Malted and unmalted oats in brewing

Abstract

Using oats as a raw material in brewing has recently become the focus of increased interest. This is due to research findings that have shown that oats can be consumed safely by coeliac sufferers. It is also a response to consumer demand for products with novel sensory properties. In this study, beer was produced entirely from oat malt, from barley malt and from oat and barley malts mixed with various quantities of unmalted oats. Compared with barley wort, wort made from malted oats provided a lower extract content and had a higher protein content, but a lower free amino nitrogen content (FAN). The oat wort also showed increased viscosity and haze. The addition of unmalted oats during wort production produced significant changes in the physico-chemical parameters of both oat and barley worts and beers. Unmalted oats caused an increase in wort viscosity and haze, and a reduction in total soluble nitrogen and FAN. Unmalted oats also contributed to lowering the concentration of higher alcohols and esters. Beer made from 100% oat and barley malts exhibited a similar alcohol content. The use of an oat adjunct in both cases resulted in a lower ethanol content. The introduction of enzyme preparations during the production of wort with oat adjunct had many benefits: increased extract content and FAN; a higher volume of wort; and a lower viscosity that led to faster wort filtration. This research suggests that the use of enzymes is necessary to make production using a high proportion of oats in the grist profitable. Copyright © 2014 The Institute of Brewing & Distilling

Introduction

Oats are a relatively minor crop in terms of the global cultivation of cereals. The main producers are Russia, the USA and Canada 1. Recently, there has been increased interest in the grain owing to its numerous health benefits 2. Oats supply key cardioprotective compounds such as folate, magnesium, vitamin B6, vitamin E and substances with known antioxidant properties 3, 4. Oats are richer in protein than many other cereals, such as barley. Globulin, which is the most valuable protein from a nutritional point of view, is the most abundant protein fraction in oats, making up to 80% of the total kernel protein 5. Oats also contain exogenous amino acids, including lysine, which is not present in other cereals. Oats have high fat content, at around 7% d.m. However, most of this fat is made up of unsaturated fatty acids (oleic, palmitic and linoleic acids), which protect the nervous and blood systems 6, 7. Moreover, oats contain high levels of micro- and macroelements, such as iron, iodine, zinc and phosphorus 3. Regular consumption of oats, even in the form of bran or oatmeal, helps maintain appropriate blood insulin levels, reduces low-density-lipoprotein cholesterol, and increases high-density-lipoprotein cholesterol 8. Owing to its high fibre content, particularly β-glucan, oats support normal intestinal peristalsis, helping to maintain a healthy body weight. Therefore, the inclusion of oats in the daily diet not only improves nutrition, but also helps in the fight against various illnesses 7, 8.

Recent studies have shown that, in appropriate quantities, oats can be tolerated by people who suffer from coeliac disease (gluten intolerance) 9. Coeliac disease is a disorder of the small intestine that occurs in genetically predisposed people of all ages, from middle infancy onwards. Gluten is a general term used to describe prolamins, which are present in many grains. Species-specific prolamins in barley are called hordeins, in wheat they are called gliadins and in rye secalins. Coeliac disease is induced by an abnormal immunological reaction towards hordein, gliadin, secalin or similar classes of protein found in crops of the Triticeae tribe (which includes common grains such as barley and rye) 10. It causes many digestive ailments, principal among which are diarrhoea, abdominal pain and bloating. Untreated coeliac disease may also lead to more serious diseases such as rickets, curvature of the spine, atrophic gastritis, skin problems, malnutrition and emotional disorders.

A growing number of people are being diagnosed with coeliac disease 11. Patients are advised to eliminate beer from their diet, since it is usually produced using barley malt. The proteins are to a large extent digested and removed during the brewing process, but owing to a lack of reliable methods of gluten testing in beer, it is illegal to label beer produced from barley malt as a gluten-free product. Beer is not an indispensable part of the human diet. However, having a wider choice of products improves the quality of life of those suffering from gluten intolerance. Attempts have therefore been made to produce beer of good quality using oat malt, which would be safe for coeliac sufferers 2, 12.

Oat beer could be an attractive product not only for people suffering from coeliac disease, but also for other consumers who are looking for new and interesting flavours. Oats were used for the production of low-quality beer during the Middle Ages. However, currently oats are mainly used as an adjunct in the production of stout. Oat and barley grains differ in chemical composition 1, 13, 14. Oats have less starch and more protein, β-glucan and fat than barley. Although advantageous from a nutritional point of view, high β-glucan and protein content can cause technical problems, including prolonged beer filtration time and haze in the final product. Oat beer is also susceptible to the development of bitter off-flavours (associated with long-chain hydroxy fatty acids) and rancidity (associated with volatile aldehydes, ketones and alcohols) 15. Therefore, it is important to optimize each stage of the beer production process, beginning with malting 16.

The aim of this study was to examine the quality attributes of wort and beer produced entirely from oat malt, as well as from oat and barley malts mixed with various quantities of unmalted oats. The influence of Dex-Lo CL, an enzymatic preparation that exhibits only amylolytic activity, and of Filtrase® BR, a complex of amylolytic, proteolytic and cellulolytic enzymes, was investigated on the improvement of the physico-chemical parameters of the worts and beers obtained.

Materials and methods

Oat wort was produced entirely from oat malt or from oat malt with the addition of various quantities of unmalted oats (22.5 and 45%). To investigate whether unmalted oats can be a good partial substitute for barley malt, wort from barley malt was also produced with 22.5 and 45% unmalted oats. A 100% barley wort was used as a control. The influence of the enzyme preparations Filtrase® BR and Dex-Lo CL on the physico-chemical parameters of the worts was examined, together with the extent to which these enzymes can improve the production yield of oat beer.

Materials

Oat malt (Koneser variety) was used to produce the wort and beer. Oat malting was performed in a micromalting machine. Steeping was performed underwater for 4 h, then in air for 2 h and finally underwater for 3 h. Germination was carried out at 14°C for 120 h. The following scheme was used during drying (temperature/time): 55°C/10.5 h; 55–60°C/0.5 h, 60°C/1.5 h, 60–70°C/0.5 h, 70°C/1.0 h, 70–80°C/0.5 h; 80°C/2.5 h, 80–84°C/0.5 h, 84°C/1.5 h. After cooling the malt, the rootlets were removed. Aside from oat malt, unmalted oats (Slawko variety) and barley malt were used.

Filtrase® BR is an enzymatic complex consisting of β-glucanases, amylases, neutral proteases and hemicellulases. A quantity of 350 mg of Filtrase® BR per kg of raw starch was used in the tests. Dex-Lo CL is a liquid α-amylase from the species Bacillus amyloliquefaciens. It degrades starch into maltodextrins. A quantity of 400 mg/kg raw starch was added, as recommended by the manufacturer. The optimum temperature for this preparation is 70°C and pH 6–7. In order to increase activity at high temperatures (during raw-starch gelatinization), 200 ppm of CaCl2 was added to the mash.

Mashing

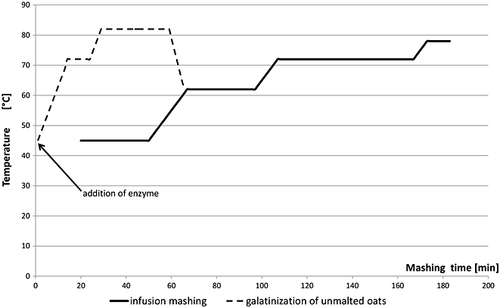

The barley and oat malts and unmalted oats were ground in a laboratory disc mill (DLFU). The slot between the discs was 0.2 mm wide. Milling was carried out directly before mashing-in. During the production of beer from 100% malt (barley or oat), the infusion–mashing process chosen was as follows: 30 min at 45°C, 30 min at 62°C, 60 min at 72°C and 10 min at 78°C (mashing-off). The heating rate was 1°C/min. When enzyme preparations were used during mashing, these were added at the beginning of the process, that is, at 45°C.

When wort was produced with oat adjunct, the adjunct was gelatinized in a separate vessel. The gelatinization process was as follows: the process was started at 45°C (with optional addition of enzyme;, 10 min at 72°C; and 30 min at 85°C. The heating rate was 1°C/min. The gelatinized oats were then added to the mash after the protein and β-glucan rest. As a result, the temperature of the mash increased to 62°C, that is, to a maltose formation rest (Fig. 1). After 30 min, the temperature rose to 72°C (1°C/min), where it was maintained for 60 min. The temperature was then increased by 1°C/min to 78°C and kept at this level for 10 min (mashing-off). Mashing without adjunct took 163 min, but with adjunct this time increased to 190 min. The hot mashes were filtered using filter paper MN 614 ¼ with a diameter of 320 mm (Macherey-Nagel), and after cooling to 20°C, the worts were analysed. All experiments were carried out in triplicate.

Brewing

When beer was produced from wort obtained entirely from oat or barley malt, or from mixtures of barley or oat malt and 22.5% unmalted oats, the wort was boiled with 0.9 g/L hop pellets (Marynka type 45) for 60 min, aiming for 25 IBU. The wort was then filtered to remove the hot break. A quantity of 400 mL of wort was pitched with 1.2 × 107 cells/mL of lager yeast strain W34/70. Fermentation was carried out at 10°C for 14 days. After fermentation, the beer was transferred to glass bottles (330 mL) and matured for 14 days at 1°C. The beer was then clarified by adding diatomaceous earth, to a concentration of 50 g/L, and analysed. All experiments were carried out in triplicate.

Beer and wort analyses

- extract (EBC method 8.3);

- colour (EBC method 8.5);

- wort viscosity using the Höppler viscometer (EBC method 8.4);

- total soluble nitrogen (TSN; EBC method 8.9.1; increasing the volume of sulphuric acid to 50 mL during digestion was the only deviation from this method);

- free amino nitrogen (FAN; EBC method 8.10);

- pH (EBC method 8.17).

Wort filterability was determined on the basis of the volume of wort, collected in a 500 mL measuring cylinder at regular time intervals.

The ethanol and fermentation by-products in the beer were analysed by headspace gas chromatography using a PerkinElmer Clarus 580 chromatograph equipped with a flame ionization detector. Samples (10 mL) were heated for 25 min at 60°C in the headspace autosampler. Separation was performed in a 30 m Elite-Wax column with 0.25 µm film thickness and a 0.25 mm internal diameter. The injection temperature was 200°C. The oven temperature programme was: 30°C for 5 min; 2°C/min to 60°C; held for 3 min; 2°C/min to 70°C; and finally 15°C min to 220°C; held for 3 min. The detector temperature was 250°C. The carrier gas, helium, was maintained at a flow rate of 1 mL/min. Volatile compounds were identified and quantified by comparison with the standards. Chromatograms were analysed using ChemStation software.

Statistical analysis

A Student's t-test was performed to determine the statistical significance. A p-value below 0.05 was considered statistically significant.

Results and discussion

Worts produced from 100% barley or oat malts, and from oat or barley malts mixed with 22.5 and 45% unmalted oats, were analysed to determine their most important technical parameters. The impact of the enzyme preparations Filtrase® BR and Dex-Lo CL on the wort parameters was also investigated.

Good malt modification and high malt enzymatic activity (glucanase, proteinase, amylase) had a positive influence on the extract content of the wort. Wort extract enables the pre-extract of the finished beer to be estimated. Wort produced entirely from malted barley exhibited the highest extract content (12.85 ± 0.31; Table 1). Oat wort had a much lower extract content than barley wort (p < 0.01). The highest of the oat wort extract contents was noted in the wort produced entirely from malted oats (11.34 ± 0.12). In both the oat and the barley worts obtained with a mixture of unmalted oats, the extract content was reduced (p < 0.001).

| Type of wort | Extract content (°P ) | Colour (EBC units) | pH | ||||||

|---|---|---|---|---|---|---|---|---|---|

| No enzyme | Filtrase® BR | Dex-Lo CL | No enzyme | Filtrase® BR | Dex-Lo CL | No enzyme | Filtrase® BR | Dex-Lo CL | |

| 100% barley malt | 12.85 ± 0.31 | 13.26 ± 0.28 | 13.53 ± 0.29 | 6.00 ± 0.00 | 6.50 ± 0.00 | 6.33 ± 0.29 | 5.77 ± 0.02 | 5.73 ± 0.02 | 5.75 ± 0.02 |

| 77.5% barley malt + 22.5% unmalted oats | 11.55 ± 0.23 | 11.92 ± 0.20 | 12.58 ± 0.18 | 6.50 ± 0.00 | 7.17 ± 0.29 | 7.00 ± 0.00 | 5.81 ± 0.02 | 5.78 ± 0.04 | 5.80 ± 0.02 |

| 55% barley malt + 45% unmalted oats | 11.18 ± 0.16 | 11.55 ± 0.15 | 11.72 ± 0.20 | 7.17 ± 0.29 | 7.33 ± 0.29 | 7.33 ± 0.29 | 5.87 ± 0.02 | 5.85 ± 0.03 | 5.88 ± 0.02 |

| 100% oat malt | 11.34 ± 0.12 | 11.62 ± 0.18 | 11.75 ± 0.20 | 8.17 ± 0.29 | 8.33 ± 0.29 | 8.33 ± 0.29 | 5.91 ± 0.03 | 5.94 ± 0.03 | 5.93 ± 0.03 |

| 77.5% oat malt + 22.5% unmalted oats | 10.28 ± 0.26 | 10.55 ± 0.16 | 10.66 ± 0.24 | 8.17 ± 0.29 | 8.33 ± 0.29 | 8.33 ± 0.29 | 5.93 ± 0.04 | 5.96 ± 0.04 | 5.95 ± 0.05 |

| 55% oat malt + 45% unmalted oats | 9.78 ± 0.22 | 10.02 ± 0.18 | 10.20 ± 0.16 | 8.33 ± 0.29 | 8.67 ± 0.29 | 8.50 ± 0.00 | 6.02 ± 0.03 | 6.05 ± 0.03 | 6.04 ± 0.04 |

The enzyme preparation Dex-Lo CL increased the extract content in the worts (p < 0.05), but less than expected. Application of Filtrase® BR produced a statistically significant increase in extract content in oat and barley worts produced with 45% unmalted oats (p < 0.05). Moreover, the increases in the extract contents of all-malt oat wort and the oat worts with adjunct were lower than those in barley wort and in the barley worts with adjunct. In all barley worts, produced with or without adjunct, the extract content rose by 0.61°P on average as a result of using Dex-Lo CL, while in the oat worts this figure was 0.4°P. This suggests that the starch in oat malt and in unmalted oats is less accessible by both endo- and exogenous amylase than the starch in barley. Barley starch exists in both large lenticular and small spherical granules 17, whereas oat starch has been found to occur in large granules that are formed by several individual granules and single irregular granules 15. Oat starch molecules may therefore be less accessible and more difficult to degrade by enzymes.

Lower glucanase and proteinase activity in oat malt may also lead to less degradation of the cell walls of the endosperm. If the cell walls are not sufficiently degraded, then access to starch molecules by enzymes is more difficult 2, 15, 18. However, it was found in the experiments that the enzyme preparation Filtrase® BR, which exhibits different enzymatic activities, including glucanases, proteinases and amylases, did not cause a higher extract yield in oat wort than Dex-Lo CL, which showed only α-amylase activity. This suggests that the low extract content in the oat wort compared with the barley wort may be mostly due to the low starch content in the oats and to the structural features of oat starch.

The colour of the wort is mainly affected by coloured compounds such as melanoidins, which form during the malting process. In addition, compounds present in the husks of malted and unmalted raw materials may influence the intensity of the colour 19. Oats contain more husks than barley, and this may be a cause of the darker colour in the wort 12. From the results (Table 1), it can be seen that the darkest wort was produced when 45% of the oat malt was replaced with oat adjunct (8.33 ± 0.29; p < 0.01). The colour of the wort obtained from oat malt alone was 8.17 EBC units. Barley wort was clearly the lightest in colour (6.00 ± 0.00). The darker colour of oat wort can also be connected with its higher pH value in comparison to barley malt wort, which favours the extraction of colouring compounds from the grist.

Higher colour values of wort produced with oat adjunct have also been observed by Schnitzenbaumer and Arendt 20. They also found that the use of enzymes affects the colour of wort. However, whereas in our experiment the difference in wort colour was statistically insignificant, in their study when the enzyme cocktail Ondea®Pro was used, the effect was much more pronounced, which is undesirable. Furthermore, the use of both oat malt and unmalted oats caused greater haze. The wort appeared opaque, which made the colour difficult to measure with a Hellige comparator.

Obtaining the optimum pH value in wort is extremely important to ensure high yeast and malt enzyme activity 21. As adjunct was added during the production of oat wort, the pH value increased (p < 0.05; Table 1). The pH value also increased with the use of adjunct in barley wort. It is possible that fewer buffer compounds, such as FAN, are present in oats. The enzyme preparations did not induce changes in the pH value of wort. Achieving optimal nitrogen content in wort is also extremely important. A protein content that is too low may negatively affect the taste of the beer and lead to problems with foam. High nitrogen content is not advantageous either, since this can contribute to the appearance of haze 22. It has been established that, for barley wort, the level of nitrogen should be between 700 and 800 mg/L 23.

It might be expected that, in wort made with oat malt, which has a higher protein content than barley malt 2, the soluble protein content would also be higher. In fact, in wort made from oat malt, the nitrogen content was 1211 mg/L, whereas in wort from barley malt this figure was 847 mg/L (Table 2). A similar phenomenon has been noted by Klose et al. 2. The use of Filtrase® BR (containing proteinase) during the production of all-malt oat wort resulted in an increase in TSN to 1351 mg/L (p < 0.05), inducing fairly strong turbidity. Again, this might suggest that, when using unmalted oats, which also have a higher protein content than barley malt, the nitrogen content of barley wort should also increase. However, it is well established that the use of adjunct causes the nitrogen level in wort to decrease. In our experiments, in barley wort made with 22.5% unmalted oats, the protein content decreased to 728 mg/L, and in wort produced with 45% of unmalted oats the protein content reduced to 609 mg/L. Adjunct also lowered TSN in the case of oat wort (p < 0.05). Replacing 45% of the oat malt with adjunct resulted in a decrease in protein to 889 mg/L (p < 0.01), but this still exceeded the recommended level. Such a reduction in the protein content of wort obtained with adjunct is not unusual, since the malting process facilitates the extraction of individual components, including proteins, into the wort 2, 23, 24. As a result, it is recommended that enzyme preparations containing proteinases such as Filtrase® BR be used in the production of barley wort with oat adjunct. The use of proteinases is not recommended in the case of oat wort because the TSN would be too high.

| Type of wort | TSN (mg/L) | |

|---|---|---|

| No enzyme | Filtrase BR | |

| 100% barley malt | 847 ± 29 | n.d. |

| 77.5% barley malt + 22.5% unmalted oats | 728 ± 19 | n.d. |

| 55% barley malt + 45% unmalted oats | 609 ± 27 | n.d. |

| 100% oat malt | 1211 ± 49 | 1351 ± 29 |

| 77.5% oat malt + 22.5% unmalted oats | 1085 ± 29 | 1190 ± 19 |

| 55% oat malt + 45% unmalted oats | 889 ± 28 | 1008 ± 19 |

- TSN, Total soluble nitrogen.

Low molecular nitrogenous compounds, such as amino acids and di- and tripeptides, are a major source of nitrogen and are essential compounds for the propagation of brewer's yeast. The majority of wort FAN is utilized for protein formation (structural and enzymatic), which is required for yeast growth and other functions such as osmoregulation 25, 26. FAN content is regarded as one of the main parameters defining the technical usefulness of wort 2, 12. The use of poorly modified malt and high substitution of malt with adjunct often causes reduced levels of FAN in wort. As a result, fermentation is slower, which prolongs the processing time or leads to the production of beer with a lower degree of attenuation 2, 12, 23. The optimal FAN content in barley wort is 200–250 mg/L 23. When adjunct is used, a lower FAN content of 140–150 mg/L is advised 27.

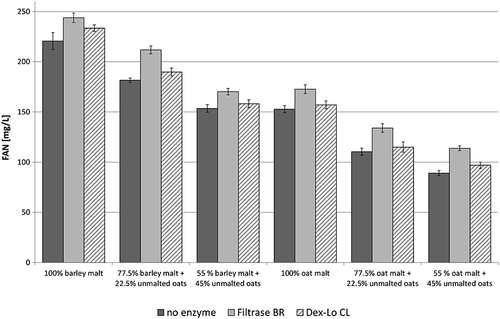

In this paper, FAN is expressed as calculated for a 12°P wort (Fig. 2). In the case of oat wort, the highest FAN content was found in all-malt oat wort (151 ± 4.54 mg/L). However, this was not within the recommended range for barley wort. In oat wort obtained with adjunct, the FAN content was lower at 89–110 mg/L. The use of Filtrase® BR (showing proteolytic activity) significantly increased the FAN content in all of the worts (p < 0.001). A lower degree of FAN utilization was observed in the all-malt beer than when beer was produced with 22.5% unmalted oats (Table 3). This tendency was observed in both barley and oat beers. The differences in FAN utilization by yeast during fermentation were not as high as would be expected given the substantial differences in the FAN content of oat and barley worts (Table 3). It can be concluded that the amino acid profile of the oat wort, particularly when made with unmalted oats, is much more beneficial for the yeast, and that nitrogen from this wort is absorbed more easily by Saccharomyces pastorianus than nitrogen from an all-malt wort.

| Type of beer | FAN (mg/L) | FAN utilization (%) |

|---|---|---|

| 100% barley malt | 107.1 ± 2.97 | 51.5 |

| 77.5% barley malt + 22.5% unmalted oat | 69.7 ± 4.95 | 61.7 |

| 100% oat malt | 65.8 ± 3.52 | 40.2 |

| 77.5% oat malt + 22.5% unmalted oat | 45.4 ± 3.39 | 49.0 |

- FAN, Free amino nitrogen content.

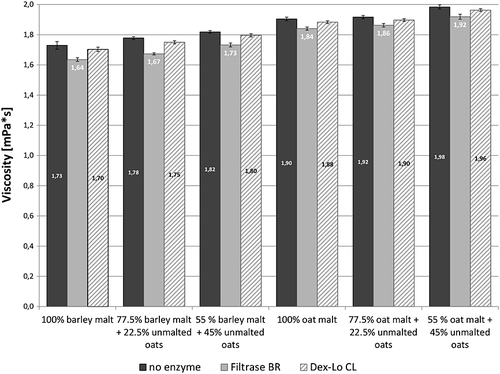

Wort viscosity can be used as a measure of the effectiveness of amylolytic and cytolytic enzymes 23, 28, 29. In a standard wort, it is usually assumed that viscosity should not exceed 1.67 mPa s 28.

Wort obtained purely from malted oats (Fig. 3) was characterized by a higher viscosity (1.90 mPa s) in comparison to barley wort (1.73 mPa s; p < 0.001). The use of unmalted oats for the production of oat and barley worts resulted in increased viscosity. The highest viscosity was observed in oat wort obtained from malted oats with 45% unmalted oats (1.98 mPa s). There is more β-glucan in oats than in barley. Moreover, oat malt exhibits a lower enzyme activity 2, 12, 17, 18, 23, 30, 31. The viscosity of the oat wort increases as a consequence. The high viscosity of oat wort may be an indication of possible problems during beer filtration 23, 30. Therefore, it is important to select appropriate exogenous enzymes for the processing of oats. Moreover, when part of the malt is replaced with adjunct, there is a lower level of malt enzymes, including β-glucanase (responsible for the degradation of β-glucan). The activity of β-glucanase in barley malt was estimated to be over 12 times higher than in unmalted oats 20. It is therefore advisable to use enzyme preparations when higher quantities of oat adjunct are applied.

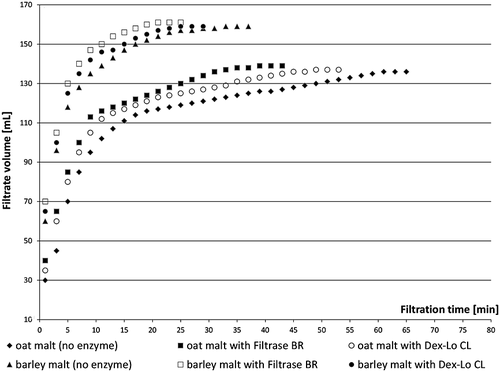

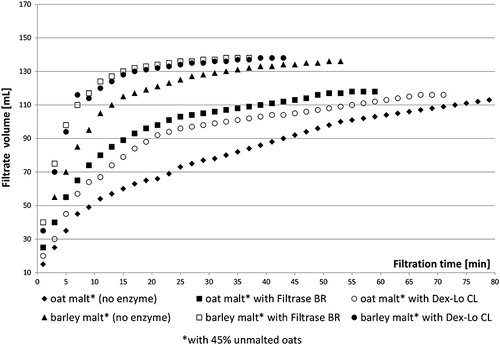

The use of enzyme preparations, in particular Filtrase® BR, which contains both cytolytic and amylolytic enzymes, led to a reduced wort viscosity (p < 0.01). However, this decline in viscosity, although statistically significant, was not substantial, even when substituting 45% of the malts with oats. The difference between the viscosities of the various worts was confirmed when their filterability was measured, in terms of the time needed to complete the filtration of the mash. A longer time means slow filtration. The filterability of oat wort in laboratory-scale production was found to be considerably lower than that of the barley wort. Both of the oat worts, produced solely from oat malt and oat wort with the addition of unmalted oats, took >60 min to filter (Figs 4-6). Low β-glucanase activity together with high β-glucan and fat content can be the cause of filtration problems 15, 24. Wort produced solely from oat malt filtered much faster than wort produced with the addition of 22.5 or 45% unmalted oats (p < 0.01) (Figs 4-6). In the case of wort produced with 45% unmalted oats, the filtration time was prolonged by around a third.

The use of the enzyme preparations Filtrase® BR and Dex-Lo CL shortened the filtration times (p < 0.01) (Figs 4-6). Filtrase® BR was particularly effective, reducing the filtration time of oat wort from 68 to 43 min. Dex-Lo CL also contributed to reducing the filtration time, but only by about 10 min.

The differences between the final volumes of the filtrates collected during the filtration of the various worts are also worth noting (Figs 4-6). A common feature of all oat worts and worts prepared with unmalted oats was not only the slower filtration time, but also the lower final volumes.

In an oat wort produced entirely from malt, the final volume of the filtrate was 118 mL (Fig. 4). The use of 45% adjunct reduced the volume to 92 mL (Fig. 6). The mean difference between oat and barley worts in terms of the final volume of filtrate was on average 22 mL. This is probably due to the existance of hygroscopic compounds in the oat husks. According to Schnizenbaumer and Arendt 15, oats have a much higher water hydration capacity than barley, which is connected to with the presence of β-glucan in the aleurone layer. This can explain the fact that the final volumes of the oat worts were smaller than those of the barley worts. The use of enzyme preparations – not only those containing cytolytic enzymes, but also simple α-amylase – resulted in a considerable increase in the final volume of wort. The greater the amount of malt that was substituted with oats, the higher was the increase in wort volume, resulting from the application of enzyme preparations (Figs 4-6). This is extremely important for brewers, since low volume and low extract content can make the production of oat wort financially non-viable.

Taking into account the filtration time and the final volume of filtrate, the mean volumes of filtrate per minute were calculated (Table 4). Table 4 shows the difference between the mean volumes of filtrate collected per minute for oat and barley worts. The filtration rate of barley wort was twice as high as that of oat wort. The use of unmalted oats caused a sharp decrease in the wort filtration rate, which accounted for 25 and 40%, respectively, when substituting 22.5 and 45% barley malt (p < 0.01). In the case of oat wort, the percentage reductions were 16 and 33% respectively. Therefore, a high proportion of oats in the grist requires the use of enzyme preparations. Preparations containing amylase and glucanase may be particularly useful, as these contribute to an increase in the rate of filtration and produce a higher volume of wort. In the study, Filtrase®BR improved the filterability of oat wort by 50% or more, in comparison to Dex-Lo CL, which improved filterability by approximately 21%. The improvements in barley wort filterability were between 44 and 50% using Filtrase® BR and between 21 and 27% using Dex-Lo CL.

| Type of wort | Wort filtration rate (mL/min) | |

|---|---|---|

| Barley malt | Oat malt | |

| 100% malt (no enzyme) | 4.30 ± 0.28 | 2.09 ± 0.15 |

| 100% malt + Filtrase® BR | 6.44 ± 0.35 | 3.23 ± 0.23 |

| 100% malt + Dex-Lo CL | 5.48 ± 0.26 | 2.58 ± 0.20 |

| 77.5% malt + 22.5% unmalted oats (no enzyme) | 3.23 ± 0.37 | 1.75 ± 0.13 |

| 77.5% malt + 22.5% unmalted oats + Filtrase® BR | 4.64 ± 0.26 | 2.76 ± 0.21 |

| 77.5% malt + 22.5% unmalted oats + Dex-Lo CL | 3.92 ± 0.14 | 2.18 ± 0.14 |

| 55 % malt + 45% unmalted oats (no enzyme) | 2.57 ± 0.23 | 1.41 ± 0.11 |

| 55% malt + 45% unmalted oats + Filtrase® BR | 3.73 ± 0.17 | 2.11 ± 0.09 |

| 55 % malt + 45% unmalted oats + Dex-Lo CL | 3.21 ± 0.18 | 1.63 ± 0.24 |

The flavour of the beer is of vital importance for consumers, and it has long been established that the type of malt used in brewing has an important impact on aroma and taste. During the alcoholic fermentation of wort, yeast excretes not only major fermentation products, such as ethanol and carbon dioxide, but also a wide range of flavour compounds, including higher alcohols, esters, carbonyls, sulphur compounds and organic and fatty acids 2, 21. The production and then partial decomposition of these substances is closely related to yeast metabolism. The unique flavour profiles of beer can largely be attributed to biochemical activities within the yeast cells during fermentation.

Flavour compounds are intermediates in pathways leading from the catabolism of wort components (sugars, nitrogenous compounds and sulphur compounds) to the synthesis of components required for yeast growth (amino acids, proteins, nucleic acids, lipids, etc.) 32, 33. By-products responsible for the formation of beer aromas and tastes can be divided into two groups. The first consists of compounds responsible for the flavour of young beer, such as diacetyl and sulfur-containing substances. These compounds give beer an unpleasant taste and aroma. When their concentrations are too high, they can lower the quality of the product considerably. However, they can be removed from beer through biochemical reactions initiated during the maturation process. The second group includes components that form the bouquet of a beer, that is, higher alcohols and esters. These cannot be removed using technical methods. If they are present in appropriate amounts, the product is of high quality 1. Volatile aroma-active esters are the largest group of flavour compounds in beer. They are responsible for fruit-like aromas. Esters are only present as trace compounds, but they are extremely important to the flavour profile. Over 100 different esters have been identified, among which two groups can be differentiated: acetate esters and medium-chain fatty acid esters 32-34.

The concentration of all measured esters was lower in beer produced from oat malt than in beer produced from barley malt (p < 0.01). It is recommended that, in order to achieve an appropriate bouquet, the ethyl acetate concentration should be between 8 and 32 mg/L 35. The ester content in beer produced entirely from oat malt was in accordance with this standard, but the addition of raw oats resulted in insufficient levels of the compound (Table 5). In barley beer, the addition of oat adjunct to the grist also decreased the concentration of ethyl acetate.

| Type of beer | Ethyl acetate (mg/L) | Isoamyl acetate (mg/L) | Ethyl caproate (mg/L) | Ethyl caprylate (mg/L) |

|---|---|---|---|---|

| 100% barley malt | 16.87 | 0.45 | 0.046 | 0.093 |

| 77.5% barley malt + 22.5% unmalted oats | 13.04 | 0.37 | 0.037 | 0.085 |

| 100% oat malt | 7.92 | 0.41 | 0.017 | 0.080 |

| 77.5% oat malt + 22.5% unmalted oats | 6.13 | 0.31 | 0.017 | 0.047 |

Isoamyl acetate gives a banana–pear flavour, and in beer should be in concentrations of between 0.3 and 3.8 mg/L. The detection threshold is 1.2 mg/L 35. In this study, each of the beers contained a sufficient amount of isoamyl acetate, but in oat beer and beer produced with unmalted oats the concentrations were lower. The concentration of ethyl caproate, which gives beer a slightly fruity, apple aroma, should be in the range of 0.05–0.21 mg/L 35. A suitable concentration of ethyl caproate was therefore only present in the beer made entirely from barley malt. Ethyl caprylate, like ethyl caproate, gives beer a fruity taste and aroma. The optimal content of ethyl caprylate in beer should be between 0.04 and 0.53 mg/L 35. Each of the beers met these requirements. The lowest concentration of ethyl caprylate was in oat beer with 22.5% unmalted oats (Table 5).

Higher extract content in wort and higher fermentation temperatures contribute to the formation of esters. In turn, higher unsaturated fatty acid and sediment content reduce the concentration of esters 31, 36, 37. It can be assumed that the decrease in the concentration of esters in oat and barley beer produced with unmalted oats is connected with the high level of unsaturated fatty acids in the oats. Unsaturated fatty acids inhibit alcohol acyl-transferase, which is involved in ester formation. Enrichment of wort in unsaturated fatty acids such as linoleic acid, which is abundant in oats, causes a sharp decline in ester formation by yeast 38. On the other hand, the lower FAN content of the worts produced with unmalted oats could influence yeast metabolism, leading to a higher ester level in the beer. However, it was observed that this effect had a minor impact.

Yeast mainly synthesizes higher alcohols from the amino acids present in the wort. These are deaminated to α-keto acids, which are then decarboxylated to aldehydes and further reduced to the corresponding alcohols. Most of the higher alcohols are formed during primary fermentation. Propan-1-ol, 2-methyl-1-propanol, 2-methylbutanol and 3-methylbutanol are the major higher alcohols in beer 2, 33, 35. Aliphatic alcohols give beer the taste of alcohol and solvents. Oat beer showed considerably lower concentrations of higher alcohols than barley beer (p < 0.05; Table 6). In barley beer and barley beer produced with unmalted oats, the concentration of n-propanal was near the lower limit of the acceptable range, that is, 5–17 mg/L 39. The n-propanol content in oat beer was even lower than the limit. The composition of amino acids in oat wort would have an influence on the production of higher alcohols. Methanol was not present in detectable levels in any of the beers.

| Type of beer | n-Propanol (mg/L) | 3-Methyl-1-butanol, 2-methyl-1-butanol (mg/L) | Ethanol (% vol) |

|---|---|---|---|

| 100% barley malt | 5.95 | 54.78 | 5.32 |

| 77.5% barley malt + 22.5% unmalted oats | 5.70 | 44.79 | 4.39 |

| 100% oat malt | 4.28 | 35.66 | 5.25 |

| 77.5% oat malt + 22.5% unmalted oats | 3.83 | 18.59 | 2.75 |

During fermentation, the nutrients are utilized and the major metabolites form, such as ethanol and CO2. Unlike higher alcohols, a high concentration of ethyl alcohol is required 32. Oat beer contained less ethyl alcohol than barley beer (p < 0.05). However, the ethanol content of the oat beer was not as low as expected, given the much lower extract content of oat wort in comparison to barley wort. The use of unmalted oats significantly decreased the concentration of ethanol (p < 0.001).

Conclusions

Oat malt and unmalted oats are rarely used in beer production. The risks of increased viscosity and turbidity and reduced extract content have probably discouraged their use. In the experiments described in this paper, both the use of oat malt and the addition of unmalted oats prolonged the filtration time and produced a smaller final volume of filtrate. The use of oat malt alone resulted in an increased protein content in the wort, but when unmalted oats were added to oat or barley malt, the protein content decreased. More efficient utilization by brewer's yeast of low-molecular-weight nitrogenous compounds was observed during the fermentation of barley and oat worts produced with a proportion of unmalted oats. When oat malt and unmalted oats were used, there was a decrease in the levels of esters, higher alcohols and ethanol in the beer. The use of oat adjunct in the production of barley beer can give a more delicate taste, as a result of a lower content of higher alcohols and a more diversified amino acid profile, but can also cause a decrease in the extract content and in the amount of soluble protein. The use of enzymes is recommended when a high proportion of oats is added to the mash (such as 22.5% or more). Enzymes contribute to increasing the extract content and the rate of filtration, and to producing a higher volume of wort. In spite of difficulties arising from the use of oats in brewing, this raw material could be an interesting alternative for people suffering from coeliac disease, as well as for those looking to experience new beer flavours. However, it appears that, for production to be profitable, large amounts of unmalted oats can only be used in beer production if exogenous enzymes are applied.

Acknowledgements

The work was supported by the Polish Ministry of Science and Higher Education under grant MNiSW N N312 359539. The authors would like to thank Mr Cezary Góral (Biochem-Art) for generously supplying the industrial enzymes used in the experiments.