The use of absorption enhancers to enhance the dispersibility of spray-dried powders for pulmonary gene therapy

Abstract

Background

Pulmonary gene therapy requires aerosolisation of the gene vectors to the target region of the lower respiratory tract. Pulmonary absorption enhancers have been shown to improve the penetration of pharmaceutically active ingredients in the airway. In this study, we investigate whether certain absorption enhancers may also enhance the aerosolisation properties of spray-dried powders containing non-viral gene vectors.

Methods

Spray-drying was used to prepare potentially respirable trehalose-based dry powders containing lipid-polycation-pDNA (LPD) vectors and absorption enhancers. Powder morphology and particle size were characterised using scanning electron microscopy and laser diffraction, respectively, with gel electrophoresis used to assess the structural integrity of the pDNA. The biological functionality of the powders was quantified using in vitro cell (A549) transfection. Aerosolisation from a Spinhaler® dry powder inhaler into a multistage liquid impinger (MSLI) was used to assess the in vitro dispersibility and deposition of the powders.

Results

Spray-dried powder containing dimethyl-β-cyclodextrin (DMC) demonstrated substantially altered particle morphology and an optimal particle size distribution for pulmonary delivery. The inclusion of DMC did not adversely affect the structural integrity of the LPD complex and the powder displayed significantly greater transfection efficiency as compared to unmodified powder. All absorption enhancers proffered enhanced powder deposition characteristics, with the DMC-modified powder facilitating high deposition in the lower stages of the MSLI.

Conclusions

Incorporation of absorption enhancers into non-viral gene therapy formulations prior to spray-drying can significantly enhance the aerosolisation properties of the resultant powder and increase biological functionality at the site of deposition in an in vitro model. Copyright © 2005 John Wiley & Sons, Ltd.

Introduction

Respirable dry powder inhaler delivery systems for pharmaceutically active molecules proffer advantages over other pulmonary delivery devices including enhanced stability, ease of administration and relatively simple formulation 1-6. The one-step spray-drying process has proved to be an effective way to prepare dry particles for pulmonary inhalation 7-11. Methods for increasing the dispersibility and subsequent pulmonary deposition of spray-dried particles range from development of the drying process, addition of supplementary carrier particles 12, and inhaler device modifications 3, 13-15. Previously, our laboratory has reported that the dispersibility of spray-dried powders for pulmonary gene therapy can be improved through additional formulation components 16, 17. The dose emission and dispersibility of spray-dried lactose particles containing the lipid-polycation-pDNA (LPD) non-viral gene therapy vector 18-21 is considerably enhanced in the presence of amino acids, specifically leucine, phenylalanine and arginine. These studies, however, suggested that the incorporated amino acids interacted with the LPD vector and led to a significant decrease in gene transfection efficiency, possibly through charge-mediated disruption of the LPD electrostatic complex caused by negative carboxylic acid groups in the amino acid chemical structure. In this study we investigate the utility of alternative molecules, with previous application in pulmonary drug delivery, for enhancing the dispersibility of spray-dried powders for respiratory gene delivery.

Pulmonary absorption enhancers, generally classified as bile salts, fatty acids, surfactants, chelating agents and other agents (e.g. cyclodextrin) 22-24, have been shown to improve the penetration of pharmaceutically active ingredients including proteins and macromolecules 25 in the airway. For example, dimethyl-β-cyclodextrin 26, 27 and the bile salt sodium taurocholate 28 have demonstrated up to 9-fold enhancement of the pulmonary penetration and subsequent bioavailability of insulin. In addition, carnitine and its derivatives are widely used to promote the penetration of natural or synthesised chemicals such as salmon calcitonin, azetirelin 29, 30 and the model polymer drug fluorescein isothiocyanate dextran 4000 31. Moreover, Kobayashi and co-workers not only showed that the absorption of proteins can be greatly improved by pulmonary absorption enhancers, but suggested that such enhancers are more effective in dry powder formulations than in liquid dosage forms 32. Although several studies demonstrate the pulmonary absorption enhancement effect on the delivery of pharmaceutically active agents, few articles report the influence of cyclodextrin derivatives on the dispersibility of drug particles for lung deposition 33, 34. The effect of these materials on the physical properties and functional deposition of spray-dried powders has yet to be investigated.

In this study, three candidate absorption enhancers, dimethyl-β-cyclodextrin, sodium taurocholate and carnitine hydrochloride, were incorporated into a spray-dried formulation of the LPD non-viral gene vector and the thermoprotectant carbohydrate excipient trehalose. We investigated the influence of the absorption enhancers on the size, morphology, transfection efficiency, dispersibility and in vitro pulmonary deposition of spray-dried powders to progress the development of a convenient, stable, dispersible and efficient pulmonary gene delivery system.

Materials and methods

1,2-Dioleoyl-3-trimethylammoniumpropane (DOTAP) was purchased from Avanti Polar Lipids (Alabama, USA). Protamine sulphate (grade X from salmon sperm) was obtained from Sigma-Aldrich Chemicals (Poole, UK). The 4.7 kb pEGFP-N1 plasmid construct containing the green fluorescent protein (GFP) reporter gene was propagated and purified as detailed previously 16, 17, 35, using kanamycin to ensure selective growth of transformed bacteria. Sodium taurocholate (STC), carnitine hydrochloride (CHC) and trehalose were obtained from Sigma-Aldrich Chemicals. Dimethyl-β-cyclodextrin (DMC) was purchased from Fisher Scientific UK Ltd. (Loughborough, UK). The following chemicals were used as received: agarose LE (Promega, Southampton, UK); ethidium bromide (EtBr) solution, sodium dodecyl sulphate (SDS) (Pharmacia Biotech, St Albans, UK); Tris base, Luria Bertani (LB) agar, LB broth (Sigma-Aldrich). All other chemicals were obtained from Fisher Scientific UK Ltd. and were of analytical grade.

Cell-culture plastics were purchased from Corning-Costar (High Wycombe, UK). Dulbecco's modified Eagle's medium (DMEM, 25 mM HEPES), foetal bovine serum (FBS), penicillin-streptomycin solution and trypsin-EDTA solution 1X were obtained from Life Technologies (Paisley, UK).

Preparation of spray-dried powders

Spray-dried trehalose-LPD powders were prepared in a similar manner to that reported previously for lactose-LPD powders 16, 17. Briefly, LPD complex preparations, comprising pDNA (400 µg), protamine sulphate (800 µg) and DOTAP (1200 µg), were added to 3% w/v trehalose solution (50 mL total volume), and spray-dried (Büchi B-191 mini-spray-dryer; Büchi Labortechnik AG, Switzerland) to produce a dry powder. Standard operating conditions employed during spray-drying were: inlet temperature, 150 °C; spray flow rate, 600 L/h; aspirator setting, 35 m3/h; pump setting, 450 mL/h. These conditions resulted in an outlet temperature of 83–85 °C.

To produce the absorption enhancer-trehalose-LPD powders, 150 mg STC, CHC or DMC were added to 3% w/v lactose solution. Each solution (total volume 50 mL) contained LPD complexes comprising pDNA (400 µg), protamine sulphate (800 µg) and DOTAP (1200 µg). Solutions were subsequently spray-dried using the standard operating conditions to produce dry powders.

Scanning electron microscopy

Spray-dried powders were sputter-layered with gold under partial vacuum in an EMScope® sputter machine and imaged using a Philips XL20 scanning electron microscope.

Particle size analysis

Laser diffraction (Mastersizer 2000; Malvern Instruments, Malvern, UK) was used to determine powder particle size using a dry dispersion technique in air. Approximately 200 mg powder per sample was used to achieve the required obscuration of 0.5–5%, and each sample was measured in triplicate.

Ethidium bromide exclusion

A 1% agarose gel was prepared in 0.5X Tris-borate EDTA (TBE) buffer, and immersed in 0.5X TBE buffer containing 0.5 µg/mL ethidium bromide (EtBr). Powdered samples were reconstituted in distilled water with gel loading buffer (0.25% bromophenol blue, 40% glycerol in TBE buffer), and added to the gel (1 µg pDNA per well). Equivalent samples were incubated with ‘digestion buffer’ (100 mM NaCl; 10 mM Tris-HCl, pH 8; 25 mM EDTA, pH 8; 0.5% SDS; 0.1 mg/mL proteinase K) for 35 min at 50 °C to release pDNA from protamine and DOTAP cationic lipid. The Wizard® DNA clean-up kit (Promega, Madison, USA) was used to purify liberated pDNA prior to loading (1 µg pDNA per well) onto the gel. The gel was run at 100 V for 1 h, then visualised under UV light with quantification of the pDNA signal using Molecular Analyst® software (Bio-Rad Gel Doc 1000; Bio-Rad Laboratories, Hercules, CA, USA).

In vitro cell transfection efficiency

A549 human lung epithelial carcinoma cells (European Collection of Animal Cell Cultures, Salisbury, UK) were cultured in DMEM with 10% FBS and 1% penicillin-streptomycin (5000 IU/mL) at 37 °C in a humidified atmosphere at 95% air/5% CO2. Cells at 85% confluency were washed twice with pre-warmed phosphate-buffered saline (PBS) and exposed to spray-dried powders reconstituted in serum-depleted DMEM (equivalent to 5 µg pDNA per well). The plates were incubated at 37 °C for 6 h, then the surfaces were rinsed thoroughly with PBS and the cells fed with 1 mL culture medium, and returned to the incubator for a further 42 h.

In vitro powder aerosolisation and deposition

The emitted dose of spray-dried powders was determined using a one-stage impinger consisting of a USP throat attached to a pump via a filter to capture all emitted particles. Powders were loaded into size 2 gelatin capsules, the capsules weighed, and placed into a Spinhaler® dry powder inhaler, located in the mouthpiece of a USP throat. The powder was aerosolised (35% relative humidity, 20 °C) at 60 L/min for 5 s. The capsules were reweighed, and the emitted dose determined as mass of powder emitted from the capsule, expressed as the percentage of the total loaded dose.

In vitro deposition was determined using a multistage liquid impinger (MSLI; Westech Instrument Services Ltd., Beds, UK), as outlined previously 16. Briefly, powders were loaded into size 2 gelatin capsules and placed into a Spinhaler® dry powder inhaler, attached to the MSLI via a stainless steel USP throat. DMEM (20 mL) was added to each stage of the MSLI. Ten capsules (equivalent to 133 µg pDNA) were aerosolised, as above, into the MSLI and the DMEM at each stage removed for analysis. The capsule and the MSLI throat and filter were each washed with 20 mL DMEM. A 4 mL aliquot of the collected DMEM was placed onto A549 cells at 85% confluency in six-well cell-culture plates for 48 h, as above, to determine gene expression.

Flow cytometry

Transfected cells were rinsed with PBS, trypsinised (0.3 mL trypsin-EDTA solution) and resuspended in 0.6 mL culture media (DMEM/10% FBS). The percentage of cells displaying GFP-associated fluorescence (FL1-H) was quantified by flow cytometry (FACScan; Becton Dickinson Immunocytometry Systems, San Jose, CA, USA) with analysis by Winmdi® Software (Joseph Trotter, The Scripps Institute, La Jolla, CA, USA).

Results

Dry powder yield

In each case the yield of spray-dried formulations in the presence of pulmonary absorption enhancer was significantly higher than trehalose-LPD alone (Figure 1). The observed increase in powder yield might initially indicate that the physical properties of the processed particles, e.g. particle diameter, density and morphology, have altered to influence their distribution in the spray-dryer.

Spray-dried powder yield. A total of 150 mg of sodium taurocholate (STC), carnitine hydrochloride (CHC) or dimethyl-β-cyclodextrin (DMC) was added to 50 mL of a 3% w/v trehalose solution to prepare spray-dried powder formulations using a Büchi B-191 mini spray-dryer with inlet temperature 150 °C, spray flow rate 600 L/h, aspirator setting 35 m3/h, and pump setting 450 mL/h. Data represented as mean ± s.e.m., n = 3. Statistical analysis by one-way analysis of variance (P < 0.05). *Significant difference from trehalose-LPD powder

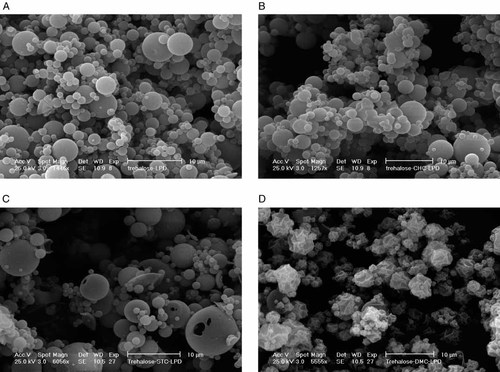

Particle morphology

The particle dimensions and surface morphology of the spray-dried powders were visualised using scanning electron microscopy (SEM; Figure 2). Spray-dried trehalose-LPD particles were perfectly spherical with a smooth surface. The particles appeared to remain in close proximity with limited inter-particle spacing (Figure 2A). CHC-trehalose-LPD particles comprised a similar morphology and particle size to trehalose-LPD (Figure 2B). The addition of both STC and DMC clearly affected particle morphology. The formulation containing STC contained a number of particles with cavities on their surface (Figure 2C). Although these surface aberrations are possibly caused by the intensity of the electron beam no holes were observed on the surface of the particles prepared in the absence of STC. The particles prepared in the presence of DMC-trehalose-LPD are non-spherical, being irregularly shaped and collapsed in nature (Figure 2D). It is interesting to observe that all of the particles prepared in the presence of absorption enhancer, and in particular DMC, were more dispersed with greater inter-particle spacing. This is indicative of a greater flowability of the prepared powder and less tendency for aggregation.

Spray-dried powder morphology visualised by scanning electron microscopy. (A) Trehalose-LPD powder; (B) CHC-trehalose-LPD powder; (C) STC-trehalose-LPD powder; (D) DMC-trehalose-LPD powder. Bar: 10 µm

Particle size distribution

The particle size distribution of spray-dried powders was determined using laser diffraction (Figure 3). The data demonstrate that spray-dried trehalose-LPD powders form a bimodal size distribution, with the majority of particles forming a population with a diameter less than 10 µm and a second population containing particles with diameters greater than 100 µm. As SEM showed that these particles were exclusively less than 10 µm in diameter (Figure 2A), it is logical to assume that this second population reflects aggregates of individual trehalose-LPD particles which are unable to be separated in the instrument air stream, as previously observed with lactose-LPD particles 16. Spray-dried powders of formulations containing STC or CHC also displayed a multimodal particle size distribution, whereas, when DMC was added to the spray-drying solution, the generated powder demonstrated a unimodal particle size distribution, possibly reflecting increased particle dispersibility in the instrument air stream.

Particle size distribution of spray-dried powders. The particle size distribution of trehalose-LPD powder, CHC-trehalose-LPD powder, STC-trehalose-LPD powder and DMC-trehalose-LPD powder was determined by laser diffraction

The laser diffraction particle sizing data are further tabulated in Table 1. The data are expressed in terms of the particle diameter at 10, 50 and 90% of the volume distribution (d[v,10], d[v,50] and d[v,90], respectively). The span of the volume distribution, a measure of the width of the volume distribution relative to the median diameter (d[v,50]), was derived from (d[v,90]—d[v,10])/d[v,50]. With a span of 2.2, trehalose-LPD particles had a mean particle diameter over volume distribution (D 4, 3) of 15.0 µm. Similarly, CHC-trehalose-LPD (mean diameter 13.2 mm, span 3.1) and STC-trehalose-LPD powders (mean diameter 16.4 mm, span 3.2) had mean diameters in excess of that required to avoid inertial impaction in the oropharyngeal cavity, i.e. <7 µm 36. In each case, the high mean diameter is a reflection of the particle aggregates observed during the particle sizing, and suggests inter-particulate cohesion. In contrast, DMC-trehalose-LPD powders displayed a uniform particle size distribution, with a mean particle size of 4.3 µm and span of 1.9, and clearly therefore show potential for efficient delivery to the airway.

pDNA and LPD complex integrity

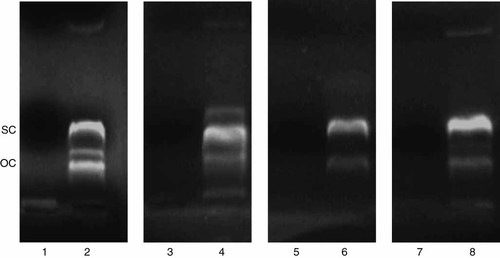

The influence of pulmonary absorption enhancer on the structural integrity of the LPD complex and the subsequent stability of the enclosed pDNA to the harsh spray-drying conditions was estimated by comparing the restrictive access to ethidium bromide (EtBr) intercalation. The extent of pDNA signal arising from the spray-dried powders was determined by gel electrophoresis with EtBr staining (Figure 4). Lanes 1, 3, 5 and 7 relate to the dry powder formulations of trehalose-LPD, CHC-trehalose-LPD, STC-trehalose-LPD and DMC-trehalose-LPD, respectively. The lack of detectable fluorescent signal in these lanes indicates that free pDNA was not present in the spray-dried powders; rather that pDNA was still contained within the LPD complex, and therefore not accessible to EtBr intercalation.

Investigation of spray-dried pDNA structural integrity. Spray-dried powders containing pEGFP-N1 plasmid were subjected to gel electrophoresis (1% agarose) and UV-illumination prior to (lanes 1, 3, 5 and 7) or after (lanes 2, 4, 6 and 8) incubation with digestion buffer with subsequent purification using the Wizard® DNA clean-up system. Lane 1: Trehalose-LPD; lane 2: trehalose-LPD following digestion and purification; lane 3: CHC-trehalose-LPD; lane 4: CHC-trehalose-LPD following digestion and purification; lane 5: STC-trehalose-LPD; lane 6: STC-trehalose-LPD following digestion and purification; lane 7: DMC-trehalose-LPD; and lane 8: DMC-trehalose-LPD following digestion and purification. SC = supercoiled, OC = open circular

Equivalent spray-dried powder samples were subjected to ‘digestion buffer’ to release the enclosed pDNA from the condensing moieties of the LPD complex. The subsequent UV-illuminated bands corresponding to free pDNA fell in the linear response range of the gel documentation software (Molecular Analyst®, Bio-Rad Laboratories). Lane 2 shows the fluorescent signal obtained from purified pDNA following disintegration of the trehalose-LPD spray-dried powder. In comparison with an equivalent quantity of purified pDNA obtained from LPD not undergoing spray-drying (control), approximately 81% of the pDNA signal was retained reflecting a high level of stability of the pDNA in the spray-drying atmosphere (temperature inlet 150 °C, outlet 83–85 °C). The addition of CHC into the spray-drying solution did not adversely affect the stability of LPD with the fluorescence signal approximately 80% of the control (lane 4). STC mediated an adverse effect on the stability of the LPD complex with approximately 65% of the pDNA signal detected in the dry powder after digestion and purification (lane 6). The reason for the reduced LPD complex stability is likely to be caused by the negatively charged sulphonic group on the taurocholate molecule electrostatically interacting with the positively charged groups of DOTAP and protamine leading to partial disruption of the LPD complex, and subsequent reduced protection of pDNA during spray-drying. The retention of fluorescent signal of the DMC-trehalose-LPD formulation (lane 8) was approximately 83% of the control, equivalent to that obtained with the absorption-enhancer-free formulation.

In vitro transfection efficiency

The influence of pulmonary absorption enhancer on the biological functionality of the spray-dried non-viral gene vector was investigated initially by in vitro transfection of human lung epithelial carcinoma (A549) cells. The transfection efficiencies of resuspended dry powder aliquots of trehalose-LPD, CHC-trehalose-LPD, STC-trehalose-LPD and DMC-trehalose-LPD containing the GFP reporter gene are shown in Figure 5. Following transfection with the trehalose-LPD powder, approximately 42% of the cells displayed fluorescence attributable to reporter gene expression (Table 2). Although the addition of CHC into the formulation resulted in a slight reduction in transfection efficiency (∼40% cells positive for GFP-associated fluorescence), there was no significant difference (P > 0.05) in comparison with trehalose-LPD. STC however caused a significant (P < 0.05) reduction in reporter gene expression to approximately 27% cells positive for GFP. The percentage decrease in gene expression efficiency (∼65%) clearly reflects the equivalent reduction of pDNA viable quantity observed using gel electrophoresis. Surprisingly, the inclusion of DMC in the formulation significantly (P < 0.05) increased the transfection efficiency, with approximately 50% cells positive for GFP. Given the reported ability of DMC to transiently disrupt cellular tight junctions through extraction of membrane cholesterol 37, 38, further studies are required to determine whether this enhanced delivery of LPD into the cells is a function of these cell membrane modifying properties.

Flow cytometry of A549 cells displaying GFP-associated fluorescence. A marked region was established containing 1% of the population of untreated control cells. The percentage of cells moving into this marked region was analysed following transfection with (i) trehalose-LPD powder; (ii) CHC-trehalose-LPD powder; (iii) STC-trehalose-LPD powder; and (iv) DMC-trehalose-LPD powder. Data represented as mean ± s.e.m., n = 6. Statistical analysis by one-way analysis of variance (P < 0.05). *Significant difference from trehalose-LPD powder

| Cell transfection (mean % gated cells ± s.e.m.) | ED (mean% ± s.e.m.) | FPF (% powder <6.8 µm) | Cum. gene expression (% gated cells) | |

|---|---|---|---|---|

| Lactose-LPDa | 45.3 (4.6) | 57.0 (5.9) | 12.2 | 51.4 |

| Trehalose-LPD | 41.9 (4.4) | 90.4 (4.2) | 15.6 | 47.9 |

| CHC-trehalose-LPD | 39.7 (0.8) | 92.6 (5.6) | 27.9 | 42.6 |

| STC-trehalose-LPD | 27.2 (5.7) | 77.2 (10.5) | 21.4 | 31.9 |

| DMC-trehalose-LPD | 50.2 (7.3) | 84.4 (4.6) | 48.2 | 54.7 |

- a Data obtained from previous studies 17.

Dose emission

A one-stage impinger was used to assess the influence of absorption enhancers on the emitted dose of the powders aerosolised (Spinhaler®) from gelatin capsules. The emitted dose is defined as the percentage of powder loaded into the capsule that is emitted during aerosolisation, determined gravimetrically. The trehalose-LPD powder had an emitted dose of 90% (Table 2), comparing favourably with previous studies with lactose-LPD spray-dried powder (emitted dose 57% 17). The addition of CHC and DMC to the formulation led to no significant (P > 0.05) change in dose emission in comparison with trehalose-LPD (92 and 84%, respectively). The mass of powder emitted from capsules containing STC-trehalose-LPD was significantly (P < 0.05) reduced to 77%.

In vitro deposition and biological functionality

The dispersibility and subsequent airflow characteristics of the dry powders after capsule emission will play a crucial role in determining the amount of particles depositing in the lower respiratory tract. The multistage liquid impinger (MSLI), the method of choice for both the European and United States Pharmacopoeias for the evaluation of in vitro deposition of dry powders in the airway, was used to assess whether the addition of absorption enhancer increased the deposition of the formulated powders following delivery via a dry powder inhaler. Figure 6 demonstrates that spray-dried trehalose-LPD powders can only mediate noteworthy powder deposition, and subsequent reporter gene expression, in the upper airway, specifically the throat and stage 1. These results clearly demonstrate that, despite a median particle diameter of 2.8 µm (Table 1), the trehalose-LPD powder demonstrates poor aerodynamic behaviour, resulting in deposition in the upper stages of the MSLI. In contrast, CHC-trehalose-LPD particles had an enhanced dispersibility and exhibited decreasing deposition on stages 1, 2, 3 and 4, respectively. The presence of STC also influenced powder flow properties with reduced powder deposition in the throat and stage 1, although the very slight gene expression observed in the lower airway (stages 3, 4 and filter) demonstrates that STC is not a superior dispersibility enhancer for spray-dried particles. The DMC-trehalose-LPD powder gave significantly (P < 0.05) greater (∼4-fold) gene expression at stages 3 and 4, in comparison with trehalose-LPD powders and other formulations. These results demonstrate that DMC has utility as an efficient dispersibility enhancer for delivering spray-dried non-viral gene vector particles into the lower respiratory tract.

In vitro deposition of spray-dried particles using a simulated lung model. The multistage liquid impinger (MSLI) was utilised to investigate the dispersibility and functional deposition of (i) trehalose-LPD powder; (ii) CHC-trehalose-LPD powder; (iii) STC-trehalose-LPD powder; and (iv) DMC-trehalose-LPD powder. Powders were loaded into gelatin capsules (size 2) and aerosolised into a MSLI using a Spinhaler® dry powder inhaler. Ten capsules (equivalent to 133 µg pDNA) were fired into the MSLI, and the DMEM at each stage (20 mL) removed for analysis. The capsule, throat and filter of the device were washed with DMEM (20 mL respectively). A 4 mL aliquot of the collected DMEM was placed onto A549 cells in 6-well cell-culture plates. Gene expression was determined by flow cytometry. Data represented as mean ± s.e.m., n = 4. Statistical analysis by one-way analysis of variance (P < 0.05)

To further investigate the predicted respirability of the spray-dried powders, the fine particle fraction (FPF) of each powder was estimated. The FPF, calculated as the level of gene expression observed for particles with an aerodynamic diameter smaller than 6.8 µm (i.e. stage 3 to filter) as a percentage of total gene expression observed for the powder (i.e. capsule to filter), was used to predict the dose reaching the lower regions of the lung 39. As indicated in Table 2, trehalose-LPD has the lowest FPF of the formulations tested (15.6%), whilst the FPF of DMC-trehalose-LPD was clearly the highest, with almost 50% of the inhaled powder displaying functionality at regions equating to the lower respiratory tract.

The cumulative reporter gene expression, from capsule, throat, stages 1–4 and filter, was calculated for each powder for further data validation (Table 2). The total gene expression observed in the MSLI study closely resembled that of the in vitro transfection assay (also presented in Table 2) demonstrating that the aerosolisation process did not adversely affect the in vitro biological functionality of the LPD powders. Furthermore, the emitted dose was validated via division of the cumulative reporter gene expression observed for throat to filter (i.e. without the capsule rinsings) by total gene expression. The percentage of emitted dose of trehalose-LPD, CHC-trehalose-LPD, STC-trehalose-LPD and DMC-trehalose-LPD was 92.6, 90.5, 76.8 and 88.2%, respectively. These data bear extremely close correlation with the emitted dose data presented in Table 2.

Discussion

Carbohydrates are commonly utilised as thermo-protectant excipients for biological macromolecules, e.g. proteins and DNA, when preparing dry particles via spray-drying. In our previous studies 16, 17, lactose has been predominantly used to prepare spray-dried non-viral gene vector powders for inhalation. Despite the proven ability of lactose to maintain the stability and functionality of spray-dried LPD powders, the processed material is cohesive and prone to aggregation with an emitted dose of less than 60%. In this study, trehalose was employed as an alternative primary spray-drying excipient and demonstrated improved emitted dose (∼90%). Moreover, the yield of trehalose-LPD powder following spray-drying was around 40% compared with 30% spray-dried lactose-LPD 16.

We have previously suggested that formulation additives containing negatively charged groups could damage the stability of LPD complexes to spray-drying and confer a partial loss in biological function 16, 17. This paper supports this observation as the addition of negatively charged sodium taurocholate (STC) into the spray-drying formula led to a decrease in LPD complex integrity and a subsequent reduction in transfection efficiency compared with spray-dried trehalose-LPD. In this study, we further observe that the neutrally charged absorption enhancer dimethyl-β-cyclodextrin (DMC), when added to trehalose-LPD, mediates reporter gene expression in 50% of A549 cells, 1.2 times that of trehalose-LPD alone, when following a standard transfection protocol (Table 2). More extensive studies are required to determine whether the effect of DMC on cell transfection is concentration-dependent and related to the suggested absorption-enhancing mechanisms of this material. Previous reports claim that DMC enhances airway absorption 1.2–2.4 times that of control through disruption of tight cellular junctions 25, 32, 40.

The in vitro deposition of spray-dried powders was assessed using a multistage liquid impinger (MSLI). Although it has been noted that the deposition pattern in an MSLI may differ from that observed in vivo, due to differences in patient inspiratory flow rate and inhaled volume 41, the MSLI is routinely employed for the evaluation of in vitro deposition of dry powders, and is the method of choice for both the European and United States Pharmacopoeias.

In this paper, we demonstrate that pulmonary absorption enhancers can also be used as dispersibility enhancers for spray-dried inhaler formulations, influencing the spray-drying yield, particle morphology, particle size distribution, dose emission and in vitro pulmonary deposition. Amongst those absorption enhancers tested, DMC proved a superior dispersibility additive for gene therapy applications, demonstrating both improved cell transfection efficiency and greatly enhanced powder dispersibility with a subsequent FPF of near 50%. Although, as reported previously 16, 17, leucine and other amino acids (e.g. arginine, phenylalanine) have been shown to act as efficient dispersibility enhancers for spray-dried lactose-LPD powders, their addition to the formulation can compromise the integrity of the LPD complex and the enclosed pDNA, mediating a decrease in transfection efficiency.

Conclusions

Pulmonary absorption enhancers may have an important role to play in delivering dry powders to the target region of the lung as well as promoting its absorption therein. Specifically, dimethyl-β-cyclodextrin has shown considerable potential for utility as a dispersibility enhancer to increase the fine particle fraction and functional deposition of non-viral gene therapy dry powder dispersions.

Acknowledgements

The authors are grateful to The Wales Office of Research and Development, National Assembly for Wales (Grant No. DTA01/1/003) for financial support and to Dr A. Hann, Cardiff School of Biosciences, for assistance with microscopy.