Evaluation of Mechanical Strength, Translucency, and Microstructure in Graded Zirconia Layers Before and After Hydrothermal Aging

Funding: This work was supported by Brazilian Federal Agency for Coordination of Improvement of Higher Education Personnel (CAPES) (P.M.S., L.S.R. and A.P.H. Doctorate's scholarships; Finance Code 001), and by the Brazilian National Council for Scientific and Technological Development (CNPq) (L.F.B.S. doctorate scholarships, #162322/2022-4, G.K.R.P. research grant, #304665/2022-3, and L.S.D. research grant #308277/2021-0). We especially thank Ivoclar for donating some materials and emphasize that those institutions had no role in the study design, data collection or analysis, decision to publish, or manuscript preparation.

ABSTRACT

This study aimed to evaluate the monotonic and fatigue strength, translucency, topography, and grain size of different layers in two types of graded zirconia, both before and after hydrothermal aging. A total of 180 bar-shaped specimens (n = 15 per group) were prepared from each layer (cervical, transitional, and incisal) of two graded zirconias (IPS e.max ZirCAD MT Multi—4 mol% yttrium stabilized at the cervical region and 5 mol% at the incisal region; IPS e.max ZirCAD Prime, Ivoclar AG—3 mol% yttrium stabilized at the cervical region and 5 mol% at the incisal region) with dimensions of 14.0 × 4.0 × 3.0 mm, following ISO 6872 standards for a three-point-bending test. These specimens were divided into two groups: baseline and hydrothermal aging (134°C under 2 bars of pressure for 20 h). Monotonic and fatigue three-point bending tests (initial stress: 250 MPa/5000 cycles at 20 Hz; increments: 50 MPa/step) were performed until fracture. The translucency parameter (TP00) was calculated using the CIEDE2000 formula, and L*, a*, b* color coordinates were measured on disc-shaped specimens (n = 6 per layer; Ø = 10 mm, 1 mm thickness) before and after aging. Additional analyses included topography, fractography, and grain size. Data were analyzed using three-way ANOVA, Kaplan–Meier, and Mantel-Cox post hoc tests (log-rank). Hydrothermal aging decreased fatigue flexural strength across all layers and types of graded zirconia. After aging, the fatigue flexural strength of Prime zirconia was higher than that of MT Multi in the cervical layer. The cervical layers exhibited the highest flexural strength and smallest grain size, while incisal layers showed higher translucency compared to other layers. The induced aging protocol impacted the mechanical properties of the graded zirconia layers. Each layer within the multilayer zirconia systems displayed distinct mechanical, microstructural, and optical properties, with variations depending on the specific zirconia material. Overall, all layers demonstrated satisfactory performance, supporting the use of multilayer zirconia systems.

1 Introduction

Dental ceramics are prominently used in oral rehabilitations due to their outstanding esthetic results, biocompatibility, and mechanical performance [1]. Monolithic zirconia restorations, in particular, have emerged as one of the most favored options, displaying superior mechanical fatigue behavior compared with other ceramics [2, 3]. The newer generations, namely 5YSZ and 4YSZ (5 and 4 mol% of yttria-stabilized zirconia, respectively), exhibit increased translucency relative to the previous generation (3YSZ), attributed to a higher stabilizer content and the presence of a crystallographic cubic phase [4]. However, these advanced materials demonstrate diminished mechanical behavior compared with 3YSZ, as evidenced by prior studies [5-7].

The increasing demand for dental materials that replicate the esthetics of natural teeth at an even more precise level has led to the development of multilayer zirconia ceramics, presenting varying levels of yttria across different regions of the same block [8-11]. This system allows for the use of a more resilient and opaque zirconia (3YSZ) in the cervical region of the crown, commonly subjected to tensile stress at the bonding surface [3, 12]. Simultaneously, a more translucent portion of the material is applied to the incisal/occlusal zone to enhance the light interaction of the restoration.

In terms of mechanical behavior, while studies have explored multilayer zirconia, only a limited number have specifically assessed differences among the cervical, transition, and incisal zones of the same material [13-17]. A previous study evaluated the properties of ZirCAD MT Multi (Ivoclar AG), featuring 5YSZ for the incisal zone, 4/5YSZ for the transition zone, and 4YSZ for the cervical zone. Their evaluation of flexural strength under both monotonic and fatigue scenarios revealed that 4YSZ exhibited higher flexural strength after both static and cyclic load applications [14]. In contrast, Schabbach et al. [13] demonstrated that intermediate layers of Katana multilayer ML displayed higher flexural strength values than the most cervical and incisal layers. Importantly, it should be noted that manufacturers typically publish scientific documentation considering a single mean value for each evaluated property, overlooking the potential impact of each layer on the restoration performance in a clinical scenario, where both esthetics and mechanical performance are crucial, mainly when considering anterior region. Thus, it is essential to determinate the isolate effect of each zirconia layer on such outcomes.

Lastly, an essential consideration is the susceptibility of each zirconia layer to low-temperature degradation (LTD) [18-20]. This phenomenon is linked to material deterioration over time due to the transformation from crystallographic phases, triggered by external factors such as humidity [21, 22]. This transformation induces residual stress and volume expansion in the zirconia grains, potentially leading to the formation of microcracks and premature material failure [22-24]. Moreover, the quantity of stabilizer also plays a role in phase transformation mechanisms, with 4YSZ and 5YSZ demonstrating greater resistance to LTD compared to 3YSZ [6]. Therefore, it is crucial to assess the microstructure, mechanical, and optical properties of multilayer zirconia ceramics, as variations in grain size, and performance across each zone may impact the integrity and longevity of the restoration.

Considering the aforementioned information, this study aimed to evaluate the monotonic and fatigue strength, translucency, topography, and grain size of different layers in two types of graded zirconia, both before and after hydrothermal aging. The hypotheses under consideration were that all the characteristics examined would be influenced by (1) the impact of hydrothermal aging (2) the specific ceramic layer (cervical, transition, and incisal zone), and (3) the type of zirconia ceramic.

2 Materials & Methods

2.1 Experimental Design

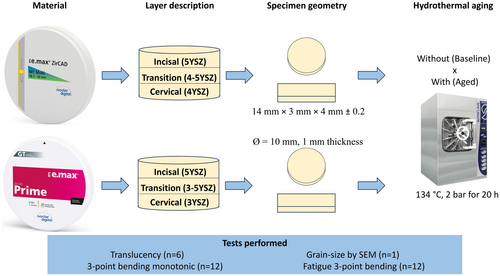

In this study, two distinct specimen geometries were adopted to evaluate different multilayer zirconia ceramics (IPS e.max ZirCAD MT Multi, A2 shade, Ivoclar AG; IPS e.max ZirCAD Prime, A2 shade, Ivoclar AG). The first one assessed mechanical and microstructural outcomes between the layers of each ceramic. For the evaluation of flexural strength (under both monotonic and fatigue conditions), zirconia bars from each layer (cervical, transition, and incisal zones) were obtained (14 × 3 × 4 mm) and subjected to a 3-point bending test (n = 15) (Figure 1). The second specimen geometry was used to evaluate optical characteristics. In this sense, ceramic discs (Ø = 10 mm, 1 mm thickness) were prepared for the translucency test (n = 6). Both tests were conducted under baseline conditions (absence of aging) and after hydrothermal aging. The details of the adopted materials are outlined in Table 1, and the experimental design is illustrated in Figure 1.

| Material | Layer zone | Manufacturer (batch number) | Composition |

|---|---|---|---|

| IPS e.max ZirCAD MT Multi A2 | Incisal (5YSZ) | Ivoclar AG | ZrO2, 5 mol% Y2O3, HfO2, Al2O3, other oxides. |

| Transition (4–5YSZ) | ZrO2, 4–5 mol% Y2O3, HfO2, Al2O3, other oxides. | ||

| Cervical (4YSZ) | ZrO2, 4 mol% Y2O3, HfO2, Al2O3, other oxides. | ||

| IPS e.max ZirCAD Prime A2 | Incisal (5YSZ) | Ivoclar AG | ZrO2, 5 mol% Y2O3, HfO2, Al2O3, other oxides. |

| Transition (3–5YSZ) | ZrO2, 3–5 mol% Y2O3, HfO2, Al2O3, other oxides. | ||

| Cervical (3YSZ) | ZrO2, 3 mol% Y2O3, HfO2, Al2O3, other oxides. |

2.2 Three-Point Bending Test

2.2.1 Specimen Preparation

For the mechanical tests, a total of 180 bar-shaped specimens were obtained for each multilayer zirconia, with dimensions of 20 × 8 × 6 mm. Initially, each zirconia block was divided into smaller sections (20 × 8 mm) using a diamond disc with an electric motor (Perfecta LA 623 T, 1000–40,000 rpm—W&H, Bürmoos, Austria). The translucent layer was identified and marked, after which metallic holders were affixed to the sections. Subsequently, the sections were transformed into bars using a diamond disc in a precision cutting machine (Isomet 1000, Buehler, Lake Bluff, USA) under continuous water cooling. The dimensions of each layer for each zirconia were taken into account during this process (Figure 1).

The bars underwent grinding on each side to eliminate defects and achieve standardized, polished surfaces by two trained operators, utilizing silicon-carbide papers (SiC) with #400, #600, and #1200 grit-size in a polishing machine (EcoMet/AutoMet 250, Buehler) under water cooling. This process continued until the bars reached their final pre-sintering dimensions of 17.5 × 5 × 3.75 mm. To minimize stress concentration at the bar edges, a chamfer was introduced by two calibrated operators after a series of pilot procedures. The bars' side edges were lightly ground for 5 s with a #600 grit SiC paper to form a chamfer ranging from 0.112 to 0.187 mm (considering a 20% contraction after the sintering process), following ISO 6872 [25] guidelines. The dimensions of each chamfer were verified using a stereomicroscope at 50× magnification (Discovery V20, Carl Zeiss, Gottingen, Germany). Any discrepancies detected led to the replacement of the affected bar. Subsequently, the specimens were cleaned in an ultrasonic bath (1440 D—Odontrobras, Ind. E Com. Equip. Med. Odonto. LTDA; São Paulo, Brazil) with distilled water for 5 min and air-dried for subsequent sintering in a specific furnace (VITA Zyrcomat 6000 MS, Vita Zahnfabrik, Germany), according to the manufacturer's instructions (heating at 10°C/min up to 900°C, holding for 30 min in 900°C, followed by an increase of 3.3°C/min up to 1500°C, holding at 1500°C for 120 min, and cooling down to 900 and then 300°C).

2.2.2 Hydrothermal Aging

Half of the obtained specimens were randomly allocated (www.OpenEpi.com) and subjected to simulated low temperature degradation (LTD) using a hydrothermal aging protocol. The aging process was conducted in an autoclave (Sercon HS1-0300 n11560389/1, Mogi das Cruzes, Brazil) at 134°C under 2 bars of pressure for 20 h, following the parameters outlined in a previous study [24].

2.2.3 Three-Point Bending Monotonic Test

2.2.4 Three-Point Bending Fatigue Test

The same test configuration used for the monotonic test was employed for a three-point bending fatigue test conducted on a universal testing machine (Instron ElectroPuls E3000, Instron Corporation, Norwood, USA). In this cyclic fatigue test (n = 15), specimens were submerged in water, subjected to an initial stress of 250 MPa for 5000 cycles at 20 Hz, followed by increments of 50 MPa (e.g., 300, 350 MPa) until fracture occurred. Fatigue strength (FS) and cycles for failure (CFF) data for each specimen were then recorded for statistical analysis.

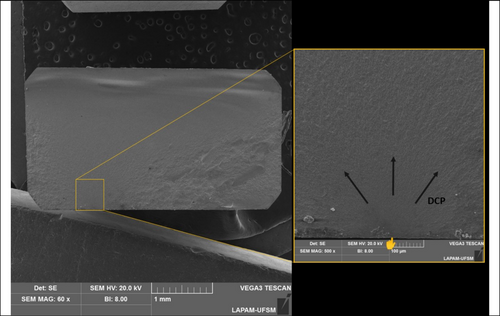

2.2.5 Fractography Analysis

Following the mechanical tests, all specimens were examined using a stereomicroscope at 10× magnification (Discovery V20, Carl Zeiss, Gottingen, Germany). Representative specimens from each group was chosen for fractographic analysis under a scanning electron microscope (SEM) to identify the origin and pattern of failure. The selected specimens underwent sputtering with a gold–palladium alloy and were subsequently analyzed at magnifications of 100× and 3000× (secondary electron signal at 20 kV; VEGA3 Tescan; Brno-Kohoutovice, Czech Republic).

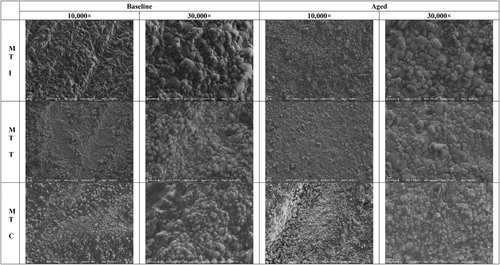

2.2.6 Microstructure Analysis (Topography and Grain Size Measurement)

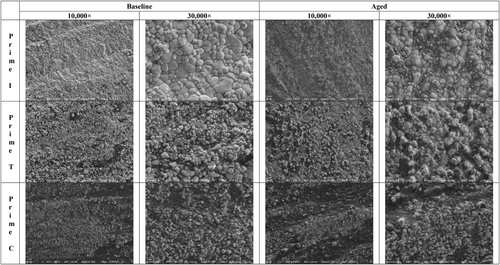

To analyze topographical changes, and grain size alterations, additional ceramic specimens from each condition were produced (n = 3). The specimens for each group underwent cleaning in an ultrasonic bath (1440 D–Odontobras) with 92% isopropyl alcohol for 5 min, followed by air-drying. Subsequently, the specimens were examined by Scanning Electron Microscopy (FEG-SEM, Sigma 300 VP, Carl Zeiss, Germany) at magnifications of 10,000× and 30,000 × .

The grain size of the specimens' surface, illustrated for each material layer in SEM images, was determined using a software program (ImageJ 1.8.0, National Institutes of Health, Bethesda, United States). Each layer was characterized through the linear measurement (in μm) of the 5 larger, smaller, and intermediate grains. Mean values and standard deviations were obtained for each layer. Comparisons between layers and materials were made qualitatively.

2.3 Translucency Parameter

2.3.1 Specimen Preparation

To assess the impact of the zirconia layer and aging condition on translucency levels, 72 disc-shaped specimens of each zirconia type (IPS e.max ZirCAD MT Multi A2 shade; IPS e.max ZirCAD Prime A2, Ivoclar AG) were prepared using previously described methodologies [26, 27]. The zirconia blocks for both materials were initially cut into smaller pieces (20 × 14 mm) using a diamond disc attached to an electric motor (Perfecta LA 623 T, 1000–40,000 rpm—W&H). Metallic guides (Ø = 12 mm) were affixed to the smaller blocks on both sides and ground with #400 and #600 SiC papers (EcoMet/AutoMet 250, Buehler) until a cylindrical shape was achieved. Metallic holders were then attached to the cylinders, which were sliced into discs using a diamond disc in a precision cutting machine (Isomet 1000, Buehler) with continuous water cooling. The dimensions of each layer for used zirconia were considered to obtain samples of each experimental group (Figure 1). Subsequently, the discs were ground until achieving a polished condition and the desired dimensions, utilizing #400, #600, and #1200 SiC papers under water irrigation. All zirconia specimens were sintered in the furnace according to the manufacturer's recommendations, resulting in final dimensions of Ø = 10 mm and 1 mm in thickness.

2.3.2 Translucency Measurement

2.4 Statistical Analysis

Shapiro Wilk and Levene tests were performed to evaluate the normality and homoscedasticity of the obtained data from the mechanical and optical tests. A three-way ANOVA was then performed to analyze the influence of the factors under investigation (zirconia material, layer zone, and aging) on both mechanical behavior and translucency. The Kaplan Meier and Mantel-Cox post hoc (log-rank) tests (α = 0.05) were carried out to evaluate the differences between groups and survival analysis after the cyclic fatigue tests, by the use of the SPSS version 21 statistical program (IBM, Chicago, USA).

3 Results

The results for the monotonic and fatigue three-point bending tests are depicted in Table 2. The 3-way ANOVA showed that the layer zone affected the monotonic results (p < 0.001), while the zirconia material (p = 0.719), aging (p = 0.821) and the interaction of both factors (p = 1.390) did not show significant effect. For the baseline comparison, the monotonic flexural strength did not differ among the layers of MT Multi, while the transitional zone showed lower values at Prime ceramic. After aging, for both MT Multi and Prime, the cervical layer showed significantly higher monotonic flexural strength in comparison with transitional and incisal layers, which did not differ between them.

| Material | Layer | Monotonic 3-point flexural strength (MPa) Mean ± SD | Fatigue 3-point flexural strength Mean (95% CI) | ||||

|---|---|---|---|---|---|---|---|

| Fatigue strength (MPa) | Cycles for failure | ||||||

| Baseline | Aged | Baseline | Aged | Baseline | Aged | ||

| MT multi | Incisal | 684 ± 114CD | 664 ± 183D | 535 (493–577)BC | 419 (362–476)D | 84,072 (76,019—92,125)BC | 60,046 (48,825—71,267)D |

| Transition | 755 ± 93ACD | 671 ± 109D | 473 (420–526)CD | 442 (369–516)CD | 70,039 (60,227—79,851)CD | 66,889 (53,593—80,185)CD | |

| Cervical | 780 ± 101ABCD | 910 ± 77ABC | 519 (465–573)BCD | 569 (514–624)BC | 81,635 (71,421—91,849)BCD | 91,910 (80,911—102,910)BC | |

| Prime | Incisal | 741 ± 84BCD | 645 ± 102D | 492 (421–563)CD | 508 (435–580)BCD | 76,015 (61,449—90,581)CD | 80,195 (64,965—95,424)BCD |

| Transition | 599 ± 128D | 642 ± 128D | 527 (483–571)BC | 454 (377–531)CD | 82,334 (74,256—90,412)BC | 69,317 (54,222—84,411)CD | |

| Cervical | 917 ± 289AB | 981 ± 253A | 619 (570–668)AB | 688 (628–749)A | 101,341 (91,661—111,021)AB | 116,141 (104,175—128,106)A | |

- Note: Different letters in each column indicate statistical differences depicted by Kaplan Meier and Mantel Cox post hoc tests (α = 0.05).

In the context of the 3-point bending fatigue test, the 3-way ANOVA indicated no influence of the evaluated factors on the results (p > 0.05). The Kaplan Meier and Mantel-Cox post hoc (log-rank) showed that, for MT Multi, all groups were similar in the baseline condition, which can also be seen in the survival analysis (Table 3). However, after aging, the fatigue strength of the incisal zone exhibited a statistically lower value than the cervical zone and also significantly lower values in comparison to baseline. For Prime, the cervical zone displayed significantly higher flexural strength than the incisal zone at baseline and significantly higher fatigue flexural strength than both incisal and transitional zones after aging. The cervical region of Prime was statistically superior than MT multi after LTD protocol. The survival analysis for Prime (Table 4) indicated that, at the 550 MPa stress level, the baseline and aged cervical zones exhibited 62% and 92% survival probability, respectively. In contrast, at the same stress level, less than 25% survival was observed for the transition and Prime incisal zones, regardless of the aging factor.

| Group | FS (MPa)/CFF | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 250/40,000 | 300/50,000 | 350/60,000 | 400/70,000 | 450/80,000 | 500/90,000 | 550/100,000 | 600/110,000 | 650/120,000 | 700/130,000 | 750/140,000 | |

| MT base I | 1 | … | … | 0.92 (0.07) | 0.77 (0.12) | 0.54 (0.14) | 0.31 (0.13) | 0.15 (0.1) | 0 | — | — |

| MT base T | 1 | 0.92 (0.07) | 0.77 (0.12) | 0.69 (0.13) | 0.62 (0.14) | 0.31 (0.13) | 0.15 (0.1) | 0 | — | — | — |

| MT base C | 1 | … | 0.85 (0.10) | 0.77 (0.12) | … | 0.54 (0.14) | 0.39 (0.14) | 0.08 (0.07) | 0 | — | — |

| MT aged I | 1 | 0.85 (0.10) | 0.46 (0.14) | 0.39 (0.14) | … | 0.23 (0.12) | 0.08 (0.07) | 0 | — | — | — |

| MT aged T | 0.77 (0.12) | … | … | 0.69 (0.13) | 0.46 (0.14) | 0.31 (0.13) | 0.08 (0.07) | 0 | — | — | — |

| MT aged C | 1 | 0.92 (0.07) | … | … | … | … | 0.39 (0.14) | 0.23 (0.12) | 0.08 (0.07) | … | 0 |

- Note: The symbol “-” indicates absence of specimen survival on the considered step. The symbol “…” indicates absence of specimen failure in the respective step.

| Group | FS (MPa)/CFF | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 350/60,000 | 400/70,000 | 450/80,000 | 500/90,000 | 550/100,000 | 600/110,000 | 650/120,000 | 700/130,000 | 750/140,000 | 800/150,000 | 850/160,000 | |

| Prime base I | 0.85 (0.1) | 0.77 (0.12) | 0.62 (0.14) | 0.23 (0.12) | 0.15 (0.1) | … | … | 0.08 (0.07) | 0 | — | — |

| Prime base T | 1 | 0.85 (0.1) | 0.77 (0.12) | 0.54 (0.14) | 0.23 (0.12) | 0.15 (0.1) | 0 | — | — | — | — |

| Prime base C | 1 | … | … | 0.85 (0.1) | 0.62 (0.14) | 0.46 (0.14) | 0.31 (0.13) | 0.08 (0.07) | … | 0 | — |

| Prime aged I | 0.92 (0.07) | 0.85 (0.1) | 0.54 (0.14) | … | 0.23 (0.12) | 0.15 (0.1) | 0.08 (0.07) | … | 0 | — | — |

| Prime aged T | 0.77 (0.12) | 0.62 (0.14) | 0.46 (0.14) | … | 0.15 (0.1) | 0.08 (0.07) | 0 | — | — | — | — |

| Prime aged Ca | 1 | 1 | 1 | 1 | 0.92 (0.07) | 0.69 (0.13) | 0.54 (0.14) | 0.23 (0.12) | 0.08 (0.07) | … | … |

- Note: - The symbol “-” indicates absence of specimen survival on the considered step. The symbol “…” indicates absence of specimen failure in the respective step.

- a The last specimen of the Prime Aged C group failed at 1000 MPa/190,000 cycles.

The power of the study was calculated using G*Power software (Version 3.1.9.6, Fraz Faul, Universität Kiel, Kiel, Germany). For the monotonic test, the sample size used, the mean values obtained in each group, and a common standard deviation (SD) of 156.09 were considered. A significance level (α) of 0.05 was applied. The calculation yielded a power of 0.99 and an effect size of 0.77, indicating a high probability of detecting statistically significant differences between the groups. Similarly, for the fatigue test, the sample size, mean values, and a common SD of 112.27 were used. With the same significance level (α = 0.05), the calculation yielded a power of 0.99 and an effect size of 0.66, demonstrating sufficient sensitivity to identify differences across the tested conditions.

Figure 2 illustrates the fractographic analysis of a representative specimen. The same failure pattern was found for all groups after the mechanical tests, showing that the crack origin was at the bottom surface of the bars (facing downward during the 3-point bending test). Subsequently, the crack propagated towards the bar until reaching the top surface, resulting in the complete fracture of the zirconia specimen.

The results for the translucency parameter are depicted in Table 5. The translucency parameter of the zirconia specimens was affected by the layer zone (p = 0.000) and zirconia material (p = 0.000), while hydrothermal aging did not have a significant effect (p = 0.213). The interaction of the factor did not affect the results either (p = 0.810). The incisal zone showed significantly higher values of the translucency parameter for both MT Multi and Prime, followed by the transition and cervical zones, which were statistically similar between them, regardless of the aging condition. No difference in translucency parameter was observed between the same layer of the two materials, and the LTD protocol did not significantly alter the translucency parameter of materials.

| Material | Layer | TP00 | Grain size (μm) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Baseline | Aged | Baseline | Aged | ||||||

| Larger | Intermed | Smaller | Larger | Intermed | Smaller | ||||

| MT multi | Incisal | 16.21 ± 0.82AB | 16.47 ± 0.78A | 1.08 ± 0.20 | 0.60 ± 0.04 | 0.35 ± 0.08 | 0.93 ± 0.06 | 0.52 ± 0.08 | 0.29 ± 0.04 |

| Transition | 11.61 ± 1.79C | 11.92 ± 1.94C | 0.64 ± 0.02 | 0.40 ± 0.01 | 0.25 ± 0.03 | 1.30 ± 0.15 | 0.57 ± 0.10 | 0.31 ± 0.06 | |

| Cervical | 11.40 ± 0.76C | 11.97 ± 0.73C | 0.57 ± 0.02 | 0.34 ± 0.04 | 0.18 ± 0.04 | 0.85 ± 0.08 | 0.51 ± 0.06 | 0.32 ± 0.06 | |

| Prime | Incisal | 17.62 ± 0.36A | 17.64 ± 0.31A | 1.05 ± 0.15 | 0.42 ± 0.06 | 0.29 ± 0.05 | 0.90 ± 0.06 | 0.55 ± 0.08 | 0.32 ± 0.03 |

| Transition | 13.11 ± 0.40C | 13.17 ± 1.02C | 0.71 ± 0.11 | 0.53 ± 0.11 | 0.33 ± 0.05 | 0.76 ± 0.09 | 0.47 ± 0.10 | 0.34 ± 0.05 | |

| Cervical | 12.55 ± 0.26C | 13.75 ± 1.78BC | 0.49 ± 0.03 | 0.39 ± 0.03 | 0.28 ± 0.08 | 0.44 ± 0.05 | 0.37 ± 0.03 | 0.26 ± 0.04 | |

- Note: Different letters indicate statistical differences depicted by three-way ANOVA and Tukey's post hoc tests.

The grain size analysis (Table 5, Figures 3, and 4) showed that the larger grains presented higher mean values at incisal and transitional zones of both zirconia materials. The mean size of intermediate and smaller grains was more homogeneous among the layers. The aging protocol resulted in grain size increase at measurements of larger, intermediate, and smaller grains of transitional and cervical layers of MT Multi. The hydrothermal aging affected the topographic aspect of both zirconia, showing superficial defects and deteriorated zones between grains when compared to the non-aged condition (Figures 3 and 4).

4 Discussion

Distinct mechanical behaviors were noted for the zirconia ceramics studied, coupled with varying translucency levels and grain sizes of each zone. Specifically, the cervical layer exhibited elevated flexural strength and reduced grain size, while the incisal layer displayed greater translucency. Besides, the hydrothermal aging affected the evaluated outcomes for certain layers. Consequently, the adopted hypotheses were accepted.

According to the manufacturers, MT Multi contains 4–5 mol% of yttrium stabilizer (4YSZ for the cervical layer, 4/5 YSZ for the transitional layer, and 5YSZ for the incisal layer). In contrast, Prime has 3 mol% in its cervical region, 3–5 mol% in the transitional layer, and 5 mol% in the incisal layer. These differences likely contribute to the varied mechanical performance of each layer, as the stabilizer content affects the fatigue strength [2, 5, 6, 11, 24].

The 3YSZ is usually reported as the most resistant material among the dental ceramics [3, 30], attributed to their polycrystalline microstructure and the toughening mechanism enabled by t-m phase transformation after stimulus [4, 31]. The findings of the present study partially corroborate these assertions, since layers with lower stabilizer content depicted higher mechanical performance (Tables 3–5), in agreement with previous reports [7, 11]. The transition layer in both zirconia ceramics used exhibits varying degrees of stabilization in crystalline grains, ranging from 4 to 5 mol% for MT Multi and 3–5 mol% for Prime. The results indicate that these layers display comparable fatigue strength values to both the cervical and incisal layers for both materials. An exception is observed in the aged cervical layer of Prime, which contains more of the 3 mol% yttria phase. However, a limitation of the present study is that no analysis of phase crystallographic arrange was made and is known that phase transformation may also play a role on altering mechanical properties of YSZ ceramics. Moreover, it is important to consider that all layers demonstrated strength values that are adequate when compared to physiological chewing loads [32], thus minimizing the possible impact of any differences between the layers in clinical scenario.

The translucency of dental ceramics is also an essential factor to be considered for the material choice and restoration production, since it depends on its microstructure [17, 28, 33]. In this sense, the literature shows that the higher stabilizer content for zirconia is associated with increased crystalline grain size [6, 17], a factor related to increased translucency measurements [8, 17]. The grain size evaluation in the present study presented the expected results related to the layers and their yttrium content, since the larger grains presented higher mean values at incisal and transitional layers (Figures 3 and 4), regardless of the hydrothermal aging. These findings are in accordance with previous studies [6, 8, 11, 14, 16, 17]. The larger size of cubic crystals at incisal zone enhances light transmittance through the material, making 5Y-PSZ more translucent than cervical layers in both MT Multi and Prime. In contrast, the smaller and juxtaposed crystals in the cervical layer absorb more light [4, 8, 17]. Thus, such finding corroborates the clinical application of multilayer zirconia ceramics, depicting proper optical effects according to the tooth zone, which have to be more translucent at the incisal/occlusal zone, while the cervical region must be opaquer due to the greater amount of dentin.

The adopted aging protocol, previously validated as a method to induce low-temperature degradation in zirconia ceramics [24], produces extrinsic stimulus over the zirconia, deteriorating the crystals over time [18-22]. In our study, effects of low-temperature degradation were observed after hydrothermal aging in the analyses of mechanical properties and grain size. As mentioned before, a limitation of the present study is that no analysis of phase crystallographic arrange was made. Moreover, as mentioned before, the mechanical strength values observed during the tests were adequate when compared to physiological chewing loads [32], and the hydrothermal aging did not have a significant effect on translucency parameters, meaning that its effects on grain size should also be considered adequate on a clinical point of view.

As an in vitro study, some limitations should be acknowledged. Firstly, there was no quantification of crystallographic phases. Nevertheless, the features observed align well with the microstructure content and stabilizer presence in each layer, as indicated by the manufacturer. Secondly, the precise transition points between the layers are not available through scientific data. This fact can contribute to the observed similarities in behavior between 4YSZ and 5YSZ layers of MT Multi, which contradicts a prior study that separately evaluated these materials [34]. Therefore, future studies focusing on these details and exploring other brands and compositions of multilayer systems are recommended.

5 Conclusion

Each layer within the multilayer zirconia systems displayed distinct mechanical and optical properties according to their microstructure, with variations depending on the specific zirconia system. Even so, all layers demonstrated a high mechanical performance, besides coherent translucency levels according to the tooth zone, supporting the use of multilayer zirconia systems for dental prostheses.

Author Contributions

Pablo Machado Soares: conceptualization; data curation; formal analysis; investigation; methodology; software; validation; visualization; writing – original draft; writing – review and editing. Luiza Freitas Brum Souza: data curation; formal analysis; investigation; methodology; software; validation; visualization; writing – review and editing. Lucas Saldanha da Rosa: data curation; formal analysis; investigation; methodology; software; validation; visualization; writing – review and editing. Luiz Felipe Valandro: formal analysis; funding acquisition; resources; visualization; writing – review and editing. Lucio Strazzabosco Dorneles: data curation; formal analysis; investigation; methodology; software; validation; visualization; writing – review and editing. Alice Penteado Holkem: data curation; formal analysis; investigation; methodology; software; validation; visualization; writing – review and editing. Paola de Azevedo Mello: formal analysis; funding acquisition; investigation; methodology; project administration; resources; software; supervision; validation; visualization; writing – review and editing. Edson Irineu Müller: formal analysis; funding acquisition; investigation; methodology; resources; software; supervision; validation; visualization; writing – review and editing. Atais Bacchi: conceptualization; formal analysis; investigation; methodology; supervision; validation; visualization; writing – original draft; writing – review and editing. Gabriel Kalil Rocha Pereira: conceptualization; formal analysis; funding acquisition; investigation; methodology; project administration; resources; software; supervision; validation; visualization; writing – review and editing.

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.