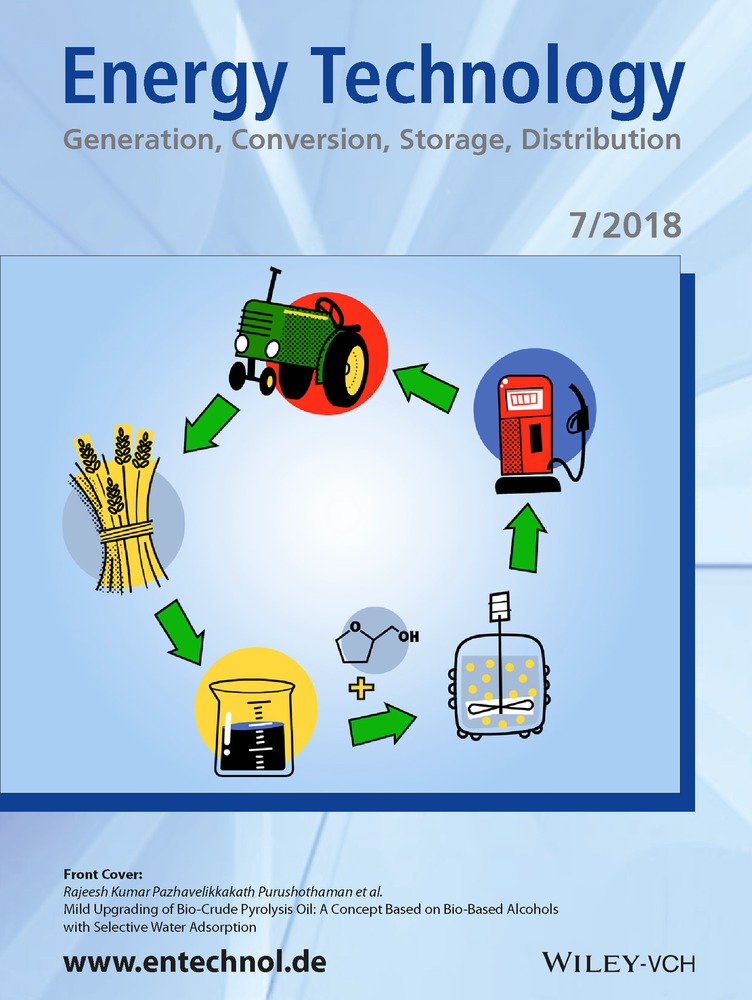

Front Cover: Mild Upgrading of Bio-Crude Pyrolysis Oil: A Concept Based on Bio-Based Alcohols with Selective Water Adsorption (Energy Technol. 7/2018)

Graphical Abstract

Towards pyrolysis oil commercialization: Bio-crude pyrolysis oil is obtained by a process called fast-pyrolysis, in which almost any organic-based feedstock is thermally processed at moderate temperatures, in the range of 400–600 °C, in the absence of oxygen at short residence times. Ideally agricultural residues or municipal solid waste are preferred as feedstocks. After condensing the vapors in a cooling tray, a dark-brown bio-liquid is obtained. The quality of the so-obtained fast pyrolysis oil has some challenges for its direct use as transportation fuel. Low-caloric value, high viscosity, and corrosion are the major obstacles for its implementation in conventional engines. There have been sustained efforts to improve the quality of the oil. In this study the authors report a breakthrough concept to improve the acidic properties, by means of a combined catalysis and adsorption approach, using tetrahydrofurfuryl alcohol, which is a biomass-derived bulk chemical. Under optimal conditions, the ultimate acidity and water content of the upgraded product are marginal. This makes the commercialization of the bio-oil blends not a myth, but a reality, being potentially able to fuel farmers’ tractors and bringing us a step closer to closing the sustainability loop. More details can be found in the Communication by Rajeesh Kumar Pazhavelikkakath Purushothaman et al. on page 1209 in Issue 7, 2018 (10.1002/ente.201700719).