Strategic Roadmap for 3D-Printed Reinforcement Using Fused Deposition Modeling: A State-of-the Art Review

ABSTRACT

With the emergence of 3D-printing technology, many objects can be manufactured, leading to notable progress in contemporary industrial applications. The present research addresses the original combination of 3-D printing with reinforcement of concrete and cementitious compounds, especially relating to Fused Deposition Modeling (FDM). The investigation comprehensively covers the effect of the use of various printing materials and reinforcement constructs, and focuses on geometry as an important parameter to adjust the mechanical properties and ductility of the printed materials. Using deep analyses, it has been concluded that FDM becomes a key technology in the 3D-printing of reinforced concrete and cement members, which permits design optimization of structural performance. The results highlight that the geometrical features of the reinforcement are crucially important to the improvement in flexural strength and energy dissipation. Specifically, auxetic and truss geometries are identified as superior configurations for improving these properties, while alternative patterns can significantly augment the ductility and energy absorption capacity of concrete. The flexural strength of reinforced concrete samples improves when concrete is reinforced with lattice truss, honeycomb, and different types of trusses by 27%, 160%, and 12% respectively. When concrete or cementitious mortar is reinforced with auxetic structure and lattice structure, the compressive strength improves by more than 18.5% and 33.7% respectively. While hyperboloid shell and steel auxetic tube are added to concrete, the compressive strength of concrete decreases by more than 20% and 24% respectively. This study provides insights into the future of 3D-printed reinforced concrete.

1 Introduction

Currently, researchers attempt to reinforce cement mortar and concrete with different 3D-printing geometries [1]. Different studies provide reinforced concrete with 3D-printing technology to improve many features of concrete, such as fracture toughness, ductility, strength, quasi-brittleness, strain behavior, and so on [2-4]. Many studies invest in different 3D-printed geometries [5-8]. For example, Farina et al. [9] compared differences in reinforced concrete beams between alloy rebar and 3D-printing rebar. It is reported that when a concrete beam is reinforced with 3D-printed rebar, the beam strain behavior changes to strain hardening, while when concrete is reinforced with alloy rebar, strain changes to strain softening [10]. Recent studies have proposed different operability criteria for 3D-printing nozzles focusing on improving printability, extrudability, interlayer bonding, and shape stability [11-14]. These criteria are a step forward in the technical development and optimization of 3D-printing technology [15]. For example, it is pointed out that while 3D-printing offers potential solutions for remote construction, significant uncertainties remain, particularly concerning material properties and the trade-offs between cost efficiency and ecological impact [16].

There are different geometries for reinforced cement and concrete [17-21]. For example, Hematibahar et al. [17] studied the effect of 3D-printing hyperboloid shell structure to reinforce ultra-high-performance concrete (UHPC). It is found that the hyperboloid shell structure can improve the ductility of UHPC while the mechanical properties decrease. Another example: Chiadighikaobi et al. [18] analyzed the effect of different types of 3D-printing trusses with high-performance concrete (HPC). It is found that reinforced HPC with trusses improved flexural strength and ductility. Moreover, Hematibahar et al. [21] understand that 3D-printing trusses can improve the mechanical properties of concrete, while 3D-printing hyperboloid shell structure improves the ductility of concrete. Salazar et al. [20] attempted to reinforce cement material with 3D-printed lattice trusses. It is found that reinforced cement material with 3D-printing lattice trusses can improve ductility and flexural strength. Katzer and Szatkiewicz [19] reinforced cement with a 3D-printed honeycomb structure. It is explored that when the height of spatial elements to the thickness of a hexagon wall is more than 5, the flexural strength will increase to 112% and the strain condition will change to strain hardening. In terms of nozzle design, it makes strides in optimizing print parameters and nozzle dimensions to reduce extrusion resistance [22]. Their work contributes to the precision and performance of round nozzle-based printing but also underscores the need for further research into the relationship between nozzle dimensions and 3D-printing quality. Similarly, it is emphasized that the importance of selecting appropriate reinforcement methodologies based on the specific application [23]. However, achieving maximum structural strength requires more than just optimizing mix design and reinforcement techniques; it also necessitates advancements in automation to fully leverage the benefits of 3D-printing technologies [24].

The current landscape of research on 3D-printing materials based on cement primarily emphasizes enhancing mechanical properties and workability [25]. While this focus is critical, it reflects a narrow scope that overlooks the complexities and interdependencies of various factors influencing the overall performance of 3D cement-based printing. One such area deserving more attention is the impact of extrusion parameters. The shape of the nozzle, layer height, nozzle direction, and the use of a scraper are crucial in determining the mechanical properties of 3D-printed concrete. However, the influence of these factors is often oversimplified [12, 26]. For example, studies have indicated that a rectangular nozzle may produce a smoother filament surface compared to circular and square nozzles [27]. However, these findings do not fully account for the complexities involved in the layer height and nozzle direction, which remain underexplored, especially in how they affect the anisotropic nature of 3D-printed concrete components [28]. A significant challenge in 3D-printed concrete is the poor bonding between layers, leading to weakened structural integrity. This issue is particularly problematic given that 3D-printed components, unlike traditionally poured ones, exhibit characteristics akin to anisotropic materials [29]. The interlayer bond strength is pivotal and is influenced by various factors, including material rheology, pumping system performance, printing speed, and nozzle shape. While these factors have been studied individually, their combined effects, especially under varying environmental conditions, need further investigation to develop a comprehensive understanding of 3D-printed construction technology [30].

Another 3D-printing structure that is used to reinforce concrete is the auxetic structure. The first mechanical model is produced by Almgren in 1985 [31]. Some studies reinforced concrete and cement with auxetic structures. For example, Zhang et al. [32] reinforced concrete with chiral lattices (auxetic structure) with and without circular holes. It is found that reinforced concrete with this type of structure improves 50% of strain. Xu and Savija [33] analyzed reinforced cement concrete with 3D printing with different types of auxetic structure. It is found that when 3D-printing re-entrant auxetic structure reinforced cement, ductility and energy absorption increase more than 853% and 708%, respectively. In another example, Xu et al. [34] reinforced cement materials with auxetic structure under cycling loads. Different studies understand that various geometries of 3D-printing reinforced structures have different effects on the mechanical properties of concrete. Moreover, the role of pore defects in influencing the mechanical properties of 3D-printed concrete cannot be overstated. Many studies have been conducted on how pore defects, particularly those introduced at the interface during the printing process, affect the mechanical characteristics of the material [35]. However, these studies often neglect the interaction between pore structural parameters, such as shape, size, orientation, and distribution—and their location-specific impacts on strength and anisotropic properties. It establishes a correlation between pore defect geometry and cracking damage, but there remains a need for further research to fully understand how these factors contribute to the anisotropic mechanical behavior of 3D-printed concrete [36].

The literature on improving interlayer bonding is divided into two main categories: enhancing the properties of the printing material and optimizing printing process parameters [37]. From a material perspective, incorporating binders, such as cement slurry, during the printing process has been suggested as a method to significantly enhance interlayer bonding [38]. Despite these advances, the optimization of process parameters, such as the time gap between layers, extrusion rate, and layer dimensions, remains underexplored. Research has shown that surface moisture content, which is influenced by the printing interval, plays a critical role in bond strength. For instance, bond strength was found to be inconsistent at different intervals, suggesting that moisture levels are impacted by both evaporation and exudation processes [39]. However, these findings are based on limited experimental data, and there is a need for more comprehensive studies to establish generalizable guidelines. In addition, innovative approaches to improve interlayer bonding, such as the incorporation of cellulose fibers or the development of novel bond stress-slip models, have shown promise [40]. It should be mentioned that these methods are still in the early stages of development, and their long-term efficacy remains uncertain. The roughness of the interface, which significantly impacts interlocking between layers, has been studied using various techniques, but the optimal roughness level for different types of 3D-printed concrete remains unclear [41]. Furthermore, the use of polymer-modified mortars to improve interlayer bonding, while effective, raises questions about the long-term durability and environmental impact of such materials [42].

The study aims to illustrate how the mechanical properties of concrete change. It examines different types of 3D-printed geometries applied to reinforced concrete and cement. This study highlights the benefits of 3D-printing reinforcement for concrete and cementitious materials, exploring technological developments, material innovations, and mechanical performance to enhance structural integrity in modern construction. This study provides insights into the future of 3D-printed reinforced concrete, paving the way for more resilient and adaptable construction materials. Besides, this study contributes to the ongoing development and implementation of 3D-printing technology in the modern construction industry today.

2 Materials and Methods

2.1 Fused Deposition Modeling (FDM)

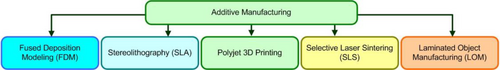

Fused deposition modeling (FDM) is one of the types of additive manufacturing. FDM uses material extrusion, which involves fusion and subsequent solidification of the material [1]. The advantage of the FDM method rather than other types of additive manufacturing models (Figure 1) is simplicity in printing, fast processing time, and affordability as a printing process. Moreover, the disadvantages of the FDM method are low dimension resolution, poor surface quality, and limited materials [2-4]. According to the FDM method, thermoplastic materials are fed as filaments to the hot end of the printer; the filaments are partially melted and extruded through the nozzle. Different software has been used to design models after printing materials layer by layer on each other [5]. Two FDM types of printers are used. The delta printer and the Cartesian printer are two types of different models. Cartesian printers have joints and arms for free movements, while the Delta printer has more space than the Cartesian printer due to the triangular shape in XYZ space (Figure 2) [6].

Each Delta printer has three carriages mounted on the axis and connected to the effector by parallel delta arms [7] (Figure 2a). In addition to this, the main advantage of the Cartesian method over the Delta method is the low cost with the same accuracy; in addition, the Delta printer has lower accuracy and calibration quality than the Cartesian method. In addition, energy efficiency is the most unique advantage of the Cartesian method [8, 9] (Figure 2b).

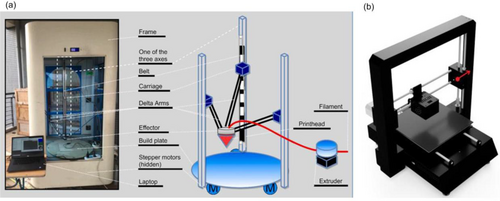

In Direct Drive, the motor is mounted on the tool head. According to this method, the end of the tool and the hot end are assembled together to melt the filament and extrude the semi-molten filament to print the shapes (Figure 3a). Moreover, it is reported that in the Bowden method, the printer is installed into the chassis rather than the tool head. This method decreases weight, reduces inertia, and allows for faster printing compared to Direct Drive [13, 14] (Figure 3b). The raster types, angle layers, and roads are important due to filling objects. Layers can be printed in XY (flat), XZ (on edge), and YZ (upright) planes. The details of coordinate systems for additive manufacturing machines are defined in ISO/ASTM52921–13 [15].

2.2 Printing Materials

Due to printing shapes through the FDM method, different types of materials are used. Table 1 illustrates the mechanical properties of different types of printing materials. According to Table 1, nylon with more than 464 MPa tensile strength had the maximum mechanical properties. In addition, the tensile modulus is more than 35.7 GPa. Some types of Poly Lactic Acid (PLA) reinforced with glass fiber had more than 478 MPa and 29.41 GPa tensile strength and tensile modulus, respectively. PLA, combined with additional materials such as wood and ceramic, exhibited tensile strengths ranging from 38.7 MPa to 46.9 MPa. Table 1 shows that when Acrylonitrile Butadiene Styrene (ABS) material is reinforced with different percentages of carbon fiber, the tensile strength increases from 52 MPa to 67 MPa. Additive materials have a significant impact on the tensile strength of filaments and printing materials. For example, Matsuzaki et al. [17] added 6.6% of carbon to PLA filaments and increased the tensile strength to more than 185 MPa, while the average tensile strength of PLA is more than 60 MPa. Klift et al. [18] added 20.7% carbon to nylon filament and increased tensile strength to more than 464 MPa. In another example, He et al. [19] found that the tensile strength of PA6 filament reached more than 939 MPa. Some studies also understand that blending two polymers can improve the mechanical behavior of materials. For example, Davood et al. [20] understood that PLA had a poor shape memory effect (SME), while a blend with Thermoplastic Polyurethanes (TPU) with a range of compressive strengths improved more than 90.9% and 96.4%. Thavornyutikarn et al. [21] studied the effect of ABS/TPU blending. It was found that the warpage of 3D-printed specimens has been decreased and printability improved too. Xu et al. [22] blended PLA with galactoglucomannan (GGM). The current material is good to print in a biomedical printing device. Poly (Vinyl Alcohol) (PVA) is a printable, biodegradable, water-dissolving substance. PVA has high mechanical properties but, due to water solubility, is not suitable for use in some related water works [23, 24].

| Refs. | Filament materials | Type of additive materials | Percentage of additive materials (%) | Tensile strength (MPa) | Tensile modulus (GPa) |

|---|---|---|---|---|---|

| Çantı [25] | ABS | ZrB2 | 1.5 | 40.2 | 2.14 |

| SiO2 | 1.5 | 44.72 | 2.49 | ||

| Al | 1.5 | 44.56 | 2.55 | ||

| Patan [26] | ABS | Carbon fiber | 12 | 31.70 | 2.72 |

| Hodzic and Pandzic [27] | PLA | Carbon fiber | 20 | 29.96 | 4.54 |

| Van Der Klift et al. [18] | Nylon | Carbon | 6.9 | 140 | 14 |

| Carbon | 20.7 | 464 | 35.7 | ||

| Li et al. [28] | PLA | Carbon | 34 | 91 | 23.8 |

| Yang et al. [29] | ABS | Carbon | 6.5 | 147 | 4.18 |

| Bettini et al. [30] | PLA | Aramid | 8.6 | 203 | 9.34 |

| Akhoundi et al. [31] | PLA | Glass fiber | 49 | 478 | 29.41 |

| Nagendra and Prasad [32] | Nylon | Aramid | 2 | 51.45 | — |

| Tian et al. [33] | PLA | Carbon fiber | 27 | — | — |

| Cu | 10 | 42 | 0.93 | ||

| Hwang et al. [34] | ABS | Cu | 30 | 26.5 | 0.91 |

| Fe | 10 | 43.4 | 0.96 | ||

| Fe | 40 | 36.2 | 0.95 | ||

| Glass fiber | 0 | 44.75 | 0.71 | ||

| Glass fiber | 1 | 43.65 | 0.81 | ||

| Zhong et al. [35] | ABS | Glass fiber | 18 | 58.6 | — |

| Carbon fiber | 10 | 52 | 7.7 | ||

| Dickson et al. [36] | Nylon | Glass Fiber | 8 | 156 | 3.29 |

| Glass fiber | 10 | 212 | 4.91 | ||

| He et al. [19] | PA6 | Carbon fiber | — | 939.7 | 83.2 |

2.3 Cement, Mortar and Concrete

In this study, reinforced concrete, cement, and mortar with 3D-printed different design shapes have been considered. Table 2 illustrates different types of concrete, cement, and mortar types. According to Table 2, the most materials that were reinforced with 3D printing were cementitious mortar. The main reason for using cementitious mortar is to decrease the failure mechanics when cement and fine aggregates play a more important role, and 3D printing reinforcement shows its role.

| Refs. | Type of concrete | Cement (kg/m3) | Water (kg/m3) | Fine aggregates (kg/m3) | Coarse aggregates (kg/m3) | Additive materials (kg/m3) | Superplasticizer (kg/m3) |

|---|---|---|---|---|---|---|---|

| Hematibahar et al. [37] | Ultra-High-Performance Concrete (UHPC) | 420 | 105 | 945 | 635 |

65 (Micro Silica) |

15 |

| Chiadighikaobi et al. [38] | High-Performance Concrete (HPC) | 550 | 187.5 | 585 | 1005 |

128 (Silica Fume) |

12.5 |

| Xu and Savija [39] | Cementitious Mortar | 526 | 344 | 526 | — |

622 (Fly Ash) |

4 |

| 473 | 413 | 473 | — |

559 (Fly Ash) |

2 | ||

| 429 | 468 | 429 | — |

507 (Fly Ash) |

0 | ||

| Wan et al. [40] | Cementitious Mortar | 1200 | 480 | 550 | — | — | — |

| Xu et al. [41] | Cementitious Mortar | 559 | 413 | 473 | — | — | 2 |

| Hao et al. [42] | Cementitious Mortar | 410 | 280 | 1350 | — |

40 (Fly Ash) |

1.35 |

3 3D-Printing Reinforced Cementitious Materials

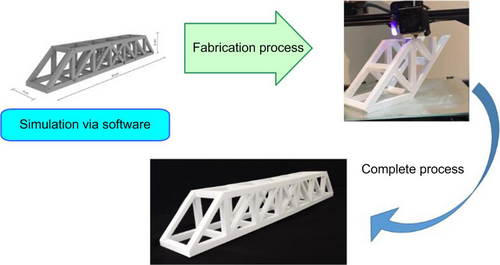

In the 3D printing reinforcement cementitious materials method process, first, the 3D-printed form is designed for specific purposes. Second, the 3D-printed form is simulated with different software, and the 3D simulation is transferred to receive G-code. Finally, printers print the shape via G-code commands (Figure 4). There are different parameters that can be affected on the improvement of the mechanical behavior of cementitious materials reinforced with 3D printing, such as the infill percentage of 3D printing, material of filament, tensile strength of 3D-printing materials, 3D-printing layers, raster and nozzle parameters, and geometry of designing shape. For example, Hematibahar et al. [43] compared the effect of 3D-printing trusses and hyperboloid shells to reinforce HPC and UHPC, respectively. In their study, truss infill was 45% and hyperboloid shell infill was 30%. The printing material was PLA, and details such as layer thickness, printing speed, extruder temperature, and bed temperature were 0.2 mm, 50 mm/s, 190°C, and 60°C for both types. According to their results, when UHPC reinforced with a hyperboloid shell structure absorbs a high amount of energy, while the decreased mechanical properties and HPC are reinforced with trusses, in some samples the flexural strength improves. It is concluded that the influence of the design geometry is greater than the infill percentage. In another example, Katzer and Szatkiewicz [44] reinforced the cement material with a 3D-printed honeycomb structure. The purpose of their study is to understand the effect of height (H) on the thickness (D) of a hexagonal honeycomb structure to improve concrete mechanical properties. It is found that the best D/H ratio is more than 0.1. In this situation, the strain behavior of concrete changed to strain hardening. According to the study [45], geometry and patterns are important factors to change the mechanical behavior of cement mortar and concrete while reinforcing. Another important issue is the bond between concrete and PLA material. Bol et al. [46] find that 3D-printed polymer reinforcement has been found to have anisotropic behavior. This work focuses on the reinforcement-matrix bond.

3.1 Auxetic Patterns

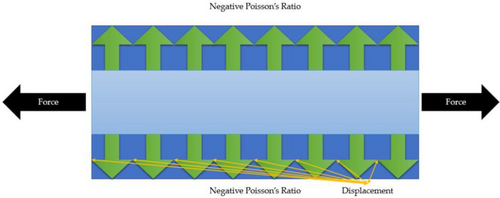

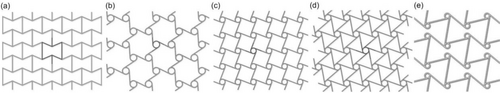

Auxetic structure was introduced by Lakes in 1987. Auxetic structure has a negative Poisson's ratio. The negative Poisson's ratio implies that the material expands transversely under uniaxial tension and contracts under uniaxial compression (Figure 5) [47-49]. The negative Poisson's ratio has many properties, such as impact resistance, negative stiffness, fracture toughness, and ultra-high stiffness [50, 51]. The auxetic structure improved shear performance, such as shear modulus and damping properties. Moreover, the auxetic structure changed the crack progressing path [51-53]. Studies show that the auxetic cellular structures' mechanical properties are examined for tensile and compressive strength [54-57]. Although some researchers analyzed shear loading for auxetic structures [58]. Liu and Liu [59] analyzed 3D printing with continuous fiber-reinforced composite auxetic. It analyzed the tensile strength of designed shapes and found that the re-entrant pattern has more than 2.8 MPa tensile strength and the tensile strength of rotating is 1.1 MPa. There are many types of auxetic structures. For example, Montgomery-Liljeroth et al. [60] analyzed three types of “re-entrant honeycomb” “chiral structures,” and “rotating plates.” Gibson et al. in 1982 [61] introduced the re-entrant hexagonal honeycomb structure. The behavior of elastic structures with reentrant rib angles in cells depends on cell deformation, so Poisson's ratio typically varies nonlinearly with nominal strain [62] (Figure 6a). Chiral structures achieve auxetic behavior when ligaments enforce wrapping and unwrapping around specific nodes. There are many types of chiral structures, such as trichiral, tetrachiral, hexachiral, and so on, as shown in (Figure 6b). Grima and Evans [63] studied the rigid rotating squares auxetic with idealized settings and found that the Poisson's ratio is equal to −1 (Figure 6c). Some studies reinforced concrete and cementitious mortar with auxetic cells to improve the mechanical properties [39, 64].

Hamed et al. [65] analyzed the shear response of a 3D printing re-entrant geometry shear wall under seismic loading. It is found to have stable hysteretic curves with a drift ratio of more than 8%. Rosewitz et al. [66] reinforced concrete with a conventional brick pattern and a re-entrant hexagon pattern. It is understood that the best mechanical properties occurred when 3D printing fibers were added to concrete due to the fibers preventing the layer shear-sliding process. Also, the re-entrant structures decreased the flexural strength too. Indres et al. [67] understand that a cross-chiral auxetic structure has more energy capacity than a re-entrant hexagonal structure when reinforced using a beam. While when a re-entrant hexagonal structure is used with an oriented core of 90°, the energy absorption increases when a chiral structure core is used. Luo et al. [68] reinforced two types of concrete with an auxetic structure. According to their results, when concrete is reinforced with an auxetic structure, compressive strength decreases. In another example, Hematibahar et al. [45] find that the honeycomb pattern has the best performance to improve the flexural strength of a reinforced cementitious beam. In another study, concrete was analyzed for impact resistance when the mold was 3D printed with auxetic patterns. The results show that the auxetic pattern can improve the impact resistance of concrete [69]. Xie et al. [70] created an auxetic pattern mold to improve the strain hardening of concrete and cementitious material. Xu et al. [41] reinforced cementitious materials with auxetic concrete to achieve dynamic strength. They found that the thermoplastic polyurethane (TPU) acoustic frame gave the best results. Another study investigated the reinforcement of cementitious materials with 3D-printed auxetics. They found that the material could absorb energy and reduce the cracking process. The auxetics absorption could improve the strength of conventional cementitious materials by more than 1.7 times [71]. Overall, the most auxetic geometries are structured, which are related to re-entrant, chiral, and cross-chiral structures [72, 73].

3.2 Trusses and Lattice Patterns

Some studies reinforced concrete via lattice patterns or trusses. For example, Chiadighikaobi et al. [38] reinforced HPC with different types of trusses. It is reinforced concrete with Pratt, Howe, Warren, and Warren with vertical members and trusses, and the best result was for the Warren truss with 27.9 kN for flexural strength. In another example, Xu and Savija [74] reinforced cementitious material with 3D-printed lattice structures with ABS materials. It is reported that nozzle diameter, temperature, layer height, line width, infill percentages, infill pattern, and printing speed are 0.8 mm, 260°C, 0.2 mm, 0.7 mm, 100% lines, and 40 mm/s, respectively. It is found that when a concrete beam is reinforced with a lattice structure, the flexural strength increases by more than 30%. In another example, Xu et al. [75] reinforced cementitious mortar with a 3D printing lattice pattern. It is understood that when cement material is reinforced with a 3D printing lattice pattern, the strain behavior changes to strain-softening and flexural strength has not improved too. Salazar et al. [76] reinforced UHPC with a 3D-printed lattice structure with ABS and PLA materials. It is found that this type of reinforcement can improve the flexural strength and strain behavior to strain-hardening. Xu et al. [77] reinforced concrete with 3D-printed lattice due to a tensile dumbbell shape strength test. It is revealed that when concrete reinforced with 3D-printed lattice fractures, energy is reduced from 37.4% to 12.4%. Xu et al. [78] found that lattice can be used as 3D-printed reinforcement for concrete and cementitious materials. Overall, lattices and trusses can improve the flexural strength of concrete.

3.3 3D-Patterns With Different Structures

Some studies reinforced cement materials with different patterns unlike auxetic, trusses, and lattice patterns. Gödek et al. [79] studied reinforced concrete with 3D-patterned triangle and honeycomb structures with ABS and PLA materials. According to their study, when concrete is reinforced using a honeycomb pattern, the strain behavior changes to strain hardening. In another example, Hematibahar et al. [37] reinforced concrete with a hyperboloid shell structure. It is observed that the compressive, tensile, and flexural strengths decreased when the concrete was reinforced with the hyperboloid shell structure, but the strain of the concrete improved.

Many studies analyzed cement and concrete reinforced with 3D-reinforced printing based on results when concrete and cement mortar reinforced with 3D-printed mechanical propertieschanged. In some studies, mechanical properties increased, and in some studies, mechanical properties decreased. However, common studies illustrate increased strain of concrete under compression and flexural loads. Meanwhile, when concrete and cement mortar are reinforced with 3D printing, ductility and energy absorption increased. Table 3 illustrates the mechanical properties, 3D-printing patterns, and different types of concrete according to different study types.

| Refs. | Concrete types | Patterns | Printing material | Infill percentages | Compressive strength | Tensile strength | Flexural strength |

|---|---|---|---|---|---|---|---|

| Hematibahar et al. [37] | UHPC | Hyperboloid Shell | PLA | 30% |

20% (Decreased) |

28% (Decreased) |

12% (Decreased) |

| Chiadighikaobi et al. [38] | HPC | Trusses | PLA | 45% | — | — |

12% (Increased) |

| Xu and Savija [39] | Cementitious Mortar |

Auxetic Structure |

ABS/PLA | 100% |

18.5% (Increased) |

— | — |

| Wan et al. [40] | Cementitious Mortar | Vascular Material | PVA | — | Self-healing Condition | ||

| Xu et al. [41] | Cementitious Mortar | Rotating-Square Auxetic | TPU | 100% | Compressive Strain-hardening (Spring like) |

||

| Hao et al. [42] | Cementitious Mortar |

Lattice Forms (Circular) (Octagonal) (Strengthened octagonal) (RO) (Cubic) (Kelvin) |

Polyamide 6 (PA6) | — |

100% (Increased) |

— | — |

| Katzer and Szatkiewicz [44] | Cementitious Mortar | Honeycomb | PLA | 100% | Improve the flexural strength more than 160%, change the strain behavior to strain hardening. | ||

| Luo et al. [68] | Concrete |

Auxetic Tube |

Steel | — |

24% (Reduced) |

— | — |

| Gödek et al. [79] | Cementitious Mortar | Honeycomb, and Triangle | PLA, ABS | 100% | Flexural strain changed to strain-hardening. The flexural strength improved 200% in strain hardening phase. | ||

| Salazar et al. [76] | UHPC | Lattice | PLA, ABS | — |

33.7% (Increased) |

— |

38% (Increase) |

| Xu et al. [75] | Cementitious Mortar | Lattice Trusses | PLA | 100% | Flexural strain behavior changed to strain-softening. Flexural strength decreased in peak of loads in maximum 10%. | ||

| Xu and Savija [74] | Cementitious Mortar | Lattice Trusses | ABS | 100% (Lines pattern) |

Increase the flexural strength more than 27%. Flexural strain changed to strain hardening. | ||

The advantage of adding reinforcing UHPC with a 3D-printed hyperboloid shell structure (PLA material) is improving the strain of concrete and improving the ductility, while the disadvantage of reinforcing UHPC with a hyperboloid shell structure is decreasing the flexural strength [38]. While adding 3D-printed trusses (PLA) to HPC beams improved 12% of flexural strength. The most important differences between the Hematibahar et al. [37] and Chiadighikaobi et al. [38] studies are understanding the influence of structure geometry on concrete mechanical properties.

Xu and Savija [39] reinforced cementitious mortar with reinforced concrete using different 3D-printing auxetic structures (rotating square “RS,” chiral “CR,” missing rib “MR,” and re-entrant “RE”) with ABS/PLA materials and 100% infill. It is found that energy absorption using RE, RS, and CR patterns increased when PLA materials were used. Another study reinforced a concrete beam with 3D printing, distributed different meshes, and distributed fibers. Their results illustrate that when 3D-printing distributed meshes have been used, the flexural strength increased, while when 3D-printing distributed fiber-reinforced concrete, the flexural strength decreased [80].

In another example, Gödek et al. [79] reinforced a cement material beam with 3D-printed honeycomb and triangle structures. It is understood that the best improvement in deformation was for reinforcement of the cement material beam via 3D-printing honeycomb (PLA materials) and the best flexural strength was for reinforcement with 3D-printing triangles. In the same way, Katzer and Szatkiewicz [44] studied the height (H) and thickness (D) of the 3D-printing honeycomb structure that reinforces concrete. It is explored that whatever D/H was less, the flexural strain behavior is more like strain hardening, and the flexural strength increased. Finally, considering the results, the materials and geometry of 3D-printing reinforcement are the most important factors to change the mechanical properties and ductility of concrete and cement materials [81-86]. According to these studies, the best geometry is for auxetic and trusses to improve the flexural strength and energy absorption of concrete, while other patterns and geometries can increase the ductility or energy absorption of concrete.

4 Discussion

The results of this study highlight the importance of selecting appropriate 3D-printed reinforcement geometries to optimize mechanical performance. The key finding is that acoustic structures that exhibit negative Poisson's ratio significantly improve energy absorption and ductility in concrete materials. This finding is consistent with previous research that demonstrated the effectiveness of acoustic patterns in modifying crack propagation and increasing toughness.

In addition, truss and lattice structures provide significant improvements in flexural strength, making them highly suitable for applications requiring increased load-bearing capabilities. This study confirms that optimal reinforcement geometries can influence strain behavior, changing it from strain-softening to strain-hardening, which is crucial in improving durability and flexibility under load conditions.

Despite these advances, challenges remain in achieving optimal interlayer bonding in 3D-printed cementitious materials. This study highlights the need for further research into the effects of extrusion parameters, nozzle design, and material composition on mechanical performance. Future work should focus on integrating advanced reinforcement techniques with emerging materials, such as fiber-reinforced composites, to improve the mechanical behavior of 3D-printed concrete.

There is a difference between 3D printing concrete with reinforcement and 3D reinforced concrete. Momeni et al. [87] reviewed studies on 3D-printed concrete and 3D-reinforced concrete. They emphasized that 3D-printed concrete reinforced with rebar is called 3D-printed reinforced concrete, while reinforced concrete with 3D-printed materials such as PLA is called “3D-printed reinforced concrete.” For example, Panda et al. [81] understood there are disadvantages of 3D printing concrete, such as strength, flowability, and durability. There are some disadvantages of 3D-printed concrete, such as thermal and acoustic conditions, material properties, layer control and rheology, and layer performance [82-84]. However, there are disadvantages. There are some advantages too, for example, reduce construction time and improve work efficiency. Reduce carbon footprint and wastage of materials, increase the recycled material usage, and decrease human labor and building cost [85, 86, 88]. In front of 3D-printed concrete, 3D-printed reinforced concrete is made fast and reinforced in different patterns. For example, Katzer and Szatkiewicz [44] find the optimal ratio of honeycomb to reinforced concrete and increase the mechanical properties. Some studies have investigated the effect of 3D-printed concrete with different reinforced cement matrix patterns. They analyzed honeycomb and triangular patterns printed with PLA, ABS, and polyethylene terephthalate glycol (PETG) as materials. They found that when the honeycomb pattern was used with different materials, the load deflection was converted to deflection hardening [79].

Overall, 3D reinforced concrete is a way to improve the mechanical properties of concrete via different patterns. For example, Hematibahar et al. [43] understood that truss pattern can improve the flexural strength of a concrete beam more than 26%, while reinforced concrete with a hyperbolic structure can reduce flexural strength. Furthermore, in another example, when concrete is reinforced with a grid pattern similar to the reservoir and filler materials such as mounding materials, the concrete can recover after the failure time [40, 89].

5 Conclusions

This study investigated the mechanical properties of cement reinforced with different types such as axotics, lattices, trusses, and so on. According to this study, axotics can improve the energy absorption potential and durability. According to this study, mechanical properties can be improved with honeycomb, axotics, and truss structures.

In addition, the study shows that printing materials such as PLA, nylon, ABS, and so on, with reinforced materials can improve the tensile strength. For example, when nylon materials are reinforced with glass fibers, the tensile strength reaches more than 939 MPa. Meanwhile, the comparison of 3D printing and pattern printing is very important for improving the mechanical properties of concrete.

- –

Combining PLA, ABS, and nylon materials with carbon or glass fiber reinforcements improves tensile properties, with PA6 achieving tensile strengths above 939.7 MPa.

- –

Steel tubes and hyperboloid shell reinforcements negatively impact compressive strength.

- –

The FDM printing process is slow, and building large structures is currently time-consuming, which is one of the limitations of 3D-printed reinforced structures.

- –

Auxetic and truss structures offer the best improvements in flexural strength and energy absorption.

- –

There have been reports of strength increases of up to 160% in flexural strength and 33.7% in compressive strength when mesh trusses and honeycomb reinforcing are used.

- –

Further research is needed to address the challenges of interlayer bonding and optimize printing parameters to improve overall structural integrity and long-term performance.

- –

Building on the findings of this study, future advances in 3D-printed reinforced concrete could contribute to more resilient and sustainable building materials, offering promising solutions to modern infrastructure challenges.

Author Contributions

Mohammad Hematibahar: funding acquisition, methodology, project administration, validation, writing – review and editing, writing – original draft. Roman Fediuk: writing – review and editing, software, formal analysis, supervision, visualization. Komeil Momeni: data curation, investigation, resources, writing – review and editing. Makhmud Kharun: formal analysis, software, visualization, supervision, writing – review and editing. Abhijit Bhowmik: data curation, formal analysis. Valentin Romanovski: data curation, formal analysis, writing – review and editing.

Acknowledgments

The authors have nothing to report.

Ethics Statement

The authors have nothing to report.

Consent

The authors have nothing to report.

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.