shear flow on the crystallization behavior of a β-nucleated P-E random copolymer. A shear-dependent polymorphic behavior was observed. Especially, the formation of β crystals was greatly suppressed by shear flow. The crystallization rate and the population of α/γ crystals were enhanced by shear. The α/γ crystals exhibited nearly identical kinetics and the kγ was nearly constant, which strongly indicated that the correlation between the two modifications. Under intense shear, the β crystals were eliminated. It was clear that the effects of shear and β-NA contradicted each other for the β crystals. Even though both the β-NA and flow reduced the nucleation barrier, the two effects could not add up. The β-NA reduced the surface energy of the nucleus while the flow increased the free energy of the melt. However, the shear-induced nucleus may not correspond to the chains in proximity to the particles of the β-NA. The reason is possibly related to the hinderance of chain alignment near the micrometer-sized β-NA particles.

ACKNOWLEDGMENTS

This work is supported by the National Natural Science Foundation of China (NSFC, U1510207, 21922308) and the Key Program for Coal-based Science and Technology of Shanxi Province (MH-2014-08). G.L., X.D., Z.L., and D.W. thank the Program of the CAS Interdisciplinary Innovation Team. The BSRF is acknowledged for providing the beam time.