Germany's Way from Russian Natural Gas to Green Hydrogen: Network Data, Procedures, and Topologies for Feasible Transition Paths to a Green Hydrogen Transport Infrastructure in Germany, GreenHyDE [gri:n'haɪ̯də] –

Abstract

Hydrogen—and thus hydrogen transport—will play an important role in the German and European transition to climate neutrality. A German hydrogen transport network is currently being planned, but its appropriate structure and size highly depend on the spatial distribution of hydrogen demand and supply and their development over time. Moreover, the security of supply with both, hydrogen and natural gas, needs to be guaranteed during the transition period, as repurposing of the existing natural gas transmission system is a highly advantageous option for the building of hydrogen networks. Therefore, the integrated analysis of natural gas and hydrogen networks is a necessary and urgent, though complex, field of research. For this purpose, the article presents the database for the existing German natural gas transmission system (which in parts will be repurposed for hydrogen transport) and procedures for the development and evaluation of network topologies for both gases. The results for the German case show feasible development steps for the design of green hydrogen transport networks and the transition from natural gas in different scenarios. Open access to data and tools for technoeconomic assessment is provided.

1 Introduction and Overview

The transition from fossil gases to renewable solutions is essential to achieve climate neutrality in Germany by 2045. In particular, green hydrogen can decarbonize large parts of industry and offers the possibility to temporarily store large amounts of renewable electricity. Modeling the infrastructure for this transformation is one of the biggest challenges of the energy transition. Therefore, this article presents a combination of both, data and tools, to address the temporal as well as spatial disaggregation in network modeling systematics.[1] This combines analytical power for changes in supply, demand, storage, and network topology for gas transmission networks. Its application to the existing German natural gas transmission system and its future transition to a green hydrogen transport network shows the technoeconomic dimensions of the latter and can be seen as exemplary for the analyses in other areas in Europe and worldwide.

In Section 2, we document the fundamentals, the German network data including open data. The current state of Germany's gas transmission system is presented here as it exists today, as it has overcome the security of supply threats posed by the Russian invasion of Ukraine, and as it will have to undergo repurposing and structural modifications in order to be integrated into Germany's 2045 net zero energy supply with its integration into the European system.

Section 3 shows the centerpiece, the methodological setup of the network modeling systematics applied for Germany, presenting the scenario data sphere, the network topology sphere, and the network simulation sphere, as well as the procedural steps and the toolchain that were developed and applied. These essential tools are made available open source.[2]

Section 4 presents how the toolchain was used to analyze the security of natural gas supply in the recent crisis caused by the Russian attack on Ukraine (In the framework of their project ‘Energy Systems of the Future’, the German Academies of Sciences commissioned a study and published a discussion paper on ‘The Impacts of the War in Ukraine on Energy Prices and Security of Supply in Europe’, cf.[3, 4]) and how the same toolchain was applied in future-oriented decarbonization research: Two subsections present the results, on the one hand, for the long-term hydrogen development in Germany with algorithmic topology determination and on the other hand for the assessment of the structural development of the German hydrogen infrastructure within the European system, based on the current planning stages of German and European governmental and industry institutions.

Section 5 combines the synergies and key elements; it prepares for a set of rules on how to put system development planning into a coherent and consistent framework and concludes with a brief outlook on system development strategies for this purpose.

2 The Database: the Gas Transmission System in Germany

The modeling of natural gas or hydrogen transport systems brings together information from three different spheres: the network topology sphere, the scenario data sphere, and the network simulation sphere.[1] By integrating the information from these three spheres, a detailed model of the gas transmission system in Germany was developed and applied. For the network topology sphere, all procedures and analyses described in this article are based on a set of natural gas and hydrogen network topologies. They provide a technophysically accurate representation of the existing German natural gas transmission infrastructure compiled in the DE_2023 topology (This DE_2023 topology was compiled by the Department of Energy and Resource Management at the Technische Universität Berlin (TUB E&R) based on previous work by the Department of Gas Supply Systems of the Institute of Petroleum Engineering at Technische Universität Clausthal). The DE_2023 topology serves as the basic framework for gas network modeling in all studies reported in this article.

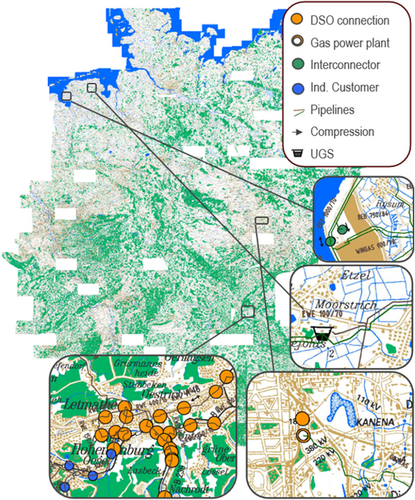

The main body of the DE_2023 database became publicly available on the grounds of the legal obligation for the German gas system operators to publish a comprehensive electronic map of the entire gas supply system, including the pipeline networks with pressure values, ancillary installations, and storages (Art. 22 of the Ordinance on Access to Gas Supply Networks (Gas-Netzzugangsverordnung, 25 July 2005). The aim of the legal provision was to compensate for severe obstacles for network users in a complex grid access regime; it should enable shippers to develop their routing strategies for network access requests.). This map provided detailed information, including individual pipelines, diameters, design/operating pressure levels, and individual network operators. It also showed other relevant infrastructures such as storage facilities, compressor stations, oil pipelines, and power lines. Figure 1 shows the full map and includes four zoomed-in tiles that provide a closer look at the level of detail and accuracy.

All data from this map was extracted, digitalized, compiled, preserved, and utilized for research projects (E.g. on the ‘Integration of Fluctuating Renewable Energies and the Convergence of Electricity and Gas Networks’, in short KonStGas[5]), and it has been updated since, in particular on the basis of national and European Network Development Plans (NDPs), publications by the European Network of Transmission System Operators for Gas (ENTSO-G), and publications of individual TSOs and the German Association of TSO (FNB Gas). As a result, our topology database covers the German gas pipeline network, including connections to neighboring countries with comprehensive information on pipelines and other network elements. It describes the spatial and functional arrangement and locations of the system elements: pipelines, compressor stations, entry/exit points for demand, supply and storage, as well as their operators. Technical parameters are assigned to the topology elements, such as pipeline diameter, operating pressure, and length. The entry/exit points include storage facilities, liquefied natural gas (LNG) terminals, interconnectors (ICs) for crossborder gas flows, as well as locations for industrial consumption, power plants, and connection points to gas distribution system operators (DSO) for consumption from other end-energy sectors.

Depending on the specific research question, the topology database can be adapted and expanded, for example, by adding (hydrogen) pipelines that are part of Network Development Plans (NDP) or strategic investment projects by the European Commission, as shown in Section 4.2 of this article for Important Projects of Common European Interest (IPCEI).

The complete topology database, including other topologies based on the DE_2023 topology, is made available under CC-BY-SA 4.0 license.[2]

3 Methodology: Network Modeling Structure and Procedures

This section clarifies the fundamental steps from real-world data to simplified network model representation for gas flow simulation. This includes data collection, database construction, and the use of an integrated toolchain to process data and perform scenario simulations. It provides an overview of the procedural steps used in the toolchain, which are instrumental in extracting, processing, and analyzing the data necessary for modeling gas transmission systems, either for hydrogen or natural gas (in the following simulated as “methane” networks). From interfacing with fluid-dynamic simulation software to adjusting data resolution, balancing supply and demand, and visualizing results, each tool serves a specific purpose within the toolchain. In the following, an overview of each tool, highlighting its functionality and contribution to the modeling process, is given. All essential tools are openly accessible at.[2]

3.1 In a Nutshell: How Data and Procedures are Compiled

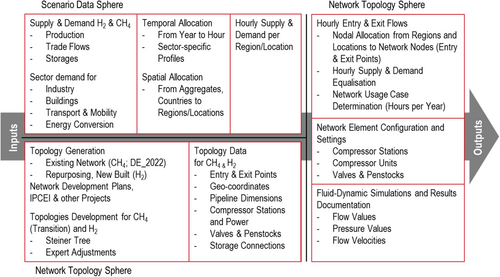

This section provides a brief overview of the data spheres and the procedures included in the network modeling toolchain. The following sections describe each aspect in more detail. Figure 2 shows the major steps involved in the development of methane and hydrogen network topologies, fluid-dynamic testing and simulation of these topologies, and the scenario data preparation necessary in the process.

3.1.1 The Network Task: Scenario Data Sphere

Scenario data represent the projected energy supply and demand for a specific year, based on various assumptions and future developments. They provides a foundation for understanding the requirements and dynamics of the gas and hydrogen infrastructure. From these scenario data, network usage cases are derived that reflect the transport tasks within the methane and hydrogen networks per unit of time, which varies across seasons, days of the week, and hours of the day. Supply and demand for methane and hydrogen are divided into four sectors: industrial, buildings, transport and mobility, and energy conversion. The industrial sector covers usage in industrial processes. The buildings sector includes residential and commercial heating. The transport sector covers gas consumption for transportation. The energy conversion sector includes power generation and hydrogen production. Each sector's importance varies per scenario, with different assumptions considered. Temporal and spatial allocation of sectoral data involves disaggregating methane and hydrogen supply, demand, and storage operation over time and space. Temporal allocation assigns values to different time units, typically the most granular unit being the hour, while spatial allocation considers regional and local distribution. These disaggregated values are then allocated to network nodes in the network topology. This process is carried out separately for each sector or subsector to enhance accuracy in allocation.

3.1.2 The Network Itself: Network Topology Sphere

Within the network topology sphere, the toolchain implements methods to generate network topologies between different formats of simulation software. For this purpose, the following key information is necessary.

Pipeline Characteristics

Location, diameter, length, and pressure levels are required to evaluate the suitability of the existing infrastructure for hydrogen transport and its capacity.

Supply, Demand, and Interconnection Nodes

The entry/exit points where gas is injected and/or withdrawn from the network are important. Ideally, they are grouped into categories. Scenario data, such as imports, exports, and demands, will be allocated to these nodes, based on their location, type, and other factors.

Active Elements

Active elements define the operation of the network to fulfill the transport task, including the configuration and setting of compressor stations, the compressors therein, and valves, and are necessary to perform fluid-dynamic simulations. Evaluation of the compression infrastructure can help to determine if modifications or additional facilities are needed to facilitate hydrogen or methane transmission. Detailed information about these stations, including their capacities and operational characteristics, is an integral part of the topology data.

Underground Gas Storages

Gas storages (methane or hydrogen) are an important aspect of topology design and should be considered in every simulation. Their importance for the hydrogen system is paramount because exactly the long-term storability of hydrogen makes it a necessary element of net zero energy systems. Storage connection points can work as both supply (entry) and demand (exit) nodes and, depending on the network usage case, they make up a large share of either demand or supply. Figures used for every storage in the network are the working gas volume, the injection, and withdrawal rates, each specific to hydrogen or methane.

3.1.3 Fluid-Dynamic Simulation: Network Simulation Sphere

Finally, the toolchain combines via interfaces the scenario data and topology generation tools and the fluid-dynamics simulation software. It also provides the interface to visualize and analyze the resulting flow data from the simulation. This means that fluid-dynamics simulations can be performed based on the generated network topology and disaggregated scenario data. The results of these simulations can be used to verify the topologies for practical use and to further improve the network design based on the bottlenecks discovered. The results can be the basis for interpretation in terms of investment and operating costs. The network simulation layer of the toolchain can be split into three groups of tasks.

Flow Data Preparations

Purpose-built Python tools provide the ability to combine the disaggregated scenario demand and supply data and the network topology into network flow data in the process of nodal allocation. The flow data preparation also involves the hourly equalization of supply and demand using storage nodes and the selection of specific interesting network usage cases for fluid-dynamic simulation.

Application Programming Interfaces’ (API) Link to Commercial Simulation Software

The toolchain establishes a connection with commercial network simulation software, such as SIMONE or MYNTS,[6] using API. Through this API, the flow data is passed on and a configuration for all active elements in the network is set.

Results’ Visualization and Validation

Finally, the toolchain offers the necessary functionalities to visualize and analyze the simulation outcomes. It enables the exploration of diverse parameters, including flow rates, flow velocities, pressure levels, and required compression power. The visualization module facilitates the validation and assessment of different network scenarios.

The disaggregated scenario data and allocation results, network topologies, simulation parameters, and results obtained from the load-flow calculation performed in a fluid-dynamic simulation software are stored in a database. This ensures efficient data management and enables data interfaces between all toolchain steps and the availability of the results output for results documentation and interpretation.

3.2 Temporal Allocation

Temporal allocation is conducted separately for each sector due to sectoral differences. A normalized vector, or “temporal profile,” is created for each sector, which is multiplied with regional scenario demands later. This multiplication results in matrices for each sector, representing demand values for each region and hour. These matrices are then summed into one matrix M for the overall hourly demand per region. Different temporal profiles capture regional demand variations, especially in building and industrial sectors. Industrial demands are categorized by branch, while building demands are further classified into private households and commercial buildings, including warm water, space heating, and appliances demands. In future scenarios, temporal profiles change due to shifts in sectoral demand patterns across regions. Appliance-specific usage patterns remain constant, but total energy consumption may vary. To ensure comparability across scenarios, all profiles use temperature and calendar data from 2010, a year with particularly low temperatures suitable for stress-testing network topologies.[7]

The following outlines the specifics of temporal allocation for different sectoral demands.

3.2.1 Industrial Demand

A distinct temporal profile is crafted for each region to capture the temporal patterns of industrial demands, derived from observed working shift patterns across various industrial branches.[5] Each industrial branch possesses its own dataset, detailing shift profiles, considering factors like work on weekends, public holidays, and specific times of day such as night shifts. These profiles are then multiplied by regional industrial demands for each branch and aggregated for each region. Utilizing such differentiated temporal profiles allows for an accurate assessment of peak load scenarios and enhances result reliability.

3.2.2 Demand in the Buildings Sector

In the buildings sector, private households and commercial buildings mainly use natural gas for space heating and warm water in decentralized boilers. This is a large part of the overall natural gas consumption today. Additionally, natural gas is used in cooking, cooling, and powering other devices needed in the commercial sector. For hydrogen, these use cases play almost no role at all in most of the scenarios developed in recent studies for the German energy system.[8] However, in those scenarios involving decentralized space heating with hydrogen, it becomes a significant contributor to hydrogen flows; for these cases, standard profiles are employed for both gases.[9] These profiles are influenced by outside temperature and weather conditions, which can vary significantly across regions. To account for this variability, an integrated approach combining regionalization and temporalization is implemented, generating individual temporal profiles for each region. Historical weather data for 2010 was obtained from the German Meteorological Service which maintains a database. Hourly temperature data for each NUTS3 region was acquired from the an Open Data Portal using a custom Python tool developed for the PostgreSQL database API, ensuring a high level of temporal resolution and accuracy.[10, 11]

3.2.3 Transport and Mobility Demand

In the transport and mobility sector, demand for natural gas is very low and will remain so according to predictions from most studies.[8] For hydrogen, more demand is to be expected, and regionalization becomes more important. From a gas network perspective, it is unlikely that the short-term temporal demand patterns of individual consumers would be reflected on the gas network level because intermediate storage tanks are a standard element of a typical fueling station. More likely, fueling stations would be supplied in a more regular manner. More research into the supply patterns of gas stations must be conducted. In a smart energy system, the hydrogen supply for gas stations could ideally take place during periods of low demand from other sectors. In such a scenario, the need for peak load dimensioning specifically for hydrogen supply would be unnecessary. Currently, for the small amount of transport and mobility demands, a flat temporal profile can be employed.

3.2.4 Energy Conversion

In the energy conversion sector, temporal allocation is tied to power plant dispatch, combined heat and power generation, and district heating peak load boilers. Hydrogen production via electrolysis aligns with high renewable production and low-electricity demand hours when renewable production exceeds consumption and electricity prices are low.

For natural gas power plants, historical dispatch data can be utilized if hourly dispatch information is unavailable in scenario data. This data, accessible from the ENTSO-E database, can inform dispatch time series for natural gas power plants, aiding in scenario demand estimations.[12] Natural gas power plant data cannot be transferred to hydrogen power plants because operational conditions are hugely different.[13] Hydrogen power plants will most likely only be used when power consumption exceeds the production of solar, wind, and hydroelectricity as well as import or transport capacities from other countries or regions.[14]

In ref. 15, hourly dispatch data for hydrogen power plants, as well as electrolyzer production, has been made publicly available. These profiles are available for several years and different scenarios with differing underlying assumptions. Depending on the scenario being analyzed, one of the time series that is based on similar assumptions can be selected and used.

From previous simulations it could be seen that the peak power plant hydrogen demands make up a large share of the overall peak demand. Therefore, the accurate modeling of demands from power plants is highly relevant for hydrogen storage and network dimensioning.

For natural gas district heating peak load boilers, historical profiles from the years 2016 and 2017 for the city Flensburg are publicly available.[16] Using these, a multivariate regression model based on the weekday, temperature, and time of day was created and applied. The results can be used as a temporal profile applied to all district heating peak load boiler demands.

3.3 Spatial Allocation

To address the regional aspect of topology development, it is crucial to disaggregate sectoral demands into a high spatial resolution. However, it is essential to strike a balance between spatial accuracy and data availability. The availability of various structural data, such as population, economic data, CO2 emissions, and temperatures, is accessible for administrative regions of counties and cities which in Germany correspond to the third level of the Nomenclature des Unités Territoriales Statistiques (NUTS3 level).[17] In many cases, data may only be available at a lower resolution, such as a single value for all of Germany (NUTS0), federal states (NUTS1), or other subdivisions. In such instances, spatial allocation of the data becomes necessary. Although scenario demand data is often available in a high regional resolution or even at a location-specific level, a flexible approach is required to accommodate various scenario data inputs. Therefore, a comprehensive spatial allocation method was developed, also referred to as regionalization, for each relevant sector. The details of this approach will be presented in the following sections.

The methods used for spatial allocation depend on the sector and gas type. The general approach used in demand regionalization is to first create a normalized vector describing the share each NUTS3 region (or individual location) has in the sectoral demand based on one or more proxies and then to multiply this vector with the overall scenario demands to generate spatially allocated demands for a given sector. In many cases these vectors can be calculated once for a base year and are then used in further scenario calculations. The methods for each of the relevant sectors are described in the following in more detail.

3.3.1 Industrial Demand

Current publicly available data for industrial hydrogen demands in Germany at the NUTS3 level is accessible through the LFS3 project, providing data for different scenarios.[15] Site-specific data for potential hydrogen industrial consumption can be found in a study focusing on the future potential hydrogen demand in energy-intensive industries in Germany.[18] Additionally, the German statistics database offers natural gas and hydrogen demands by the industrial branch for 2021.[19]

The methodology was expanded to regionalize natural gas industrial demands based on emissions data per industrial location. This allows for the distribution of scenario demands among NUTS3 regions. For hydrogen demands, a similar approach is outlined in ref. 18. These methods create normalized regional allocation vectors for industrial demands, providing a regional distribution profile for each industrial branch across Germany.

This branch-specific regional distribution is utilized in temporal allocation to generate different load profiles for each region. Disaggregating industrial demands by branch also facilitates nodal allocation in later steps of the scenario data generation process, accounting for variations in consumption and grid connections accurately.

3.3.2 Demand in the Buildings Sector

For hydrogen-focused scenarios in which household and commercial hydrogen use for heating does occur in spite of the poor efficiency, the regional distribution of hydrogen use in buildings can be expected to be similar to that of natural gas. Therefore, the same regionalization approach is used for both gases. As the demands for natural gas from this sector are very high and predicted to remain so for some years to come, a detailed approach was conceived for both private households and commercial demands, making use of model building types, census data, and other sources.[20]

3.3.3 Transport and Mobility Demand

No dedicated method has yet been developed to perform transport and mobility demand regionalization. For future development of transport demand regionalization, the locality of fuel stations must be considered. This could be done by referring to major road infrastructure or even the actual locations of fuel stations. It is possible that many of the actual hydrogen demands would be transported to the fuel stations by the truck instead of pipeline.[21]

3.3.4 Energy Conversion

In the energy conversion sector, power plants as well as combined heat and power plants, district heating peak load boilers, and electrolyzers must be considered. Their locations are highly dependent on the modeling of other energy infrastructures as well, especially the power grid. Therefore, electrolyzer production and power plant demand for hydrogen or natural gas are usually not spatially allocated to a NUTS3 level, but instead directly allocated to certain power plants/electrolyzer sites, based on power grid models or plant/site capacities. Capacities of power plants are taken from refs. [12, 22]. Similarly, for hydrogen power plants, data from current project announcements is used.[23]

For district heating peak load boilers, a different approach can be taken. These demands can be allocated to the NUTS3 regions of German cities supplied via district heating.[24]

3.4 Network Topology Development

Subsequent to the allocation of the scenario data temporally as well as spatially, the network topology is determined. The scenario data generation is inter-related, in part, with the network topology development. Based on the disaggregated scenario data as well as the existing gas network infrastructure and planned hydrogen infrastructure, the topologies for hydrogen and methane are also interrelated. In the following, the main aspects and existing approaches for topology determination and development are described.

Brownfield methods for topology development rely on existing infrastructure which is expanded, repurposed, or reduced to meet the scenario requirements. Greenfield approaches on the other hand start on a blank slate, meaning the topology design is more flexible. However, since there is a large existing gas infrastructure in Germany, cost-effective network development makes use of the existing network. In the case of hydrogen topologies, the brownfield approach allows the repurposing of natural gas infrastructure for hydrogen when it is not needed for reduced natural gas transmission.

3.4.1 Base Topologies

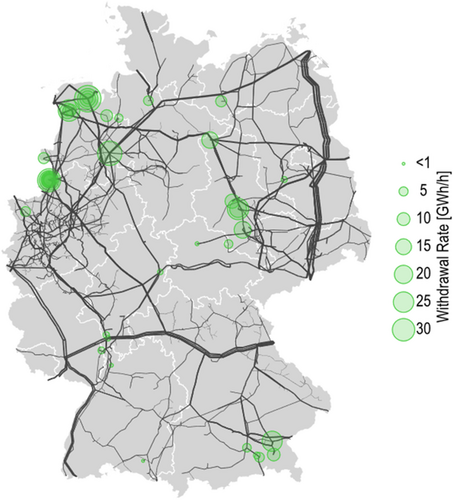

In brownfield modeling, it is important to consider the simultaneity of natural gas and hydrogen demands to ensure security of supply of both energy carriers. For both the theoretical repurposing of pipelines as well as for the analyses of the remaining methane infrastructure, a “base topology” of the methane transmission network in its current state is used, namely, the DE_2023 network described in Section 2. A summary of all relevant components included in this topology is given in Table 1 and Figure 3.

| Component | Element type | Number | Note |

|---|---|---|---|

| Nodes | Demand | 3864 | Incl. Industry, power plants, DSO connections, etc. |

| Supply | 133 | Incl. IC with other countries, LNG, UGS, gas production, etc. | |

| Elements | Pipelines | 7064 | DN 50-1400 mm Total Length: 33 346 km |

| Active elements | 1539 | Compressors, (control) valves |

Additionally, already existing projects are considered. The European Hydrogen Backbone proposed by a multitude of European gas network operators has been a long-used reference for hydrogen topologies.[25] Furthermore, the IPCEI list of hydrogen projects has been published for Germany.[26] From project reports to the Federal Network Agency as part of the consultation for the 2022 NDP, a list of hydrogen projects currently planned or already in construction to be completed within 10 years can be found in ref. 27. These sources were combined into multiple starting topologies (IPCEI-Base Network, IPCEI + 27, IPCEI + 32) available for analysis and further development, see details in Section 4.2.

To meet the future hydrogen demand, particularly during peak hours when hydrogen import and production may not be sufficient, it is essential to transform and expand the existing storage facilities in Germany. Therefore, the selection of storages for hydrogen conversion is an important part of network development. For that purpose, a database on existing underground gas storage facilities in Germany is maintained and updated regularly based on publicly available data.[28] This comprehensive database stores information such as storage type, capacity, maximum withdrawal, and injection rates. Additionally, published plans for hydrogen transition were also included in the database.[29-31] The collected storage data was integrated into the existing network model, providing a representation of the storage infrastructure. Figure 3 illustrates the locations of all gas storage facilities within the model and their respective withdrawal rates.

3.4.2 Topology Development

Based on both the existing methane infrastructure and the future hydrogen infrastructure is performed using a combined automated and manual approach using graph algorithms.

Graph algorithms are employed to split the base topology into a scenario-specific hydrogen topology and a remaining methane topology. For that purpose, the Steiner-Tree and Dijkstra shortest path algorithms, to determine optimal routes and connections between a selection of nodes, were implemented. The Steiner-Tree algorithm is a mathematical optimization technique to find the minimum tree spanning a selection of nodes based on available edges/pipelines. An approximation of the Steiner-Tree algorithm was developed in ref. 32 and applied to hydrogen network development in ref. 33. It is used in the toolchain to select optimal routes for the hydrogen network by considering the given base and terminal nodes to be connected to the starting topology. The selection of nodes to be connected is based on demand clusters, trade flows, and storage needs among other factors from the given scenario data. Customized edge weights can be used to prioritize shorter pipelines with larger diameters to optimize the network structure. To include a starting hydrogen network in the topology development for a scenario year, the starting topology's edge weights are set to zero, resulting in an inclusion of all its pipelines in the minimum spanning tree. After new nodes have been connected to the hydrogen network, the same pipelines are removed from the methane network, automatically. Wherever the removal of a pipeline from the methane network results in a disconnected subnetwork, the pipeline is marked as one that cannot be repurposed and must be newly built. Manual checks and validations are also conducted to ensure the reliability and accuracy of the network splitting procedure.

Based on results of fluid-dynamic simulations of the resulting methane and hydrogen infrastructure, the topologies can be further updated and improved to meet the scenario transport task. This is done manually wherever bottlenecks occur.

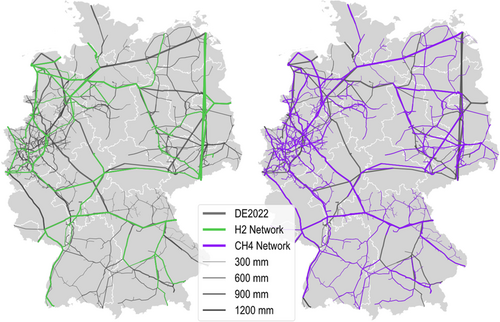

The procedural steps described earlier have been applied on the basis of the predecessor, the DE_2022 topology. Figure 4 illustrates the generated network topologies, illustrating the split into methane and hydrogen networks based on the existing German gas network.

3.5 Nodal Allocation

After the preparation of regionalized hourly supply and demand data, based on the overall demands for both hydrogen and methane for a modeled scenario year, to be able to analyze the developed hydrogen topologies using fluid-dynamic simulation software, a nodal allocation of the gas demand and supply to the entry and exit nodes of the network is necessary. At this point, all data is available in a regionalized format as a time series of demands or supplies for each NUTS3 region or for specific locations. The temporal aspect of the data is not relevant for nodal allocation and therefore in the following we consider the data as one data point for each region or location. The network topologies for hydrogen and methane consist of nodes and pipelines along with active network elements such as compressor stations and valves. The nodes of the network are either there to connect different pipelines with each other or to inject or withdraw gas into or from the network. Nodes that only connect different pipelines are referred to as internal nodes and are not used for nodal allocation of gas flows.

DSO nodes represent the points at which gas is passed on to the DSOs on a lower network layer. UGS nodes represent underground gas storage facilities and can be used for injection and/or withdrawal from the grid. IC nodes and LNG nodes are used for trading, both for injection or withdrawal as well. Other special node types used for the allocation are specific power plant nodes, electrolyzer nodes for injection of hydrogen from electrolyzer production, or industry nodes which represent specific large industrial sites that consume gas directly from the transmission grid at high pressures.

Based on the sector, different node types are used for nodal allocation as well as different allocation approaches suitable for that sector. Table 2 shows the major supply and demand sectors and the corresponding general allocation approach used. The approach used is strongly dependent on the data source and the resolution of the data. In general, more distributed demands, especially for natural gas, need to be allocated to DSO nodes from NUTS3 regions, whereas location-based demands such as those of a small number of power plants can be allocated directly to their corresponding nodes.

| Sector | Industry TSO | Industry DSO, Buildings, Mobility | Energy Conversion | Storages | Trading |

|---|---|---|---|---|---|

| Data Sphere Spatial Resolution | Individual locations or Regional (NUTS3) | Individual locations/Regional (NUTS3 or different) | Individual locations | Cross-border Interconnections | |

| Nodal Allocation Method | Pipe capacitiesa), Voronoi polygon intersection areab) | Capacities, nearest node | Capacitiesc) | Capacitiesd) | |

- a) For regions with nodes of the given type.

- b) For regions without nodes of the given type.

- c) Based on the demand and supply equalization method described in Section 3.8.

- d) Only used between multiple IC nodes of one neighboring country.

3.5.1 Allocation from NUTS3 Regions to Nodes

For the NUTS3 region-based nodal allocation, the developed procedure is based on node and pipeline characteristics as well as the locality of nodes and regions in relation to each other. First, an intersection of each NUTS3 region's border with the coordinate locations of the nodes is calculated, assessing which nodes are located within which region. For this allocation, only DSO nodes are typically considered, as these are the ones that are used to supply distributed demands. However, this method can be performed independent of the selected node type. A mapping of regions and their corresponding nodes is created. There are three cases which could occur regarding the number of nodes per region that are relevant for nodal allocation: a region can contain either one node 1), more than one node 2), or zero nodes 3) of the relevant type. In the trivial case that there is only one node within a region (1), and all its demands can be allocated to that node directly. The other two options are discussed in the following.

Allocation Based on Local Network Characteristics (2)

In case there are multiple nodes in a region, a ratio to distribute the demands among the region's nodes is needed. From a network perspective, it makes sense to have nodes where large demands occur, connected to larger pipelines, and at smaller pipelines, only connecting nodes which connect consumers with a smaller share of the region's demand. Therefore, an allocation weight is introduced. For each node, the connected pipeline's diameter and maximum pressure was checked and a table of nodes and their corresponding allocation weight W according to the formula was applied.[5]

Using this allocation weight, the share of the demand to allocate to each of the nodes can be calculated for any set of nodes by normalization. This approach also helps at a later stage with fluid-dynamic network simulations, as it is less likely to have high demands at nodes connected to smaller pipelines which could otherwise create bottlenecks.

Allocation Using Voronoi Diagrams (3)

In cases where there are no nodes in a region with hydrogen or natural gas demands, nodal allocation based solely on transmission grids can be insufficient. Much of the demand, especially in natural gas infrastructure, is supplied via distribution grids with longer regional pipelines. For hydrogen, distributed demands might also be served via train, truck, or distribution pipelines.[34]

Allocating demands to the nearest node seems intuitive but presents challenges. One node might quickly become overloaded if it serves multiple regions, and it's unlikely that only one node would meet all the demand in regions with multiple nodes. The solution involves using Voronoi diagrams, which divide an area into cells based on node locations. Each cell represents the area closest to its respective node. By constructing Voronoi diagrams from selected nodes across the area of consideration, the likelihood of supply through each node can be determined geometrically.[35, 36] For regions lacking nodes, the Voronoi cells of neighboring nodes intersect that region.

A distribution key for nodal allocation can be generated by considering the intersection area of each node's Voronoi cell with the region's area. This method ensures fair allocation among intersecting nodes, as illustrated in Figure 5. The allocation is applied uniformly across hourly demand time series data.

3.5.2 Allocation of Industrial Demands on TSO Level

For industrial demands that are connected directly to the transmission grid, a separate allocation is performed. These demands are not allocated to DSO nodes, as they are not supplied via distribution grids, but directly to industrial nodes on the TSO level. For that purpose, a thorough analysis was performed comparing maps of the gas transmission grid and industrial sites in Germany. Locations where the transmission grid and these industrial sites intersect or pipeline segments connecting industrial sites exist; industry nodes were introduced to the Base Network topology. Natural gas or hydrogen demands from high-demand industrial branches are allocated to these nodes whereas demands from other industrial branches are allocated to DSO nodes. Depending on whether the industrial demand data is given per site or per NUTS3 region, either the NUTS3 to node allocation approach described above is used or demands from individual locations are directly allocated to industry or DSO nodes.

3.5.3 Allocation of Trade Flows

Nodal allocation for trading data is straightforward. Specific nodes are designated as IC nodes, facilitating international trade flows. Depending on the country, there may be zero, one, or multiple IC nodes available. If there are no IC nodes for a given trading partner, the trade can either occur through a sea terminal (LNG node) or through one or more intermediate countries of which at least one shares an IC with Germany. If there is only one IC, it would be selected for all the trade flows, and if there are multiple, they can be used in combination with the share based on each IC capacities or only manually selected ICs could be used. These decisions are made in an integrated fashion during topology development considering both natural gas and hydrogen trade flows simultaneously. General trading capacities for each IC from ENTSO-G[37] are used.

3.5.4 Allocation of Electrolyzers and Power Plants

For electrolyzers and power plants, the allocation depends on the data available. If location-specific power plants dispatch data and electrolyzer production data is available (e.g., Section 4.1), the nearest power plant and electrolyzer nodes from the network topology can be selected from a list of available gas network nodes based on proximity. Otherwise (e.g., Section 4.2), an approach using planned power plant/electrolyzer capacity as a distribution proxy is proposed. The nodes available depend on the topology and parallel power grid modeling and simulation results and on other demands, trade flows, and necessary remaining methane infrastructure.

3.5.5 Allocation of Storage Flows

For the nodal allocation of storage flows, a selection of storage nodes must be made first. Again, this highly depends on the other influencing factors and is a decision made by the modeler during network development. The allocation of storage flows to these nodes is performed as part of technical balancing and described in the Section 3.6.

3.6 Hourly Supply and Demand Equalization

Once all data has been allocated to network nodes, one obtains a data table of nodal flows per hour. Per definition, injections into the grid, that is, supply, are often given a negative sign, while withdrawal from the grid, or gas demands, usually has a positive sign. Summing up the flows for each hour, one obtains a time series of hourly imbalances between supply and demand. For a functioning gas network, supply and demand must be (nearly) equal or “balanced” for every hour.[38] Therefore, all imbalances must be equalized for every hour for the application of steady-state simulation without changing the scenario assumptions.

The basic idea of supply and demand equalization for both hydrogen and methane network simulations is to select the network nodes that have a degree of freedom in terms of injecting or withdrawing gas into or from the grid and using those to counteract the hourly imbalances. Depending on the model, usually only the storage flows and in some cases the trade flows can be modified to achieve an equilibrium without compromising scenario assumptions. However, for these nodes as well, technical restrictions apply. For both storages and ICs this means that for no hour the maximum hourly flow rates[28, 37] should be exceeded. When only looking at a single hour this should suffice; however, when looking at a whole year it becomes more complicated. For storage nodes, the amount of gas injected throughout a year should be as high as the amount withdrawn, returning to a similar fill level at the end of the year as in the beginning. Additionally, the fill levels of each storage must be tracked and should never exceed the technical maximum of the given storage.[28] To track fill levels, a starting fill level for each storage must be selected. This can be done by an estimate based on historical data and the time of year.[28] If a storage is empty—in terms of working gas—based on the fill level tracking, no additional gas should be able to be withdrawn from the storage in the model. For higher accuracy, fill level-dependent withdrawal and injection rates[39] can be used based on the same fill level tracking.[28] This way the available injection rate into a storage will decrease as it approaches its maximum fill level, and the withdrawal rate will decrease as the storage empties.

A method which implements these constraints was developed. The general methodology is to share each hour's imbalance among the available balancing nodes—usually the storage nodes—pro rata. The distribution ratio would usually be the available storage withdrawal rates for negative imbalances and the available storage injection rate for positive imbalances. The technical constraints are then checked and in case any constraints are exceeded, a better allocation of the imbalance is found using backtracking.[40] This can be done by setting the injection or withdrawal at nodes that otherwise exceed any of the technical constraints to the maximum possible without exceeding the constraints and then removing these nodes from the list of available balancing nodes for that time step. By calculating the now remaining imbalance and distributing it among the remaining nodes, a working solution can be found if it exists.

The result already indicates whether the topology was built in such a way that it can meet the transport task in terms of the storages needed. In cases where equalization is not possible given the technical constraints, an imbalance remains after all constraints have been met for the given time step and might necessitate changes to the available storages or other aspects of the topology.[3]

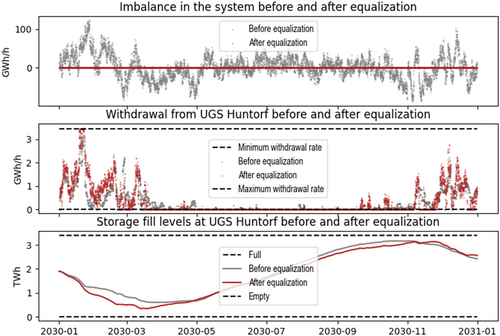

Figure 6 shows an example of the overall hourly gas flows in an exemplary scenario before and after supply and demand equalization. The hourly flows were highly unbalanced before but are completely balanced afterward. Below it shows the resulting changes to storage withdrawal and the corresponding storage fill level curve for one exemplary storage. Dashed lines indicate the constraints set for this storage in terms of fill levels and injection/withdrawal rates.

This sequence of diagrams in Figure 6 visualizes the importance of underground storages (UGS) for the facilitation of the equalization—as a preparation for the execution of fluid-dynamic simulations and for the feasibility of the network tasks. Even though the equalization is highly important for the overall transport network, the effect for the individual UGS is clearly in a range that does not undermine the original scenario values and network usage case data because the changes for the modeled storage operation are very small and far away from reaching technical feasibility limitations.

3.7 Determination of Network Usage Cases

Network usage cases represent the task the network must cope with; in the long term, they depend on the scenario design, and in the short term they change routinely over time (cf.[1]). The critical network usage cases are identified based on the hourly, node-specific demand and feed-in or import and export flows.[41, 42] The consideration of critical network use cases in the form of extreme situations (maximum, but also minimum gas flows) is relevant for designing the network. A successful simulation of these network usage cases ensures that the infrastructure is available to a sufficient extent to fulfill the specified transport task. Based on this, it is implicitly assumed that the supply tasks of the remaining hours can also be fulfilled, and secure operation can be guaranteed for the further hours of the respective year. Table 3 summarizes the network use cases identified as relevant for dimensioning. Typical network usage cases for validating a (gas) network are the maximum/minimum overall system load or assuming maximum and minimum flows for injecting into the DSO level or withdrawing for power plants, storages, or industry nodes.

| Network Usage Case | Description |

|---|---|

| Max. Overall System Load | Hour with the highest cumulative gas demand across all transport network nodes |

| Min. Overall System Load | Hour with the lowest cumulative gas demand across all transport network nodes |

| Max. DSO Withdrawal | Hour with the highest cumulative gas withdrawal for DSO level |

| Max. Power plant Withdrawal | Hour with the highest cumulative gas withdrawal for power plants |

| Max. Industry Withdrawal | Hour with the highest cumulative gas withdrawal for industry |

| Max. Imports | Hour with the highest cumulative gas imports |

| Max. Storage Withdrawal | Hour with the highest cumulative gas withdrawal from storages |

| Max. Others | Hour with the highest cumulative withdrawal to other consumption nodes |

| Min. DSO Withdrawal | Hour with the lowest cumulative gas withdrawal from DSO level |

| Min. Power plant Withdrawal | Hour with the lowest cumulative gas withdrawal for power plants |

| Min. Industry Withdrawal | Hour with the lowest cumulative gas withdrawal for industry |

| Min. Imports | Hour with the lowest cumulative gas imports |

| Min. Storage Withdrawal | Hour with the lowest cumulative gas withdrawal from storages |

| Min. Others | Hour with the lowest cumulative withdrawal to other consumption nodes |

3.8 Execution of Fluid-Dynamic Simulations

Fluid-dynamic modeling plays the final role in understanding the behavior of gases within a network during the transition to a green hydrogen transport infrastructure. It involves studying how gases flow through pipelines and interact with storage facilities, compressors, and demand points. By solving complex mathematical equations, such as the Navier–Stokes equations, the behavior of the gas can be accurately predicted, considering factors like pressure, flow rates, and gas properties. This enables the assessment of network performance, optimization of infrastructure design, and evaluation of operational strategies to ensure efficient and reliable gas transport. The simulation toolchain used in this context interfaces with professional dynamic simulation software, such as SIMONE, MYNTS, or pandapipes to conduct simulations for specific network scenarios. MongoDB, a NoSQL database, serves as the data process center, facilitating the interactive processing of input and output data with the simulators. Moreover, the toolchain can be connected to other simulation tools through appropriate interfaces, expanding the modeling framework's capabilities and providing flexibility in the simulation process. This integration of different simulation tools enhances the overall functionality and versatility of the modeling approach.

The process of fluid-dynamic modeling consists of several steps, summarized in Table 4:

| Step | Tasks |

|---|---|

| 1 | Defining network geometry and component specifications: The gas network is conceptualized as a graph with interconnected nodes representing supply facilities (import terminals, gas storages, electrolysis locations) and demand groups (industry locations, power plant sites, DSO connectors, etc.). The edges within the graph symbolize pipelines, enabling the transfer of gas between supply and demand points, while incorporating gas flow controlling facilities like compressor stations and valves to regulate gas flow. This comprehensive representation of the gas network's structure and connectivity serves as the foundation for modeling and analysis. |

| 2 | To ensure precise simulation of hydrogen behavior within the network, we carefully determine fluid properties and establish appropriate boundary conditions. The GERG function[25] is employed to account for the compression factor of hydrogen gas, allowing accurate calculations of gas compression under different pressures and temperatures. Furthermore, the one-parameter version of friction force theory[55] is used to determine the viscosity of hydrogen, considering its molecular properties. By incorporating these specific gas properties into our fluid-dynamic simulations, we enhance the accuracy and reliability of the obtained results for hydrogen. |

| 3 | Configuration settings for compressor stations: compressors are vital in long-distance gas transport, and ensuring an integrated configuration of all compressor stations within the network is crucial for delivering sufficient gas to meet demands and achieving high pipeline efficiency. The configuration settings of compressor stations include decisions on flow direction, which can be complex when multiple connection points and potential flow paths exist within a station. Additionally, specific parameters such as input/output pressure are set for each compressor station. In our toolchain, we utilize a compressor station configuration model based on[41] to optimize these settings and enhance network performance. |

| 4 | Numerical methods and solvers are then employed to solve the governing equations of fluid-dynamics. This enables the calculation of fluid flow rates, pressure profiles, and other pertinent parameters. |

| 5 | Based on the results of the simulation, bottlenecks are identified and changes to the configuration of the active elements such as compressors and valves may become necessary. The configuration is updated, and the simulation is executed again until an efficient solution within the technical boundaries of the system is found. |

| 6 | To ensure the reliability of the model, calibration and validation procedures are conducted using available data and real-world observations.a) |

| 7 | Finally, if through simulation it is found that certain infrastructure elements might not be necessary or additional infrastructure is needed to fulfill the network task, adequate infrastructure changes are implemented, and the process is restarted. |

- a) The detailed steps here encompass 1) pre-setting of configurations like pressures, valves, compressor station configurations, 2) executing simulations, 3) checking velocities and pressures results, 4) adjusting configurations and settings, 5) potentially changing the infrastructure and setting/configurations details, 6) iterative simulations execution.

3.9 Documentation, Validation, and Analysis of Results

The validation process involves several key steps to ensure the accuracy and reliability of the system. Initially, all intermediate stages undergo validation through various methods such as check sums, visualizations, and domain knowledge. Visualizations play a crucial role in not only confirming the correctness of the process but also in gaining in-depth insights into the scenario data.

The validation process covers various aspects, including 1) verifying input data using summary checks; 2) validating temporal allocation through profiles and heatmaps; 3) ensuring spatial allocation accuracy through regional choropleth maps; 4) confirming nodal allocation via nodal supply and demand maps; and 5) validating supply and demand equalization using storage curves, withdrawal and injection profiles, and system balance checks.

Additionally, the process involves verifying topologies with interactive map visualizations to ensure structural accuracy. The final stage focuses on validating the simulation itself, examining pipeline energy flows, flow directions, pressures, and velocities using purpose-made plots.

This comprehensive validation ensures the robustness and reliability of the entire system, providing meaningful insights into scenarios including network infrastructure costs, storage requirements, and security of supply.

4 Application and Results: Transition Toward Net Zero Energy Supply

In this section, we illustrate how the toolchain described in Section 3 was successfully applied in previous cases. One application, restricted to natural gas systems only, was the assessment of the security of natural gas supply during the recent gas supply crisis caused by the Russian invasion of Ukraine. Compared to normal levels, Russian deliveries to Germany were reduced in 2021, even before the Russian invasion of Ukraine.[43] In 2022, Russia further decreased the deliveries[44] and eventually completely halted direct shipments in September 2022,[45] just before three out of four Nordstream pipelines were sabotaged.[46] In light of these events, the German Academies of Science (Acatech) initiated an investigation into the impact on supply security from a network perspective.[3] In order to verify the results of previous models in terms of physical implementation of the gas transmission networks, our toolchain in Section 3 was applied to examine bottlenecks in selected European countries. The combined utilization of flow optimization and detailed fluid-dynamic network simulation represented a state-of-art approach.

The application and the results were reported in detail in ref. 4 and showed Europe's potential to achieve gas independence from Russia utilizing its current and additional LNG terminals, gas storages, and pipeline infrastructure, under the main conditions of reduction in gas consumption of a ≈15%, adequate cooperation among European nations, filling gas storage facilities in Germany and Europe to their maximum capacity, and expediting the commissioning of Floating Storage Regasification Units for the fall and winter of 2022.

This application of the toolchain was proven successful by the real development, but limited to the methane transmission network only. In the following subsections, we explore more complex applications for the combined analysis of methane and hydrogen networks.

4.1 Long-Term Scenarios for the Transformation of the German Energy System

In this section, we present the main results of the research project Long-Term Scenarios 3 (LFS3) on behalf of the German Federal Ministry for Economic Affairs and Climate Action.[15] In the LFS3 project, scenarios for the future development of the energy system are modeled in order to develop pathways to meet the energy and climate policy goals. This project covers the entire energy system from renewable electricity generation, over transport of electricity, heat, and hydrogen, to the application of different energy carriers like the reconversion of hydrogen to electricity as well as modeling electricity and gas infrastructures. Our data and modeling toolchain account for the methane and hydrogen infrastructures’ analysis, using the step-by-step application of the toolchain presented in Section 3 to determine the necessary infrastructures. In the following sections, the development of a hydrogen network will be shown based on the scenario T45-Strom (In a nutshell, this scenario describes the most cost-efficient path to climate neutrality for Germany in 2045. In T45-Strom direct utilisation of renewable electricity plays out its efficiency advantages. There are no additional scenario assumptions to reduce technology neutrality (like e.g., to foster a higher usage of electricity or hydrogen); in contrast, such assumptions – and obstacles for the energy transition, like e.g., delays in grid expansion or efficiency improvements – are investigated in further scenarios (cf.[19]).) of the LFS3 project. Due to the large scope of the analysis, this article only shows an excerpt of final networks/simulations for 2045. Further information and more detailed transformation paths are shown on the Long-Term Scenarios III homepage.[19]

4.1.1 Long-Term Scenarios in the Scenario Data Sphere

Mainly due to a high share of the direct usage of renewable electricity, the network task in the T45-Strom scenario is characterized by the lowest final energy demand as well as the lowest total system costs, compared to other LFS3 scenarios.[47] It contains an overall hydrogen demand for Germany in 2045 of 363 TWh; out of that, 186 TWh are supplied by domestic electrolyzers. The biggest shares of the overall 178 TWh imports enter Germany from France, Belgium, and the Netherlands. In 2045, Germany only exports ≈3 TWh to mainly Czech Republic, Austria, and Switzerland.[48]

Within the Scenario data sphere, these supply values from production and trade flows, as well as the sectoral demand values for methane and hydrogen, and, last but not least, storage inflows and outflows, were processed and allocated temporally and spatially according to the methodology in Section 3.1.1.

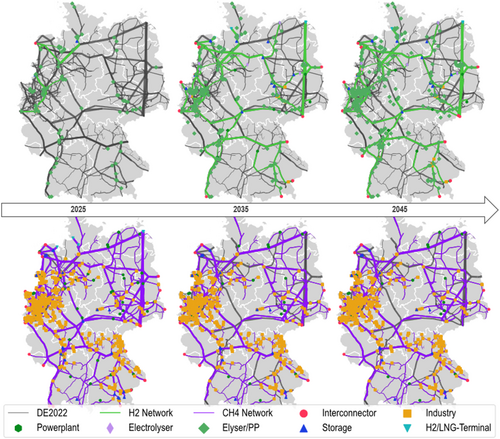

4.1.2 Long-Term Scenarios in the Network Topology Sphere

Within the network topology sphere, based on the existing methane network DE_2023 and applying the methodology in Section 3.4.2, the hydrogen grid was determined on Steiner-Tree basis for repurposing methane pipelines to hydrogen (with very limited new lines added). Both resulting topologies take into account the sources of the trade flows, the location and connection of storages, and compressor stations to ensure a secure supply to all connected regions. Figure 7 and Table 5 show the different network development steps as well as the corresponding grid lengths for 2025, 2035, and 2045.

| Year | 2022 | 2025 | 2035 | 2045 |

|---|---|---|---|---|

| Methane [km] | 33 363 | 32 149 | 25 066 | – |

| Hydrogen [km] | – | 1038 | 6926 | 7638 |

In 2035, most of the crossborder capacities to neighboring countries are established. Due to the high hydrogen imports of Germany from France, the IC to France was added in 2040. The development path for the hydrogen expansion measures is shown in Table 6. In the beginning of the considered period, the hydrogen network has a length of 1038 km and is repurposed from the existing methane grid. More than 90% of the necessary hydrogen infrastructure in 2045 was already established in 2035 ≈94% of the infrastructure in 2045 can be provided by repurposed methane pipelines. In this scenario, 19 compressor stations are needed to ensure the security of supply.

| Year | 2025 | 2035 | 2045 |

|---|---|---|---|

| Repurposing [km] | 1038 | 6926 | 7142 |

| New [km] | 0 | 0 | 496 |

| Compressor Stations (Number) | 3 | 16 | 19 |

If there is no more methane transmission required, the obsolete pipeline segments which are not needed for the hydrogen grid can be decommissioned, in total 26 221 km. Alternatively, pipeline segments could remain in case of transit tasks or for other fluids. According to the scenario assumptions (5% Removal, 30% Filling & Plugging, 65% Sealing), 1311 km would be removed, 7866 km filled and plugged, and 17 044 km sealed over all respected years. The development path for the decommissioning measures of the methane grid is shown in Table 7.

| Year | 2025 | 2035 | 2045 |

|---|---|---|---|

| Removal [km] | 9 | 69 | 1311 |

| Filling and Plugging [km] | 53 | 411 | 7866 |

| Sealing [km] | 114 | 891 | 17 044 |

| Compressor Stations (Number) | 3 | 21 | 86 |

4.1.3 Long-Term Scenarios in the Network Simulation Sphere

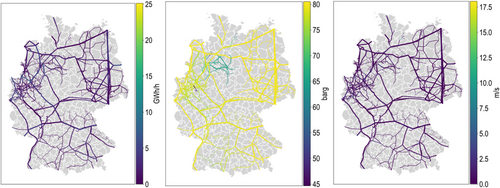

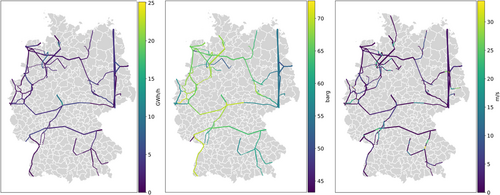

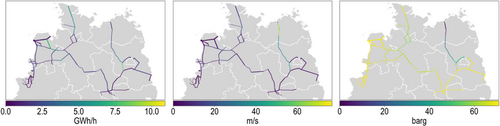

For the validation of the generated hydrogen and methane network topologies every year, a fluid-dynamic network simulation was carried out for both energy carriers and the reference years, according to Section 3.8. As final preparation for the network simulation, the T45-Strom scenario data (4.1.1) and the topologies described earlier (4.1.2) were combined and the network usages cases were selected (c.f. Table 3). For these network usage cases, the nodal allocation and equalization was executed, that is, hourly demand and supply values from all regions and locations were allocated to the nodes of the two topologies and balanced by usage of storages. The full dataset of equalized and allocated hourly entry and exit flows for the T45-Strom scenario was passed on to the fluid-dynamic simulation software. Here, the setting of penstock, valve, and compressor stations configurations was carried out to ensure a flow pattern which stays within physical limits. The iterative model runs yielded the following results (Figure 8).

In the T45-Strom scenario, the methane network is most stressed in 2025 because the demands in Germany are still high while the available pipeline network is starting to be reduced for the hydrogen network. In contrast, the hydrogen network has to cover the most difficult task in 2045 due to high hydrogen amounts which need to be transported. Therefore, the results of the fluid-dynamic simulation for methane (2025) and hydrogen (2045) are shown in Figure 8 and 9.

The results for the methane network topology show that the supply task can be fulfilled with a reduced topology. The power flows reach a maximum of ≈16 GWh h−1 in the northwestern part of the network due to high methane imports from Norway. For hydrogen in 2045, the power flows do not peak as high as for methane and are more uniformly distributed.

Regarding the pressure levels, both topologies do not exceed the physical limits. The methane network reaches pressure levels up to 85 barg and drops to 40 barg in some areas. For hydrogen, the pressure levels are between 40 and 75 barg but differ slightly more than in the methane network.

The flow velocities reach a range up to 20 m s−1 for methane and 30 m s−1 for hydrogen—what is both inside the technical limitations.

With these three crucial parameters within the physical limits, the networks were successfully validated and the transport tasks can be considered as feasible.

Subsequent to the application of the toolchain, the economic assessment of the fluid-dynamically validated networks was carried out.

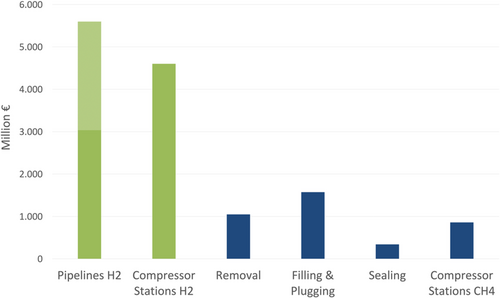

4.1.4 Economic Evaluation

Based on the validated topologies, the economic network evaluation includes capital (capital expenditures) and operational expenditures for both infrastructures and in addition the decommissioning costs for the methane network. Using the transformation paths developed in Figure 7 and Table 6, the investment costs for repurposed and newly built hydrogen pipelines and new compressor stations were determined (see Figure 10). Depending on the cost assumptions for repurposed and newly built hydrogen pipelines,[49] the hydrogen networks in the T45-Strom scenario lead to investments between €3 and €6 billion (green to light green). In addition, there is a further €4.5 billion for the construction of new compressor stations. Decommissioning accounts for nearly €4 billion (dark blue), with filling & plugging dominating. The grand total is between €12 and €15 billion.

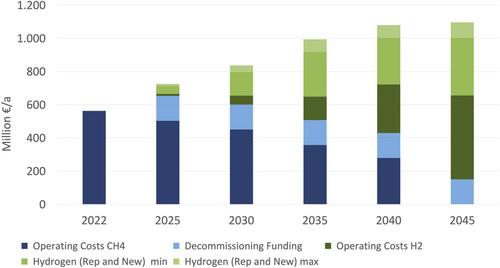

With the total investment and decommissioning costs determined, the total annuity values were calculated, including OPEX (see Figure 11). For this purpose, the investment as well as decommissioning costs were converted on an annual basis for hydrogen and methane. Furthermore, the OPEX for methane and hydrogen were estimated, in particular based on the compressor drives’ energy consumption and simplified cost factors for general maintenance. Drive energy depends on the volumes of gas to be transported, which leads to an increase of the operating costs for hydrogen (green to light green), while the operating costs for methane (blue to light blue) are fading out (Operating costs for methane: 0.30–0.40 € MWh−1; operating costs for hydrogen: 1.20 € MWh−1). In 2045, the total annuity costs do only contain the operating costs for hydrogen as well as the funding for investment/decommissioning. In summary, total annuity costs increase from about €600 million per year in 2022 to slightly above €1 billion per year in 2045, with the largest increase occurring by 2035.

4.2 Planning Projects of Governmental and Industry Institutions in Germany

This subsection presents the first results of the research project TransHyDE. In this context, our toolchain was applied based on scenario-dependent data and planning projects of governmental and industry institutions in the European context. Thus, for the network topology sphere in Section 3.1.2, the topology was not developed inside the toolchain, but imported and then assessed. For the German and European backdrop for these topologies, the German government aims to promote the use of green hydrogen technologies with its National Hydrogen Strategy published in 2020. This German National Hydrogen Strategy includes domestic transport and application as well as the cooperation with other European countries.[26, 50] These goals are also reflected in the European Hydrogen Strategy 2020. It states that opportunities for cooperation in the field of clean hydrogen technologies should be actively promoted in the EU.[27] For this purpose, the EC has selected 62 German research projects as IPCEI in 2021. These selected projects are divided into generation, conversion of industry, and mobility as well as infrastructure development. The total investment volume is over €33 billion, of which about €8 billion are going to be funded under the IPCEI.[28]

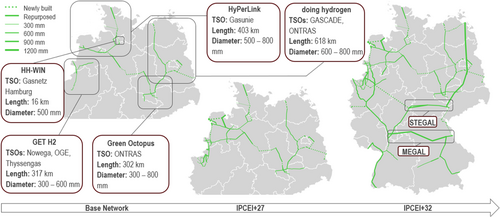

Particularly relevant for our analyses were the 15 projects in the subdivision infrastructure, which include pipeline as well as storage projects. The network consisting of repurposed and newly built hydrogen pipelines has a total length of about 1800 km. For most projects, the project developers are Germany's gas transmission system operators.

To determine the requirements of hydrogen transport in Germany, the gas transmission system operators conducted a customer consultation for the first time as part of the NDP 2020–2030 and updated the consultation as part of the 2022–2032 NDP.[30] Based hereon, the German TSOs identified possible repurposable and newly built hydrogen pipelines. A total pipeline length of about 6300 km has been reported for 2032.[51]

To characterize a possible stress case for hydrogen with low electricity production (no sunshine and no wind, the almost proverbial German Dunkelflaute), the TSOs created possible scenarios with supply and demand values. With the aid of a balance sheet allocation, the hydrogen grid pipelines for the years 2027 and 2032 were identified. The details of these grids can be found in the appendix of the 2022–2032 NDP.[52] The BNetzA was tasked to scrutinize these plans for the criteria reasonable and purposeful.[52, 53]

4.2.1 Planning Projects in the Network Topology Sphere

Due to the existing government acceptance, the projects with IPCEI funding commitments served as the ‘Base Network’ for the topologies presented in this section. Other topologies for different network tasks are derived from publicly available information provided by the projects in the NDP 2022–2032 as addressed in Section 3.4. Some manual adjustments are also required to connect the subprojects into a coherent network. Repurposed and newly constructed pipeline sections are determined with the help of the project overview of the reported pipelines in the NDP Gas 2022–2023.[53] Figure 12 shows the topologies, while a detailed collection of relevant information is given in Table 8.

| Topology | Base Network | IPCEI + 27 | IPCEI + 32 |

|---|---|---|---|

| Based on | Infrastructure Projects in Germany with IPCEI funding | Projects until 2027 in NDP 2022–2023 and IPCEI funding | Projects until 2032 in NDP 2022–2023 and IPCEI funding |

| Total length [km] | 1913 | 2903 | 6690 |

| Repurposed | 1340 km (70%) | 2177 km (75%) | 5420 km (81%) |

| Newly built | 573 km (30%) | 726 km (25%) | 1270 km (19%) |

| Connected countries | DK, FR, NL, PL | DK, FR, NL, PL | AT, BE, CH, CZ, DK, FR, NL, PL |

| Hydrogen terminals | Brunsbüttel, Rostock | Brunsbüttel, Rostock, Wilhelmshaven | Brunsbüttel, Rostock, Wilhelmshaven, Lubmin |

The Base Network with funded IPCEI infrastructure projects is connected to both eastern and western neighboring countries, such as Poland, the Netherlands, Denmark, and with France, in order to ensure the import and, if necessary, export capability. The connection to France will be realized in Saarland. However, no other connections between Saarland and other German states are funded. The ship delivery of hydrogen is planned via terminals in Rostock and Brunsbüttel. The projects enable energy-intensive industrial regions such as Hamburg, Salzgitter, and Duisburg as well as Halle/Leipzig to be connected to the hydrogen network. Infrastructure projects were not planned in Bavaria, Baden-Württemberg, and Hesse as part of the IPCEI funding program. The southern German states are therefore not included ≈70% of the total length of 1913 km consists of repurposed pipelines.

The second stage of development of the network topology is expanded toward 2027: IPCEI + 27. This network includes the Base Network as well as the pipeline sections reported in NDP 2022–2032 for 2027, which alone do not form a coherent German hydrogen network and thus make a consistent fluid-dynamic investigation of the network impossible. Compared to the Base Network, the difference in western federal states as North Rhine-Westphalia and Lower Saxony is noticeable in IPCEI + 27. North Rhine-Westphalia and the ICs to the Netherlands located there are completely connected to the rest of the German hydrogen network. The import of hydrogen via ship (We do not analyze which of the shipping technologies (ammonia, liquid or organic carriers) should or will be used but allocate import terminals at the ports for injections into the network in a neutral manner.) is also planned in Wilhelmshaven. On the demand side, the chemical industry locations in Saxony and North Rhine-Westphalia are connected by longer pipelines. The western and eastern federal states are only connected via Salzgitter, while there are still no transport options to the southern federal states. This network has a length of 2903 km and about 75% of all pipelines are repurposed.

The complete connection of all federal states is realized in the third development stage. This topology includes the pipeline sections reported in NDP 2022–2032 as well as the Base Network and is therefore called IPCEI + 32. In addition to neighboring countries already connected in previous topologies, crossborder hydrogen transport is also planned here with Austria, Belgium, Switzerland, and the Czech Republic. The connection between western and eastern federal states is now being established through the repurposing of various large methane pipelines. STEGAL and MEGAL can be considered as likely candidates. The import of hydrogen via ship is planned in Lubmin, in addition to Rostock, Wilhelmshaven, and Brunsbüttel. For the connection of the hydrogen terminal in Lubmin, either OPAL or EUGAL could be repurposed and connected to the rest of the network. This network has a length of 6690 km and about 81% of all pipelines are repurposed.

4.2.2 Planning Projects in the Network Simulation Sphere

For the validation of these IPCEI/NDP-based topologies, the toolchain in Section 3 was applied based on the IPCEI + 27 topology presented in Section 4.2.1. Figure 13 showcases the overall maximum network usage case achieved in all simulations. The gas flow, the pressure values, and the velocity of the gas in the pipelines are displayed from left to right respectively. In this case, all supply nodes inject gas into the network with a pressure of 70 barg, which is then withdrawn from the demand nodes in the different areas of the network.

Figure 13 reveals a uniform network, with the exception of a few pipelines carrying a significant amount of gas flow, particularly the Danish connection after the Hamburg area and the Wilhelmshaven–Oldenburg connection pipeline. By examining the pressure, it is possible to determine the locations of the supply nodes. As the ICs are positioned on the country borders of Germany, these areas of the network exhibit high pressure. However, as moving toward the center and particularly in the north, toward Rostock, the pressure gradually decreases at the end node of that pipeline. In contrast, the velocity shows the opposite trend. The gas velocity is low at the outer areas of the network and increases when moving toward the Rostock direction.

5 Conclusions and Outlook

As hydrogen and thus hydrogen networks will play an important role in the transition toward climate neutrality, their planning is an urgent task. The existing natural gas transmission systems play a pivotal role for this task for two main reasons: Their repurposing for hydrogen transport is a highly advantageous option, compared to newly built hydrogen pipelines; at the same time, the natural gas transmission system still has to guarantee security of supply until natural gas is phased-out. The appropriate size and structure of hydrogen transport networks depend on the spatial distribution of hydrogen demand and supply and its time-dependence, still uncertain development; the same is true for natural gas transmission systems. This makes the transition planning for both infrastructures a complex research field with multiple dimensions, layers, and spheres, which must be coherently addressed in a dedicated network modeling systematics.[1]

For the case of Germany, where the political and industry discussions are advanced and momentous decisions are under discussion, we have developed and madee available open source in ref. 2 the database and the toolchain for the parallel analysis of both infrastructures. The database covering the existing German natural gas transmission systems has been presented in Section 2.