Time-optimal trajectory planning of a redundantly actuated planar parallel robot driven with series elastic actuators

Abstract

This paper addresses the time-optimal trajectory planning of a redundantly actuated parallel robot driven by series elastic actuators. Here, the actuation redundancy allows prestressing the elastic components of the drives and enables more degrees of freedom in the trajectory planning. To this end, a time-optimal control problem is formulated that takes also the physical constraints into account, that is actuation torques, task and joint space limits and self-collisions. A flatness-based parametrization of the dynamics is used in the nonlinear optimization problem and solved with the multiple shooting technique within the CasADi framework using IPOPT as a solver. Results are shown and compared to time-optimal trajectories, both redundantly and non-redundantly actuated with rigid drives.

1 INTRODUCTION

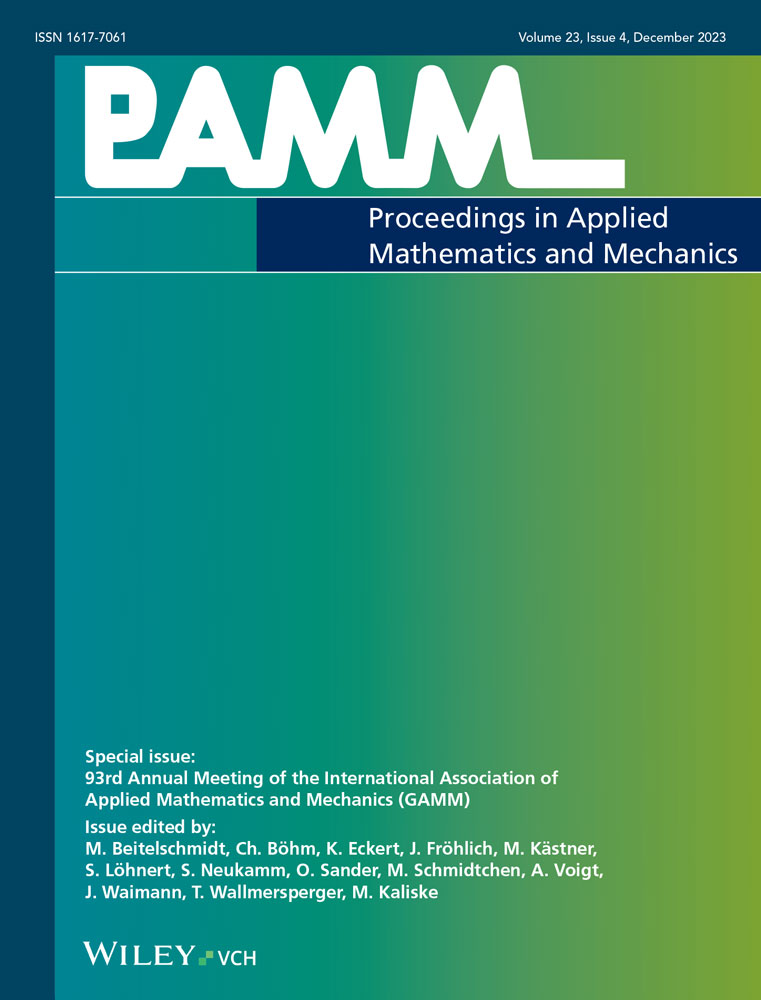

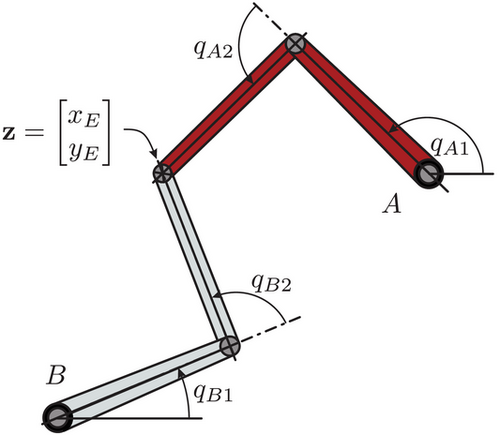

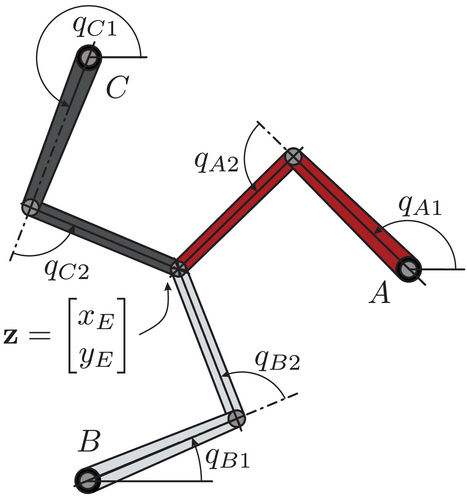

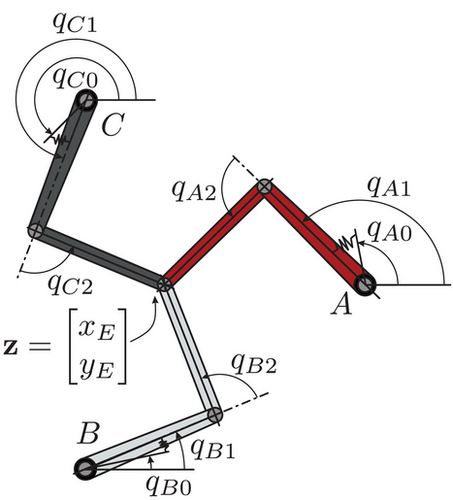

Current research on parallel kinematic mechanisms (PKM) addresses the use of elastic components aiming at applications where well-defined physical compliance is important, for example human-robot interaction and rehabilitation. Redundant actuation of PKM is another research direction that was proposed to increase their dynamic capabilities and performance. In this paper, the topics of redundant actuation and series elastic actuators (SEA) for a planar parallel robot are combined and exploited for time-optimal trajectory planning. Time-optimal motion planning for redundantly actuated robots driven by rigid drives has been addressed in [1, 2], whereas research about motion planning of parallel robots equipped with SEA is directed towards energy-optimality ([3]). The resulting dynamic model of a SEA-actuated PKM splits into two dynamical systems coupled by the elastic component of the SEA only. The redundant actuation of the compliant PKM further results in an additional degree of freedom, which allows preloading the elastic components. This enables to store and release potential energy at the starting and terminal points. This control system is also differently flat ([4, 5]). This contribution focuses on the time-optimal motion planning of redundantly actuated SEA-driven PKM taking into account physical constraints and system dynamics. Time-optimal control problems (TOCP) for the offline point-to-point trajectory planning are formulated for a non-redundantly and a redundantly actuated planar PKM prototype, each equipped with SEA and standard rigid drives, in order to compare to conventionally actuated PKM. This results in considering four different PKM setups. In Section 2, necessary model properties are highlighted and in Section 3, the nonlinear optimal control problems are derived. Section 4 shows and compares solutions for a numerical example and in Section 5 future work ideas are proposed.

2 MODELING

To take into account the dynamic limits for the time-optimal trajectory planning, the dynamics of the systems need to be determined. Various approaches for the dynamic modeling of PKM equipped with rigid actuators are established in [6-9]. For PKM equipped with SEA the derivation of the equations of motions (EOM) can be found in [10]. In the following Sections 2.1 and 2.2 only the final motion equations are provided to highlight the systems' properties addressed in Section 3. In both cases the minimal coordinate formulation is used. For a detailed modeling we refer to the quoted literature.

2.1 Dynamic model of PKM driven with rigid actuators

2.2 Dynamic model of PKM driven with SEA

3 TIME-OPTIMAL POINT-TO-POINT TRAJECTORY PLANNING

The time-optimal control problem is formulated to plan a trajectory between a starting and terminal point in minimum time, while taking into account the robots dynamic limits and avoid self-collision as well as task and joint space violations. The common approach is to define the objective as the weighted sum of the terminal time T and a regularization term for better convergence. All four considered robot setups in Section 2 are differentially flat ([5]). Therefore, using a coordinate transformation, the system dynamics can be included in the TOCP by an integrator chain described by ODE with the integrator state vector and input . Each TOCP described in Sections 3.1-3.3 is solved using the multiple shooting method [11] within the CasADi framework [12]. As a solver, IPOPT [13] was applied. Numerical integration is done with the explicit Runge-Kutta method of fourth order, assuming piecewise-constant integrator inputs .

3.1 PKM driven with rigid actuators

3.2 Non-Redundantly actuated PKM driven with SEA

3.3 Redundantly actuated PKM driven with SEA

Loop-closure conditions and box constraints are formed in (25) and (27)–(29) and the initial and terminal states are given. No initial or terminal states are defined for as possible preload at said times might lead to faster trajectories.

4 NUMERICAL RESULTS

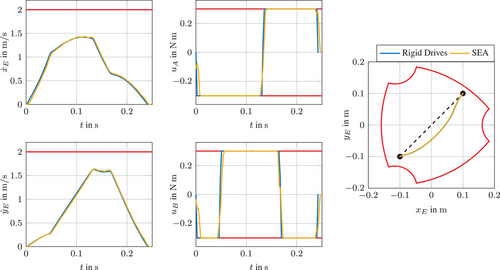

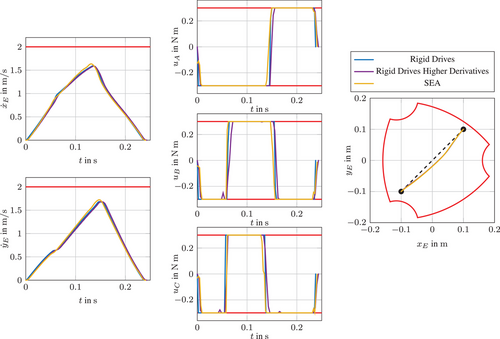

To show the validity of our approaches, for all cases the TOCP connecting the initial position and terminal position , exploiting the task space as effectively as possible, are solved. The comparison of the performance for the non-redundantly actuated PKM setups is depicted in Figure 5 and Figure 6 shows the equivalent for the redundantly actuated ones. The anticipated bang-bang behaviour of the motor torques is clearly visible and it can be seen, that similar results are achieved both, for the redundantly and non-redundantly actuated PKM. All moments of inertia and masses of the PKM can be found in [10]. For actuation torque limits and each and for all spring stiffnesses are chosen. Physically meaningful limits for the remaining box constraints were applied and kept the same for all TOCP.

However, it is not entirely fair to compare the results of Section 3.1 to those of 3.2 and 3.3 as more constraints for the higher derivatives of the EE trajectory have to be applied for the TOCP of PKMs with elastic drives. When those same higher derivative constraints are also included in the TOCP of the PKM with rigid drives, faster trajectories for SEA-driven PKM are attainable, additionally solved and shown in Figure 6.

An Intel(R) Core(TM) i7-6700HQ CPU @ 2.60GHz CPU running Windows 10 was used for all computations. The terminal times T and computation times are listed in Table 1.

| Considered PKM Setup | Terminal Time T | Computation Time |

|---|---|---|

| Non-redundantly actuated PKM with rigid drives | 0.242 s | 2.10 s |

| Non-redundantly actuated PKM with SEA | 0.246 s | 39.17 s |

| Redundantly actuated PKM with rigid drives | 0.237 s | 2.03 s |

| Redundantly actuated with SEA | 0.240 s | 136.13 s |

| Redundantly actuated PKM with rigid drives considering higher EE-derivative constraints | 0.243 s | 2.54 s |

- Abbreviations: EE, end-effector; PKM, parallel kinematic mechanisms; SEA, series elastic actuators; TOCP, Time-optimal control problem.

5 CONCLUSION AND OUTLOOK

In this paper, a new approach on the time-optimal point-to-point trajectory planning for a planar SEA-driven PKM is introduced. Tailored time optimal trajectory planning problems for a planar parallel robot on the one hand, equipped with rigid drives and, on the other hand, driven by series elastic actuators, are proposed and the results are compared. It can be shown that by employing SEA for (redundantly-actuated) parallel robots similar or even faster results on the topic of time-optimality can be achieved. As for typical pick and place tasks the path-planning is done offline beforehand, the higher computational costs are of less concern. The next step will be to test the calculated trajectories on the real prototype and to compare the results. Future work will regard the time optimal control problem for cyclic pick and place like trajectories, further exploiting the loading of elastic elements and the tracking of energy consumption when redundantly actuated PKM are driven with SEA.

ACKNOWLEDGMENTS

This work has been supported by the “LCM K2 Center for Symbiotic Mechatronics” within the framework of the Austrian COMET-K2 program.