Revisiting Traceability of Vegetable Fresh-Products in the EU: Why Blockchain Does (Not) Work?

Funding: This work was supported by the grant PID2020-114410RB-I00 MCIN/AEI/10.13039/501100011033, formed part of the AGROALNEXT program, and was supported by MICIU with funding from European Union NextGenerationEU (PRTR-C17.I1) and by Fundación Séneca with funding from Comunidad Autónoma Región de Murcia (CARM).

ABSTRACT

Food safety is paramount for a healthy society. Traceability provides the means for a rapid response to any type of food-related problem at any stage of the supply chain. This study delves into the application of blockchain technology in tracking vegetable products within the European Union's regulatory framework. It addresses the significant gap between the theoretical potential of blockchain and its practical implementation challenges, such as integration with existing systems, scalability, and cost. Here, we show that while blockchain offers enhanced traceability and transparency, substantial barriers are posed for its adoption. This research reveals that the effectiveness of blockchain in real-world applications is less straightforward than previously anticipated, challenging the notion of blockchain as a one-size-fits-all solution for food traceability. The findings contribute to a better understanding of technology application in food safety, emphasizing the need for tailored solutions that consider both technological capabilities and practical constraints.

1 Introduction

Traceability is the ability to track food, feed, food-producing animals, or substances used for consumption through all stages of production, processing, and distribution [1]. It is a critical pillar in health and food safety, enabling identification and response to potential risks. In the European Union (EU), traceability is mandatory, requiring food and feed operators to implement systems that identify product origin and destination (one-step forward and one-step back) and provide this information to authorities when needed. Traceability also offers additional benefits [2], such as providing consumers with detailed farm-to-fork information to make informed choices and adding value for operators, like promoting fair trade. Traceability systems trace food products throughout the entire chain, from seed selection to point of sale, encompassing all intermediate stages. Blockchain technology, a distributed ledger technology (DLT), has shown potential for traceability but has not yet become a standard solution despite scientific support.

1.1 Literature Review

Blockchain technology, with its decentralized and immutable ledger, has gained attention as a solution for enhancing traceability in sectors like food safety and agriculture. In supply chains, it enables real-time tracking from farm to consumer, reducing fraud and counterfeiting. QR codes let consumers trace food origins, building trust in safety and quality [3]. Smart contracts automate payments upon delivery, ensuring timely transactions and minimizing delays, while real-time tracking prioritizes perishables, reducing waste. In Industry 4.0, blockchain fosters transparency and accountability in global value chains and the circular economy [4, 5].

Blockchain automates financial processes for farmers' insurance, subsidies, and crowdfunding. Smart contracts trigger insurance payouts based on weather data, ensuring fast claims processing [6]. Subsidies are distributed transparently, reducing fraud. Blockchain platforms connect farmers to investors, promoting accountability and fair fund distribution. It secures digital land records, simplifying transactions and reducing conflicts [7]. Decentralized marketplaces allow direct sales, ensuring fair pricing by reducing middlemen. Precision agriculture benefits from blockchain-secured IoT data, optimizing resources and enhancing yields [2]. Data integrity supports collaboration and automated AI recommendations. For inventory and waste management, blockchain improves resource use, tracks by-products for repurposing, and supports circular economy practices. Digital twins further optimize operations using real-time simulations [8].

1.2 Research Gap and Motivation

Despite its promise, blockchain's practical application in agricultural traceability remains limited, particularly within the EU. While literature highlights its benefits, scant attention is given to barriers like regulatory complexity, high costs, and technical challenges. Many studies lack critical analysis of blockchain's alignment with EU-mandated traceability frameworks. This gap is crucial for food traceability, where consumer safety and supply chain transparency are vital, but adoption lags due to unresolved practical constraints.

Given these challenges, this study aims to bridge the gap by critically examining whether blockchain can overcome these barriers to function effectively as a traceability solution within the EU framework. Specifically, we address the following research question: Can blockchain's theoretical advantages be realized in practical applications for vegetable product traceability within the EU? By focusing on these challenges, this research contributes a nuanced understanding of blockchain's fit for traceability in regulated industries, offering insights for both policymakers and industry stakeholders.

The article is structured as follows: Section 2 discusses the EU's traceability laws and labeling requirements. Section 3 outlines the traceability process and current technologies. Section 4 critically examines blockchain's role in traceability, highlighting its benefits, limitations, and potential solutions. Finally, the conclusion summarizes key outcomes.

2 Traceability-Related Legislation

EU traceability regulations track agricultural products from farm to fork, ensuring safety and authenticity. This section reviews vegetable traceability laws and labeling standards.

2.1 Legislation in the EU

- General Food Law Regulation (EC) No 178/2002. It supports food safety and traceability in the EU, applying to all food products, including vegetables. It requires food and feed business operators to identify suppliers and customers, maintain traceability records for at least 5 years, and ensure product origin and movements can be traced. This facilitates rapid source and destination identification during safety concerns or recalls.

- Regulation (EU) No 1169/2011 on Food Information to Consumers. It applies to all food products, including vegetables. It mandates clear, accurate labeling with traceability details such as the producer's or seller's name and address, helping consumers make informed choices. Allergen information must be highlighted, and origin labeling is required when its absence could mislead consumers or enhance authenticity, as with Mediterranean diet products. Labels must meet standards for font size, legibility, and prominence. For processed vegetables, additional nutritional information, including energy value and nutrient content, is required.

- Traceability requirements for sprouts and seeds intended for the production of sprouts No. 208/2013. It complements Regulation 178/2002 by imposing additional traceability requirements for sprouts and seeds due to the risk of contamination with bacterial pathogens, as identified by the European Food Safety Authority (EFSA). It mandates that food business operators at all production, processing, and distribution stages keep records of specific information about batches of seeds and sprouts. Operators must also ensure this information is transmitted to those receiving the seeds or sprouts to maintain compliance.

- Regulation (EC) No 852/2004 on the Hygiene of Foodstuffs. It establishes hygiene requirements for food business operators handling all food types, including vegetables. It mandates high standards of cleanliness, personal hygiene, and contamination prevention during production and handling. Operators must implement food safety management systems based on Hazard Analysis and Critical Control Points (HACCP) principles and establish traceability procedures. These ensure the identification of raw material origins and finished product destinations, aiding in the rapid detection of contamination or quality issues.

- Regulation (EU) No 2019/1381 on Transparency and Sustainability of the EU Risk Assessment in the Food Chain. It enhances food safety and transparency across all food products by mandating that risk assessments related to food safety be publicly accessible while ensuring traceability of the data used. To balance transparency with intellectual property protection, it includes provisions to safeguard sensitive or confidential business data. The regulation also highlights stakeholder involvement as a key element in the risk assessment process.

- Organic Farming Regulation (EC) No 848/2018. It requires organic products, including vegetables, to meet specific traceability standards. These ensure tracking from farm to consumer with detailed records of production methods and inputs. Only vegetables complying with these standards can be labeled “organic.”.

The EU regulations outlined here and in Table 1 form a comprehensive framework for agricultural traceability, ensuring food safety, consumer protection, and supply chain integrity. They mandate strict compliance from producers, processors, and distributors to uphold these standards.

| #Regulation | Name | Description |

|---|---|---|

| 178/2002 | General Food Law Regulation | It establishes the principles of food safety, including traceability of food and feed in the supply chain. |

| 1169/2011 | Food Information to Consumers | It involves labeling requirements that aid in the traceability of vegetables, providing consumers with information about the origin and contents of food products. |

| 208/2013 | Traceability requirements for sprouts and seeds intended for the production of sprouts | It establishes traceability rules for batches of sprouts and seeds used for sprout production but does not apply to sprouts treated to eliminate microbiological hazards, in accordance with EU legislation. |

| 852/2004 | Hygiene of Foodstuffs | It sets out basic hygiene requirements for all foodstuffs, including vegetables. |

| 1381/2019 | Transparency and Sustainability of the EU Risk Assessment in the Food Chain. | It improves transparency/sustainability in the EU's food chain risk assessment. |

| 848/2018 | Organic Production | It defines standards for organic farming and processing, including traceability requirements for organic vegetables. |

| 2073/2005 | Microbiological Criteria for Foodstuffs | It establishes safety criteria for various foodstuffs, including vegetables, to ensure they are free from harmful microorganisms. |

| 396/2005 | Maximum Residue Levels of Pesticides in or on Food and Feed of Plant and Animal Origin | It sets maximum residue levels for pesticides in vegetables, ensuring food safety and contributing to the traceability of chemical usage in vegetable production. |

| 625/2017 | Official Controls | It provides a framework for monitoring and enforcing health and safety rules in the food supply chain, including those related to vegetable production. |

| 1151/2012 | Quality Schemes for Agricultural Products and Foodstuffs | It includes provisions for geographical indications and traditional specialties, relevant for certain vegetable products with specific regional origins. |

| 2283/2015 | Novel Foods | It applies to vegetables that fall under the category of novel foods, setting out rules for their safety and traceability. |

| 1107/2009 | Placing of Plant Protection Products on the Market | It concerns the placing of plant protection products on the market and is relevant for the use of pesticides in vegetable farming. |

| n.a. | Integrated Administration and Control System (IACS) | It supports traceability in vegetable farming through land parcel identification systems and monitoring agricultural activities. |

| n.a. | Directive 2000/29/EC | It concerns protective measures against the introduction and spread of harmful organisms to plants or plant products. |

2.2 Labeling Information

- Name of the Food (M): The exact name under which the product is being sold.

- Ingredient List (M): All ingredients, listed in descending order of weight as used in preparation, including additives.

- Allergens (M): Legislation-specified allergens must be highlighted in the ingredient list if present.

- Net Quantity (M): Indicated in metric units.

- Date Marking (M): Labels must indicate a “best before” or “use by” date, specifying the period for maintaining product quality or safety.

- Batch or Lot Number (M): For tracing production runs in case of recalls.

- Country of Origin or Place of Provenance (M): Labels must specify origin or provenance if its omission could mislead consumers.

- Food Business Operator or Importer Information (M): Name and EU address.

- Instructions for Use and Storage (M): Clearly state any specific storage conditions or preparation instructions required for the product.

- Nutrition Declaration (M): Includes energy value and amounts of fat, saturates, carbohydrates, sugars, protein, and salt.

- Alcohol Content (M): Listed if exceeding 1.2% by volume.

- Production Date/Packaging Date (R): Helps in tracking the product, particularly those with a short shelf life.

- Traceability Codes (R): Specific codes used within the supply chain to track the product.

- Certification and Approval Numbers (R): Relevant for products with organic certification or quality standards.

- Quantitative Ingredient Declaration (QUID) (R): Percentage of ingredients featured in the product name, shown on the label, or emphasized, critical for distinguishing the product.

- Additional Requirements for Specific Types of Products (R): For special treatments like irradiation or freezing.

- Voluntary Information (R): Such as environmental claims, can be included provided it is accurate and not misleading.

3 The Traceability Process

3.1 Process Description

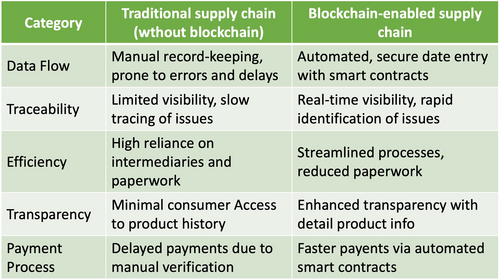

The traceability process with and without blockchain is represented in Figure 1. The traditional supply chain in agriculture often relies on manual processes, leading to data inaccuracies, inefficiencies, and delays, particularly in traceability and payments. It lacks transparency and relies on intermediaries, resulting in slow responses to recalls. In contrast, a blockchain-enabled supply chain offers automation, real-time tracking, and improved transparency, as seen in early adopters like IBM Food Trust [10], significantly reducing tracking times. Blockchain also enhances efficiency by streamlining data entry, automating payments, and ensuring compliance with regulations.

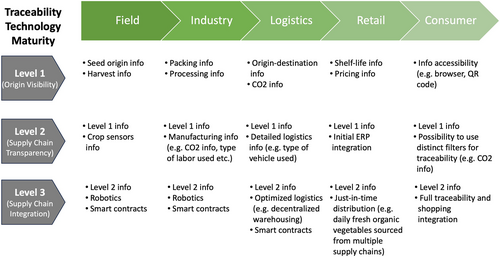

It is important to remember the obligatory nature of the one-step forward and one-step back approach in traceability. Figure 2 depicts the traceability process, and the maturity level required to exploit the full potential of blockchain technology. The first phase involves recording seed selection and planting details, such as the seed type, origin, planting dates, and field locations. For example, a lettuce farmer would document the specific variety used and the exact field. The next phase covers agricultural practices, including fertilizers, pesticides, or organic methods applied; the farmer records the use of organic fertilizers during the season. During harvesting, it is essential to document the dates and locations, specifying fields or greenhouses where the vegetables were harvested, such as noting exact harvest dates and field numbers.

The next phase involves processing and packaging, where data on cleaning, processing, and packaging must be recorded, for example, the type of packaging used, like biodegradable materials for organic products. Storage conditions, like temperature and humidity, and transportation methods should also be documented. Our farmer shipping lettuce would record refrigerated truck temperatures and transport routes. Next is distribution and retail, which requires tracking where vegetables are distributed and sold, whether to supermarkets, local markets, or online platforms, ensuring each batch can be traced back to its origin. Finally, labeling at the point of sale might include QR codes on packages, allowing consumers to scan and view the product's journey from farm to store. This comprehensive traceability system ensures that in a recall or quality issue, detailed records at every stage enable quick identification of affected batches, minimizing consumer risk.

3.2 Traceability Technologies

Various technologies are employed in traceability systems, each with specific benefits. Taken together, they ensure data are stored throughout every stage of the traceability process. Barcodes and QR codes, known for their ease of use and cost-effectiveness, are very common in product labeling, but have limited data capacity and can be easily damaged. RFID tags offer robust data storage and durability, allowing remote reading, but have a higher cost and raise some privacy concerns. Global Positioning System (GPS) technology allows real-time tracking, but obviously their efficacy will depend on the level of satellite signal coverage. Database management systems efficiently handle large volumes of data but could require a significant IT infrastructure for large agricultural exploitations. In recent years, IoT and cloud computing technologies are also being used. The use of this type of technology facilitates data exchange and accessibility, although it depends on connectivity and could raise data security issues. Blockchain could enhance EU agricultural traceability by creating a secure, transparent, and immutable record of planting, harvesting, processing, and distribution of data. It ensures real-time tracking and compliance with EU food safety regulations, helping to address incidents swiftly and boost consumer confidence in product authenticity. There are many works proposing its use to provide complete traceability systems. However, blockchain still faces significant challenges that limit its adoption by stakeholders.

4 Blockchain Challenges in Traceability

Traceability ensures quick identification and resolution of food safety issues, boosting consumer confidence by verifying product origins. Food businesses benefit through more effective recalls, cost savings, and informed management decisions, helping manage safety risks. Regulators rely on traceability to monitor compliance, enable swift action during emergencies, and support risk assessments. Internationally, traceability meets regulatory demands and assures alignment with global standards. Overall, it safeguards food safety, enhances transparency, and strengthens trust in the food supply chain.

Arranging the properties of blockchain alongside the requirements of a food traceability system would reveal a perfect alignment. Therefore, what is limiting the adoption of blockchain as de facto solution for food traceability? After analyzing the related scientific literature [11, 12], technical reports [13, 14], and public case studies such as those by IBM Food Trust [10] or Agrichain [15], we argue that blockchain technology has not yet become the preferred solution for traceability primarily due to challenges associated to complexity, cost, regulatory uncertainty, and novelty.

First, stakeholders must deal with blockchain complexity and understanding. Blockchain is still seen as a complex technology that requires a high level of comprehension, and this becomes a barrier to widespread adoption. The technical nature of blockchain requires a deep understanding of decentralized systems, the cryptographic principles on which it is based, and deep software programming knowledge, which is an obstacle for those without a technical background. Acquiring this knowledge can have too high a learning curve and outsourcing this activity impacts costs.

The cost and infrastructure requirements, including ongoing maintenance, can be significant, making it a difficult investment for smaller agricultural entities. For example, building a blockchain might require both significant computing resources to operate the nodes and a robust IT infrastructure. When we talk about large volumes of data, the technical complexity of blockchain requires specialized hardware for efficient processing and storage of blockchain data. Integration with existing systems is often complex and requires customized solutions to reconcile different data formats and standards, which also has an economic impact. In addition, ensuring compliance with EU security and data protection regulations may require additional security measures and systems, further increasing costs. This technical and financial burden may be particularly daunting for smaller EU producers.

Given blockchain's evolving legal landscape, regulatory uncertainty is another key issue. It creates a risky environment for adoption, especially for companies operating internationally. In the EU, blockchain and DLT regulation is only linked to topics like cryptocurrencies and digital identity. Last, the relative newness of the technology means there are fewer long-term studies or real-world applications to evaluate its effectiveness in agriculture. The consequence is a sense of caution in its adoption and the perception of a regulatory burden.

To overcome these challenges, we suggest three lines of work. First, legislation as a top-down action. Legislative initiatives are needed to set the framework for the use of blockchain in the agricultural sector. Part of the problem lies in the use of public blockchains in which the location of the nodes, and therefore of the information stored, is unknown or, being known, they are located outside the EU. In this sense, the use of consortium-based (also known as federated) or private blockchains would solve the problem, facilitating compliance with GDPR. Let us remember that depending on the different levels of permission to insert data or to access the recorded information, a blockchain is categorized as: (i) public (e.g., Bitcoin or Ethereum), (ii) consortium-based (e.g., Ripple), or (iii) private (e.g., Hyperledger). In a public blockchain, virtually anyone can participate, and each participant is usually anonymous. In this context, there can be no more trust than the fact that from a certain depth the blockchain is immutable. The larger the blockchain is the lower the likelihood to alter its data. However, private blockchains operate the blockchain among a set of known, identified participants operating under a governance model that produces a certain degree of trust. Thus, they offer us a way to secure interactions between a group of entities that have a common goal but may not fully trust each other. In this way, legislation can be more easily applied.

Second, standardization led by the stakeholders. The P2418.3 “Standard for the Framework of Distributed Ledger Technology (DLT) Use in Agriculture” is an ongoing initiative in this direction. Its goal is to provides a common framework for the use, implementation, and interaction of blockchain technology in agriculture. Third, digitation as the bottom-up action. The agricultural sector needs to be reconverted. Traditionally, it is a sector with low digitalization. The idea to convey is that when they are steeped in the use of IT, taking the step towards more advanced technology, which may seem more obscure or complex, will be much smoother.

This is well represented in Figure 2. Viewed as a matrix, the columns represent the steps in the traceability process, and the rows represent the level of maturity in IT incorporation. Level 1 may currently be the most representative for many companies in the industry. At this point, it is simplest and most feasible to use blockchain technology solely to provide visibility into the origin of the product. For highly verticalized companies, where all columns are under the same supervision, it is a straightforward step. Level 2 includes Level 1 and would apply to companies with a higher degree of digitization and automation, for example, by collecting sensor data deployed in the growing and planting areas. Level 3 would be reached by those companies, or groups of companies where there is full digitalization. In this scenario, blockchain's potential can be fully realized, incorporating legally valid smart contracts, decentralized warehousing, and just-in-time distribution, a practice already common in other industries.

5 Conclusion

The integration of blockchain technology in the EU's agricultural traceability framework offers significant benefits, including enhanced transparency, efficiency, and supply chain integrity. However, practical adoption remains challenging due to high costs, technical complexities, and regulatory uncertainties. To address these barriers, the EU needs to establish a supportive legislative framework, particularly for private and consortium blockchains that align with data privacy standards. Additionally, fostering digital transformation in the agricultural sector through stakeholder collaboration and increased digital literacy is essential. A combined focus on regulatory support, standardization, and technological adaptation will be crucial in fully leveraging blockchain's potential for improving food traceability and safety.

Acknowledgments

This work was supported by the grant PID2020-114410RB-I00 MCIN/AEI/10.13039/501100011033, formed part of the AGROALNEXT program, and was supported by MICIU with funding from European Union NextGenerationEU (PRTR-C17.I1) and by Fundación Séneca with funding from Comunidad Autónoma Región de Murcia (CARM).

Open Research

Data Availability Statement

Data sharing is not applicable to this article as no data sets were generated or analyzed during the current study.