Evaluation of the Operational, Economic, and Environmental Benefits of Adopting Blue Economy in the Change of Aircraft Engine Washing Process: A Case Study

Funding: This work was supported by National Recovery and Resilience Plan, PE00000004.

ABSTRACT

The aviation industry has a significant impact on the environment, accounting for 13% of global fossil fuel consumption and 2% of annual CO2 emissions. One of the factors that increase this consumption is engine degradation due to the accumulation of dirt on compressor blades. To mitigate this effect and restore efficiency, compressor washing is essential, but it requires high water consumption. This study analyzes the operational, economic, and environmental benefits of optimizing this process, based on the Blue Economy. Fuel efficiency was assessed using the Fuel/RTM indicator, financial viability using ROI, and environmental impacts using the MIF index. The results indicate a 1.8% gain in fuel efficiency, annual savings of $179,000, a 6.9% reduction in environmental impact, and a 50% drop in water use. The findings demonstrate that sustainable maintenance practices generate economic and environmental gains, contributing to the conservation of water resources in aviation.

1 Introduction

Aviation represents 13% of global fossil fuel consumption and 2% of CO2 emissions. Efficiency in engines is influenced by particle deposition on blades, which alters geometry, increases roughness, and causes aerodynamic distortions [1]. It restricts airflow, raises exhaust gas temperature (EGT), increases fuel consumption [2] and the control system compensates by adjusting fuel flow, which wears out the turbine faster [3].

The washer of the compressor reduces these effects and allows better engine performance. Research studies expose the relationship between compressor damage and optimal cleaning schedules thus reinforcing manufacturers' recommendations. Increasing the water-to-air ratio by 50% offers enhanced removal of deposit materials [4] but financial analyses have confirmed its feasibility [5, 6]. Optimized techniques allow online and offline washing, thus maintaining the length of intervals between maintenances [7-9]. Deionized water contributes further to efficiency [10, 11].

Economic factors have been studied well [12], industrial applications have been covered too [13], and washing fluid behavior was also taken into consideration [14]. Artificial intelligence estimates fuel savings after the wash [2]. Other research works analyze emission reduction, energy efficiency [1], and particle-droplet interactions in cleaning [15, 16].

Despite these advances, very few studies link the washing of compressors to the Blue Economy, which is a concept introduced by the UN in 2012 promoting sustainable resource use [17, 18]. The inappropriate disposal of wash waste would pose a risk to the contamination of soil and waters, and this calls for environmentally responsible alternatives [19].

No study has ever evaluated aircraft compressor washing from the operational, economic, and environmental perspectives under the Blue Economy paradigm. This therefore becomes the gap that informs the central research question: how can washing commercial engine compressors create operational, economic, and environmental benefits in line with the Blue Economy? The objective of the study is to evaluate these benefits as both a theoretical and practical contribution.

It helps the manager evaluate the economic factor, minimize the adverse environmental effects, and maximize operations important for engine efficiency in reducing costs while being sustainable.

The paper is organized into six sections. Section 1 presents the introduction and research objectives. Section 2 covers the literature review and theoretical background. Section 3 introduces the case study, including the operational, economic, and environmental assessments. Section 4 presents the results obtained. Section 5 provides a discussion of the findings. Finally, Section 6 concludes the paper, highlighting the theoretical and practical contributions of the study.

2 Materials and Methods

2.1 Literature Review

This study systematically reviewed articles on compressor washing in aeronautical and aero-derivative engines, including industrial gas turbines. It aimed to identify applied methods, conduct evaluations, and the use of water reuse and recycling practices.

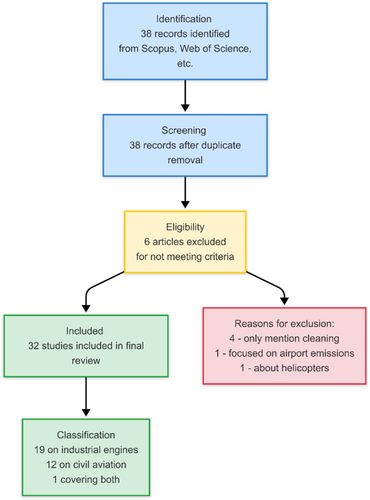

Articles were sourced from databases such as Scopus, Science Direct, Web of Science, Scielo, Emerald, Wiley, ProQuest, Ebsco, and Taylor & Francis. Keywords were grouped into five combinations, including “gas turbine” AND “online compressor washing” AND “water reuse” and similar variations. Using the PRISMA protocols [20], 38 studies were identified, with 6 excluding for not meeting predefined criteria, resulting in 32 included articles (see Table 1). The selection process is illustrated in Figure 1.

| Method | Assessment | ||||||

|---|---|---|---|---|---|---|---|

| Authors (Year) | Sector | Methodology | Quantitative | Qualitative | Environmental | Economic | Operational |

| Madsen and Bakken [4] | Industrial | Literature review | ✓ | ✓ | |||

| Kang and Kim [21] | Industrial | Literature review | ✓ | ✓ | |||

| Musa et al. [6] | Industrial | Case study | ✓ | ✓ | |||

| Igie et al. [3] | Industrial | Multiples cases | ✓ | ✓ | |||

| Xenos et al. [9] | Industrial | Case study | ✓ | ✓ | |||

| Madsen and Bakken [7] | Industrial | Field research | ✓ | ✓ | |||

| Tsoutsanis et al. [22] | Industrial | Multiples cases | ✓ | ✓ | |||

| Brun et al. [10] | Industrial | Experimental | ✓ | ✓ | |||

| Ujam et al. [11] | Industrial | Case study | ✓ | ✓ | |||

| Aretakis et al. [12] | Industrial | Literature review | ✓ | ✓ | |||

| Ogbonnaya [13] | Industrial | Experimental | ✓ | ✓ | |||

| Igie [23] | Industrial | Experimental | ✓ | ✓ | |||

| Schneider et al. [24] | Industrial | Field research | ✓ | ✓ | |||

| Fabbri et al. [25] | Industrial | Literature review | ✓ | ✓ | |||

| Rao and Naikan [26] | Industrial | Literature review | ✓ | ✓ | ✓ | ||

| Boyce and Gonzales [27] | Industrial | Case study | ✓ | ✓ | ✓ | ||

| Mund and Pilidis [28] | Industrial | Literature review | ✓ | ||||

| Mund and Pilidis [29] | Industrial | Experimental | ✓ | ✓ | |||

| Stalder [30] | Industrial | Literature review | ✓ | ||||

| Zhiqi et al. [31] | Aeronautical | Modeling and simulation | ✓ | ✓ | |||

| Wehrspohn et al. [32] | Aeronautical | Modeling and simultation | ✓ | ✓ | |||

| Musa et al. [33] | Aeronautical | Modeling and simulation | ✓ | ✓ | |||

| Tang et al. [34] | Aeronautical | Experimental | ✓ | ✓ | |||

| Cui et al. [2] | Aeronautical | Experimental | ✓ | ✓ | |||

| Chen and Sun [1] | Aeronautical | Case study | ✓ | ✓ | ✓ | ✓ | |

| Wang et al. [16] | Aeronautical | Experimental | ✓ | ✓ | |||

| Mishra [15] | Aeronautical | Literature review | ✓ | ||||

| Giesecke et al. [5] | Aeronautical | Experimental | ✓ | ✓ | ✓ | ||

| Zhu and Zuo [14] | Aeronautical | Case study | ✓ | ✓ | |||

| Syverud and Bakken [8] | Aeronautical | Case study | ✓ | ✓ | |||

| Brittain [35] | Aeronautical | Descriptive theoretical research | ✓ | ||||

| Igie [36] | Aeronautical and Industrial | Literature review | ✓ | ||||

The review followed four stages: identification, screening, eligibility, and inclusion. Research conducted until December 2024 classified articles into three categories: 19 on stationary industrial engine washing, 12 on civil aviation engines, and 1 covering both sectors.

Among excluded articles, four addressed compressor blade contamination but mentioned washing only as routine cleaning [37-40]. One analyzed operational time and taxi emissions at Shanghai Airport, referencing washing only in a literature review [41]. Another focused on helicopter engine washing [42], outside this study's scope. Papers lacking procedural details were also excluded.

Approximately 69% of selected articles assessed engine performance post-wash, 25% discussed financial savings, and 7% addressed environmental impacts. Results were categorized as follows: 22 articles reported operational gains, 8 highlighted economic benefits, and 2 evidenced environmental improvements.

2.2 Operational Performance Assessment Related to Compressor Washing Process

Two qualitative studies analyzed industrial engine performance. Mund and Pilidis [28] found that online compressor washing reverses degradation. Stalder [30] recommended preventive maintenance, combining online and offline washing for optimal operation.

A meta-analysis of 17 quantitative studies revealed key findings. In Norway, Madsen and Bakken [4, 7] recorded a 2% increase in engine activity after offline washing and defined the ideal online washing water/air ratio at 1.5%. In the UK, Igie et al. [37] found that offline washing increased corrected energy production by 5% and extended cycle intervals. Earlier tests by Igie [23] showed up to 50% power recovery. In Germany, Xenos et al. [9] combined online and offline washing, reducing operating time by 35%. In Italy, Fabbri et al. [25] identified offline washing as the most efficient, exceeding the 50% (GW) limit. Kang and Kim [21] limited energy degradation to 2.8%.

Field studies support these results. In Switzerland, Schneider et al. [24] reported energy recovery of 0.065% with daily washing and 0.21% with weekly washing. In Nigeria, Ujam et al. [11] recorded compressor efficiency gains of 81.6% and operating efficiency gains of 28.3%. Ogbonnaya [13] increased total efficiency from 39.2% to 46.25%.

In the US, Brun et al. [10] used wind tunnel tests to remove 95% of blade dirt. Boyce and Gonzalez [27] showed that combining online and offline washing reduced fuel consumption by 3%. In India, Rao and Naikan [26] developed a mathematical model increasing operating time from 90.7% to 97.3%. In the UK, Mund and Pilidis [29] analyzed liquid dispersion at compression start, reducing liquid thickness by 21% and overcoming a 17% airflow drop. In Qatar, Tsoutsanis et al. [22] reported up to 108% maintenance cost reductions, proving the effectiveness of diagnostics and performance predictions.

In aviation, two qualitative studies stand out. Mishra [15] in India demonstrated washing improves performance recovery and removes impurities. Brittain [35] emphasized cleaning to maintain PT6 and Dart engine performance.

Seven quantitative studies further highlight aviation benefits. Musa et al. [33] reported a 7.2% reduction in power degradation and a 1.6% increase in thermal efficiency after a year of flushing. In China, Zhiqi et al. [31] used neural networks to simulate post-flushing changes in 281 samples. Cui et al. [2] reported 14,485.36 kg of fuel savings. Chen and Sun [1] recommended flushing every 500 cycles or 4 months, saving 5471 tons of fuel. Wang et al. [16] found 50 μm droplets reduced temperature from 80°C to 54.65°C before reaching compressor blades.

In Norway, Syverud and Bakken [8] defined the ideal water/air ratio as 0.8%–2%. In the UK, Giesecke et al. [5] recorded a 2.6% compression ratio drop after washing.

A qualitative study unified industrial and aeronautical perspectives. Igie [36] in the UK optimized washing with computational fluid dynamics, improving efficiency. These studies confirm the operational benefits of compressor and engine washing.

2.3 Economic Performance Assessment Related to Compressor Washing Process

Four studies of a quantitative nature measured the economic gains that would accrue from washing compressors in the industrial sector. Musa et al. [6] working in England, registered a 1.7-fold increase in ROI and annual savings of $34,000. Aretakis et al. [12] had based washing programs on literature and achieved, through 14 optimized washes, a cumulative profit of $2.559 million. Rao and Naikan [26] utilized a mathematical model to reduce the operating costs of an industrial plant by $148,920. In America, Boyce and Gonzales [27] evaluated online and offline washing in 36 industrial engines; it represented savings of $2.288 million per year.

In aviation, four studies have confirmed the economic benefits of engine washing. In Germany, Wehrspohn et al. [32] used modeling and simulation to prove that a fuel cost reduction of 1.2% could be achieved. In England, Giesecke et al. [5] carried out an experimental study from which savings of £75,000 per engine per year were realized. In China, Chen and Sun [1] washed three times a year as the optimal washing interval, which would save $20.15 million yearly. Zhu and Zuo [14] showed a decrease in annual operating costs of $17,892. These studies show the financial benefits of cleaning compressors and engines.

2.4 Environmental Performance Assessment Related to Compressor Washing Process

No specific studies assess the environmental impact of compressor washing in industrial engines, highlighting the need for research on resource consumption, waste generation, and emissions. The lack of data hinders sustainability assessments and potential improvements.

In aviation, two studies analyzed compressor washing's environmental effects. In China, Chen and Sun [1] found a reduction of 5471 tons in fuel consumption and 17,250 tons in CO2 emissions. Tang et al. [34] conducted an experiment on residues accumulated on compressor blades. Using JKR theory, they identified the removed particles as 49.9% silicon dioxide, 14.4% iron oxide, 11.5% aluminum oxide, and 9.4% calcium oxide.

3 Case Study

This research employed a mixed methods approach, combining qualitative and quantitative techniques in a case study based on primary and secondary data. According to Eisenhardt [43], case studies enable real-world investigations by integrating both methods. Yin [44] adds that this approach offers a realistic perspective, especially in initial studies, with interviews as a key data source.

The study examined a major international airline operating scheduled flights between the United States and Brazil. The company averages 6700 daily flights to 350 destinations in 50 countries, employing 133,000 people. Research was conducted in the line maintenance department at Guarulhos International Airport, São Paulo. Data collection included technical visits, questionnaires, interviews, and document analysis.

Compressor washing techniques include abrasive, manual, offline, and online cleaning. This study used offline washing, performed with the engine off. The process requires cooling the engine and deactivating the fuel and ignition systems. The pneumatic system turns the engine, allowing water to enter while keeping the turbine section inactive. A pneumatic actuator directs air from the auxiliary power unit to drive the compressor, while injectors apply water or detergent to the compressor inlet.

The company adheres to international environmental standards, including greenhouse gas reduction initiatives. To enhance sustainability and optimize water use in compressor washing, equipment replacement was recommended and approved as part of process improvements.

3.1 Operational Assessment Based on Fuel Efficiency by Means of Revenue Ton-Miles

This study used RTM and Fuel/RTM metrics in operational analysis. RTM is the product of transported cargo—passengers and freight—by distance traveled, serving as a standard fuel efficiency indicator. To validate this approach, the company took advantage of the possibility offered by the Breguet Range Equation to estimate fuel consumption in relative terms, expressed in gallons per 100 RTM. The airline's data for the 2022–2023 years was treated confidentially and used only for academic purposes.

RTM, in relation to the sectors of transport and shipping, calculates the tonnage of cargo moved; it is done by mile. If it is related to consumption measures, such as gallons per 100 RTM, it will measure economic efficiency very accurately. This measure has great importance for monitoring fleet performance over time; it is important for both passenger and cargo aircraft, irrespective of their configuration. Its availability in generic databases adds to its significance in analytic work regarding productivity and efficiency in aviation.

3.2 Economic Assessment by Means of Return of Investment

The economic evaluation calculated return on investment (ROI). This involves identifying and classifying tangible and intangible benefits, converting them into cash flows to assess investments and monitor results [47]. This study used ROI for the following reasons: (i) it is a widely applied, integrated approach across industries; (ii) companies value its simplicity, ease of calculation, and presentation; (iii) it is a recognized standard method; (iv) numerous studies use ROI to estimate payback.

3.3 Environmental Assessment by Means of Mass Balance

The environmental evaluation employed the methodology developed by the Wuppertal Institute [48] using the Mass Intensity Factor (MIF) tool, which considers the mass (M) and intensity factor (IF) of each material, as shown in Table 2. The material input per unit of service (MIPS) calculation determines the substances in abiotic, biotic, water, and air compartments resulting from raw material and resource consumption in compressor washing.

| Elements | Abiotic material | Biotic material | Water | Air |

|---|---|---|---|---|

| Water | 0.01 | 1.30 | ||

| Kerosene | 1.36 | 9.45 | 0.02 | |

| Diesel | 1.36 | 9.70 | 0.02 | |

| Oil | 1.50 | 11.45 | 0.03 | |

| Steel | 9.32 | 81.86 | 0.77 | |

| Rubber | 5.70 | 146.00 | 1.65 | |

| Paper | 1.86 | 0.75 | 93.56 | 0.33 |

| Aluminum | 37.00 | 1047.70 | 10.87 | |

| Plastic | 2.51 | 164.04 | 2.80 | |

| Chlorine | 3.84 | 100.90 | 1.09 | |

| Grime | 2.58 | 7.13 | 2.54 | |

| Nickel | 141.29 | 233.34 | 40.83 | |

| Dust | 1.97 | 5.42 | 0.04 | |

| Sodium Chloride | 1.24 | 2.29 | 0.02 |

3.4 Contributions to the Blue Economy

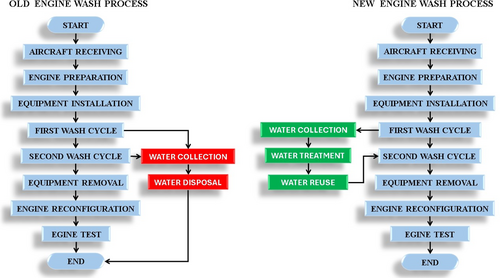

The primary change implemented in the compressor washing process by the airline was the reuse of the water used during the process. Figure 2 presents the flowchart of both the previous and the updated processes.

The improvement in compressor washing significantly supports Blue Economy strategies. Previously, wastewater was discharged into the soil and rainwater systems, posing a contamination risk to groundwater and surface water. The new process recovers and reuses water, aiding resource conservation.

This study is grounded in a real-world application conducted in the maintenance operations of a major international airline at Guarulhos International Airport in São Paulo, Brazil. It involved the analysis of 103 engine compressor washes performed with two different technologies over a one-year period. The findings are based on primary operational, economic, and environmental data provided by the airline, including maintenance logs, fuel and water consumption records, and official documentation such as the Waste Movement Certificate (CADRI) issued by CETESB. These real-case conditions demonstrate the practical feasibility of implementing sustainable compressor washing technologies in commercial aviation and highlight the replicability of the process in similar airline maintenance environments.

4 Results

This section presents the outcomes of the case study, organized into four subsections: operational, economic, and environmental performance, as well as the estimated water savings resulting from the adoption of the new compressor washing process.

4.1 Operational Performance Evaluation

To improve operational performance and promote resource conservation, the company replaced the previously used Model A compressor washing equipment—which discharged water directly into the environment or stormwater system—with Model B, a commercially available system designed to enable water reuse. Model B collects used water, channels it to an integrated treatment station, and allows full reuse after reverse osmosis demineralization.

This change directly impacted key operational parameters such as fuel and water consumption, as summarized in Table 3.

| Operational information | Model A | Model B |

|---|---|---|

| Fuel consumption | 6.09 L/h | 3.33 L/h |

| Water tank capacity | 908.499 L | 170 L |

| Water consumption | 436 L | 150 l |

| Water pressure | 55 psi | 70 psi |

| Average operation time | 4 h | 4 h |

The airline is a signatory of IATA's Fuel Efficiency Program, which promotes initiatives to reduce CO2 emissions and optimize fuel use. Among various operational indicators, Revenue Ton Miles (RTM) are considered one of the most comprehensive metrics, as they account for both passengers and cargo transported over distance.

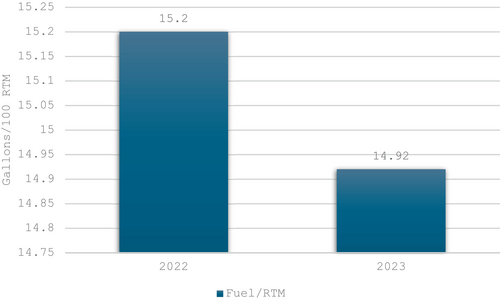

According to IATA, a 1.5% annual improvement in fuel efficiency is considered a short-term target. In this study, fuel efficiency was calculated as gallons of jet fuel consumed per 100 RTM. A lower value indicates better operational performance.

In 2022, the airline consumed 4103 million gallons of jet fuel, generating 26,998 million RTM. In 2023, fuel consumption increased slightly to 4207 million gallons, but RTM rose to 28,195 million, resulting in a 4.43% increase in productivity. Despite the rise in total fuel used, the Fuel/RTM metric improved from 15.20 to 14.92 gal/100 RTM, a gain of 1.8%, as shown in Table 4.

| Year | |||

|---|---|---|---|

| Fuel efficiency | Definition of metrics | 2022 | 2023 |

| Jet Fuel (Gallons in Millions) | Mainline aviation fuel + connecting transport operations | 4103 | 4207 |

| Passenger revenue tons miles (RTM in millions) | Weight, in tons, of paying passengers (estimated at 100 kg per passenger, including luggage) multiplied by the distance traveled. | 24,829 | 26,200 |

| Cargo tons miles (RTM in milions) | Weight, in tons, of the revenue-generating load multiplied by the distance traveled. | 2170 | 1995 |

| Total RTM (RTM in millions) | Sum of revenue from passenger and cargo miles | 26,998 | 28,195 |

| Fuel efficiency (Galons/100 RTM) | Fuel/RTM | 15.20 | 14.92 |

These results demonstrate that even with a 2.53% increase in total fuel consumption, operational efficiency improved. The reduced Fuel/RTM indicates that the airline used fuel more effectively in transporting its passengers and cargo. This confirms the positive effect of improved maintenance—especially compressor washing—on overall fleet performance.

This gain is visually illustrated in Figure 3, which shows the downward trend in Fuel/RTM between 2022 and 2023.

The airline achieved a 4.43% increase in RTM production in 2023 while maintaining only a 2.53% rise in total fuel consumption. This led to an improvement in fuel efficiency, with the Fuel/RTM indicator dropping from 15.20 to 14.92 gal per 100 RTM.

This 1.8% gain is aligned with IATA's target of a 1.5% annual improvement in fuel efficiency. It reflects the direct impact of the new compressor washing equipment and maintenance strategy, which contributed to an estimated savings of approximately 6.5 million gallons of fuel.

These results reinforce the airline's commitment to operational efficiency and environmental responsibility. In addition to enhancing engine performance and reducing specific fuel consumption, the upgrades support lower carbon emissions—contributing to a more sustainable aviation sector.

4.2 Economic Performance Evaluation

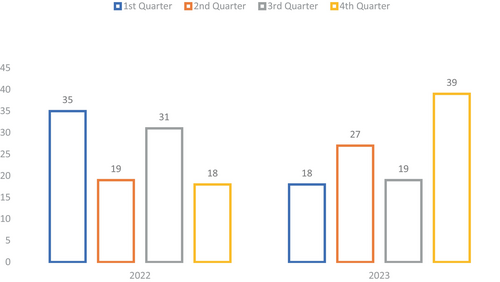

A total of 103 engines were analyzed during the study period, which gave comprehensive insight into service frequency and distribution. This dataset was instrumental in pattern identification and maintenance efficiency measurement. It is shown in Figure 4 the number of engines washed by the maintenance department at the Guarulhos base in São Paulo. This reinforces the strategic role of engine cleaning and preservation through maintenance. Comparative analysis in this case aids process improvement and operational planning.

In 2022, the company leased a machine, referred to as Model A, for compressor washing at a total cost of $372,009.10. Operational expenses included $179,951.57 for diesel, Jet A1 kerosene for engine testing, water, and labor, plus $15,349.80 for maintenance. In 2023, the company invested $179,265.00 in purchasing a new machine, Model B, covering water injection nozzles for different engine types and a water collector compatible with all wide-body aircraft engines. As a result, total costs dropped from $567,310.47 in 2022 to $141,191.15 in 2023. The average price of Jet A1 kerosene was $0.85 per liter in 2022 and $0.70 in 2023 [50]. Diesel prices averaged $0.86 in 2022 and $0.77 in 2023. Water costs followed the industrial tariff of Guarulhos Airport's utility provider. Table 5 presents the annual economic evaluation for 2022 and 2023.

| Components of the compressor washing process | Before 2022 | After 2023 | Before and after difference |

|---|---|---|---|

| Water injection nozzle rental (RR Trent 800 engine) | $24,000.50 | $0.00 | $24,000.50 |

| Water injection nozzle rental (GE90 engine) | $24,000.50 | $0.00 | $24,000.50 |

| Water injection nozzle rental (GenX engine) | $24,000.50 | $0.00 | $24,000.50 |

| Engine washing machine rental | $300,007.60 | $0.00 | $300,007.60 |

| Subtotal (Rental) | $372,009.10 | $0.00 | $372,009.10 |

| Fuel for engine washing machine (Diesel) | $2385,70 | $1215.04 | $1170.66 |

| Fuel for engine test (Jet A-1 Kerosene) | $40,637.46 | $31,969.22 | $8668.24 |

| Water consumption in the washing process | $46.28 | $20.50 | $25.78 |

| Manpower for the washing process | $136,882,13 | $95,020.23 | $41,861.90 |

| Subtotal (Operational) | $179,951.57 | $128,224.99 | $51,726.58 |

| Air filter (machine) | $29.15 | $28.13 | $1.02 |

| Fuel filter (machine) | $38.02 | $38.89 | −$0.87 |

| Oil filter (machine) | $27.88 | $19.00 | $8.88 |

| Machine lubricants (SAE 15 W-40) | $45.63 | $30.40 | $15.23 |

| Manpower for machine maintenance | $15,209.12 | $10,557.80 | $4651.32 |

| Demineralization filter kit (water treatment) | $0.00 | $826.68 | −$826.68 |

| Particle removal filter kit (water treatment) | $0.00 | $1465.26 | −$1465.26 |

| Subtotal (Maintenance) | $15,349.80 | $12,966.16 | $2383.64 |

| Total (US $) | $567,310.47 | $141,191.15 | $426,119.32 |

The equipment investment totaled $179,265.00, with a 10-year depreciation period, resulting in an annual depreciation of $17,927.00. The annual cost reduction, shown in Table 6, led to net annual savings of $185,803.00 after taxes and depreciation. Using the annual cash generation, the cash flow per period was calculated. The ROI reached 110.9% per year, with a payback period of 15.72 months. These values are presented in Table 6.

| Investment in equipment | 179,265 | |||

| Depreciation period (years) | 10 | |||

| annual depreciation | 17,927 | |||

| Annual cost reduction obtained | 283,360 | |||

| Annual depreciation | −17,927 | |||

| Base for calculating income tax (IT) | 265,434 | |||

| IRPJ + CSLL (social contribution on profit) | 30.0% | |||

| IT value + annual CSSL | −79,630 | |||

| Annual net cost reduction | 185,803 | |||

| Annual net cost reduction | 185,803 | |||

| Annual depreciation | 17,927 | |||

| Annual cash generation | 203,730 |

| Cash flow | Year 0 | Year 1 | Year 2 | Year 3 |

|---|---|---|---|---|

| Investment | −179,265 | |||

| Annual Cash Generation | 203,730 | 203,730 | 203,730 | |

| Total Cash Flow | −179,265 | 24,465 | 228,195 | 431,925 |

| ROI or IRR | 110.9% | Per year | ||

| Payback Discounted at 15% per year | 1.31 | Years | ||

| Payback Discounted at 1.25% per month | 15.72 | Months |

These financial results confirm the economic feasibility of investing in more efficient compressor washing technologies. In addition to reducing operational costs, the investment contributes to overall engine performance optimization and long-term sustainability.

4.3 Environmental Performance Evaluation

The environmental evaluation applied a mass balance approach to quantify materials, calculating inputs, outputs, accumulation, and transformations in operations. Common in engineering, this method aligns with production management while also identifying failures and addressing specific issues.

Key process requirements included water for compressor washing, Jet A1 kerosene for ground engine testing and aircraft consumption, and diesel for washing equipment. Preventive maintenance materials, such as oil, fuel, and air filters, were also considered.

Machine B's water treatment station uses three particle removal filters and one demineralization filter, replaced every 4 months. During the replacement of the filters, physicochemical analyses were conducted, and a Waste Movement Certificate of Environmental Interest (CADRI) was issued by the Environmental Company of the State of São Paulo (CETESB).

The CADRI, a mandatory document within the jurisdiction of São Paulo State in Brazil, authorizes the transport and environmentally appropriate destination of hazardous waste. CETESB is the governmental agency responsible for environmental monitoring, licensing, and enforcement in São Paulo, ensuring compliance with sustainable waste management practices.

Analysis identified paper, plastic, water, sodium chloride, nickel, soot, dust, and chlorine. Soot, a major pollutant, results from poorly controlled combustion. The company maintains detailed maintenance records for aircraft and ground equipment.

Archived data from Machines A and B include maintenance program details and physicochemical analyses of oil, air, and fuel filters. Oil filters contain steel, plastic, and paper, with identified substances including aluminum and SAE 15 W-40 oil. Air filters consist of plastic, rubber, and paper, with soot as a key component. Fuel filters contain plastic, rubber, and paper, with identified substances including water, diesel, and sulfur.

Table 7 presents a detailed mass balance of all components and substances involved in compressor washing.

| Elements | Before 2022 | After 2023 |

|---|---|---|

| Water | 44,908 L | 7725 l |

| Kerosene (for engine test) | 67,189.76 L | 67,189.76 L |

| Diesel | 2509.08 L | 1371.96 L |

| Oil (SAE 45 W-40) | 7.5 L | 7.2 L |

| Oil filter (composition) | ||

| Steel | 0.10 kg | 0.10 kg |

| Rubber | 0.03 kg | 0.03 kg |

| Paper | 0.10 kg | 0.10 kg |

| Oil (SAE 15 W-40) | 0.40 kg | 0.40 kg |

| Aluminum | 0.002 kg | 0 kg |

| Subtotal | 0.632 kg | 0.63 kg |

| Air filter (composition) | ||

| Plastic | 0.13 kg | 0.20 kg |

| Rubber | 0.07 kg | 0.05 kg |

| Grime | 0.08 kg | 0.10 kg |

| Paper | 0.17 kg | 0.23 kg |

| Subtotal | 0.45 kg | 0.58 kg |

| Fuel filter (composition) | ||

| Plastic | 0.14 kg | 0.14 kg |

| Rubber | 0.07 kg | 0.07 kg |

| Paper | 0.20 kg | 0.20 kg |

| Diesel | 0.10 kg | 0.10 KG |

| Water | 0.005 kg | 0.005 kg |

| Subtotal | 0.65 kg | 0.65 kg |

| Water treatment filter (composition) | ||

| Paper | 0 kg | 20 kg |

| Plastic | 0 kg | 16 kg |

| Water | 0 kg | 20 L |

| Sodium chloride | 0 kg | 0.5 kg |

| Nickel | 0 kg | 0.7 kg |

| Grime | 0 kg | 0.4 kg |

| Dust | 0 kg | 0.4 kg |

| Chlorine | 0.4 kg | |

| Subtotal | 0 kg | 58.4 kg |

Environmental impact is calculated by the Mass Intensity product per Compartment (MIC) and Mass Intensity Factor (MIF). Total Mass Intensity is obtained by summing abiotic, biotic, water, and air compartments. Environmental impact for compressor washing process Year 2022 (Machine A) was calculated at 814,551.09 kg/year, as shown in Table 8.

| 2022 | |||||

|---|---|---|---|---|---|

| Elements | Abiotic material | Biotic material | Water | Air | Environmental impact (kg/year) |

| Water | 449.08 | 0.00 | 58,380.40 | 0.00 | 58,829.48 |

| Kerosene | 91,378.07 | 0.00 | 634,943.23 | 1343.80 | 727,665.10 |

| Diesel | 3412.50 | 0.00 | 24,339.05 | 50.18 | 27,801.73 |

| Oil | 11.85 | 0.00 | 90.45 | 0.24 | 102.54 |

| Steel | 0.93 | 0.00 | 8.19 | 0.08 | 9.20 |

| Rubber | 0.97 | 0.00 | 24.82 | 0.28 | 26.07 |

| Grime | 0.21 | 0.00 | 3.57 | 0.20 | 3.97 |

| Paper | 0.88 | 0.35 | 43.97 | 0.16 | 45.36 |

| Aluminum | 0.74 | 0.00 | 20.95 | 0.22 | 21.91 |

| Plastic | 0.68 | 0.00 | 44.29 | 0.76 | 45.72 |

| Total | 95,255.90 | 0.35 | 717,898.92 | 1395.91 | 814,551.09 |

After the setup of Equipment B, the environmental impact was audited using 2023 data. The total impact for the period was 758,211.15 kg/year, reflecting a 56,339.94 kg/year (6.9%) decrease compared to 2022. Water consumption dropped by 34%, with the manufacturer ensuring 50% recovery of water. Diesel usage for the operation of the machines has reduced by 54%. Environmental impact calculation is shown in Table 9 for the year 2023.

| 2023 | |||||

|---|---|---|---|---|---|

| Elements | Abiotic material | Biotic material | Water | Air | Environmental impact (kg/year) |

| Water | 77.25 | 0.00 | 10,043.21 | 0.00 | 10,120.46 |

| Kerosene | 91,378.07 | 0.00 | 634,943.23 | 1343.80 | 727,665.10 |

| Diesel | 1866.00 | 0.00 | 13,308.98 | 27.44 | 15,202.42 |

| Oil | 11.40 | 0.00 | 87.02 | 0.29 | 98.71 |

| Steel | 0.93 | 0.00 | 8.19 | 0.08 | 9.20 |

| Rubber | 0.86 | 0.00 | 21.90 | 0.24 | 23.00 |

| Paper | 38.16 | 15.40 | 1920.79 | 6.77 | 1981.12 |

| Aluminum | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Plastic | 41.01 | 0.00 | 2680.41 | 45.75 | 2767.18 |

| Chlorine | 1.54 | 0.00 | 40.36 | 0.44 | 42.33 |

| Grime | 1.29 | 2.85 | 1.27 | 5.41 | |

| Nickel | 98.90 | 0.00 | 163.34 | 28.58 | 290.82 |

| Dust | 0.79 | 2.17 | 1.02 | 3.98 | |

| Sodium Chloride | 0.50 | 0.00 | 0.92 | 0.01 | 1.42 |

| Total | 93,516.69 | 15.40 | 663,223.36 | 1455.69 | 758,211.15 |

The 6.9% reduction in total environmental impact demonstrates the effectiveness of the new washing system. Combined with reductions in water and diesel consumption and compliant hazardous waste management (as evidenced by CADRI certification), the company advances toward sustainable practices in line with Blue Economy principles and regulatory expectations.

4.4 Estimated Calculation of Water Resource Savings in the Process

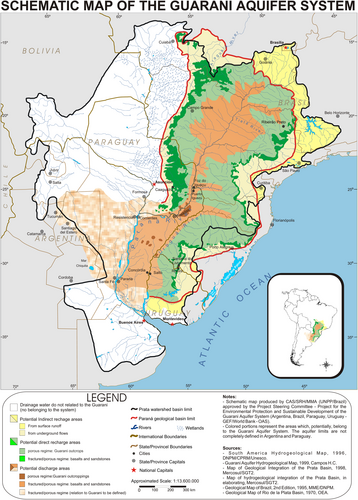

Water reuse also contributes to the preservation of the Guarani Aquifer, one of the largest underground freshwater reserves in the world, with an area of approximately 1.2 million square kilometers.

Another relevant aspect is the connection between the waters of the Paraná River and the Atlantic Ocean, since this basin drains into the Río de la Plata. In addition, the Guarani Aquifer connects to the Paraná River system along its course (see Figure 5). The Río de la Plata Basin is formed by the Paraná, Paraguay, and Uruguay rivers, covering Brazil, Paraguay, Uruguay, and Argentina.

(Source: [51])

.The irregular discharge of harmful chemicals at any point along the Paraná River and its tributaries can contaminate the Guarani Aquifer in the Paraná River delta region, potentially reaching the South Atlantic. To mitigate such pollution, this study integrates the improvements implemented in the compressor washing process for aircraft engines with the concept of the Blue Economy. Figure 6 presents the schematic map of the Guarani Aquifer system.

(Source: [52])

.5 Discussion

The scientific contribution of this study lies in its integrative approach to sustainable aviation maintenance. It is the first to apply the Blue Economy framework to aircraft compressor washing, combining operational, economic, and environmental metrics in a single case analysis. Using real-world data from 103 engine washes, the research quantifies water savings, fuel efficiency improvements, and environmental impact reduction—demonstrating the feasibility and replicability of sustainable practices in commercial aviation. This multidisciplinary assessment bridges a documented gap in the literature and provides managers with actionable metrics for decision-making in sustainability and performance optimization.

Fuel is a major airline expense, making efficiency optimization essential. Worn engines consume more fuel, and compressor washing mitigates this effect. This study demonstrated a 1.8% fuel efficiency gain across the fleet, aligning with research linking fuel savings to operational conditions (Cui et al.). Airline efficiency is measured by fuel consumption, seat density, air cargo, and occupancy rate. Maintenance and route optimization help reduce consumption. Mathematical models predict engine performance improvements based on fuel consumption [1] and exhaust gas temperature after compressor washing [31]. Various approaches assess the operational benefits of this practice. This study used the Fuel/RTM metric to estimate kerosene savings and fleet efficiency, linking operational metrics to compressor washing. Beyond performance improvements, economic impacts are significant.

The study indicated an annual gain of USD 179,000, with a 13-month return on investment (ROI) after installing Equipment B. Compressor washing also affects maintenance costs [32]. Economic viability studies compared benefits and recurring costs [6], emphasizing reduced operating costs [1, 12, 32, 14] and financial impact [5, 32]. Washing costs influence the ideal frequency [12], but companies follow manufacturer recommendations, performing it every 500 cycles.

Beyond economic gains, the study highlighted waste generation, which can pollute soil and groundwater, requiring proper management. In aviation, effluents from cleaning aircraft and vehicles contain degreasing agents and detergents that risk contaminating water sources.

New technologies reduced environmental impacts by 6.9%, according to the Mass Intensity Factor (MIF) of the Wuppertal Institute [48]. Studies analyzed soot particles in water samples [34] and found a reduction of 17,250 tons of CO2 with compressor washing [1]. Few studies examine this process's environmental impact, increasing this study's relevance.

Sustainable aviation balances environmental impact, economic viability, and quality of life. Water conservation and reuse are key to sustainability. New equipment enabled 50% water recovery, saving 7725 L annually and an estimated 231,750 L over 30 years. Calculations considered five daily aircraft on USA–Guarulhos routes in a fleet of 908 aircraft.

In the Blue Economy context, Tucci et al. [53] linked its environmental benefits with Six Sigma methodology in aircraft refueling. Research has explored strategies to reduce water pollution in rivers and groundwater [53]. This study integrates Blue Economy principles with compressor washing water reuse, preventing contamination and promoting public health benefits.

The literature highlights compressor washing's operational, economic, and environmental benefits in aviation and industry but lacks empirical studies linking it to the Blue Economy. This research fills that gap.

The findings help managers identify economic gains and calculate ROI from sustainable improvements. No prior studies examine water reuse in compressor washing, making this work a contribution to water conservation and the protection of the Guarani Aquifer within a Blue Economy strategy.

Despite the positive results, the implementation of the new compressor washing system presented several challenges. These included the adaptation of the water reuse system to different engine types, integration with existing maintenance protocols, and the need for personnel training to operate the new equipment effectively. Regulatory compliance, particularly with respect to environmental licensing and hazardous waste management, also required alignment with local standards such as those enforced by CETESB.

Future developments may include the automation of the washing process, reducing manual handling and increasing process consistency. Another promising direction is the integration of the washing system with predictive maintenance technologies, enabling more efficient scheduling and reducing unnecessary interventions. Additionally, the Blue Economy framework adopted in this study could be extended to other aircraft systems, encouraging circular practices in broader areas of aviation maintenance.

6 Conclusions

The operational, economic, and environmental impact of compressor washing contributes to the Blue Economy. Further, it brings out the relationship between the process and the principles of the Blue Economy.

Improvements in compressor washing brought about operational benefits: savings in fuel, reduction of costs, quick payback on investment, and environmental gains due to a lesser ecological footprint. The new machine allowed process water reuse, which means saving—the central point of the Blue Economy. In the past, it used to discharge wastewater into the ground and stormwater systems, endangering contamination of groundwater.

The review of operational, economic, and environmental performance reveals that process improvements can dramatically reduce fuel consumption plus operating costs and the environmental impact of aviation. Direct factors are easy to quantify; indirect ones, like kerosene consumption and energy efficiency of airlines, are much harder to measure. This study used fuel consumption per revenue ton mile (RTM) as the basis for demonstrating that compressor washing enhances energy efficiency and maintenance practices. It was also evidenced through fuel consumption data.

Before investment, economic and financial feasibility analysis is essential. The results also showed that the ROI and payback period justify acquiring new compressor washing equipment. Installing a water recycling system will make sure that the projects retain their profitability and sustainability in the environment, which goes beyond the financial benefits. Water is life and human activity; it has to be conserved, and this change helped reduce environmental impact.

Process improvements also advanced Blue Economy practices. The contaminated water disposal used to threaten surface and groundwater pollution, which is very vital for soils, especially for communities not having formal water systems, would have remained inappropriate.

Finding as an exploratory case study cannot be generalized. Future studies need to look at the technical, economic, environmental, and social aspects of biofuels in aviation regarding their ability to decrease emissions in all life cycles of the aircraft from manufacturing to use.

This study does fill a gap in the literature. While some research has been done to highlight the operational, economic, and environmental benefits of compressor washing, very few have linked it to the principles of Blue Economy. The findings will help managers evaluate returns on sustainable investments. No studies, up to now, have addressed water reuse in compressor washing.

Thus, the research contributes to natural resource conservation by promoting water reuse. Water is an increasingly scarce resource. It goes beyond mitigating water scarcity; it prevents soil contamination, thus strengthening strategies aligned with the Blue Economy.

Author Contributions

Flavio Luiz Rodrigues: writing – original draft, methodology, conceptualization. Geraldo Cardoso Oliveira Neto: validation, resources, investigation, methodology, data curation. Henrricco Nieves Pujol Tucci: writing – original draft, visualization, supervision. Luiz Fernando Rodrigues Pinto: formal analysis, validation. Francesco Facchini: supervision, validation, funding acquisition.

Acknowledgments

This work was supported by the National Recovery and Resilience Plan (NRRP), Mission 4 Component 2 Investment 1.3—Call for tender No. 341 of 15/03/2022 of the Italian Ministry of University and Research funded by the European Union—NextGenerationEU under Grant PE00000004, Concession Decree No. 1551 of 11/10/2022 adopted by the Italian Ministry of University and Research, CUP D93C22000920001, MICS (Made in Italy—Circular and Sustainable). The authors are grateful to CNPq Conselho Nacional de Desenvolvimento Científico e Tecnologico (National Council for Scientific and Technological Development) and Research funding in Productivity and PQ-2 09/2020—in the field of Production and Transportation Engineering—Process: 305272/2020-9—for funding the study. Open access publishing facilitated by Politecnico di Bari, as part of the Wiley - CRUI-CARE agreement.

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.