Mechanical and Dynamic Properties of Banana Fiber-Reinforced Polyester Composites: A Multi-Analytical Characterization Study

Funding: The authors received no specific funding for this work.

ABSTRACT

The principal objective of this investigation is to assess the damping properties of polyester composites reinforced with short banana fibers. The analysis includes evaluating mechanical characteristics, conducting free vibration examinations, measuring damping efficiency (tan δ), and utilizing Scanning Electron Microscopy (SEM). A comprehensive examination assesses Tensile Strength, Flexural Strength, Impact Strength, Hardness, free vibration attributes, damping coefficients, and SEM imagery from the fractured tensile sample surface. The composite samples are fabricated using a hand layup procedure with randomly arranged 10 mm-long fibers. Banana fiber content varies at 5, 10, 15, and 20 wt.%. Experimental results demonstrate a direct relationship between fiber quantity and improvements in Tensile Strength, Flexural Strength, Impact Strength, Hardness, Natural Frequency, and Damping ratio. Composites containing 15 wt.% banana fibers show the most significant improvements across various temperature and frequency ranges. Simultaneously, the presence of fibers reduces peak values in the damping curves (tan δ). The most notable improvement occurs in composites with 15 wt.% banana fibers, exhibiting characteristics similar to 100% polyester. This empirical study identifies a clear association between increasing fiber content and enhanced natural frequency and damping properties of the composite material.

1 Introduction

Natural fiber composites exhibit substantial advantages when compared to synthetic fiber composites across a diverse array of applications. The prominent benefits include economic efficiency, improved strength-to-weight ratios, and environmental sustainability. The integration of fibers derived from botanical sources with synthetic polymer matrices has demonstrated significant effectiveness, resulting in extensive adoption within industrial settings [1].

Banana fiber, derived from the pseudostems of the Musa plant, presents a compelling alternative to traditional natural fibers. Its remarkable mechanical characteristics encompass substantial tensile strength (529–914 MPa), noteworthy Young's modulus (27–32 GPa), and a low density (1.35 g/cm3). The fiber demonstrates exceptional capabilities in vibration damping and sustains outstanding thermal performance, preserving 85% of its storage modulus at 60°C and exhibiting stability up to 150°C. Although it does not match the strength of synthetic fibers, the distinctive combination of strength-to-weight ratio, vibration absorption, and biodegradable properties of banana fiber renders it suitable for diverse applications—ranging from automotive interiors and sound-dampening panels to packaging and furniture [2]. This material, however, is not without limitations: it exhibits sensitivity to moisture, and its properties may fluctuate depending on cultivation conditions. Such challenges necessitate meticulous engineering consideration. Nonetheless, banana fiber is particularly advantageous in contexts that require lightweight materials with robust vibration-dampening attributes while simultaneously providing environmental advantages [3].

These composite materials leverage the intrinsic properties of natural fibers, particularly their tensile strength, compressive strength, energy absorption capacity during impacts, and flexural characteristics, thereby establishing themselves as viable alternatives in applications that prioritize resource efficiency. A thorough comprehension of the ramifications of vibrational phenomena is imperative for the adept design and application of composite materials [4]. While the exploration of vibrational behavior and damping characteristics constitutes essential methodologies for assessing the mechanical attributes of polymer composites, the damping mechanisms inherent to these composites reveal substantial differences from those identified in conventional polymers.

In contrast to homopolymeric materials, fiber-reinforced composites possess complex internal architectures that significantly influence their mechanical properties. The efficiency of damping in these composites is contingent upon a multitude of factors, including the filler content, the integrity of interfacial bonding, the orientation of applied stresses, and the extent of polymer plasticization [5]. The aforementioned materials mitigate vibrational energy through an assortment of mechanisms, which include the viscoelastic properties intrinsic to both the matrix and the fibers, energy losses resulting from friction at the matrix-fiber interfaces, energy dissipation linked to crack propagation and delamination induced by impact, as well as viscoplastic and thermoelastic damping phenomena [6].

The curing duration associated with the hand lay-up method is dependent on the specific polymer utilized, with polyester-based composites typically necessitating a duration of 24 to 48 h under ambient temperature conditions. Although this technique is particularly advantageous for thermosetting polymer composites and requires a relatively modest capital investment, it is not without its limitations, which encompass extended production times and challenges in achieving high fiber volume fractions [7]. Despite these constraints, the hand lay-up method is widely adopted across numerous industries, including aerospace, automotive, marine, and construction, thereby facilitating the use of a diverse range of composite materials. Composite materials augmented with fillers exhibit complex internal structures that markedly affect their functional performance.

The effectiveness of their vibration attenuation is influenced by a plethora of factors, including the reinforcement volume, the quality of interfacial bonding, the degree of polymer plasticization, and the orientation of applied loads [8]. These fiber-reinforced composites dissipate energy through a multitude of mechanisms, including the viscoelastic characteristics of both the matrix and the fibers, friction arising from movement at the matrix-fiber interface, energy absorption at defect sites and areas of impact-induced delamination, along with the synergistic effects of viscoplastic and thermoelastic damping [9].

The present research endeavors to advance the development of composite materials utilizing natural Banana fibers specifically for the fabrication of automotive dashboards. This study meticulously evaluates a spectrum of natural fibers and optimization strategies aimed at enhancing mechanical performance while simultaneously investigating manufacturing methodologies that extend beyond conventional hand layup techniques [10]. Fundamental considerations encompass aesthetic attractiveness, scratch resistance, ultraviolet protection, and the promotion of environmental sustainability through comprehensive life cycle assessments. The investigation aspires to augment mechanical properties such as tensile strength, flexural strength, impact resistance, and hardness, in conjunction with the assessment of dynamic mechanical behavior under varied conditions. The research includes free vibration tests and Scanning Electron Microscopy analysis to scrutinize fiber-resin interfacial interactions and explores various fiber orientations to achieve optimal interior comfort, with a concentrated emphasis on industrial scalability and the potential for mass production [11].

Banana fiber-reinforced polyester composites have garnered significant academic attention as viable sustainable alternatives to synthetic composites. These materials exhibit exceptional mechanical and dynamic properties, making them suitable for numerous industrial applications. Their mechanical characteristics, including tensile, flexural, and impact strengths, are significantly influenced by factors such as fiber orientation, fiber content, and manufacturing techniques. Their dynamic properties, including thermal stability and dynamic mechanical behavior, further enhance their versatility across various industries [12].

The tensile strength of banana fiber composites directly correlates with increasing fiber content. Composites with 40% fiber volume fraction show enhanced tensile strength, particularly at specific orientations like 0°, which produce optimal performance. Cross-directional fiber arrangements significantly improve both flexural and impact strengths, with certain alignments achieving substantial improvements over alternative configurations [13]. Compressive properties also show enhancements due to increased fiber content, with improvements in compressive modulus reaching up to 200%. Banana fibers play a crucial role in enhancing composite thermal stability, an effect further amplified through hybridization and nanofiller addition. Dynamic mechanical analysis indicates that effective fiber combinations, such as jute/banana fiber blends, significantly improve dynamic mechanical properties, contributing to superior interlaminar strength and structural integrity [11].

The hand lay-up technique is frequently employed, but the Vacuum Assisted Resin Transfer Molding (VARTM) technique has demonstrated superior mechanical characteristics, exhibiting notable enhancements in tensile and flexural strengths. Various fiber orientations, including 0°, 45°, and 90°, influence the mechanical properties, with particular orientations yielding optimal performance for specific applications. Although banana fiber-reinforced composites present promising mechanical and dynamic attributes, issues such as moisture sensitivity and fiber-matrix adhesion must be addressed to further improve their performance [14]. Future investigations may concentrate on refining fiber treatments and hybridization approaches to overcome these challenges and expand the applications of these environmentally sustainable materials.

2 Materials and Method

2.1 Polyester Resin

Polyester resins are the most cost-effective option for manufacturers producing Natural Fiber-reinforced plastic (FRP) vessels using molds. Despite their economic advantage, these resins have several limitations: poor adhesion, high water permeability, significant volumetric shrinkage during curing, and high volatile organic compound (VOC) emissions [15]. Their compatibility is limited to natural fibers, preventing the use of alternative reinforcement materials. Polyester resins are most suitable for simple applications where weight is not critical and high structural integrity is unnecessary. They perform best when producing basic natural fiber components in a single operation without bonding, particularly in situations where precise geometry is not essential, moisture exposure is not a concern, and adequate ventilation is available [16].

2.2 Banana Fiber

Plant fibers are derived from the cell walls of botanical organisms, which are characterized by their high cellulose content, thereby establishing them as the most abundant organic compound on Earth. Noteworthy examples of fibers that fall within this classification encompass banana fibers, specifically those extracted from the banana genus. The illustrations provided in this study delineate the processed banana fibers employed in the research endeavor. Banana fiber, frequently referred to as banana basting fiber or banana stem fiber, constitutes a natural fiber obtained from the outer layer of the stem of the banana plant (Musa spp.). It exhibits distinctive characteristics that make it suitable for a wide range of applications [17]. Figure 1 clarifies that banana fiber is obtained through the mechanical removal of the outer layers of the banana plant's pseudo-stem or external sheath, which are generally discarded after the fruit has been harvested, and is extracted from the elongated fibers contained within. Thereafter, these fibers undergo purification and processing to eliminate contaminants and prepare them for potential applications. Comprising primarily cellulose, hemicellulose, and lignin, along with additional constituents such as proteins and minerals, banana fiber demonstrates resilience, flexibility, and enduring qualities attributable to this structural composition, as referenced in Table 1. The composite material displays an intricate internal structure owing to the presence of a filler or reinforcing medium. The energy dissipation characteristics of the material are influenced not only by the properties of the constituent materials but also by factors including volume fraction, interface integrity, polymer plasticization, and load orientation. The fiber-reinforced composite is equipped with multiple mechanisms to absorb energy, such as the visco-elastic characteristics of the matrix, the attributes of the fiber constituents, the friction produced by slippage within the matrix, the energy absorption at cracks and delaminations induced by localized deformations, as well as the visco-plastic and thermoelastic damping properties.

| Property | Banana |

|---|---|

| Density | 1.30–1.35 g/cm3 |

| Young's modulus | 29 GPa |

| Tensile strength | 721.5 MPa |

| Specific strength | 534.3 |

| Elongation at break | 3 (%) |

Table 1 demonstrates the physical and mechanical characteristics of banana fibers, which show their potential usage as sustainable reinforcement material within composites. Banana fibers present 721.5 MPa tensile strength and 534.3 specific strength values, so they possess good weight-to-strength ratios for load-bearing applications. The Young's modulus value of 29 GPa indicates average stiffness, yet the material exhibits low ductility through its 3% elongation before break. Banana fibers demonstrate properties that qualify them to function in light-weight applications that require high strength for biodegradable composites and green engineering solutions.

2.3 Fabrication and Experimental Methodology

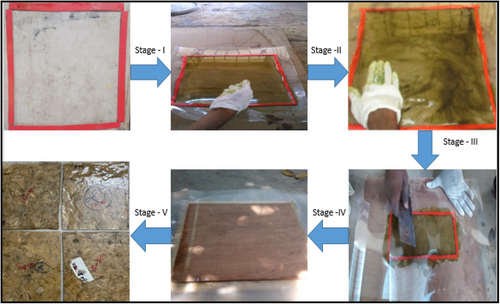

The hand lay-up technique is a simple, cost-effective method for creating composite materials that involves arranging reinforcement materials in a mold, adding resin, removing air bubbles, and curing. While economical for small-scale production of items like aircraft and marine components, it cannot achieve high reinforcement-to-resin ratios. Despite this limitation, the technique is widely used across industries for its versatility in creating various shapes [18]. Current research explores using this method with polyester resin and natural materials to develop composites with specific properties (Refer to Figure 2 and Table 2).

| Sample | Volume (cm3) | Mass (g) |

|---|---|---|

| Sample—1 | 13.5 | 20.25 |

| Sample—2 | 27 | 40.5 |

| Sample—3 | 40.5 | 60.75 |

| Sample—4 | 54 | 81 |

The investigation encompassed a thorough examination of composite materials through the application of diverse testing methodologies. The research utilized dynamic mechanical analysis, scanning electron microscopy, and assessments of mechanical properties, while meticulously recording laminate specifications such as fiber orientation and stacking sequence. The testing procedures adhered to ASTM standards across a range of properties encompassing strength (including tensile strength, flexural strength, impact resistance, and hardness), natural frequency with damping ratio, and microscopic structure. For the selected composite materials, banana fibers (trimmed to lengths of 10 mm) were incorporated as reinforcement, utilizing unsaturated polyester resin as the matrix. Specimens were fabricated in a mold measuring 300 × 300 × 3 mm, employing varying mass percentages of banana fiber ranging from 0% to 20% in increments of 5% [19].

2.3.1 Volume & Mass Calculation

Total volume of the composite materials: 30 × 30 × 0.3 cm = 270 cm3.

Banana: 5%, 10%, 15%, 20%.

Polyester resin: 95%, 90%, 85%, 80%.

Banana fiber (Sample 1).

Volume of the banana fiber = Total volume × % of the fiber/100.

Volume of the banana fiber = 270 × 5/100 = 13.5 cm3.

Density of the fiber: 1.5 g/cm3.

Mass = Density of the fiber × volume of the fiber.

Mass = 1.5 × 13.5 = 20.25 g.

3 Result and Discussion

3.1 Mechanical Properties for Banana Fiber Reinforced Composite Materials

The fabricated specimens of banana and banana fiber to measure mechanical properties as shown in Table 3.

| S.No. | Banana | Fiber | Impact strength (Joules) | Flexural strength (MPa) | Hardness, HRR | Ultimate strength (MPa) |

|---|---|---|---|---|---|---|

| 1 | 5 | B5 | 72 | 86 | 55 | 53 |

| 2 | 10 | B10 | 78 | 95.5 | 57 | 63 |

| 3 | 15 | B15 | 99 | 103.5 | 60 | 71 |

| 4 | 20 | B20 | 91 | 101.51 | 58 | 67 |

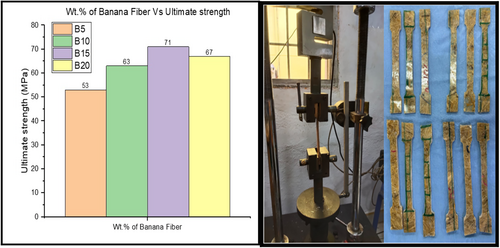

Figure 3 illustrates the results pertaining to the ultimate tensile strength of specimens characterized by varying concentrations of banana fiber. The principal outcomes reveal that specimens incorporating 5% banana fiber (B5) exhibited the lowest tensile strength, whereas those containing 15% banana fiber (B15) manifested the highest tensile strength across all specimens subjected to testing. This observation implies the existence of an optimal concentration of banana fiber that serves to enhance tensile strength within these composite materials. The correlation between banana fiber content and tensile strength is not linear, suggesting that an incremental increase in fiber does not necessarily lead to an improvement in mechanical properties. B15 demonstrates superior performance, indicating its potential as the optimal fiber concentration for achieving the most favorable mechanical properties in the polymer resin.

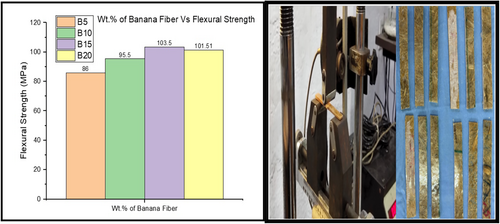

The flexural strength values of specimens with different amounts of banana fiber are displayed in Figure 4. Among all evaluated specimens, specimens with 5% banana fiber (B5) had the lowest flexural strength, while those with 15% banana fiber (B15) had the maximum flexural strength, which is comparable to the tensile strength results. According to this pattern, a lower fiber content (B5) does not offer enough reinforcement to increase the bending resistance of the material. At B15, where the balance between matrix material and fiber content yields maximum flexural strength, the ideal reinforcing seems to be attained. The findings show that up to the B15 level, flexural strength typically rises with fiber content, indicating that this is the ideal concentration for improving the material's resistance to bending.

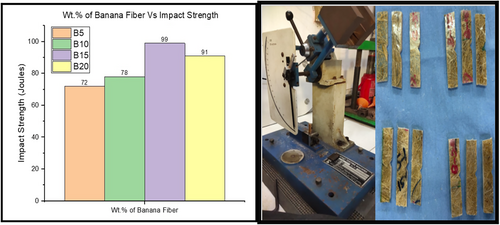

Figure 5 presents the impact strength results of specimens with varying banana fiber content. Following the same trend as tensile and flexural strength, specimens with 5% banana fiber (B5) showed the lowest impact strength, while those with 15% banana fiber (B15) demonstrated the highest impact strength among all tested specimens. The lower performance of B5 specimens suggests that minimal fiber content does not provide adequate reinforcement for energy absorption during impact loading. The superior performance of B15 specimens indicates this is the optimal concentration for achieving maximum impact resistance. The relationship between fiber content and impact strength appears to show gradual improvement as fiber content increases up to the B15 level, where the ideal balance between matrix material and fiber reinforcement is achieved for optimal energy absorption and impact resistance.

Figure 6 shows the hardness measurements of specimens with varying banana fiber content. Following the same pattern as the previous mechanical properties, specimens with 5% banana fiber (B5) demonstrated the lowest hardness, while those with 15% banana fiber (B15) exhibited the highest hardness among all tested specimens. The poor performance of B5 specimens suggests insufficient reinforcement at low fiber content. The superior hardness of B15 specimens indicates this concentration provides optimal reinforcement, resulting in better resistance to deformation and improved material stiffness. The gradual increase in hardness from B5 to B15 suggests that higher fiber content (up to 15%) contributes to better durability and resistance to abrasive forces. This confirms that B15 represents the optimal fiber content for achieving desired hardness properties in the composite material.

3.2 Percentage of Water Observation for Banana Fiber

The hydrophilic property of banana fiber displays its water absorption percentage in Table 4. The ability to absorb large amounts of water diminishes the dimensional stability needed for moist environment applications.

| S.No. | Banana | Fiber | Initial weight | Final weight | Increasing weight | Percentage of water observation % |

|---|---|---|---|---|---|---|

| 1 | 5 | B5 | 4.7 | 4.93 | 0.23 | 4.89 |

| 2 | 10 | B10 | 4.7 | 4.98 | 0.28 | 5.95 |

| 3 | 15 | B15 | 4.7 | 5.31 | 0.61 | 12.97 |

| 4 | 20 | B20 | 4.7 | 5.22 | 0.52 | 11.06 |

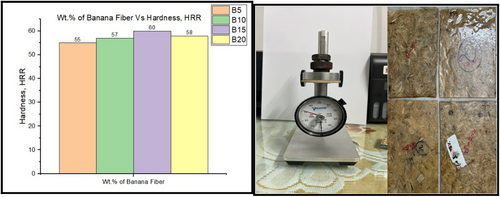

Figure 7 shows the water absorption characteristics of specimens with varying banana fiber content, revealing a pattern opposite to the mechanical properties previously discussed. Specimens with 5% banana fiber (B5) demonstrated the lowest water absorption rate, while those with 15% banana fiber (B15) showed the highest water absorption among all tested specimens. This inverse relationship suggests that higher concentrations of banana fiber, while beneficial for mechanical properties, lead to increased water absorption due to more pathways for water infiltration. The lower water absorption in B5 specimens indicates that reduced fiber content results in better water resistance. This presents a trade-off in the composite design: while B15 offers optimal mechanical properties, it also leads to higher water absorption, suggesting that the ideal fiber content may depend on the intended application and its exposure to moisture.

3.3 Free Vibration Testing (FVT)

During a free vibration assessment, the natural frequency of a substance or combination is evaluated by exposing it to a disturbance and monitoring the subsequent oscillations [19]. A chart is commonly employed to illustrate the intrinsic frequencies while analyzing the impact of incorporating banana fibers into pristine polyester and polyester composites at different weight proportions (5 wt%, 10 wt%, 15 wt%, 20 wt%). This graphic facilitates the analysis of how the inclusion of fibers impacts the vibrational characteristics of the material.

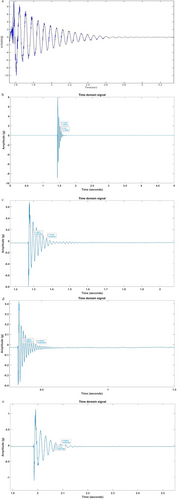

The Figure 8a–e displays the results of experimental assessments conducted on unfilled polyester and polyester composites that were reinforced with banana fibers. The fiber mass ratios used in the composites varied between Neat, 5 wt%, 10 wt%, 15 wt%, and 20 wt%. The data can be categorized into multiple sections. The components will encompass the mean damping coefficients and inherent frequencies, together with precise statistics illustrating the correlations among frequency, amplitude, and duration.

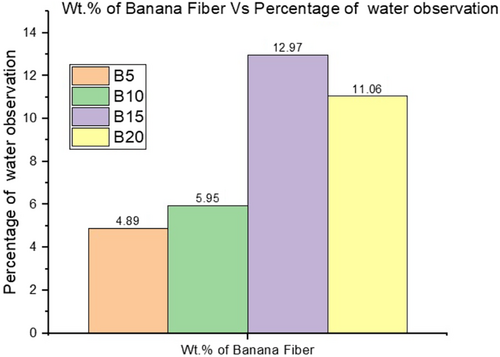

Figure 9 states how adding different amounts of banana fibers to polyester resin affects the material's natural frequency. Pure polyester resin starts at 14.38 Hz. Adding banana fibers initially improves the frequency: 5 wt% raises it to 30.31 Hz, 10 wt% to 54.53 Hz, and 15 wt% reaches the peak at 64.84 Hz. However, increasing to 20 wt% causes a drop to 50.47 Hz, suggesting that too much fiber can be detrimental due to issues like clumping. The optimal fiber content appears to be 15 wt%, after which the benefits begin to decrease.

3.4 Damping Curve

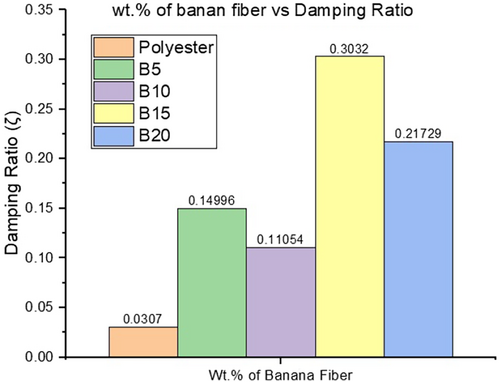

The research investigates the vibrational properties of polyester composites with varying amounts of banana fiber (5–20 wt%). Pure polyester showed a natural frequency of 14.38 Hz, which increased to a peak of 64.84 Hz with 15 wt% banana fiber, before decreasing to 50.47 Hz at 20 wt%. Time history analysis revealed that while pure polyester had minimal damping, composites with higher fiber content showed improved damping characteristics through faster decay rates. The study concludes that 15 wt% is the optimal fiber content, beyond which benefits decrease due to possible issues like fiber clumping or poor fiber-matrix adhesion [20]. These results are valuable for developing composites where vibrational properties are important.

Figure 10 the graphs (a–e) depict the relationship between time and acceleration for pure polyester. The composite consists of polyester reinforced with banana fiber at weight percentages of Neat, 5%, 10%, 15%, and 20% correspondingly. Calculation for Damping Ratio.

Where: X0 is ith peak. X1 is the peak acceleration of the peak after ith peak.

Pure polyester: 0 = 4.799, 1 = 3.792, 2 = 3.323, 3 = 2.697.

Figure 11 analyses damping ratios in polyester composites with varying banana fiber content. Pure polyester starts with a damping ratio of 0.0307. Adding banana fibers improves these ratios: 5 wt% increases it to 0.15, 10 wt% to 0.1105, 15 wt% reaches the highest at 0.3031, and 20 wt% drops to 0.2172. The study concludes that 15 wt% is the optimal fiber content for maximum damping performance, after which effectiveness slightly decreases. These improvements in vibration mitigation make banana fiber-reinforced composites potentially valuable for aerospace and automotive applications where vibration control is crucial.

In Table 5 shows a clear relationship is shown between banana fiber content and decay time in composite materials. As more banana fiber was added, the decay time decreased, with the 15 wt% banana fiber composite showing the fastest decay time. This improved decay rate indicates better vibration dampening properties, as the material more quickly dissipates vibrational energy. The 15 wt% composition proved most effective at dampening vibrations, demonstrating that banana fiber reinforcement can significantly improve the dynamic performance of polyester composites, particularly in applications where rapid vibration reduction is important.

| S.No. | Sample | Time (s) |

|---|---|---|

| 1 | Pure polyester | 3 |

| 2 | 5 wt.% of fiber | 2 |

| 3 | 10 wt.% of fiber | 1.7 |

| 4 | 15 wt.% of fiber | 0.9 |

| 5 | 20 wt.% of fiber | 2.2 |

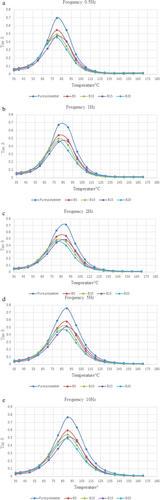

3.5 Loss Factor Versuss Different Wt. % of Fiber With Varying Thermal Level Constant Frequency

The Loss Factor is utilized to quantify the dissipation of energy within a material subjected to loading with fibers. The visual representations depicted in Figure 12a–e elucidate the relationship that exists between the Loss Factor and varying amounts of Banana fiber incorporated in the polyester composite. Glass transition thermal level (Tg) serves as an indication of the α-transition observed in amorphous polymers. It is essential to highlight that the dissipation of energy peaks at a thermal level of 80°C. The magnitude of the loss factor peak functions as a marker of the inherent damping properties of the material. A decreased value for the Loss Factor delta peak indicates an enhanced adhesion between the fiber and matrix, thereby constraining molecular motion and enhancing the material's damping capability.

The Figure 12a Illustration depicts the relationship between Loss Factor and Thermal level while maintaining a constant Frequency of 0.5 Hz. The specimens under study, consisting of B15 & B20, exhibit low Loss Factors at the specified frequency of 0.5 Hz. It is observed that the Loss Factors vary across different thermal level levels for all fabricated specimens.

The Figure 12b Illustration depicts the relationship between Loss Factor and Thermal level while maintaining a constant Frequency of 1 Hz. The specimens under study, consisting of B20, exhibit low Loss Factors at the specified frequency of 1 Hz. It is observed that the Loss Factors vary across different thermal level levels for all fabricated specimens.

Figure 12c depicts the relationship between Loss Factor and Thermal level while maintaining a constant Frequency of 2 Hz. The specimens under study, consisting of B20, exhibit low Loss Factors at the specified frequency of 2 Hz. It is observed that the Loss Factors vary across different thermal level levels for all fabricated specimens.

Figure 12d illustrates the relationship between Loss Factor and Thermal level while maintaining a constant Frequency of 5 Hz. The specimens under study, consisting of B20, exhibit low Loss Factors at the specified frequency of 5 Hz. It is observed that the Loss Factors vary across different thermal level levels for all fabricated specimens.

Figure 12e Illustration depicts the relationship between Loss Factor and Thermal level while maintaining a constant Frequency of 10 Hz. The specimens under study, consisting of B20, exhibit low Loss Factors at the specified frequency of 10 Hz. It is observed that the Loss Factors vary across different thermal level levels for all fabricated specimens.

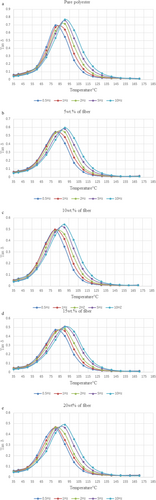

3.6 Loss Factor Versus Constant Composite Materials With Varying Thermal Level & Constant Frequency

The Loss Factor is utilized to quantify the dissipation of energy within a material while undergoing loading with fibers. The visual representations depicted in Figure 13a–e demonstrate the relationship that exists between the Loss Factor and varying proportions of Banana fiber within the polyester composite. The Glass transition thermal level (Tg) serves as an indication of the α-transition observed in amorphous polymers. It is important to note that the dissipation of energy peaks at a thermal level of 80°C. The magnitude of the loss factor peak acts as a signal of the inherent damping properties within the material. A decrease in the value of the Loss Factor delta peak suggests an enhanced adhesion between the fiber and matrix, thus limiting molecular movement and increasing the material's damping capability.

Figure 13a Illustration depicts the relationship between Loss Factor and varying Thermal level and Frequency while maintaining constant Materials. The specimens under study, consisting of pure polyester composite material, exhibit low Loss Factors at the specified frequency of 1 Hz. It is observed that the Loss Factors vary across different frequency levels for all fabricated specimens.

The Figure 13b Illustration depicts the relationship between Loss Factor and varying Thermal level and Frequency while maintaining constant Materials. The specimens under study, consisting of B5 composite material, exhibit low Loss Factors at the specified frequency of 1 Hz. It is observed that the Loss Factors vary across different frequency levels for all fabricated specimens.

The Figure 13c Illustration depicts the relationship between Loss Factor and varying Thermal level and Frequency while maintaining constant Materials. The specimens under study, consisting of B10 composite material, exhibit low Loss Factors at the specified frequency of 2 Hz. It is observed that the Loss Factors vary across different frequency levels for all fabricated specimens.

The Figure 13d Illustration depicts the relationship between Loss Factor and varying Thermal level and Frequency while maintaining constant Materials. The specimens under study, consisting of B15 composite material, exhibit low Loss Factors at the specified frequency of 1 Hz. It is observed that the Loss Factors vary across different frequency levels for all fabricated specimens.

The Figure 13e Illustration depicts the relationship between Loss Factor and varying Thermal level and Frequency while maintaining constant Materials. The specimens under study, consisting of B20 composite material, exhibit low Loss Factors at the specified frequency of 1 Hz. It is observed that the Loss Factors vary across different frequency levels for all fabricated specimens.

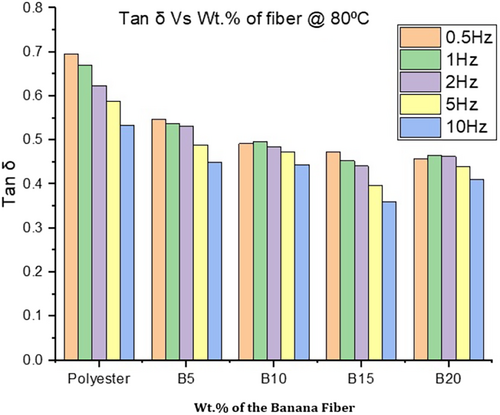

In Figure 14, the relationship between the damping coefficient and fiber content at 80°C across different frequencies is presented. At 10 Hz, pure polyester resin shows a damping coefficient of 0.533, which decreases with fiber addition: B5 (0.449), B10 (0.444), B15 (0.360), and B20 (0.411), with B15 showing the lowest damping coefficient. The research also found that natural fiber composites have a higher damping modulus than pure polyester at the glass transition temperature (Tg), though Tg values were lower when measured from the damping modulus compared to Tan δ curves. All samples showed decreased elastic modulus (Eo) with temperature changes, but banana fiber composites maintained higher Eo values than pure polyester at Tg. The fiber reinforcement affected the matrix's Tg, with banana composites showing the lowest Loss Factor delta peak intensity. The research suggests banana fibers could be valuable in developing cost-effective hybrid composites with good stiffness, damping, and thermal properties.

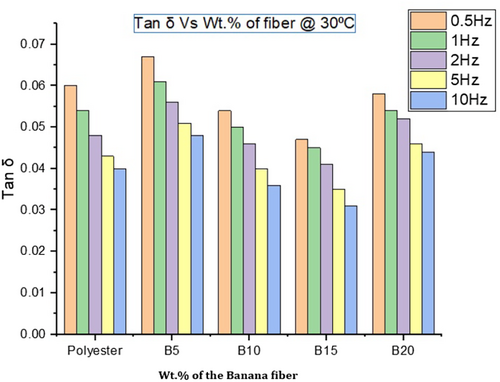

In Figure 15 the damping coefficient values at 30°C across different fiber compositions and frequencies are presented. At 10 Hz, pure polyester resin has a damping coefficient of 0.04, which varies with different banana fiber contents: B5 (0.048), B10 (0.036), B15 (0.031), and B20 (0.044). The 15% banana fiber composition (B15) showed the lowest damping coefficient at 0.031. Above the glass transition temperature (Tg), the natural fiber composites demonstrated a higher damping modulus compared to pure polyester.

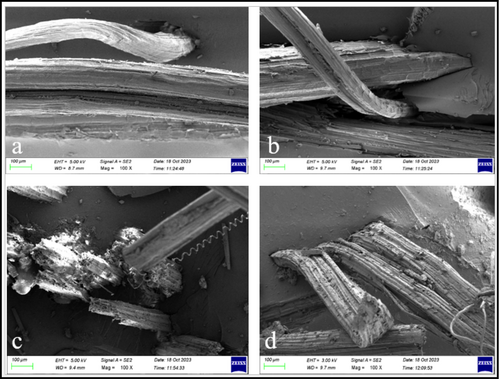

3.7 Microstructural Analysis for Banana Fiber Composite Materials

Picture 16 illustrates the scanning electron microscopy (SEM), which is a form of electron microscopy that employs a concentrated electron beam to examine the surface of a specimen [9, 21], leading to the production of visual representations. The interaction between electrons and atoms in the specimen generates diverse signals that yield insights about the surface topography and chemical composition of the specimen.

Figure 16a–d examines how banana fiber content affects tensile strength in composite materials. At 5 wt% banana fiber, the tensile strength decreases to 53 MPa. However, increasing the fiber content to 15 wt% raises the tensile strength to 71 MPa. This improvement occurs because fibers help distribute stress more evenly and inhibit crack propagation throughout the material [22]. The research demonstrates that fiber content can be optimized to achieve specific mechanical properties, with higher fiber content generally leading to improved tensile strength, though proper fiber dispersion is essential for these benefits to be realized [23-25].

4 Conclusions

The research examined the mechanical and damping attributes of polyester composites reinforced with short banana fibers. Adding 15 wt.% banana fiber to the polyester matrix significantly enhanced mechanical properties, including tensile strength, flexural strength, hardness, and impact strength. The 15% banana fiber composite displayed the highest natural frequency at 64.84 Hz, suggesting increased rigidity and load-bearing capacity. This same composition recorded the maximum damping ratio (ζ) of 0.303 and a minimum Decay Time of 0.9. Additionally, the Damping Factor (tan δ) was notably low at 0.360 at 10 Hz with 15 wt.% banana fiber. The polyester matrix composite with 15 wt.% banana fiber demonstrated the most beneficial combination of mechanical properties, stiffness, and damping characteristics. Banana fiber composites are increasingly recognized for their environmental sustainability in applications including lightweight automotive components, construction insulation, and weight reduction in consumer products and aerospace. Despite moisture sensitivity challenges, ongoing research aims to expand their use in intelligent packaging, architectural innovation, biomedical applications, and energy storage systems.

Author Contributions

G. Sathish Kumar: conceptualization, investigation, validation, writing – review and editing, software, project administration, supervision, data curation. R. Sridhar: conceptualization, investigation, writing – review and editing, validation, visualization, project administration, resources, formal analysis, supervision. A. Parthiban: conceptualization, investigation, validation, software, formal analysis, supervision, writing – review and editing. S. Sivabalan: investigation, funding acquisition, validation, methodology, formal analysis, data curation, writing – review and editing. T. Sathish: conceptualization, investigation, funding acquisition, writing – original draft, writing – review and editing, visualization, validation, methodology, software, formal analysis, project administration, data curation, supervision, resources. Jayant Giri: conceptualization, investigation, validation, visualization, writing – review and editing, formal analysis, software, supervision, resources. J. Isaac Joshua Ramesh Lalvani: investigation, funding acquisition, writing – original draft, writing – review and editing, visualization, validation, formal analysis, project administration, supervision, resources, conceptualization, methodology, software, data curation. Ahmad O. Hourani: conceptualization, validation, writing – review and editing, formal analysis, resources. Nidhal Becheikh: writing – review and editing, validation, investigation, formal analysis, supervision, data curation, software, methodology. Boutheyna Belhaj Bettaieb: visualization, project administration, resources, conceptualization, methodology, funding acquisition, writing – review and editing, data curation, formal analysis, investigation.

Acknowledgments

The authors extend their appreciation to Northern Border University, Saudi Arabia, for supporting this work through project number (NBU-CRP-2025-2933). The authors highly acknowledge the testing facility provided by the Department of Mechanical Engineering, Vels Institute of Science, Technology & Advanced Studies, Chennai, India, and Saveetha School of Engineering, Saveetha Institute of Medical and Technical Sciences, Saveetha University, Chennai, India.

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

Data available on request from the authors.