Organic Molecule-Driven Polymeric Actuators

Abstract

Inspired by the motions of plant tissues in response to external stimuli, significant attention has been devoted to the development of actuating polymeric materials. In particular, polymeric actuators driven by organic molecules have been designed due to their combined superiorities of tunable functional monomers, designable chemical structures, and variable structural anisotropy. Here, the recent progress is summarized in terms of material synthesis, structure design, polymer–solvent interaction, and actuating performance. In addition, various possibilities for practical applications, including the ability to sense chemical vapors and solvent isomers, and future directions to satisfy the requirement of sensing and smart systems are also highlighted.

1 Introduction

The broad interest in developing biomimetic actuating systems has largely been inspired by shape transformations of plant organs in response to varying external stimuli.1-5 For example, pinecones can open/close their scales upon humidity changes in ambient air,6 ice-plant seed capsules open upon contact with liquid water,1 and Banksia seed capsules open with heat from bush-fires.5 Shape changes are driven by differential strains in different tissues induced by anisotropic volume changes. Anisotropy in swelling arises from aligned stiff cellulose microfibrils in a swelling polymeric matrix.7, 8 Till now, biomimetic actuating materials have been developed with the aim of using them as active components for practical and potential applications, such as chemosensors,9-12 soft robotics,13, 14 artificial muscles,15, 16 drug delivery,17 etc. They can respond to various stimuli, such as solvents,18-23 temperature,24-26 light,27-29 humidity,30-33 redox potential,34-36 ion,37 pH,38-41 etc. Among them, actuators capable of mechanical motions driven by organic solvents, so-called organic solvent-driven actuators, are an important type of soft actuators featuring distinctive applications in sensing and process control in chemical production lines. In addition, the knowledge acquired from their synthesis and actuation mechanism is a source of inspiration for further development of other actuators.

Organic solvent-driven actuators have been constructed popularly by polymers, carbon materials, or their composites to produce motions for task-specific functions. Specifically, polymers of possible biocompatibility, biodegradability, and/or simple fabrication, can be tailor-made with distinctive responsive properties by flexible design of chemical structure on the molecular level and the following ordering of their chains on the nanoscale. Till now, most efforts on the exploration of actuating polymeric materials with fast actuating speed, programmable deformation, and large-scale locomotion focused on creating the structural anisotropy inside polymeric films. A straightforward approach is to construct single- or bi/multilayered films with different cross-linking density of building blocks or chemical groups.42-49 Due to the anisotropic arrangement, each layer generates a volume change varying in extent or orientation upon exposure to a single stimulus. The combination of layers with different volumetric strains, or through the application of gradients in stimuli in a single layer, drive micro-/macroscopic motion, the general principle best being illustrated by Timoshenko's classic paper on the thermal actuation of bimetallic strips.50 Up to now, the principle has been widely applied in fascinating examples, including polyimide film with different swelling properties,51 poly(ionic liquid) (PIL) film with gradient cross-linking density,52 carbon nanotubes (CNTs)-polymeric bilayers,53 and single-layered polymeric film with different crystal phases,54 etc.

Here, we present the recent progress in organic solvent-driven polymeric actuators. It first details the design principle via tuning molecular order, introducing inhomogeneous swelling, inducing molecular reconfiguration, and varying geometric design. Specifically, the key achievements on bilayer and gradient types of actuators are discussed. Second, a general description of actuating behavior in liquid/gas phase is added to reveal the mechanism closely related to molecular diffusion and capillary force. Third, the remaining challenges and promising applications are presented to showcase their practical usages.

2 Design Principle of Organic Solvent-Driven Polymer Actuators

Generally, the chemical structure, nanofillers, swelling ability, porosity, and geometric ratios have significant impact on the design of organic solvent-driven polymer actuators, and major researches have been developed to describe these effects and their functions. Most of the latest advance in the polymer actuator field (microstructures, hydrogels, membrane, etc.) is based on the construction of anisotropic volume change (e.g., expansion or contraction) in contact with organic molecules by tuning the molecular order, swelling ability, crystallization/molecular reconfiguration, and alignment of low-dimensional elements.

2.1 Tuning Molecular Order

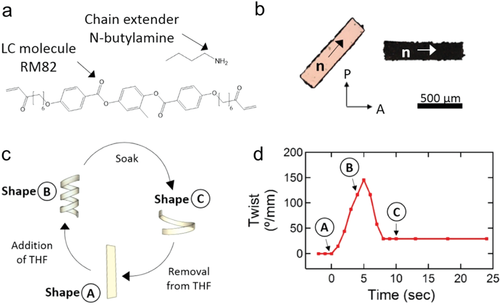

Liquid crystal elastomers (LCEs), a class of easily stretchable polymers, can respond to organic solvents and give rise to shape deformation induced by degeneration of highly ordered to less ordered molecular state.55-58 For instance, Boothby et al.59 synthesized LCEs made of 1,4-bis-[4-(6-acryloyloxyhexyloxy) benzoyloxy]-2-methylbenzene (RM82) and n-butylamine (Figure 1a), which swell in contact to solvents or vapors of acetone, N,N-dimethylformamide (DMF), tetrahydrofuran (THF), and chloroform. By patterning the molecular orientation spatially and hierarchically (director n, Figure 1b), these LCEs contract along the alignment direction and transform from a flat sheet into a complex shape. When the director n is programmed at an angle to the long axis of the LCEs, it results in a helical shape, capable of multiple actuation forms without affecting their chemical structures (Figure 1c,d). By a delicate twisted alignment, the hierarchically patterned materials deliver a torsional actuation and twist reversibly with a velocity of over 200o mm−1 from a flat sheet to a helix. Taking advantage of the twisting deformation, the LCEs can lift up a paddle 100 times heavier than itself. Unfortunately, the sophisticated molecular design/synthesis, time-consuming process, and high cost limit its scale-up production and further practical applications.

2.2 Introducing Inhomogeneous Swelling

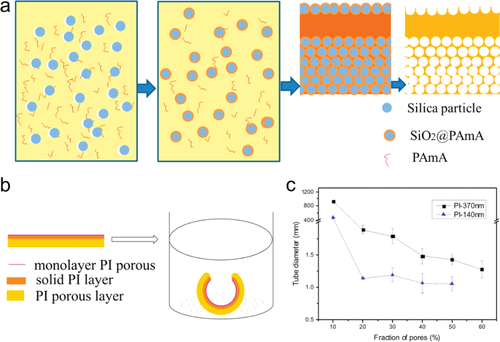

Alternatively, by introducing inhomogeneous porosity across a film, unbalanced stress can be generated to bend the film. For example, Ionov et al. reported a porous polyimide actuating film.51 By etching out silica particles as templates at the bottom part of film, a vertical anisotropy of porosity was created along the film (Figure 2a). This porous polymer film rolls into tubes when exposed to organic solvents/vapors and reversibly unfolds by drying out in air. As illustrated in Figure 2b, benefiting from different swelling degree of the porous and nonporous parts in the film, rolling proceeds with the porous layer outward and the solid dense layer inward, forming a tube. The swelling degree (SD) is defined as SD = (ms − md)/md, where md and ms correspond to the weight of the sample in dry state and incubated in acetone during different times. The porosity and the pore size are key factors governing the swelling degree. The porosity can be tuned by the fraction of silica particles inside the films. Films with a higher porosity, that is, more pores show higher swelling degree, leading to a decrease in diameter of the formed tubes. In addition, the pore size plays an equally important role. Smaller pores are proposed to provide the film with a larger surface area, therefore forming tubes of smaller diameters and exerting a higher bending force under the identical swelling condition (Figure 2c). Not to be neglected is the role of porosity on the elastic modulus of the strips, with stiffness decreasing with porosity. Furthermore, mechanical properties change with swelling degree, and more theoretical work needs to be done to understand this behavior.60 The design principles here were further applied to explore other materials, such as a Janus PDMS film possessing porous and nonporous regions.22 The Janus structure of the film induces differential expansion rates on different faces, thus causing a rapid response and large-scale locomotion.22

2.3 Inducing Molecular Reconfiguration (or Phase Transformation)

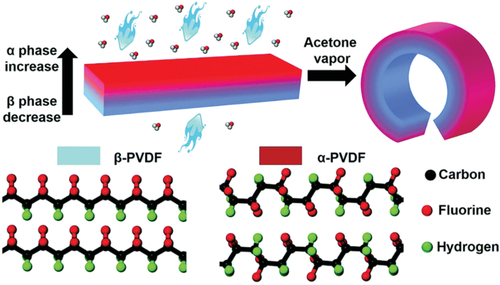

Different from the inhomogeneous swelling/shrinking of polymer networks (e.g., hydrogel actuators), semicrystalline polymers can respond to organic solvent vapor, exhibiting reversible swelling-crystallization conversion. Feng et al.61 described a thermoset semicrystalline polymer actuator composed of poly(ε-caprolactone) (PCL) and isophorone diisocyanate trimer. The semicrystalline polymer shows reversible swelling-crystallization conversion of the polyester segment induced by solvent vapor (thus a shape variation of the polymer was observed). This phenomenon can be detailed as follows: 1) The semicrystalline polymers contain crystalline and amorphous domains spontaneously. 2) When the crystalline domains are in contact with solvents, it turns into swollen crystalline state by breaking the intermolecular interactions between crystalline domains and expanding the polymer volume due to the strong interaction formed between crystalline domains and solvent molecules. 3) When the swollen polymer returns to air, solvent molecules are released accompanied by the polymer volume shrinking due to re-crystallization of the previously swollen domains. Then, a soft crawler based on this polymer was fabricated, which can walk steadily in response to ethyl acetate vapor, providing a model for sensors, artificial muscle, and energy harvesting devices. In another example, Lin et al.54 reported a single-layer responsive polymer film composed of poly(vinylidene fluoride) (PVDF) driven by the anisotropy of two crystalline forms (α and β phases) (Figure 3), in which the swelling ability is stronger in the α than β phase toward acetone vapor, thus forming the macroscopic shape deformation. Moreover, the anisotropy distribution of crystalline phase inside a PVDF film can be programmed via direct laser writing, enabling the design of a 3D structure, such as a blooming PVDF flower.

2.4 Introducing Aligned Nanofiller Elements

Single-layer actuating polymers can produce deformation due to asymmetric physical properties of its layer matrix, which can be readily achieved by introducing oriented nanofillers into the polymer matrix. Incorporation of oriented cellulose fibers,6, 8 aligned CNTs,62-65 and magnetic platelets66 can transfer structural anisotropy to the single-layer polymer, resulting in distinctive volume changes according to their spatial relationship to the aligned elements in response to the stimuli. Pinecones open/close their scales upon dehydration/hydration with the preferred motion directed by the orientation of one-dimensional (1D) stiff cellulose microfibrils located in different regions of the scales.67 To mimic pinecone scales, Studart et al. constructed alumina platelets-gelatin composites in which alumina platelets were aligned horizontally or vertically to the long axis of the object under external magnetic field to create 2D reinforcement and cause a bending action.66 Another efficient strategy to achieve actuation in a specific direction is to composite the polymer with aligned CNTs. Peng et al.53 proposed the idea and fabricated the actuator with accurate control of the actuating direction. The conjugated polymer composited with aligned CNTs exhibits anisotropic bending/unbending actuation perpendicular to the orientation direction (the long axis) of aligned CNTs and is repeated for 300 cycles. Next, Peng et al.68 designed a desired tunable solvent actuator made of the hierarchical and helical assembly of aligned CNTs. The actuator can respond to both organic solvent and vapor with a response rate up to 2050 revolutions per meter.

2.5 Geometric Design of Organic Solvent-Driven Polymeric Actuators

Apart from the above-mentioned methods to introduce structural anisotropy inside a film from a single polymer source, an alternative is to construct bilayers/multilayers, in which each layer consists of different chemical structures which give rise to different strains, or alternatively one can create a film with a gradient in structure/properties.

2.5.1 Polymeric Bilayer Actuator

In principle, materials with different expansion/contraction in one direction in response to environmental variation can be designed for responsive materials. By virtue of this design concept, researchers have succeeded in stimuli-responsive actuation in bilayer materials. Shim et al.46 fabricated a bilayer hydrogel film and observed the reversible curling and un-curling behavior in water and ethanol, respectively (Figure 4). The hydrogel film was fabricated by grafting the copolymer of polyacrylamide (PAAm) and poly(acrylic acid) (PAA) onto carboxymethyl cellulose (CMC) and the formed hydrophilic [poly(AAm-co-AA)-g-CMC] hydrogel is able to uptake water quickly. Then, poly(AAm-co-AA)-g-CMC solution was cross-linked with a polyamide-6 (PA-6) substrate as a bottom layer under UV-irradiation to form a bilayer film. The film curls in water while uncurls in ethanol due to the expansion and contraction of the CMC layer in these two solvents, and the converse actuation is durable owning to the tight adhesion of the CMC-based top layer to the PA-6 bottom substrate.

Overall, the bilayer structure, usually consisting of an active and an inactive (or less active) layer in response to environmental stimuli, has been proven to be the most common architecture for actuators.69 Furthermore, their deformation resembles that of bimetallic actuators, which can be well predicted by the Timoshenko equation.50 Taking the bilayer model made up from a porous and a nonporous layer as an example, the porous layer speeds up the diffusion of solvent molecules into the polymer matrix and swells faster than nonporous layer, causing the bilayer to bend in a way with the porous part outward and the nonporous part inward. Though much success has been achieved in bilayer actuators, delamination often occurs between layers and remains challenging.70

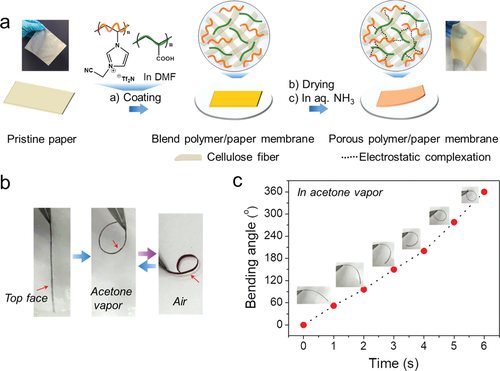

2.5.2 Polymeric Actuator in Gradient Structure

Recently, gradient-type actuators71 have aroused much interest due to lack of sharp interface across the materials that can effectively avoid the delamination in actuation. When subjected to external stimulus, single-layer gradient polymers can deform due to the asymmetric chemical properties, such as a gradient cross-linking density along the axial or vertical direction. Recently, our group reported an actuating porous PIL film carrying a gradient cross-linking density along its cross section (Figure 5).52, 72 This film was built up by electrostatic complexation between a cationic polyvinylimidazolium-based PIL and a multiacid/polyacid, such as PAA and a citric acid. The function of carboxylic acid here was to neutralize the polycation and electrostatically cross-link the PIL porous network upon ammonia treatment.52, 72 On one hand, due to the gradient in the degree of electrostatic complexation (DEC) of the PIL and polyacid along the cross section of film, the film was very sensitive to organic vapor. On the other hand, in comparison to a dense structure, the pores inside the film create transport highways for solvent molecules and thus accelerate the diffusion rate, as well as lowering the bending rigidity to speed up bending motion. In another design, a water-soluble vinylimidazolium-based PIL was fabricated into porous films that show reversible pore change between being open/close when shuttling between isopropanol and water due to pore swelling.73 By virtue of the porous architecture and electrostatic interaction, a porous PIL membrane with high sensitivity toward stimuli was developed.74 The bending curvature defined to be the reciprocal of the radius of the bent arc of the membrane can reach 0.076 mm−1 at 0.25 mol% aqueous acetone solution, which is at least one order of magnitude more sensitive than other solvent-driven polymer actuators. Besides, the bending curvature is linearly proportional to acetone content. Moreover, the gradient porous PIL can even discriminate butanol solvent isomers according to their different hydrophobicities.

The two types of configurations mentioned above have their distinctive advantages and related drawbacks. In the case of actuators in bilayer structure, they are simply constructed by the combination of active and inactive layers, which allows for a variety of materials to be involved through facile processing methods. However, delamination may occur due to different strains in the layers thus reducing the actuating performance. As for gradient structures, the actuators can maintain stable actuating performance under many repeated cycles with the delamination problem well addressed. The actuating mechanism relies more on the engineering of complex chemical structures, and may conflict with the “simple and green chemistry” concept. Therefore, more efforts are to be directed to develop actuating systems in a simplified process, such as the incorporation of aligned magnetic particles into polymers tuned by external magnetic field at varying angle to achieve controllable motions.66

3 Actuating Behaviors in Organic Liquid and Vapor Media

As mentioned above, tuning the molecular chemical groups and structuring the nanoscale building blocks are important and feasible tools to construct actuators. In addition, the properties of organic solvents are equally crucial for the actuating performance of the as-prepared polymeric actuators. Essentially, the molecular interaction between the organic molecules and the materials in the actuator determines the performance of actuation in terms of kinetics, shape, and scale, though the cycling performance is largely governed by the intrinsic structure in the actuators.

3.1 Liquid Phase Actuation

Usually, the actuating behaviors of polymeric films were tested by immersion into organic liquids. Efforts have been spent on exploring the relationship between the generated actuation and the polymer–liquid interaction. Lu et al.75 reported a porous polyurethane (PU) “spring” with a superhydrophobic surface and a water contact angle of 150o. After compression of a cubic PU sample into a slice, it can be readily wetted by organic solvents, showing a fast (2–3 s) and nearly complete shape recovery. The fast kinetics can be attributed to a capillary effect, which is enhanced by the wettable surface and porous structure. Specifically, porous structure with interconnected micro-channels inside its matrix could promote organic solvents to permeate into and diffuse through polymeric films. Furthermore, this PU material can serve as a liquid sensor. When compressed into a bar shape with two ends coated with silver paste, and connected with electric wires of a light-emitting diode (LED) light, the LED light could emit bright blue light as a result of the desirable electrical conductivity of the sensor (0.97 MΩ) under a voltage of 9 V. After dropping a small amount (16 mg) of petroleum ether, a common organic solvent, onto the sensor, it expanded quickly (<2 s), and the LED was immediately extinguished due to a dramatic increase of electrical resistance to >220 MΩ of the sensor. Such fast and visible sensing behavior allows us to detect organic liquids in a simple and effective way.

Ghosh et al.76 reported a cross-linked chitosan film which can fold and unfold reversibly or irreversibly at various ratios of aromatic alcohols. Furthermore, they fabricated some folded membranes in a flower shape, showing a superior lifting capacity, which can load 200 times weight of themselves. Utilizing poly(N-isopropylacrylamide) gels cross-linked by tris-methacrylated phloroglucinol derivatives, Itahara et al.77 prepared a solvent-driven actuator that can swell in ethanol and acetic acid but shrinks quickly in water in all directions. The deformation behavior is significantly influenced by solvent quality (e.g., polarity, miscibility, and hydrogen bonding). To clarify these effects, Harris et al.78 investigated a monolithic polymeric actuator built up from hydrogen-bonded liquid crystal (LC) polymer networks, which can swell and collapse anisotropically by engineering director profiles. When soaked in water, the film expanded and curled preferentially perpendicular to the director direction. When the water-soaked film is transferred to a water-miscible and polar solvent (such as acetone or isopropyl alcohol), instead of swelling the network, water is extracted due to the osmotic pressure difference between the film and fluid medium, thus forcing the film to bend in the opposite direction. On the contrary, when the water-soaked film is transferred to a water-immiscible and nonpolar solvent (such as toluene or xylene), water cannot be extracted from the film, and only little bending motion is observed. As such, the LC polymer actuators are envisioned for valves and pump application because of its relative stiff nature and controllable bending motion.

3.2 Gas Phase Actuation

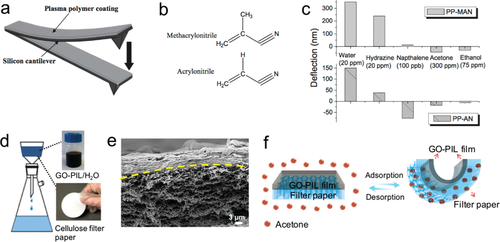

As for the organic vapor-induced actuation, the process of actuating motions is relatively slow as limited by the amount of solvent molecules diffused into the bulk materials per unit time. Concerning the actuating kinetics, the rate-determining step is the diffusion of solvent vapor molecules through the dense polymer network to solvate the membrane. For a nonporous membrane, the diffusion distance is almost equal to the membrane thickness (D). Whereas, in the case of a porous membrane, solvent molecules can have instant access to the pore surfaces with the diffusion distance of roughly the average thickness of the pore wall (h), much smaller than overall membrane thickness. The relationship between diffusion times for porous membranes (tp) and nonporous membranes (tnp) follows the equation: , indicating the diffusion rate can be greatly accelerated by introducing porosity into membranes.52 Therefore, in order to reach a fast actuating rate, approaches to reduce the diffusion path length have been tested such as decreasing membrane thickness and introducing porosity. Tsukruk et al.79 reported a bimaterial vapor-sensitive actuator by employing a plasma-polymerized methacrylonitrile (PP-MAN) or acrylonitrile (PP-AN) nanolayer coated on a silicon microcantilever (Figure 6a,b). The coating layer acts as an active mechanical actuator and enables fast response to vapor. When exposed to certain vapors, a preferential swelling of the PP-based domain causes a change in surface stress, resulting in bending motions (Figure 6c).

Song et al. reported a rationally designed bilayer membrane through vacuum filtration method (Figure 6d).70 The bilayer material comprises a lower porous substrate of a filter paper coated on the top with a deposited layer of PIL-modified graphene oxide nanosheets (GO-PIL) (Figure 6e). Such a bilayer structure shows a different response of the substrate and the top coating layer to organic vapors such as acetone and THF, thus triggering the bilayer membrane to undergo reversible bending/unbending motions (Figure 6f). Compared to the GO film without PIL modification, the PIL modified GO layer has a stronger binding adhesion between GOs and the filter paper surface, thus efficiently extending the lifetime without interfacial delamination. In this actuator, the dominant mechanism is the asymmetric swelling of the dense top GO layer and the porous filter paper layer. The porous bottom filter paper allows the solvent vapor to diffuse rapidly into the structure, while the top GO-PIL film with layered GO nanosheets densely packed onto each other hinders the diffusion of acetone vapor from the top side and interacts poorly with acetone molecules. As such, the swelling of the hybrid membrane in the filter paper substrate bends the membrane actuator in a way that the porous filter paper part is outward and the GO-PIL film inward. In the degassing step, acetone molecules diffuse easily out through the macropores, leading to the recovery of the original shape of the bilayer membrane. From a structural viewpoint, the porous membrane actuator is similar to asymmetric porous polyimide actuators mentioned above51 that bend with the porous part outward and the nonporous part inward, where the porous part exhibits a higher expansion than nonporous part and their actuation behavior follows the Timoshenko equation.50

4 Conclusion and Outlook

It is worth noting that the research on the organic solvent-induced actuators, especially referring to polymeric actuators, has attracted extensive attention and developed rapidly in the recent years for applications in micro-electronics, programmable origami, and energy generators.25, 80, 81 In synthetic polymeric materials, actuating behavior is driven by anisotropic or spatially inhomogeneous swelling/shrinking. Compared with the actuators sensitive to aqueous solvents (e.g., water or humidity), organic solvent-induced actuators are usually constructed with functional monomers, realizing various possibilities for practical applications, including the ability to respond distinctively to several chemical vapors, allowing for the detection of toxic and explosive chemicals.

A variety of design parameters can be controlled to realize polymeric actuators including tuning the molecular order, swelling ability, crystallization/molecular reconfiguration, and alignment of low-dimensional elements to construct anisotropic volume change upon organic solvents. For controllable actuation, incorporation of aligned CNTs into polymeric matrix has been widely exploited due to their outstanding mechanical properties. However, the current technology is not convenient and cost-efficient for obtaining aligned CNTs on a large scale. In addition to the incorporation of aligned CNTs, some research have been conducted on using 2D magnetic platelets to construct shape-deformation.66

Despite these great advances mentioned above, they are still far away from practical usage and extra efforts need to be further exerted not only to accelerate the responding speed and control the actuating direction, but also improve the sensitivity and fabricate diverse functional devices for real-life usage. The critical issue for actuating materials to deliver fast responding speed and superior sensitivity is to enhance the polymer-stimuli interaction (e.g., introduction of the suitable functional groups) and modify the actuator dimension (e.g., the relative thickness of active and inactive layers). Developing porous architecture can also promote the responding speed via accelerating the solvent molecules to penetrate into the polymeric materials compared to bulk materials, thus triggering the fast motions. Besides, multilayer structures can easily realize macroscopic motions by simple combination of active and inactive components. However, interfacial delamination of the active layer from the inactive layer may happen under continuous bending/unbending cycles which reduces the reproductivity and durability of actuators. Moreover, the process to prepare multilayers usually involves several steps, which is time-consuming and not favorable for scale-up production. The proposed solution is the introduction of gradients in the structure or composition or the application of a graded stimulus. The former is, for example, built up by the electrostatic complexation, while the latter is via introducing the gradient wetting/dewetting from the solvent. Besides, more attention should be attracted on the development of new gradient-type actuators by rational design of different structures to optimize actuating performance, mechanical flexibility, and interaction between constructing component and solvent. Another critical concern about the polymeric actuators for practical usage is the accurate motions to complete tasks. The actuators should accomplish complicate motions under the control of stimulus. Although some programmable polymeric actuators can efficiently solve this problem through the introduction of oriented elements or tuning actuator shape, their relatively low speed and bending curvature greatly limit the actuator performance.

To summarize, although much effort is still required to optimize the polymeric actuators in terms of material synthesis and structure design to achieve more functions, it is promising to realize sensing materials and smart systems for targeted practical applications in future.

Acknowledgements

H.L. and S.Z. equally contributed to this work. This work was financially supported by the National Natural Science Foundation of China (21403234), the Natural Science Foundation of Shanghai (18ZR1410200), the Jiangsu Provincial Foundation for Distinguished Young Scholar (BK20170045), start-up fund at Nanjing Tech University (3827400203), and National Key Basic Research Program of China (973) (2015CB932200). J.Y. acknowledges financial support from the European Research Council (ERC) Starting Grant (No. 639720-NAPOLI), the Wallenberg Academy Fellow program (No. KAW2017.0166) from the Knut and Alice Wallenberg Foundation in Sweden, and the Strategic Fund from Stockholm University (Contract number: SU FV-2.1.1-005).

Conflict of Interest

The authors declare no conflict of interest.

Biographies

Huijuan Lin earned her master's degree from Fudan University in 2014. Her Ph.D. project was carried out at the Max Planck Institute of Colloids and Interfaces under the supervision of Dr. Jiayin Yuan and Dr. John W. C. Dunlop. There, she studied porous poly(ionic liquids)-based actuators and received her Ph.D. degree from Potsdam University. In 2017, she joined the Institute of Advanced Materials (IAM) at Nanjing Tech University in China. Currently, she is interested in developing porous materials and nanostructured materials for sensing and energy storage applications.

John Dunlop studied materials engineering and chemistry at the University of Western Australia and then completed his Ph.D. studies in materials science at the Institut National Polytechnique de Grenoble in 2005. After a short postdoc, he started his own research group in the Department of Biomaterials at the Max Planck Institute of Colloids and Interfaces and started working on topics related to understanding morphogenesis in biological and synthetic systems. Since 2017, he has held the position of professor of biological physics at the Paris Lodron University of Salzburg and runs the morphophysics group there.

Jiayin Yuan studied chemistry at Shanghai Jiao Tong University, China, and received his master's degree at Uni Siegen, Germany, in 2004. He completed his Ph.D. with Axel Müller at Uni Bayreuth, Germany, in 2009, and then joined the Max Plank Institute of Colloids and Interfaces as a postdoc supervised by Markus Antonietti. From 2011 to 2016, he was a research group leader there. In 2017, he was appointed as an associate professor at Clarkson University, USA, and then moved to Stockholm University in 2018, where he became a full professor in 2019. His research focuses on polymers and carbons.