An Overview of the Impact of Vibrations on Li-Ion Battery Performance, Degradation, Battery Thermal Management System and Key Focus Areas

Funding: Enersys Delaware Inc. provided crucial financial support, which made this research possible.

ABSTRACT

Lithium-ion batteries (LIBs) have gained significant attention in recent years due to their widespread applications in electric vehicles, portable electronics, energy storage, and renewable energy systems. However, their increasing use raises concerns about safety, reliability, and performance under various operating conditions. Among these, the impact of vibrations encountered during transportation, operation in vehicles, and industrial environments on battery performance, state of charge (SoC) and other critical parameters is of particular importance. This study is an overview that focuses on understanding the effects of vibrations on Li-ion batteries (especially cylindrical, pouch, and prismatic cells) through a combination of experimental testing and simulation modeling results. The experimental results highlight the influence of vibration-induced stress on electrical performance and battery degradation behavior. Simulations complement these findings by providing insights into the mechanical and electrochemical responses, effect on battery thermal management systems under different vibration frequencies and amplitudes. By addressing these effects comprehensively, this overview aims to contribute to the design of more robust Li-ion battery systems capable of withstanding dynamic environments. The experimental studies show that discharge capacities were consistently decreasing depending on the cycles, frequencies, and the amplitudes of vibrations; this could be attributed to the separator and graphite anode material degradation. Also, the simulation results showed that the battery temperature management systems will be more effective under vibration conditions.

1 Introduction

Lithium-ion batteries (LIBs) have emerged as a cornerstone of modern energy storage systems, powering an extensive range of applications that span consumer electronics, electric vehicles, renewable energy systems, and even aerospace technologies. These batteries have revolutionized how energy is stored and utilized, thanks to their superior performance characteristics compared to traditional battery technologies. Notably, LIBs exhibit exceptionally high energy densities, reaching up to 300 Wh/kg, which is significantly higher than the energy density of lead-acid batteries at only 50 Wh/kg [1]. This substantial advantage in energy density allows for the development of lightweight and compact devices and vehicles, making LIBs a preferred choice across industries. Additionally, LIBs boast a long cycle life and relatively low self-discharge rates of approximately 2% per month at a stable temperature of 25°C, which contributes to their reputation as reliable and efficient energy storage solutions [2].

Despite these advantages, the integration of LIBs into various applications exposes them to challenging environments, particularly those characterized by mechanical fatigue due to cyclic loading. This is especially relevant in sectors such as automotive, aerospace, and industrial applications, where external factors like vibrations can significantly influence the performance, reliability, and safety of these batteries [3]. Vibrations, defined as oscillatory mechanical motions, are a ubiquitous phenomenon in real-world operational environments. For instance, in electric vehicles (EVs), vibrations arise from road irregularities, the operation of electric motors, and structural resonances [4]. These stresses subject the battery pack to continuous mechanical loading, which can result in structural and functional degradation over time. Similarly, in aerospace and marine systems, vibrations are induced by propulsion systems, turbulence, and other environmental factors, creating a highly dynamic and demanding operational context for LIBs [5].

Traditionally, research on LIBs has primarily focused on improving their energy density, extending their cycle life, and enhancing their safety features. However, as LIBs become increasingly integrated into vibration-prone environments, the impact of mechanical stresses on their performance has gained prominence [6]. Vibrations can induce both physical and electrochemical changes within the battery, presenting a multifaceted challenge that requires deeper investigation. Existing studies have demonstrated that prolonged exposure to vibrations can lead to structural degradation of critical battery components, including electrode delamination, separator deformation, and electrolyte leakage [7]. These mechanical damages can adversely affect key performance metrics, such as capacity retention, internal resistance, and thermal stability. Furthermore, vibrations may exacerbate uneven current distribution within the battery, leading to localized heating and accelerating degradation mechanisms such as lithium plating and dendrite formation [8]. These effects not only compromise the efficiency and lifespan of the battery but also pose potential safety risks.

One of the critical aspects of understanding the impact of vibrations on LIBs is the examination of different cell geometries. The predominant LIB structures in use today are cylindrical, pouch, and prismatic cells, each with distinct mechanical and electrochemical properties. Among these, cylindrical cells have been found to be particularly susceptible to vibration-induced performance degradation. Studies have shown that cylindrical cells experience considerable capacity loss and an increase in internal resistance compared to pouch and prismatic cells when subjected to vibrational stresses [9]. Prismatic batteries show moderate performance, while cylindrical batteries are the most susceptible, with significant degradation observed. These findings are based on scientific studies using standardized tests, providing a clear ranking of pouch > prismatic > cylindrical. This heightened vulnerability underscores the importance of prioritizing research on cylindrical cells to mitigate their limitations and enhance their robustness in dynamic environments.

Beyond the direct effects of vibrations on the battery cells, there is also growing interest in understanding how vibrations influence Battery Thermal Management Systems (BTMS). BTMS are critical for maintaining the optimal operating temperature of LIBs, ensuring their performance, longevity, and safety. Some studies have explored the effects of vibrations on different BTMS designs, such as water-cooled and air-cooled systems [10]. These investigations have revealed the complexity of modeling vibration-induced phenomena, including the nonlinear behavior of vibration frequencies and amplitudes. By extending the focus to BTMS, researchers can gain a more comprehensive understanding of how vibrations affect the entire battery system, not just the individual cells [11].

The significance of studying vibration-induced effects on LIBs cannot be overstated, especially as these batteries are increasingly deployed in critical applications where reliability and safety are paramount. For example, in EVs, ensuring the structural and functional integrity of the battery under vibrational stresses is essential for delivering consistent performance and preventing failures [12]. Similarly, in aerospace applications, where operational conditions are even more extreme, understanding these effects is crucial for designing batteries that can withstand high-stress environments without compromising their functionality [13]. Table 1 provides additional details on vibration test standards.

| Application | Standard | Test type | Frequency range (Hz) | Duration | Acceleration levels | Axes |

|---|---|---|---|---|---|---|

| EVs | SAE J2380 [14] | Random vibration | 5–200 | 9 min–38 h | PSD-based (vibe due to road surface between 0.75 and 1.9 gRMS) | X, Y, Z |

| IEC 62660-2 [15] | Random vibration | 10–2000 | 8 h | PSD-based (vibe due to road surface around 3 gRMS) | X, Y, Z | |

| GB/T 31467.3-2015 [16] | Random vibration | 7–50 (sweep), broader | 21 h total | PSD-based (vibe due to road surface around max of 3 gRMS) | X, Y, Z | |

| Aerospace | MIL-STD-810G [17] | Sine, random, shock | 5–2000 | Several hours | 0.5–50+ g | X, Y, Z |

| RTCA DO-160G [18] | Sine, random, mixed | 10–2000 | Several hours | 0.2–10 g (avionics) | X, Y, Z | |

| NASA-STD-7001B [19] | Sine, random, shock | 20–2000 | Several hours | 3–10 g (higher for missions) | X, Y, Z | |

| Shipping any batteries | UN 38.3 (T3) [20] | Sine sweep | 7–200 | 3 h total | Around 2 g's | X, Y, Z |

Despite the growing body of research on this topic, significant gaps remain in our understanding of the relationship between vibration-induced stresses and battery performance. Many existing studies have focused on specific aspects of this issue, such as the mechanical degradation of individual components or the thermal effects of vibrations on BTMS. However, there is a need for a more holistic approach that integrates experimental studies with analytical modeling to provide a comprehensive understanding of these phenomena. By combining insights from various disciplines, researchers can develop more robust models and testing methodologies to evaluate the effects of vibrations on LIBs systematically.

This paper aims to consolidate the existing research on the impact of vibrations on LIBs, with a particular focus on their performance, degradation mechanisms, and thermal management systems. By synthesizing findings from experimental studies and analytical models, we seek to elucidate the underlying mechanisms through which vibrations influence battery behavior. Specifically, this review will explore how vibrations affect electrical performance, chemical degradation processes, and the effectiveness of BTMS. Furthermore, we aim to identify key areas where future research efforts should be directed to address the limitations and challenges identified in the current literature.

Understanding the effects of vibrations on LIBs is essential for ensuring their safe and reliable operation in vibration-prone environments. This knowledge will not only contribute to the development of more resilient battery technologies but also enable their broader deployment in critical applications, ranging from EVs and renewable energy systems to aerospace and marine systems. By advancing our understanding of these complex interactions, we can pave the way for innovations that enhance the performance, durability, and safety of LIBs, ultimately supporting the transition to a more sustainable and energy-efficient future.

In conclusion, LIBs represent a transformative technology with immense potential to drive progress across multiple sectors. However, their integration into environments characterized by mechanical vibrations presents unique challenges that require careful consideration and targeted research. By addressing these challenges, we can unlock new opportunities for LIBs to excel in demanding applications, ensuring their continued role as a cornerstone of modern energy storage solutions. This paper endeavors to provide a comprehensive overview of the current state of research on this topic, offering valuable insights and guidance for future investigations aimed at optimizing the performance and reliability of LIBs in dynamic operational contexts.

2 Experimental Studies

Experimental studies play a critical role in understanding the impact of vibrations on LIBs. These studies yield essential empirical data to validate analytical models and pinpoint vulnerable components, such as electrodes and separators, susceptible to mechanical degradation. By exploring how vibrations influence battery performance, namely capacity retention, internal resistance, and cycle life, research reveals key degradation mechanisms, including electrode delamination and electrolyte leakage. This insight is crucial for advancing resilient battery technologies that ensure reliability and safety in dynamic environments. The studies referred to under this section will provide the relevant information on the changes that occur in the cell-level electrical performance and chemical degradation.

2.1 Influence of Vibration on Cell Capacity and Internal Resistances (Before and During Vibration Test)

A 2018 study examined Panasonic NCR18650PF 18,650 commercial cylindrical lithium-ion cells subjected to vibration excitation simulating harsh road surfaces and the interior environment of a car body (including motor operations). The vibrations were applied within a frequency range of 5–50 Hz, under a temperature of 18°C ± 30°C.

Specifically, sine dwell tests were conducted in the Z direction for low-frequency groups (5, 10, and 20 Hz) and high-frequency groups (30, 40, and 50 Hz) while simultaneously discharging the cell cluster at a 1C rate (approximately 2.6 Ah). Each group comprised four cell samples. The results indicated a reduction in cell capacity [21, 22], ranging from 0.2 to 0.3 Ah for cells exposed to vibrations compared to those under non-vibration conditions at an excitation frequency of 5 Hz [23]. Table 2 provides a more detailed overview of the observed behavior.

| Battery cell ID | No vibration | F = 5 Hz | F = 10 Hz | F = 20 Hz | Battery Cell ID | No vibration | F = 30 Hz | F = 40 Hz | F = 50 Hz |

|---|---|---|---|---|---|---|---|---|---|

| Cell 1 | 2.611 | 2.427 | 2.500 | 2.509 | Cell 5 | 2.612 | 2.582 | 2.615 | 2.611 |

| Cell 2 | 2.584 | 2.375 | 2.406 | 2.493 | Cell 6 | 2.618 | 2.590 | 2.617 | 2.612 |

| Cell 3 | 2.617 | 2.397 | 2.408 | 2.506 | Cell 7 | 2.620 | 2.573 | 2.618 | 2.611 |

| Cell 4 | 2.614 | 2.373 | 2.415 | 2.500 | Cell 8 | 2.618 | 2.555 | 2.618 | 2.616 |

The test was repeated on two additional sets, each comprising four samples, as described previously. Using the Wilcoxon Rank-Sum results method, the significance level for vibration conditions at 30 Hz was determined to be at least 0.05.

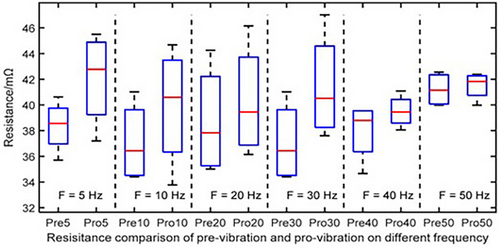

Internal resistances increased for cells exposed to vibrations, which aligns with the observed capacity loss [24-26]. Figure 1 illustrates this with box plots showing the variation within sample populations without assuming any specific statistical distribution. The plots display the maximum, minimum, median, and upper and lower quartiles of the data before and during vibrations. The difference in internal resistance distribution between batteries subjected to no vibration and those exposed to vibrations at various frequencies was found to be significant. Internal resistance was notably higher in the Y direction under the significance level of 0.05. A significance level of 0.05 in this context implies a 5% risk that internal resistances are not influenced by vibrations, as determined using the Wilcoxon Rank-Sum test method. The study generated a bell curve based on this method and found that, at a frequency limit below 30 Hz, the significance level is under 0.05.

However, the study faced a few limitations. The arrangement and directional orientation of the cells, as well as the vibration profiles, were not clearly defined. Cell capacities were only reported for Z-direction vibration conditions, even though internal resistances were analyzed in all directions. Additionally, only a single charge–discharge cycle was performed, whereas other studies typically conduct over 25 cycles to build confidence and assess long-term electrical performance decline.

It was found that structural issues like electrode delamination and micro-cracks, which can lead to capacity fade and internal short circuits from Zhang L et al. studies that are causing the decline of cell capacities from 2988.9 to 2920.1 mAh after vibration, suggesting a shorter lifespan [27]. Over time, these stresses accelerate aging, reducing the battery's usable life [8, 28].

2.2 Influence of Vibration on Cell Capacity and Internal Resistance (Before and After Vibration Test)

A study was conducted on 32 NCR18650BE lithium-ion cylindrical cells by Zhang et al. Unlike the previous study, where capacity checks were performed during sine dwell, this study measured discharge capacity (at 1C) before and after subjecting the cells to a UN38.3-compliant vibration profile [27].

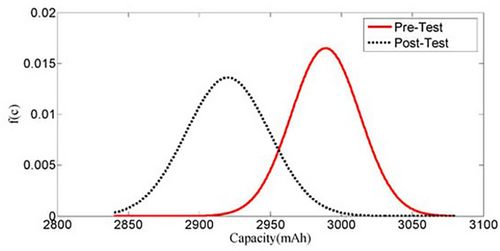

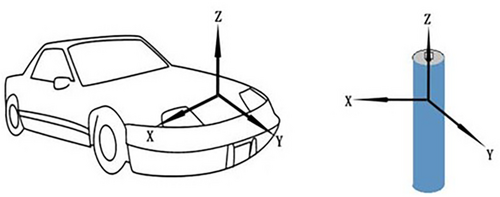

The mean discharge capacity before the vibration test was approximately 2.997 Ah. After undergoing the vibration profile, the mean discharge capacity decreased to around 2.935 Ah, reflecting a 2.1% reduction and indicating degradation in the cells' electrical performance [29]. Figure 2 illustrates this effect clearly. Additionally, the directions were explicitly defined in this study (as shown in Figure 3), unlike the previous one. This clarity helps manufacturers safely pack batteries to minimize cell degradation during transportation, extend battery life, and improve battery management system (BMS) strategies [30].

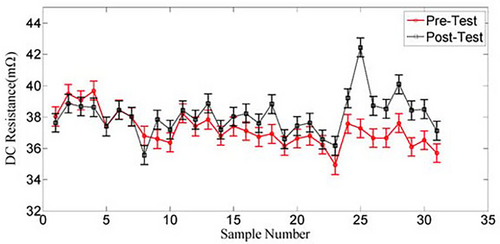

Internal resistance increased in 26 out of the 32 sample cells, while 6 showed a slight decrease. This discrepancy may be attributed to measurement errors, variations in operating temperatures, or other incidental factors. Figure 4 provides the DC resistance values for the 32 samples and shows that DC resistance can rise from 37.20 to 38.09 mΩ after vibration, reducing energy output. This means more energy is lost as heat, affecting performance in devices like EVs.

This study provides a confidence level of 95%. This means that there is a 95% probability that the sample mean after the vibration test exceeds the sample mean recorded prior to the test. In other words, there is strong evidence to suggest that vibrations are one of the contributing factors causing an increase in internal resistance [27].

However, this study did not specify the number of charge–discharge cycles performed to build confidence in the results or account for potential degradation due to cell chemistry changes. Overall, most studies show an increase in internal resistance after exposure to vibration conditions [31-33].

2.3 Effects of Vibrations on Electrochemistry

While previous studies primarily explored the impact of vibrations on electrical performance, one study specifically examined how vibrations affect the electrochemical characteristics of batteries. This included analyzing energy storage reduction after vibration, microscopic damage to the separator and anode surfaces, cycling performance deterioration, impedance increases after each cycling stage, and the exacerbation of lithium inventory loss (LLI) and active material loss (LAM) [34]. The study also highlighted the significance of battery arrangement and vibration direction, which greatly influence cell degradation [35].

For this study, 18,650 cylindrical lithium-ion cells from the same production batch were used. The cell with NMC (LI (Ni0.8Co0.1Mn0.1) O2) as cathode and graphite as anode materials has a voltage range of 2.7–4.2 V, a capacity of 2.6 Ah, and a max discharge rate of 5C.

Together 3 sets of vibration tests were performed at frequencies of 20, 50, and 75 Hz with 8 g acceleration amplitude for 12 h each. For a fair comparison, 3 sets of cells before and after vibration exposure were subjected to 100 cycling performance tests at 1C charging and discharging, as shown in Table 3.

| Battery | Frequency (Hz) | Vibration acceleration (g) | Vibration time (h) | Cycle number |

|---|---|---|---|---|

| Fresh battery | / | / | / | / |

| 20 Hz | 20 | 8 | 12 | / |

| 50 Hz | 50 | 8 | 12 | / |

| 75 Hz | 75 | 8 | 12 | / |

| Fresh +100 cycles | / | / | / | 100 |

| 20 Hz + 100 cycles | 20 | 8 | 12 | 100 |

| 50 Hz + 100 cycles | 50 | 8 | 12 | 100 |

| 75 Hz + 100 cycles | 75 | 8 | 12 | 100 |

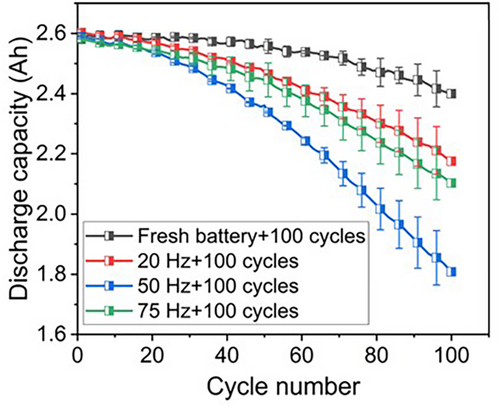

The cell capacities plotted in Figure 5 clearly indicate the stored energy decrease after vibration:

It was observed that after the 100th cycle, the capacities faded by 16.3%, 30.16%, and 18.51% at 20 Hz, 50 Hz, and 75 Hz, respectively. However, the batch of cells with no vibration conditions experienced a decline of 7.5% cell capacity after the 100th cycle.

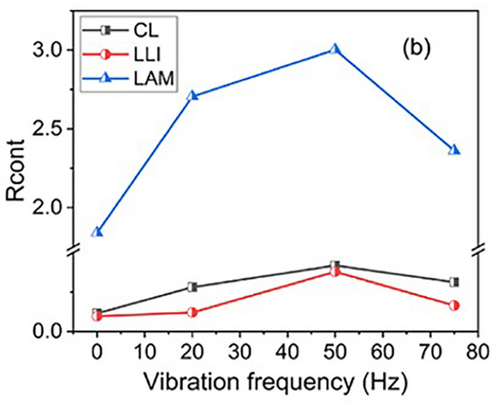

The degradation mechanism of the battery during the cycling process following vibration is illustrated in Figure 6. It can be seen that, out of conductivity loss (CL), LLI, LAM, LAM tends to be more influential than the rest of LLI and CL. Besides, they all show peaking around 50 Hz.

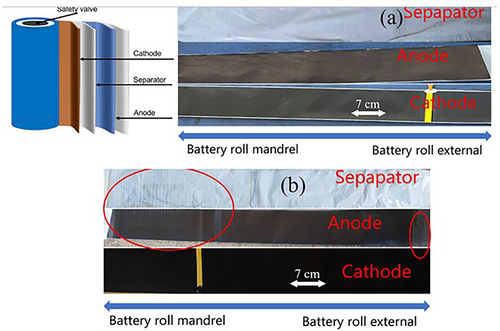

It was observed that vibrations at a 50 Hz frequency caused significant damage by accelerating the progression of LLI and LAM. This understanding was further supported by macro-morphological analysis, which compared a fresh cell, a cell subjected to 50 Hz vibration, and a cell subjected to 100 charge–discharge cycles following the vibration.

The analysis revealed that vibrations induced cracks and changes in the surface gloss of the graphite negative electrode, as shown in Figure 7b compared to Figure 7a. Additionally, after charge–discharge cycling subsequent to the vibration, sediment accumulation was noted on the surface of the battery separator. This was accompanied by an increase in the reflectivity of the graphite negative electrode surface, as illustrated in Figure 8.

A similar behavior was observed in prismatic cells (LFP); however, a tower-like structure was found growing on the anode. This phenomenon was likely due to the deposition of elements from the cathode caused by abrupt movements [36] at frequencies above 150 Hz.

2.3.1 Detailed Effects on the Separator

- Puncturing or Deformation: Vibrations, particularly in the vertical direction, can puncture or deform the separator, compromising its integrity. This is critical as the separator's role is to physically separate the anode and cathode, preventing short circuits. For instance, the study observed serious damage in cylindrical cells under UN 38.3 T3 sine vibrations and long-term tests over 186 days, with no electric current applied and cells at 50% SOC [35].

- Failure Modes and Electrical Resistance: Cannarella and Arnold discuss mechanical loading effects on separators, identifying two failure modes under biaxial loading. Mode A, associated with lower force and displacement, showed a significant drop in electrical resistance (from 782 to 223 kΩ, a 70% reduction), potentially leading to “soft shorts.” While this study focused on static mechanical tests, the dynamic nature of vibrations could exacerbate these effects, suggesting vibrations may induce similar failure mechanisms over time [37].

The impact is cell-type dependent, with pouch cells showing no effects from mechanical stress, likely due to their flexible, laminated structure, contrasting with the rigid, wound design of cylindrical cells [35].

2.3.2 Detailed Effects on the Electrolyte

- Overheating and Degradation: Short circuits caused by separator failure or other mechanical disruptions can lead to localized overheating, potentially degrading the electrolyte. This degradation can affect ion transport, reducing battery efficiency and capacity over time [35].

- Structural Damage Correlation: Wang et al. noted that capacity fading in LiFePO4 batteries is linked to crack formation in electrode materials, a process potentially exacerbated by vibrational stress. While not directly addressing the electrolyte, this suggests that mechanical stress can create conditions (e.g., cracks) that indirectly impact electrolyte stability and performance [38].

Vibrations significantly affect lithium-ion battery separators and electrolytes, with cylindrical cells being more vulnerable due to mechanical design. Separator damage can lead to short circuits and reduced resistance, while electrolyte degradation occurs indirectly through internal damage. These insights are critical for designing vibration-resistant batteries, particularly for mobile applications.

Based on the observations above, it can be inferred that the degradation mechanisms of LLI and LAM are primary factors contributing to battery capacity degradation [34, 39]. Vibration can cause the separation of the graphite layers in the battery and the breakage of the positive electrode's active material, which exacerbates irreversible side reactions during cycling [7]. As a result, the battery experiences significant capacity loss and an increase in internal resistance as it undergoes repeated charge and discharge cycles over time.

3 Simulation Works

Simulation works discusses how vibrations challenge batteries in dynamic environments; attention shifts to their impact on battery thermal management systems. These systems are essential for regulating battery temperatures to ensure performance, longevity, and safety. Vibrations strangely show a positive effect on their functionality and the ability to maintain critical temperature conditions. This section presents studies exploring how vibrational stress affects these systems. These investigations address the complexities of modeling such effects, given the nonlinear behavior of vibration frequencies and amplitudes. By understanding these dynamics, the aim is to enhance resilience in vibration-prone settings, ensuring reliable battery operation across diverse applications.

3.1 Mechanical Vibration Model and Experimental Result Comparison

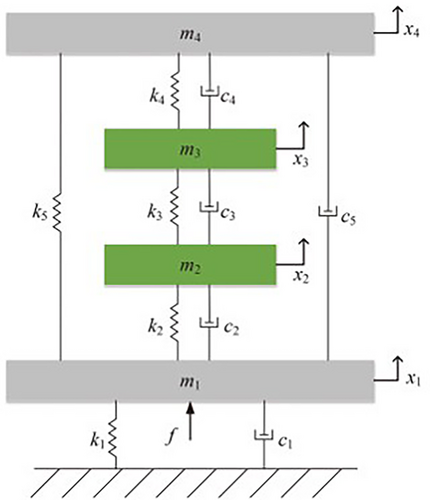

For the simulation work which helps in identifying the locations on the battery systems that are susceptible to failure, thereby coming up with the design changes (for durability improvement), a study was conducted on the structural modeling of plastic-cased LiFePO4 prismatic cells, comparing the results with experimental data produced by China Aviation Lithium Batteries (CALIB) for validation. The plastic casing (m1 and m4) of the battery was attached to two cells (m2 and m3), with the interior of the plastic casing filled with electrolyte. This configuration is illustrated in Figure 9 from the perspective of the mechanical vibration model [40].

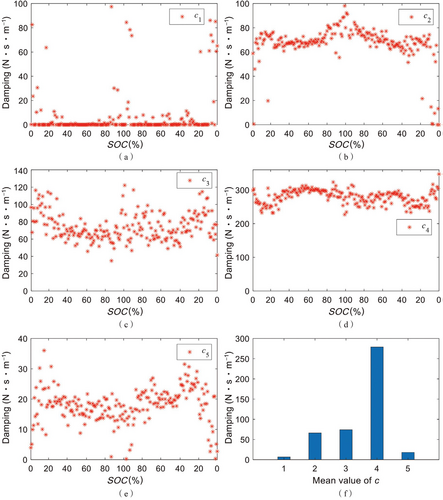

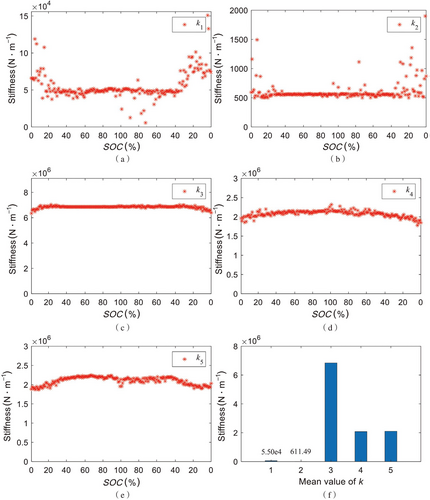

Unlike previous studies, this research focused on experimental vibration sweeps at various state-of-charge (SOC) levels, including 0%, 20%, 40%, 60%, 80%, and 100%, and compared these with the battery vibration model. The results showed that the mean relative errors between the model and the charging/discharging data were 10.16% and 10.17%, respectively. Notably, this study revealed that the damping ratios (C1, C3, and C5) had a negative correlation with SOC, while C2 and C4 showed a positive correlation, as shown in Figure 10. Additionally, stiffness values (k3, k4, and k5) exhibited a positive correlation with SOC, as shown in Figure 11.

To accurately model a mechanical system with a 10% error margin, the damping and stiffness values from plastic to cell and plastic to plastic are essential. However, despite outlining the necessary specifics for modeling the system, the study did not suggest how to improve the damping ratio or stiffness of the battery system to reduce the impact on cell capacities or prevent other forms of degradation.

Some studies are beginning to explore solutions, such as embedding carbon fiber laminates strategically to prevent damage to Li-ion polymer (LIPo) cells. These studies have shown up to a 310% improvement in damping ratios at various natural frequencies [41]. Additionally, FEA results from Vijayaraghavan et al. indicate that amplitudes caused by indentation are the most effective factor in increasing the risk of thermal runaway in LIBs, followed by temperature and strain rate. These findings were validated by pinch torsional tests [42].

3.2 Effect of Mechanical Vibrations on PCM as Battery Thermal Management Systems (BTMS)

Various studies have been conducted to explore the effect of mechanical vibration on PCM layers [43] (Passive cooling- no external power sources for cooling the battery systems), with most suggesting that optimal thickness or arrangement of the layers can leverage vibrations to enhance heat transfer [11, 44].

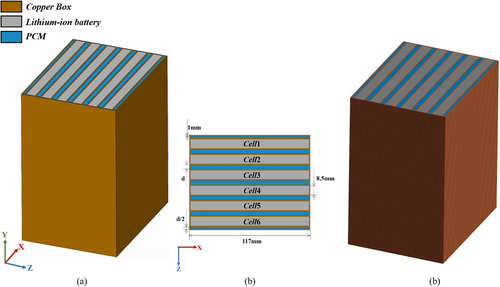

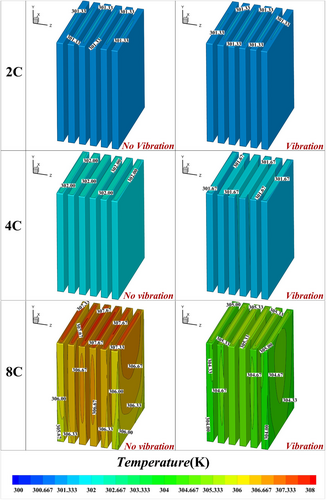

This study investigates the impact of mechanical vibrations on PCM-based Battery Thermal Management Systems (BTMS). The battery system consists of six prismatic cells, each separated by a PCM layer of varying thicknesses, as shown in Figure 12. The vibration conditions involve a 30 mm displacement Sine dwell at 20 Hz.

The results revealed that mechanical vibrations had a negligible effect on the BTMS at lower discharge rates. However, a positive effect was observed at an 8C discharge rate (where C represents the prescribed charge capacity of the battery in amperes), resulting in a temperature drop of 2.28 K under vibration conditions, as shown in Figure 13. Similar temperature reductions were observed in cells encapsulated in an 8.5 mm thick PCM layer with fins [46-48].

The thickness of the PCM layer was a critical factor in the temperature difference, especially between 2 and 3 mm, where the temperature difference significantly increased. As the thickness increased, the temperature reduction also grew. For example, under vibrational conditions compared to non-vibrational conditions, the temperature decreased by 0.84%, 1.99%, 4.90%, 23.00%, and 24.48% for 2, 3, 4, 5, and 6 mm thicknesses, respectively [45].

Finally, as vibration amplitude increased, the temperature difference between vibrational and non-vibrational conditions grew. However, beyond 50 mm amplitude, the difference became negligible. A similar study on a 12 mm thick PCM layer found that optimal temperature uniformity occurred at vibration frequencies of 10 Hz and 50 Hz, with a vibration amplitude of 100 mm compared to non-vibrational conditions [46].

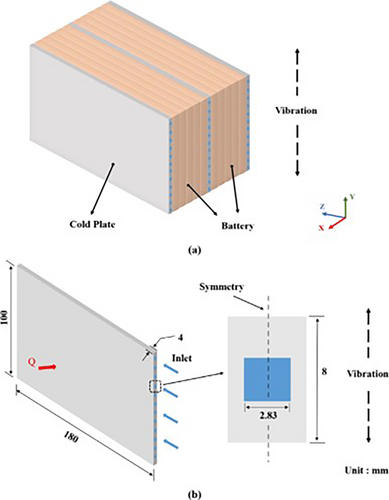

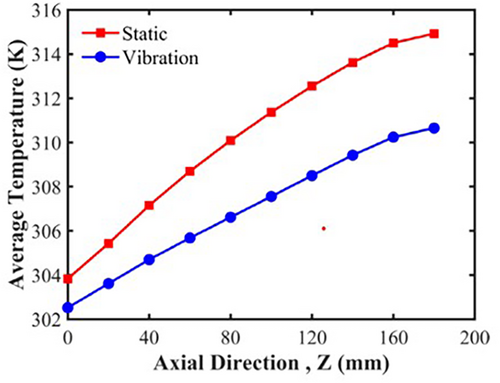

3.3 Effect of Vibrations on Mini-Channel Cold Plates as BTMS

Another study examined the impact of vibrations on Battery Thermal Management Systems (BTMS) as part of active cooling (where external pump is used in circulating fluid), specifically focusing on a mini-channel cold plate with water coolant as the BTMS, as shown in Figure 14. Using numerical analysis of the continuity, momentum, and energy conservation equations for the mini-channel cold plate, the study found that the maximum temperature was reduced by 4.35 K (Figure 15) when subjected to vibrations at 10 Hz with a 0.8 mm amplitude. Additionally, the temperature drop across the mini-channel cold plate was approximately 3.03 K [49].

This behavior has been observed in various published studies, many of which base their claims on simulation results. One such study suggested that their cold plate design could improve cooling performance by at least two times, as part of active cooling systems (pumping fluids from external sources) [50-52].

However, the major disadvantage of these technologies is the power consumption associated with pumping coolant, as temperature control requires increasing the flow of the coolant [53].

4 Design Optimization Strategies

Design optimization focuses on mitigating vibration-induced damage through structural and material enhancements. Key strategies include.

4.1 Tight Packaging and Fixed Internal Components

Research indicates that tight packaging and fixed internal components are critical for robustness. For example, pouch cells with tightly packed internals showed no damage under vibration and shock tests, while cylindrical 18,650 cells with a loose mandrel experienced serious damage, including bruised active materials and short circuits, especially under vertical stress [35]. This suggests that securing internal components, such as the mandrel, is essential for cylindrical cells to prevent movement during vibrations.

4.2 Orientation Optimization

The orientation of batteries within the pack significantly affects their durability. A comparative study found that cylindrical LIBs are more susceptible to degradation (up to 9.52% capacity reduction) when vibrated along their radial axis, compared to longitudinal orientation, while prismatic and pouch batteries showed less than 1% degradation along their length [54]. This highlights the importance of aligning batteries to minimize exposure to vibrations in their most vulnerable directions, particularly for structural applications in EVs.

4.3 Mechanical Design Features

Incorporating mechanical features can enhance vibration isolation. Strategies include integrating cell spacers, damping pads, pressure relief valves, and structural elements like end-plates and tie-rods. These features help distribute vibrational forces, reducing stress concentrations and preventing mechanical failure [55]. For instance, damping pads can absorb vibrational energy, while end-plates provide additional structural support.

4.4 Material and Structural Optimization

Optimizing materials and structures to withstand mechanical stresses is another approach. Research on pouch cell modules emphasized ensuring that stresses from lithium-ion intercalation/deintercalation, cell breathing, and swelling do not exceed yield strength, fitting within designed spaces [56]. This involves selecting materials with high mechanical resilience and optimizing enclosure designs to handle vibrational loads.

4.5 Reliability-Based Design Optimization (RBDO)

RBDO methods can maximize energy density while ensuring reliability under vibrations. This involves using Monte Carlo simulation for reliability analysis and genetic algorithms for optimization, considering uncertainties like manufacturing tolerances and mechanical properties [57]. This approach ensures batteries are robust against both expected and unexpected vibrational stresses.

5 Packaging Optimization Strategies

Packaging strategies focus on the physical arrangement and protection of battery packs to mitigate vibration effects. Key approaches include:

5.1 Support Systems and Mounting

Effective vibration isolation can be achieved through mounting brackets, axles, and integration with the vehicle chassis. These systems distribute vibrational forces, enhancing crash-worthiness and overall robustness. For example, mounting brackets can help isolate the battery pack from chassis vibrations, reducing transmitted stress.

5.2 Battery Cell Type Selection

The choice of battery type impacts robustness. Pouch cells, with their soft packaging, showed no damage in some tests but may require additional structural support due to vibration sensitivity, increasing assembly costs (e.g., USD 0.125 per unit in 2016 for pouch cells vs. USD 0.0692 for prismatic cells). Cylindrical cells, while common, need additional design considerations to secure internals, as loose components can lead to failure under vibrations.

5.3 Packaging Architecture

The architecture of the battery pack can influence vibration exposure. Configurations like “T-shaped” (e.g., GM Chevrolet Volt) and “Floor” (e.g., Tesla Model S, Audi e-tron Sportback) are used, with the latter potentially exposing packs to bottom impacts. Protective measures, such as metal/plastic shell casings (1–6 mm thick), can shield against vibrations and impacts.

5.4 Thermal Management System (TMS)

A modular TMS, using phase change materials (PCMs) and thermoelectric circuits, can ensure thermal independence, reducing the impact of vibrations on thermal stability. This is crucial as mechanical modularity depends on thermal modularity, given heat transfer between adjacent cells cannot be eliminated [55].

6 Future Work

-

Extended Environmental Testing: Future work should investigate the effects of vibrations across a broader range of environmental conditions, such as varying temperatures, humidity levels, and atmospheric pressures. These conditions may interact with vibration-induced stress to accelerate degradation processes, besides affecting stiffness and damping.

- Combining Vibration with Temperature Variations: Temperature affects battery performance and degradation, with standards like ISO 12405-1(2) (2012) already testing temperature shock cycling from −40°C to 85°C. Future research can extend vibration testing to include ultra-low temperatures (e.g., −40°C for Arctic applications) and ultra-high temperatures (e.g., 80°C for desert settings), as suggested by recent reviews in Journal of Power Sources [58]. This will assess how thermal conditions influence mechanical stability during vibration.

- Integrating Humidity into Vibration Tests: Humidity can exacerbate mechanical degradation, particularly in marine or tropical environments. Standards like IEC 60068-2-52 (2017) for salt mist testing (cyclic sodium chloride) can be combined with vibration tests to evaluate the impact of moisture. Research could focus on testing under 0%–95% relative humidity, as noted in environmental test chambers described by Aress Scientific [59], to ensure robustness in humid conditions.

- Low-Pressure and Altitude Simulations: For aerospace and high-altitude applications, vibration testing under low-pressure conditions (e.g., 11.6 kPa for 6 h per IEC 62619 (2022)) is crucial. This simulates the vacuum or reduced pressure environments of space or high altitudes, assessing how pressure affects cell sealing and mechanical integrity during vibration, as highlighted in studies like Xie et al. (2020) in Journal of Electrochemical Society [60].

By pursuing these expansions, future research can significantly enhance the robustness and reliability of Li-ion batteries, ensuring they perform safely and efficiently across a broader range of environmental conditions. This aligns with the ongoing evolution of safety standards and the need to bridge the gap between laboratory and real-world conditions, as highlighted in recent literature. In extreme scenarios, the battery systems' temperature, due to space constraints and a malfunctioning air conditioning system in an EV, could reach approximately 95°C (assuming an ambient temperature of 54°C) with humidity at 10% RH, simulating the environmental conditions of Death Valley, USA. Additionally, a temperature of 75°C (with an ambient temperature of 34°C) and humidity at 90% RH, representing the conditions in Lake Charles, Louisiana, USA, is also recommended.

- Diverse Vibration Profiles: Future studies should expand the range of vibration profiles analyzed, including more complex real-world patterns, such as those encountered in transportation, industrial machinery, and portable electronics, especially the speed sweeps in the EVs. This would allow for a better understanding of how varying frequencies and amplitudes affect different types of batteries and whether natural frequencies play any role.

- Impact on Emerging Battery Technologies: As new battery chemistries and designs, such as solid-state batteries and advanced lithium-ion systems, continue to emerge, their response to vibrational stress should be explored. Comparative studies could identify whether these technologies are more resilient or prone to degradation.

- Development of Mitigation Strategies: Based on insights from vibration studies, the development of materials, designs, or external dampening mechanisms to mitigate the effects of vibrations on battery performance should be pursued. These could include shock-absorbing battery enclosures or vibration-resistant electrode materials.

- Integration with Predictive Models: Incorporating vibration data into predictive models for battery life and performance can enhance the accuracy of state-of-health (SOH) and remaining useful life (RUL) estimations. Future work should aim to integrate experimental findings with machine learning and finite element modeling tools.

- Validation of BTMS Technologies: BTMS simulation results are accessible, but no studies validate these findings experimentally. There is a need for such experimental research, offering opportunities for researchers to explore this area.

- Applications in Specific Industries: Industry-specific studies can provide actionable insights for sectors where vibrations are a critical concern, such as automotive, aerospace, and renewable energy storage. Customized experimental protocols for these applications can enhance the reliability of batteries in these environments.

By addressing these areas, future research can provide a more comprehensive understanding of vibration-induced battery degradation, improve the reliability of battery systems, and contribute to the development of more robust energy storage solutions.

7 Conclusions

The first study referred to in this research focused on sine dwell at various frequencies and found that 5 Hz sine dwell will have a severe effect on the capacity degradation of 7%. However, the following study said it subjected the cells to the vibration profile under UN38.3-T3 sine sweep, and the capacity degradation here was around 2.1%. The discrepancy is the amplitude levels and time spent, which ultimately will close the gap between these two studies about capacity degradation. The internal resistance, on the other hand, seems to vary in most of the studies, before and after vibrations. The justification for the capacity degradation occurrence needs further investigation into the electrochemical level, where some level of damage is seen on the separator and anode layers at vibrations at all frequency conditions (< 80 Hz), especially pronounced at 50 Hz, the study conducted by Zhi W. research team. In any case, multiple other studies have pointed out similar behavior. With that said, areas like the implication of sine dwell at the natural frequencies of the cell can give a better idea of safety risks, which seems like an area still untouched in the literature.

The simulation results showed that the damping ratios between casing and cells are dependent on the SOCs. However, these damping ratios and stiffnesses will be hard to assess in intracellular structures due to lack of comprehensive data.

Finally, mechanical vibrations affect BTMS positively; for example, one of the research projects mentioned above showed that the PCM layers separating Prismatic cells will increase greater temperature difference between vibration and non-vibration conditions, and the same is the case for the cold plate (with all studies pointing increase in thermal efficiency with vibrations).

Nomenclature

-

- CL

-

- conductivity loss No units

-

- LLI

-

- loss of lithium inventory No units

-

- LAM

-

- loss of active materials No units

-

- K1

-

- stiffness between plastic casing and external support N/m

-

- K2

-

- stiffness between cell 1 and plastic casing on one side N/m

-

- K3

-

- stiffness between cell 1 and cell 2 N/m

-

- K4

-

- stiffness between cell 2 and Plastic on the other side N/m

-

- C1

-

- damping between plastic casing and external support Ns/m

-

- C2

-

- damping between cell1 and plastic casing on one side Ns/m

-

- C3

-

- damping between cell 1 and cell 2 Ns/m

-

- C4

-

- damping between cell 2 and plastic casing on the other side Ns/m

-

- C5

-

- damping between the plastic casing on one side and the plastic casing on the other side Ns/m

-

- m1

-

- mass of plastic casing on one side Kg

-

- m2

-

- mass of the cell 1 Kg

-

- m3

-

- mass of the cell 2 Kg

-

- m4

-

- mass of plastic casing on another side Kg

-

- t

-

- time sec

-

- v

-

- velocity mm/s

-

- fv

-

- frequency of vibrations Hz

-

- A0

-

- amplitude of the vibration mm

Author Contributions

Boozula Aravind Reddy: conceptualization, investigation, funding acquisition from Enersys Delaware Inc, writing – original draft, methodology, validation, writing – review and editing, formal analysis, visualization, project administration, data curation, supervision.

Acknowledgments

This research was fully funded by Enersys Delaware Inc. The funding, including the application fees provided by Enersys Delaware Inc enabled the acquisition of necessary resources for the study. The author expresses his gratitude for Enersys's financial support, which made this work possible.

Conflicts of Interest

The author declares no conflicts of interest.

Open Research

Data Availability Statement

This review article is based entirely on information sourced from publicly available literature. No new data was generated in this study. All references cited within the manuscript provide the original sources of the data and information discussed. Readers are encouraged to consult the referenced publications for detailed insights and further information.