Artificial Polymer Lightweight Aggregate Concrete With Coal Fly Ash for Biomedical Infrastructure: Mechanical, Physical, and Microstructural Investigation

Funding: This research was funded by Universitas Tridinanti.

ABSTRACT

Aggregates constitute ~60%–80% of concrete volume and play a crucial role in determining its mechanical and durability properties. In the context of sustainable construction, artificial aggregates derived from industrial by-products are gaining prominence as environmentally responsible alternatives to natural aggregates. This study presents the development and performance evaluation of a novel lightweight concrete incorporating artificial polymer lightweight aggregate synthesized from coal fly ash (CFA), epoxy resin, and a hardener in varying CFA-to-resin ratios (70:30, 74:26, and 80:20 by weight). The proposed mix design aims to address the increasing demand for lightweight, durable, and sustainable materials suitable for biomedical infrastructure applications, which require enhanced thermal insulation, fire resistance, and seismic performance. Concrete mixtures were designed to achieve target compressive strengths of 17.5, 20, and 30 MPa, with both lightweight (BR series) and normal weight (BN series) concrete formulations evaluated. Results demonstrated that the incorporation of polymer lightweight aggregates reduced the bulk density of concrete by up to 15.36%, while meeting or exceeding the required compressive strength thresholds for BR_17.5 and BR_20 mixtures. Although the BR_30 mix did not meet the target strength, polymer lightweight aggregate-based concrete exhibited significantly improved flexural strength (up to 60.57% higher than conventional mixes) and enhanced chemical durability when exposed to acidic and saline environments. However, its resistance to elevated temperatures was lower compared to that of conventional concrete. The findings suggest that polymer lightweight aggregate concrete offers a promising sustainable material solution for biomedical infrastructure and other applications demanding lightweight, durable, and thermally efficient construction materials. The utilization of industrial waste in polymer lightweight aggregate production not only contributes to environmental conservation but also advances the development of next-generation building materials aligned with circular economy principles.

1 Introduction

Concrete is a widely utilized construction material due to its versatility [1], cost-effectiveness [2], high compressive strength [3], and resistance to environmental factors [4]. Its adaptability allows for the creation of various shapes and configurations, making it a preferred choice in the industry. Aggregates, constituting a significant portion of concrete's volume, play a vital role in determining the physical properties and overall performance of the final product. Lightweight aggregates, in particular, can diminish the overall mass of concrete while improving its strength-to-weight ratio and other advantageous characteristics [5].

Aggregates can be classified as natural [6] or artificial [7]. Natural lightweight aggregates, such as pumice [8] and volcanic ash [9], have a long history of use, but the increasing demand and declining availability of high-quality natural resources have led to a growing interest in artificial lightweight aggregates. These materials, sourced from industrial by-products like coal fly ash (CFA) and steel slag, offer a sustainable alternative while addressing the environmental impacts of resource depletion. The incorporation of waste-derived aggregates can also support the circular economy by reducing reliance on virgin materials [10]. The use of artificial aggregates presents a promising solution to mitigate the environmental impact of natural resource depletion. Additionally, the incorporation of waste-derived aggregates in concrete can reduce the reliance on virgin materials, providing a sustainable alternative that contributes to the circular economy [11, 12].

With global aggregate demand reaching ~55 billion tons in 2020 and projected to double by 2030, the construction sector faces challenges due to urbanization and shortages of natural aggregates. Consequently, industrial by-products, particularly CFA, which is rich in silica and alumina that have gained attention for use as a substitute in concrete applications [13, 14]. Despite challenges related to its management and quality control, CFA remains a valuable resource [15]. To address this challenge, the use of industrial by-products as a substitute for natural aggregates has garnered significant attention. Despite the challenges related to the management and quality control of CFA, its potential as a raw material in concrete production remains a valuable resource for sustainable construction.

Artificial polymer lightweight aggregates, formed by combining waste materials such as CFA with epoxy resin, have emerged as an innovative approach to producing lightweight aggregates with enhanced properties. Epoxy resin, a polymer material, is well-known for its high strength and durability [16], making it a suitable binder for producing polymer lightweight aggregates [17]. While polymer lightweight aggregates have shown promising results in terms of strength and flexibility, their durability under extreme environmental conditions, such as high temperatures and chemical exposure, remains underexplored [18-20]. Recent studies by Firda et al. [21, 22] have demonstrated that polymer lightweight aggregates, made from varying ratios of CFA and epoxy resin, can significantly reduce the weight of concrete while maintaining adequate compressive and flexural strength. However, the impact of polymer lightweight aggregate on the long-term durability of concrete, particularly in aggressive environments, warrants further investigation.

Given the critical role of durability in the life-cycle performance of concrete used in infrastructure, it is essential to explore the resilience of polymer lightweight aggregate-based concrete mixtures to environmental degradation, such as heat and sulfate attack [23, 24]. The development of lightweight concrete mixtures incorporating polymer lightweight aggregates offers an opportunity to reduce the consumption of natural aggregates, thereby alleviating environmental pressures associated with resource extraction. Furthermore, lightweight concrete's inherent benefits, such as improved seismic performance, enhanced thermal insulation, and reduced density [25], are particularly advantageous for biomedical infrastructure. Biomedical infrastructure refers to the physical structures and facilities that support healthcare services, including hospitals [26], medical research labs [27], and clinics [28], where material performance must meet specific standards for safety, longevity, and environmental sustainability [29-33]. These structures often face extreme and dynamic conditions, requiring materials that can withstand constant exposure to varying temperatures [34], chemicals [35], and moisture [36], while ensuring high durability and minimal maintenance [37]. In the context of biomedical infrastructure, lightweight concrete with polymer lightweight aggregates offers not only enhanced mechanical properties but also improved thermal insulation, reducing energy consumption in climate-controlled environments. Moreover, the use of fly ash in these mixtures promotes sustainability by reducing carbon emissions [38] and enhancing the material's overall durability [39]. These properties make polymer lightweight aggregate-based concrete mixtures an ideal candidate for building resilient, cost-effective, and energy-efficient biomedical facilities, which are crucial for advancing healthcare infrastructure in a sustainable manner.

This study aims to investigate the potential of polymer lightweight aggregate-based lightweight concrete incorporating CFA and epoxy resin for use in biomedical infrastructure applications. By developing a suitable mix design and evaluating the performance of polymer lightweight aggregate concrete under various environmental conditions, this research seeks to provide a sustainable, durable alternative to conventional concrete, advancing the use of industrial waste in building materials. The findings of this study have the potential to contribute significantly to the ongoing efforts to enhance sustainability in the construction industry, particularly in sectors where material performance is critical for safety and longevity.

2 Materials and Methods

2.1 Materials

The materials utilized in the production of polymer lightweight aggregate include CFA, epoxy resin, and hardener (Erh). For this study, CFA is incorporated in three specific weight ratios with epoxy resin: 70:30 (PLA_70:30), 74:26 (PLA_74:26), and 80:20 (PLA_80:20). The selection of this composition is based on previous tests conducted by Firda et al. [21, 22], where the study explored compositions ranging from 50% to 90% CFA. The research measured the specific gravity parameters, resulting in the identification of the optimal composition at PLA_74:26, which exhibited an average compressive strength of 43.46 MPa. PLA_70:30 and PLA_80:20 were used as comparative aggregates to PLA_74:26, as they also demonstrated average compressive strengths of 67.40 and 43.80 MPa, respectively.

CFA, sourced from the combustion of coal, is classified as Class F fly ash based on its chemical composition, which consists of 55.81% SiO2, 29.63% Al2O3, 5.62% Fe2O3, and 2.72% CaO. This composition is typical of fly ashes that exhibit pozzolanic activity, making them suitable for use in geopolymer concrete applications [21, 22]. The epoxy resin used in the formulation is a high-strength, solvent-free material with low viscosity, which ensures effective bonding when mixed with CFA [40].

The laboratory preparation of polymer lightweight aggregate follows a systematic procedure to ensure consistent material properties. Initially, CFA is oven-dried at 105°C for 24 h to eliminate moisture content, after which it is cooled to room temperature. The epoxy resin and hardener are mixed in a 2:1 weight ratio, as specified in previous studies [40]. The CFA is then combined with the prepared epoxy resin mixture in the predetermined ratios (PLA_70:30, PLA_74:26, and PLA_80:20). The thoroughly mixed composite is subsequently poured into an aggregate mold and allowed to cure for 24 h, forming the final polymer lightweight aggregate product, which is ready for use in concrete mixtures [21, 22].

For concrete mixtures, Tanjung Raja sand is employed as the fine aggregate. Normal concrete (BN) is made with natural coarse aggregate and Portland cement, whereas lightweight concrete (BR) incorporates polymer lightweight aggregate as the coarse aggregate, maintaining Tanjung Raja sand as the fine aggregate and Portland cement as the binder. The materials' characteristics were tested and summarized in Table 1, which includes the dry and saturated surface-dry (SSD) specific gravity, apparent specific gravity, volume weight, water absorption, abrasion, and fineness modulus, among other properties.

| Test type | Unit | Test result | Method | ||||

|---|---|---|---|---|---|---|---|

| PLA 70:30 | PLA 76:24 | PLA 80:20 | Spilit | Tanjung Raja sand | |||

| Dry specific gravity | gr/cm3 | 1.668 | 1.728 | 1.621 | 2.549 | 2.31 | ASTM C-128-93 |

| SSD specific gravity | gr/cm3 | 1.676 | 1.744 | 1.660 | 2.547 | 2.38 | |

| Apparent specific gravity | gr/cm3 | 1.682 | 1.755 | 1.687 | 2.613 | 2.49 | |

| Volume weight | gr/cm3 | 1.42 | 1.17 | 0.88 | 1.698 | 1.363 | ASTM C-29/29 M-91a |

| Water absorption | % | 0.50 | 0.806 | 2.401 | 0.97 | 3.09 | ASTM C-128-93 |

| Abrasion | % | 3.60 | 7.00 | 9.30 | 12.20 | — | ASTM C-31-69 |

| Fineness modulus | — | — | — | — | 2.62 | ASTM C-33 | |

The mix designs for both normal and lightweight concrete were determined using the Job Mix Formula (JMF), as specified by established standards. The JMF for normal concrete (BN) is based on the ACI 211.1–91 Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete, with target compressive strengths (fc') of 30, 20, and 17.5 MPa, corresponding to the BN_30, BN_20, and BN_17.5 samples, respectively. The JMF for lightweight concrete (BR) follows ACI 211.2–98 (Standard practice for selecting proportions for structural lightweight concrete), with compressive strengths of 30 MPa (BR_30), 20 MPa (BR_20), and 17.5 MPa (BR_17.5), utilizing the various polymer lightweight aggregate formulations (70:30, 74:26, and 80:20) based on previous polymer lightweight aggregate compressive strength test results [21, 22].

2.2 Durability Treatment

2.2.1 Durability of Immersion Sulfuric Acid

This experimental procedure is designed to assess the compressive strength of concrete specimens subjected to immersion in sulfuric acid solutions [41], simulating aggressive environments often encountered in biomedical infrastructure applications. Specifically, the concrete samples were immersed in sulfuric acid solutions with concentrations of 1% and 2%, corresponding to immersion liquids with a pH < 7. The sulfuric acid solution was prepared by mixing sulfuric acid with distilled water in the following proportions: for the 1% sulfuric acid solution, 0.1 L of sulfuric acid was added to 9.9 L of water, and for the 2% solution, 0.2 L of sulfuric acid was mixed with 9.8 L of water. Compressive strength tests were conducted on cylindrical concrete specimens (diameter = 15 cm, height = 60 cm) using a compression testing machine after the specimens were cured for 28 days. The concrete specimens were then immersed in sulfuric acid solutions for a predetermined period, and compressive strength was measured to evaluate the degradation of the concrete matrix due to the acidic exposure. This simulation helps evaluate the material's resilience to chemical attack [25].

2.2.2 Durability of Immersion Brackish Water

The aim of this test is to determine the compressive strength of concrete exposed to brackish water [42], which is commonly found in various environmental conditions and may pose a significant challenge to the longevity of materials used in biomedical infrastructure. The test simulates the impact of brackish water immersion, where the immersion solution has a pH greater than 7, indicating the presence of alkaline components. In this study, the immersion water was measured to have a pH > 4, as verified using a pH meter. Concrete specimens, with a diameter of 15 cm and a height of 60 cm, were subjected to immersion in brackish water for 28 days. Following the immersion period, compressive strength testing was performed using a compression testing machine to assess the material's resistance to degradation due to the alkalinity and chemical composition of brackish water.

2.2.3 Durability of High Temperature (Burning)

The objective of this test is to investigate the effect of elevated temperatures on the compressive strength of concrete, particularly in scenarios where the material is exposed to high heat environments [43], such as those encountered in medical facilities, hospitals, or other biomedical infrastructures. In this study, cylindrical concrete specimens (diameter = 15 cm, height = 60 cm) were subjected to combustion in a furnace at temperatures reaching 1000°C for durations of 1, 2, and 3 h as shown in Figure 1. The concrete specimens were heated in a furnace constructed from heat-resistant materials and fueled by LPG gas, which was evenly distributed throughout the furnace to ensure uniform heat exposure [44]. After the specified exposure times, the specimens were allowed to cool, and compressive strength testing was carried out using a compression testing machine.

2.3 Testing Method

2.3.1 Compressive Strength

The compressive strength test is a critical parameter for evaluating the load-bearing capacity of concrete [45, 46], particularly when using artificial lightweight coarse aggregates, such as polymer lightweight aggregate incorporated with fly ash. This test measures the maximum compressive force that concrete can withstand per unit area before failure occurs. The test procedure involves applying a controlled compressive load to cylindrical concrete specimens (150 mm in diameter and 300 mm in height), which have been cured by immersion in water for a specific period. Compressive strength testing was conducted on both normal concrete and lightweight concrete at multiple curing intervals, specifically at 3, 7, 14, 21, and 28 days. This temporal assessment allows for the evaluation of the concrete's strength development over time. A compression testing machine was employed to apply the force, with the ultimate goal of determining the concrete's capacity to resist compressive loads [25].

2.3.2 Flexural Tensile Strength

Flexural tensile strength is a critical property that measures the ability of concrete to resist bending stresses when subjected to loads that cause deformation [47, 48]. The test is designed to evaluate the resistance of concrete beams to bending, providing valuable insights into the material's performance under tensile stresses induced by external forces [49]. The test specimens consist of beam-shaped concrete blocks, with dimensions of 60 cm in length, 15 cm in width, and 15 cm in height, and are subjected to loading until failure occurs due to pure bending. In the flexural strength test, a two-point loading system is used, where the concrete specimen is positioned on two supports. The test aims to generate a bending moment [50], which induces flexural stresses within the concrete. The flexural tensile strength is calculated based on the observed deformation and failure characteristics of the concrete specimen. This test is conducted after the concrete has cured for 28 days. The apparatus used for this test includes a compression testing machine equipped with a manometer to measure the load, ensuring precise load application and accurate reading of the minimum load scale (12.5 kg) [51].

2.3.3 Scanning Electron Microscope (SEM) Testing

SEM is employed to investigate the microstructural properties and morphology of the investigated material [52, 53], with a focus on understanding the effects of varying polymer lightweight aggregate compositions and their interaction with fly ash. SEM analysis provides high-resolution imaging of the concrete's internal structure, enabling the identification of particle shape, size, and distribution within the matrix. This microscopic investigation helps to elucidate the role of polymer lightweight aggregate in enhancing the mechanical properties of the concrete and its potential benefits in terms of durability, porosity, and resistance to aggressive environmental factors. By analyzing the microstructure of the concrete at various magnifications, SEM allows for the evaluation of the interface between polymer lightweight aggregates and the cementitious binder, offering insights into the bonding characteristics and overall material performance. This method is particularly valuable for assessing how different polymer lightweight aggregate compositions influence the concrete's behavior under environmental stresses and its suitability [54].

3 Results and Discussion

3.1 Concrete Mix Design (Job Mix Formula)

The Job Mix Formula (JMF) is a methodical approach used to determine the appropriate proportions of cement, water, and aggregate components in concrete mixtures [55]. The JMF serves as the foundation for preparing concrete specimens for testing compressive strength, flexural tensile strength, and durability, specifically for both normal and lightweight concrete. The concrete quality is designed to meet different compressive strength requirements, expressed as the characteristic compressive strength , for both normal concrete (BN) and lightweight concrete (BR). The following concrete grades were considered in this study: normal concrete grades of = 30 MPa (BN_30), 20 MPa (BN_20), and 17.5 MPa (BN_17.5), as well as lightweight concrete grades of = 30 MPa (BR_30), 20 MPa (BR_20), and 17.5 MPa (BR_17.5). The design of the concrete mix for lightweight concrete was based on the compressive strength of the polymer lightweight aggregate at 28 days, with varying compositions of polymer lightweight aggregate and fly ash. The polymer lightweight aggregate compositions selected for this study were PLA_70:30, PLA_76:24, and PLA_80:20, which exhibit compressive strengths of 74.60, 60.80, and 43.80 MPa, respectively. These values correspond to the design of lightweight concrete with compressive strengths of 30 MPa (BR_30), 20 MPa (BR_20), and 17.5 MPa (BR_17.5).

The results of the JMF for both normal concrete and lightweight concrete, as detailed in Tables 2 and 3, demonstrate a distinct difference in the mix proportions of coarse aggregate and polymer lightweight aggregate. The weight of cement, sand, and water in the mixtures remains constant across both types of concrete. However, the main difference arises from the substitution of traditional coarse aggregate with polymer lightweight aggregate in the lightweight concrete mix. Polymer lightweight aggregate, being less dense than conventional coarse aggregates, leads to a reduction in the total weight of the mixture for lightweight concrete. Additionally, as the target compressive strength of the concrete decreases, there is a corresponding increase in the amount of coarse aggregate used in the normal concrete mix, which compensates for the reduced strength characteristics. This comparative analysis of the JMF for both normal and lightweight concrete highlights the adaptation of conventional concrete mix designs to accommodate the use of alternative, sustainable materials such as polymer lightweight aggregate. This approach is integral to the development of environmentally friendly, durable, and lightweight concrete for applications in biomedical infrastructure, where the need for both structural integrity and sustainability is paramount.

| No | Materials | Mix weight of normal concrete (BN) | ||

|---|---|---|---|---|

| BN_30 | BN_20 | BN_17.5 | ||

| 1 | Cement (kg) | 450 | 398 | 303.06 |

| 2 | Sand (kg) | 654.98 | 659 | 660.43 |

| 3 | Coarse Aggregate (kg) | 966.97 | 1063 | 1117.37 |

| 4 | Water (L) | 203 | 203 | 202 |

| Total | 2274.95 | 2323 | 2282.87 | |

| No | Materials | Mix weight of light concrete (BR) | ||

|---|---|---|---|---|

| BR_30 | BR_20 | BR_17.5 | ||

| 1 | Cement (kg) | 450 | 398 | 303.06 |

| 2 | Sand (kg) | 654.98 | 659 | 660.43 |

| 3 | Polymer lightweight aggregate (kg) | 599.52 | 611 | 620.76 |

| 4 | Water (L) | 203 | 203 | 202 |

| Total | 1907.5 | 1871 | 1786.25 | |

3.2 Normal Concrete (BN) and Lightweight Concrete (BR) Slump Test Result

The slump test is a standard procedure used to assess the workability and viscosity of a concrete mix before it is cast, providing an indication of the mix's consistency and fluidity. The slump values obtained for both normal concrete (BN) and lightweight concrete (BR) are presented in Table 4. These results demonstrate that both types of concrete meet the specified standards for their respective mix designs, in accordance with the required workability for each concrete quality. In the case of normal concrete (BN), which includes concrete grades with characteristic compressive strengths = 30 MPa, = 20 MPa, and = 17.5 MPa, the slump values were found to be higher compared to the corresponding lightweight concrete (BR) with the same compressive strength. This observation is consistent with expectations, as normal concrete typically exhibits greater workability due to the use of denser aggregates and a more traditional mix design.

| Slump test | Normal concrete (BN) | Lightweight concrete (BR) | ||||

|---|---|---|---|---|---|---|

| BN_30 | BN_20 | BN_17.5 | BR_30 | BR_20 | BR_17.5 | |

| Average | 55 mm | 85 mm | 108 mm | 52 mm | 80 mm | 90 mm |

Furthermore, an interesting trend emerged in the slump test results: as the target compressive strength of the concrete decreases, the slump value tends to increase. This can be attributed to the fact that lower-strength concrete mixes generally require a higher water-to-cement ratio, which in turn enhances the fluidity and workability of the mix. In contrast, higher-strength mixes tend to have a lower water content, resulting in a stiffer and less workable mixture. This correlation between compressive strength and slump value is significant for both normal and lightweight concrete, as it impacts the ease of placement and compaction during construction. These findings further underline the importance of optimizing the mix design to achieve the desired properties, such as adequate workability for placement, while maintaining the required strength and durability characteristics for biomedical infrastructure applications. The results also highlight the suitability of lightweight concrete, made with artificial polymer aggregate, for specific applications where workability and reduced weight are prioritized without compromising the overall structural performance.

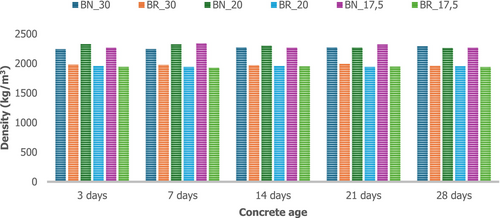

3.3 Normal Concrete (BN) and Lightweight Concrete (BR) Density Test Results

The density of concrete is a crucial parameter that influences both its structural performance and overall sustainability, especially for lightweight concrete intended for specialized applications such as biomedical infrastructure. Following the casting of cylindrical concrete specimens (150 mm × 300 mm), the concrete was subjected to a curing process by immersion in water for a period of 28 days. After curing, the density of each specimen was determined using a digital balance to ensure precise measurements. The density test results for both normal concrete (BN) and lightweight concrete (BR) are presented in Figure 2. The tests were performed at various intervals: 3, 7, 14, 21, and 28 days, providing a comprehensive understanding of the density variation over the curing period.

The findings indicate that lightweight concrete exhibits consistently lower density values compared to normal concrete. Specifically, the average bulk density of BR_30 is 12.72% lower than that of BN_30. Similarly, BR_20 shows a 15.09% reduction in density compared to BN_20, and BR_17.5 is 15.36% less dense than BN_17.5. This trend is consistent across all tested ages, highlighting the effect of the artificial polymer aggregate on the overall density of the concrete mixture. The observed reduction in density for lightweight concrete can be primarily attributed to the incorporation of polymer lightweight aggregate as a coarse aggregate replacement, which has a lower specific gravity compared to conventional coarse aggregates used in normal concrete that is in line with the previous findings by Firda et al. [21, 22]. As the quality of the concrete decreases (from BR_30 to BR_17.5), a corresponding decrease in density is observed. This is due to the higher proportion of polymer lightweight aggregate relative to the other components, which results in a lighter mix.

3.4 Normal Concrete (BN) and Lightweight Concrete (BR) Compressive Strength Test Results

The compressive strength of concrete is a critical factor in evaluating the structural performance and durability of building materials. To assess the performance of normal and lightweight concrete mixes, compressive strength tests were conducted on cylindrical concrete specimens (150 mm ×300 mm) that were subjected to water curing for 28 days. Testing was carried out at multiple intervals (3, 7, 14, 21, and 28 days) using a standard compression testing machine. The results of these tests for both normal concrete (BN) and lightweight concrete (BR) are presented in Table 5.

| Age | Compressive strength of concrete (MPa) | |||||

|---|---|---|---|---|---|---|

| Fc 30 MPa | Fc 20 MPa | Fc 17.5 MPa | ||||

| BN_30 | BR_30 | BN_20 | BR_20 | BN_17.5 | BR_17.5 | |

| 3 days | 15.53 | 14.58 | 8.44 | 6.03 | 5.48 | 7.43 |

| 7 days | 18.89 | 18.21 | 13.34 | 11.29 | 7.71 | 9.52 |

| 14 days | 22.91 | 21.79 | 16.74 | 13.91 | 10.34 | 12.63 |

| 21 days | 26.76 | 25.53 | 18.91 | 16.54 | 14.78 | 16.48 |

| 28 days | 30.81 | 29.52 | 22.16 | 20.93 | 18.04 | 18.88 |

At the 28-day mark, the compressive strengths of the normal concrete mixes were as follows: BN_30 exhibited a compressive strength of 30.81 MPa, BN_20 showed 22.16 MPa, and BN_17.5 displayed 18.04 MPa. In comparison, the compressive strengths for the lightweight concrete mixes were slightly lower: BR_30 reached 29.52 MPa, BR_20 achieved 20.93 MPa, and BR_17.5 attained 18.88 MPa. Notably, BR_20 and BR_17.5 met the required compressive strength for their respective mix designs by 28 days, while BR_30 fell short by 4.19%, yielding a strength that was 4.19% lower than that of BN_30. Similarly, BR_20 exhibited a 5.55% reduction compared to BN_20, while BR_17.5 surpassed BN_17.5 by 4.66%.

These results suggest that the lightweight concrete mixtures, particularly BR_30, may require further optimization to meet the specified compressive strength for structural applications. However, the slight reductions observed in BR_30 and BR_20 are still within acceptable tolerances for certain lightweight applications, particularly where weight reduction is prioritized. Additionally, the improvements observed in BR_17.5 highlight the potential of optimizing the polymer lightweight aggregate content for enhancing the strength of lightweight concrete.

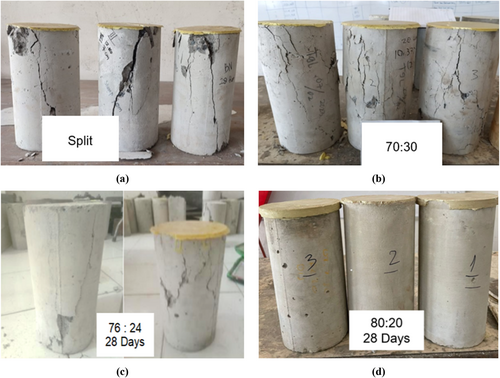

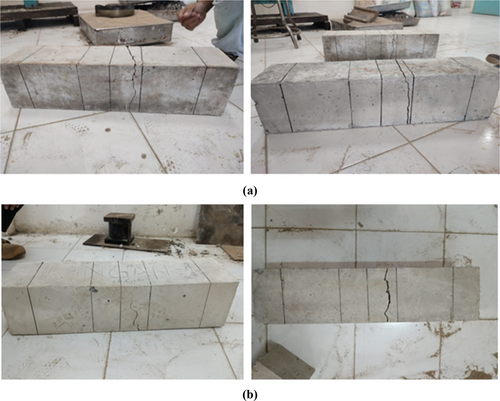

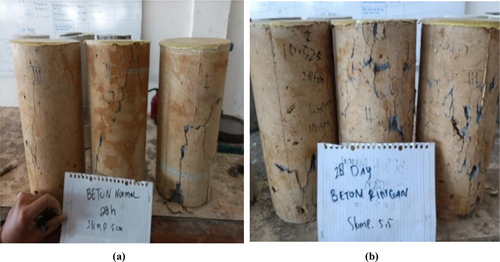

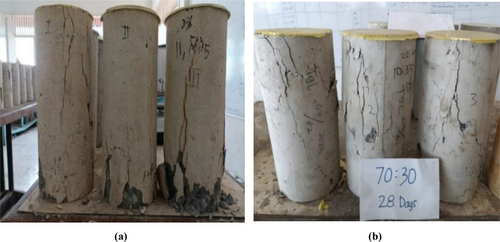

The crack patterns observed during the compressive strength testing of the lightweight concrete specimens (BR_30, BR_20, and BR_17.5) provide valuable insight into the behavior of the artificial polymer aggregate-based mixes under stress. Figure 3a shows the typical crack formation in normal concrete (BN), while Figure 3b–d illustrates the behavior of the lightweight concrete specimens at varying levels of strength.

In the case of BR_30 (Figure 3b), a 45° crack pattern was observed, primarily originating from the point of maximum stress. This phenomenon is indicative of the relatively high strength of the PLA_70:30 used in the BR_30 mix, which exceeds the planned concrete strength of 30 MPa. As a result, cracks predominantly propagated through the mortar matrix, leaving the polymer lightweight aggregate intact. In some instances, the PLA_70:30 particles separated from the surrounding mortar due to the weak interface bond, which is likely caused by the smooth surface and low porosity of the polymer lightweight aggregate material. This weak bond is a known issue in polymer lightweight aggregate-based concrete mixes and may necessitate the development of surface treatments or additives to enhance the interface between polymer lightweight aggregate and mortar.

For BR_20 (Figure 3c), the crack pattern was similar to that of BR_30, but with additional random cracks appearing in areas subjected to high localized pressure. This behavior can be attributed to the use of PLA_76:24, which has a higher-strength than the target 20 MPa compressive strength. The weak bond between the polymer lightweight aggregate and the mortar was again the primary cause of failure, with the PLA_76:24 particles appearing to remain intact while the surrounding matrix collapsed.

Finally, the crack pattern observed for BR_17.5 (Figure 3d) showed micro-cracks that propagated from top to bottom, but with smaller gap widths compared to BR_30 and BR_20. This is likely due to the lower strength of PLA_80:20, which is more compatible with the 17.5 MPa concrete mix strength. The reduced intensity of cracking in BR_17.5 suggests that, at this level of polymer lightweight aggregate content, the material properties are more closely aligned with the target compressive strength, resulting in a more balanced interaction between the polymer lightweight aggregate and the surrounding mortar.

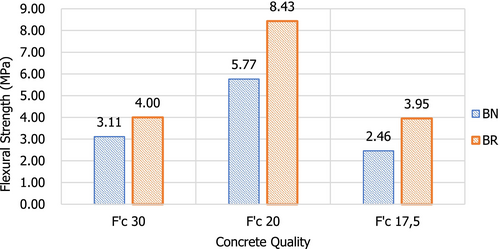

3.5 Normal Concrete (BN) and Lightweight Concrete Flexural Tensile Strength Test Results

Flexural tensile strength is an essential mechanical property that reflects the ability of concrete to resist bending and is a crucial factor for evaluating its performance in structural applications. The flexural tensile strength tests were conducted on beam-shaped concrete specimens measuring 150 mm × 600 mm after they had been fully immersed in water for a curing period of 28 days. The results for both normal concrete (BN) and lightweight concrete (BR) mixes are presented in Figure 4.

The data from these tests revealed that the flexural tensile strength of lightweight concrete made with polymer artificial aggregates (BR) surpassed that of normal concrete (BN) across all tested mix designs. Specifically, for concrete with a target compressive strength of = 30 MPa, BN exhibited an average flexural tensile strength of 3.11 MPa, whereas BR achieved a higher average of 4.00 MPa, representing an improvement of 28.62%. For mixes targeting f'c = 20 MPa, the flexural tensile strength for BN was 5.77 MPa, while BR demonstrated a significant increase to 8.43 MPa, marking a 46.1% enhancement. In the case of = 17.5 MPa, BN's flexural tensile strength was 2.46 MPa, while BR achieved 3.95 MPa, indicating a substantial increase of 60.57%. These findings demonstrate that lightweight concrete, particularly those incorporating polymer artificial aggregates, exhibits superior flexural performance compared to normal concrete at equivalent compressive strength levels.

The enhanced flexural tensile strength of lightweight concrete can be attributed to the unique characteristics of the polymer artificial aggregates, which contribute to improved energy absorption and crack resistance. The presence of polymer aggregates, such as those derived from polymer lightweight aggregate, likely provides additional resilience under bending stress, thereby enhancing the overall ductility and toughness of the material. This improvement in performance is particularly beneficial for biomedical infrastructure applications, where both durability and weight reduction are critical factors.

In addition to the observed differences in flexural strength, the crack patterns of both normal concrete and lightweight concrete were also analyzed following the flexural tensile strength testing. As depicted in Figure 5a–c, the crack patterns exhibited by both types of concrete were similar in nature, suggesting that the polymer-based lightweight aggregates did not significantly alter the fundamental cracking behavior of the material under bending stress. The cracks typically initiated at the tension face of the specimens and propagated through the matrix, although the propagation and ultimate failure of the lightweight concrete specimens appeared to be more gradual, likely due to the improved ductility provided by the polymer aggregates.

These observations highlight the ability of lightweight concrete to maintain a similar cracking behavior to that of normal concrete while offering significant improvements in tensile strength. The increased flexural performance of BR, particularly at lower strength grades ( = 17.5 MPa), suggests that polymer-based lightweight concrete mixes may offer a viable alternative to traditional concrete in applications where both strength and reduced weight are essential.

3.6 Concrete Durability Test Results

To evaluate the durability of artificial polymer aggregate concrete incorporating fly ash, a series of immersion and high-temperature resistance tests were conducted. The immersion tests simulated exposure to various environmental conditions over 28 days presented in Figure 6. The immersion media included neutral water obtained from the Tirta Musi Palembang (PDAM) distribution system (pH 6.5), sulfuric acid solutions at 1% (pH 4) and 2% (pH 3.5) concentrations, and brackish water (pH 7.2) sourced from Tanjung Api-Api in the Banyuasin Regency. The sulfuric acid solutions were prepared by diluting 0.1 L (1%) and 0.2 L (2%) of H2SO4 in 9.9 and 9.8 L of PDAM water, respectively. The results of compressive strength tests after 28 days of immersion are summarized in Table 6.

| Variation | Age | Compressive strength of concrete (MPa) | |||

|---|---|---|---|---|---|

| Days | PDAM water | Sulfuric acid 1% | Sulfuric acid 2% | Brackish water | |

| Normal concrete (BN) = 30 MPa | 28 | 30.79 | 20.65 | 20.37 | 15.11 |

| 30.85 | 22.63 | 20.63 | 20.93 | ||

| 30.78 | 22.06 | 20.08 | 18.10 | ||

| Average | 30.81 | 21.78 | 20.36 | 18.05 | |

| Lightweight concrete (BR) = 30 MPa | 28 | 29.98 | 21.27 | 19.82 | 18.25 |

| 28.93 | 20.67 | 19.79 | 17.97 | ||

| 29.64 | 21.41 | 19.77 | 17.63 | ||

| Average | 29.52 | 21.12 | 19.79 | 17.95 | |

Immersion in sulfuric acid significantly reduced the compressive strength of both normal and lightweight concrete. The 1% sulfuric acid solution resulted in a strength reduction of ~30% for normal concrete and about 28.5% for lightweight concrete. This decline became even more pronounced with the 2% sulfuric acid solution, which caused reductions of around 33.9% for normal concrete and 33.0% for lightweight concrete. The aggressive nature of sulfuric acid likely initiated chemical reactions that compromised the structural integrity of the concrete. In addition, exposure to brackish water also led to significant reductions in compressive strength. Normal concrete experienced a decrease of ~41.5%, while lightweight concrete showed a decline of about 39.2%. This suggests that the ionic solutions present in brackish water negatively impacted the hydration products and bonding within the concrete matrix. In contrast, immersion in neutral PDAM water demonstrated the least impact on compressive strength, serving as a baseline for comparison and highlighting the protective role of neutral pH conditions. Overall, the durability tests clearly indicate that exposure to aggressive chemical environments, such as acidic solutions and saline waters, significantly decreases the compressive strength of concrete.

Additionally, high-temperature durability was assessed by subjecting cylindrical concrete specimens to combustion in a controlled environment using a custom-built furnace constructed from refractory materials. The furnace was heated with LPG burners installed on both sides to ensure uniform temperature distribution. The specimens were exposed to temperatures up to 1000°C for durations of 1, 2, and 3 h, and their post-combustion compressive strengths are provided in Table 7.

| Code | Age | Compressive strength of concrete with combustion time (MPa) | Reduction from normal concrete (BN) (%) | |||||

|---|---|---|---|---|---|---|---|---|

| Days | Normal | 1 h | 2 h | 3 h | 1 h | 2 h | 3 h | |

| BN_30 | 28 | 30.81 | 18.48 | 16.97 | 11.69 | 40.02 | 44.92 | 62.06 |

| BR_30 | 28 | 29.52 | 16.97 | 12.73 | 9.32 | 42.51 | 56.88 | 68.43 |

| BN_20 | 28 | 22.16 | 12.37 | 9.44 | 5.41 | 44.18 | 57.40 | 75.59 |

| BR_20 | 28 | 20.93 | 10.65 | 5.85 | 4.62 | 49.12 | 72.05 | 77.93 |

| BN_17,5 | 28 | 18.04 | 9.77 | 5.83 | 4.04 | 45.84 | 67.68 | 77.61 |

| BR_17,5 | 28 | 18.88 | 8.75 | 4.03 | 3.15 | 53.65 | 78.65 | 83.32 |

The data provided in Table 7 clearly demonstrate a significant reduction in compressive strength post-exposure, with samples designated as BR, which incorporate polymer lightweight aggregate containing epoxy resin that exhibits even more pronounced strength losses compared to their normal counterparts (BN). For instance, BR_30 experienced a compressive strength reduction of up to 68.43% after 3 h of exposure to high temperatures, while BN_30 had a relatively lower reduction of 62.06%. The presence of PLA, known for its lightweight and biodegradable properties, poses specific challenges at elevated temperatures due to the inclusion of epoxy resin. While epoxy resins provide good adhesive and mechanical properties under standard conditions, they are vulnerable to thermal degradation. As temperatures increase, epoxy resins begin to decompose, leading to a loss of structural integrity and the potential formation of volatiles, which can weaken the concrete matrix. The pyrolysis of PLA and its epoxy components can generate internal pore pressure, causing microcracking and spalling, which further exacerbates the reduction in compressive strength. Research indicates that such thermal instability is particularly concerning for materials exposed to prolonged high temperatures [56, 57]. This explains the trade-offs involved in utilizing lightweight aggregates like polymer lightweight aggregate that contain epoxy resin, highlighting the need for careful consideration of material selection in applications requiring fire-resistant properties. The pronounced reduction in compressive strength observed in BR samples ultimately reflects the complex interplay between material composition and thermal effects, necessitating further exploration to enhance fire resistance while maintaining structural performance. To address the significant reduction in compressive strength observed in samples containing polymer lightweight aggregate and epoxy resin post-exposure to high temperatures, it is crucial to explore alternative materials and design strategies that enhance thermal stability while preserving the benefits of lightweight aggregating. One approach could involve modifying the formulation of the epoxy resin to improve its heat resistance, such as incorporating heat-resistant fillers or additives that can help mitigate thermal degradation during exposure to elevated temperatures [58].

To address the significant reduction in compressive strength observed in samples containing polymer lightweight aggregate and epoxy resin post-exposure to high temperatures, it is crucial to explore alternative materials and design strategies that enhance thermal stability while preserving the benefits of lightweight aggregating. One approach could involve modifying the formulation of the epoxy resin to improve its heat resistance, such as incorporating heat-resistant fillers or additives that can help mitigate thermal degradation during exposure to elevated temperatures [59]. Moreover, integrating hybrid composites that combine polymer lightweight aggregate with more thermally stable polymers could provide a synergistic effect, leveraging the lightweight and biodegradable attributes of polymer lightweight aggregate without compromising the structural integrity typically associated with conventional polymers. Additionally, using protective coatings or reinforcing fibers could help improve the thermal and mechanical properties of the concrete matrix, offering a more resilient composite material under thermal stress. Future research should focus on optimizing these alternative materials and their combinations to enhance fire resistance, ensuring that the performance of lightweight aggregates remains viable for various construction applications [60].

3.6.1 Immersion Durability Analysis

The compressive strength results showed a decline in mechanical performance in chemically aggressive environments. Normal concrete experienced greater strength reductions in sulfuric acid and brackish water compared to lightweight concrete that used artificial polymer aggregate. This indicates that the lightweight concrete mixture had better resistance to chemical attack, likely due to the polymeric properties of the aggregate and the pozzolanic effect of fly ash, which can help densify the matrix.

In comparison to the findings of Gence et al. [63], which indicated that the addition of glass sand to foam concrete positively influenced various material properties, these results highlight the importance of utilizing alternative materials to improve mechanical properties and resistance to aggressive environments. Gence et al. [63] reported that increased glass sand content enhanced flowability and overall strength due to better bonding between the glass and the matrix, even reducing alkali-silica reaction (ASR) expansion by up to 38%, thereby demonstrating its durability benefits. Similarly, Bayraktar et al. [64] showed that replacing silica sand with wood powder could improve compressive strength while maintaining effective workability, presenting a potential avenue for lower CO2 emissions and costs. Their findings regarding freeze–thaw resistance further complement the current study's observations, highlighting how various materials can significantly enhance concrete durability. Finally, the insights from Bayraktar et al. [64], which identified beneficial effects from incorporating whey protein and cellulose powder into foam concrete, emphasize the importance of innovative approaches to enhance concrete performance under environmental stressors. Given these insights, it is essential for future research to include freeze–thaw resistance testing on concrete samples utilizing polymer lightweight aggregate to further validate their durability in low-temperature conditions. This exploration will serve as a critical avenue for future investigations aimed at enhancing the performance of concrete structures in challenging environments, ultimately strengthening their longevity and resilience [65].

3.6.2 Thermal Resistance Performance

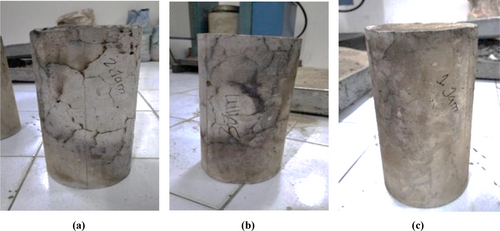

As shown in Table 7, exposure to elevated temperatures caused a significant reduction in compressive strength for both normal and lightweight concrete specimens. Lightweight concrete (BR_30, BR_20, and BR_17.5) experienced strength losses ranging from 40.02% to 83.32%, depending on the duration of exposure. The reduction was more pronounced in lightweight concrete due to the thermal degradation of the polymer aggregate, particularly the epoxy component, which undergoes decomposition and evaporation at elevated temperatures. This phase change not only weakens the interfacial transition zone but also generates internal pore pressure, leading to microcracking and spalling [60].

Water in the micro and capillary pores evaporates at temperatures exceeding 100°C, leading to dehydration of calcium silicate hydrate (C-S-H) gels (an essential binding phase in concrete), which begins to destabilize at temperatures around 400°C. Additionally, the combustion of polymer-based aggregates contributes to the formation of voids, exacerbating structural deterioration. The use of polymer lightweight aggregate as a lightweight aggregate replacement further contributes to the observed effects, as polymer lightweight aggregate and its epoxy components are susceptible to pyrolysis and volatilization under high thermal loads. The pronounced odor and blackened patterns observed in burned specimens (Figure 10a,b) affirm the degradation of organic components within the artificial polymer aggregates. These results emphasize the trade-off between weight reduction and thermal resistance in designing sustainable concrete materials for critical biomedical infrastructure applications where temperature regulation and fire safety are paramount.

In contrast, the study by Koksal et al. [66] explored the use of waste brick powder (WBP) as a supplementary material in alkali-activated lightweight mortars, demonstrating significant improvements in fire resistance performance. WBP, noted for its pozzolanic properties, was combined with ground blast furnace slag (GBFS) as precursors, producing mortars that exhibited varying performance based on curing regimes. Air-cured mortars showed superior compressive and flexural strengths, with the 50% WBP incorporation exhibiting remarkable thermal resistance during high-temperature tests. The findings indicated that WBP can enhance the mechanical properties while also providing additional fire resistance benefits, establishing it as a promising alternative for high-performance construction materials. Similarly, Koksal et al. [67] investigated the impacts of calcium aluminate cement (CAC) and Portland cement (PC) in conjunction with expanded vermiculite powder (EVP) to enhance the insulating and fire-resistant properties of lightweight mortars. Their results revealed that the EVP/CAC ratio significantly influenced performance under high temperatures, with a ratio of four yielding the best compressive strength and a ratio of 6 achieving the lowest thermal conductivity at both 20°C and 1100°C. This study further substantiated the potential of using CAC and EVP in creating effective fire-resistant cement-based composite coatings, thus reinforcing the importance of optimizing materials for improved mechanical, insulating, and fire-resistant properties in modern construction applications. Overall, the findings across these studies emphasize the necessity of balancing thermal resistance and structural integrity in designing lightweight concrete and mortar systems suitable for critical applications.

3.7 SEM Analysis of Normal and Lightweight Concrete Under Immersion Durability Conditions

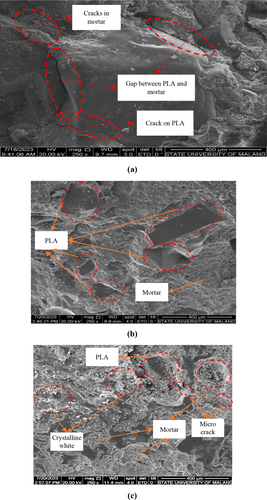

To assess the microstructural characteristics and surface morphology of artificial polymer aggregate lightweight concrete (BR) compared to conventional concrete (BN), detailed SEM analysis was performed on samples with a polymer lightweight aggregate-to-fly ash ratio of 70:30. After a 28-day curing period, the specimens were immersed in three different aqueous environments: drinking water (PDAM), a 2% sulfuric acid solution, and brackish water sourced from Tanjung Api-api. The SEM micrographs presented in Figure 11a–c illustrates the microstructural variations of the BR samples under these different immersion conditions. The BR specimens immersed in PDAM water (Figure 11a) demonstrate a relatively intact and compact microstructure, reflecting the basic morphology of the concrete without significant aggressive chemical changes. It is evident that the polymer lightweight aggregate and the matrix are well bonded; however, there are cracked areas in both the mortar and the polymer lightweight aggregate. This observation is attributed to the fact that the SEM samples were taken from specimens that had undergone compressive strength testing.

In contrast, the BR specimens exposed to the 2% sulfuric acid solution (Figure 11b) show minimal microstructural changes compared to the PDAM-immersed samples. Visually, it is clear that the polymer lightweight aggregate component is distinctly visible, while the matrix appears smoother compared to the normal sample. The smoother and more homogeneous surface of the acid-treated BR sample can be attributed to the partial dissolution of reactive components in the cement matrix, particularly calcium hydroxide [Ca(OH)2]. This compound reacts with sulfuric acid to form soluble by-products such as calcium sulfate, which promotes surface smoothing by altering the microtexture. As a result, this chemical interaction effectively neutralizes the inherent alkalinity of the concrete and transforms irregular surface textures into a more planar form, as supported by relevant literature demonstrating that acid exposure can lead to material degradation through the dissolution of alkali hydroxides [68-70].

Conversely, the BR specimen immersed in brackish water (Figure 11c) exhibits a significantly rougher and more granular surface. Visually, it can be observed that many white crystalline deposits cover parts of the matrix, with the polymer lightweight aggregate component becoming less distinct. The presence of these white crystalline precipitates indicates the precipitation of calcium hydroxide or other salt-based by-products resulting from ionic exchange reactions in this alkaline environment (pH > 7). This granulation raises concerns, as it can compromise the long-term durability of the material by promoting increased porosity and initiating microcracks, potentially leading to premature degradation of the concrete matrix. Moreover, this phenomenon highlights the important role of environmental pH and ionic concentration on hydration kinetics and leaching dynamics that affect concrete integrity. Overall, these findings highlight the significance of understanding the microstructural response of concrete to various chemical environments for the development of more resilient construction materials.

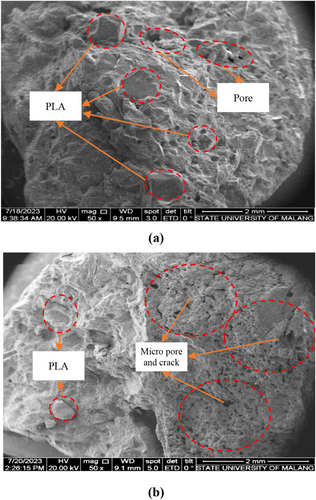

3.8 SEM Analysis of Combustion Durability in Normal and Lightweight Concrete

To further assess the thermal resistance of polymer aggregate concrete, combustion resistance tests were conducted on lightweight concrete (BR) specimens using a polymer lightweight aggregate-to-fly ash ratio of 70:30, which were cured for 28 days. This evaluation aimed to simulate the material's behavior under high-temperature conditions, reflecting potential fire exposure scenarios relevant to biomedical infrastructure and other built environments requiring lightweight and fire-resistant materials. SEM microstructural analysis was performed to compare unexposed BR specimens (control) with those subjected to a controlled combustion simulation for 3 h. Figure 12a,b present the respective SEM micrographs, which clearly illustrate the morphological changes induced by thermal loading. Prior to combustion (Figure 12a), the BR specimens exhibited a relatively smooth and homogeneous surface, indicating effective integration between the polymer and the cement matrix, as well as minimal porosity. The arrangement of the polymer lightweight aggregate and matrix is visually evident, albeit with some porous edges. This microstructure supports mechanical integrity and promotes effective bonding between the fly ash-modified binder and the polymer lightweight aggregates. However, post-firing analysis (Figure 12b) revealed substantial microstructural degradation. Visually, the SEM image shows that the polymer lightweight aggregate turns white due to the combustion process, with the matrix also exhibiting visible holes and microcracks. The surface of the BR specimen exposed to high temperatures shows extensive micropore formation and a significantly rougher texture. This degradation is primarily attributed to the thermal decomposition of the polymer lightweight aggregate components and the forced evaporation of trapped moisture, along with the residual thermal energy within the matrix. The pyrolysis of polymer lightweight aggregate leads to volumetric contraction, gas release, and void formation, all of which compromise the structural cohesion of the composite. The resulting porous structure weakens the interfacial transition zone between the synthetic polymer aggregate and the cementitious binder, thereby reducing overall compressive strength and increasing the brittleness of the material. This observation highlights an important trade-off in the use of polymer lightweight aggregates: while they offer benefits such as sustainability and weight reduction, thermal exposure beyond a certain threshold can significantly compromise the load-bearing capacity and long-term performance of the material. The incorporation of polymeric constituents can improve initial properties but may lead to reduced thermal stability due to the volatile nature of the organic components at elevated temperatures.

3.9 Comparison With Previous Study

The proposed study offers an innovation by utilizing synthetic lightweight aggregates made from a mixture of fly ash, epoxy resin, and a hardener. These polymer lightweight aggregates not only reduce the bulk density of concrete by up to 15.36% but also significantly enhance the flexural strength compared to conventional mixes. However, one limitation noted is the aggregate's resistance to high temperatures; nevertheless, its improved chemical durability and mechanical performance make it an attractive option for biomedical infrastructure applications. In addition to the mechanical benefits, the use of synthetic aggregates derived from industrial by-products like fly ash contributes significantly to the reduction of carbon dioxide (CO2) emissions associated with concrete production. Traditional concrete production is known to be a major contributor to global CO2 emissions, primarily due to the cement manufacturing process, which involves the calcination of limestone at high temperatures, resulting in substantial CO2 release. By incorporating fly ash, a by-product of coal combustion, into the aggregate formulation, the need for conventional cement is diminished, effectively lowering the CO2 footprint of the material. Furthermore, synthetic lightweight aggregates like those proposed in this study can be produced with lower energy inputs compared to traditional aggregates, as they do not require the same high-temperature processing that cement does. This further contributes to a decrease in greenhouse gas emissions associated with aggregate production.

In recent studies on the development of artificial aggregates, several previous research works have shown diverse results, reflecting both the potential and challenges in using alternative materials to enhance sustainability and the performance of concrete. Notably, the research by Dong et al. [71] focused on aggregates produced through alkali activation technology, employing fly ash and sodium silicate/hydroxide solutions. Meanwhile, Kalinowska-Wichrowska et al. [72] explored the use of fly ash and slag (FA-S) mixtures in geopolymer concrete. Their findings indicated that an increase in the molarity of sodium hydroxide could improve compressive strength and reduce water absorption, suggesting that the proportion of pozzolanic materials significantly influences the performance of concrete. This aligns with the results from Mathew et al. [73], who developed artificial aggregates from a mixture of fly ash and sand dust, noting that aggregates with a sodium hydroxide concentration of 12 M demonstrated superior mechanical properties. In comparison with similar studies, Adhitya et al. [13] found that artificial aggregates produced through crushing and pelletizing fly ash with alkali activators resulted in concrete with compressive strength that met the expected design criteria. A comparison of the testing results from various previous studies shows that, although each technique and material composition has its advantages and disadvantages, overall, industry waste-based artificial aggregates provide a sustainable solution capable of meeting the demands of modern construction materials. This is in line with the increasingly emphasized principles of the circular economy in the infrastructure industry, where the use of recycled and alternative materials not only reduces environmental impact but also has the potential to enhance the quality and durability of structures.

Therefore, the integration of synthetic lightweight aggregates derived from waste products like fly ash into concrete formulations not only serves to enhance the mechanical properties of the final product but also plays a crucial role in mitigating CO2 emissions and advancing the sustainability goals of the construction industry. This multifaceted approach not only addresses the immediate needs of performance and durability but also aligns with global efforts to combat climate change through reduced carbon outputs.

4 Conclusions

This study evaluated the mechanical and durability performance of lightweight concrete incorporating polymer lightweight aggregate and fly ash, aiming to develop a sustainable material for biomedical infrastructure. The results showed that using polymer lightweight aggregate reduced the concrete's bulk density by up to 15.36% while meeting compressive strength standards for BR_17.5 and BR_20 mixtures. Flexural strength improved significantly, with increases up to 60.57% compared to normal concrete, indicating enhanced crack resistance. Durability tests revealed that polymer lightweight aggregate-based concrete exhibited better resistance to sulfate and brackish water, with lower reductions in compressive strength than conventional concrete. Although high-temperature exposure reduced compressive strength due to polymer lightweight aggregate decomposition, the performance decline was gradual, suggesting potential for further thermal enhancement. Overall, the combination of lightweight properties, mechanical performance, and chemical durability positions this concrete as a promising sustainable material for future biomedical infrastructure applications.

Author Contributions

Ani Firda: conceptualization, data curation, formal analysis, funding acquisition, methodology, investigation, writing – original draft. Rosmalinda Permatasari: resources, supervision, writing – review and editing. Hendrik Jimmyanto: software, visualization, writing – review and editing. Muhammad Imam Ammarullah: project administration, validation, writing – review and editing.

Acknowledgments

The authors gratefully thank the authors' respective institutions for their strong support in this study. The authors declare the use of generative artificial intelligence (AI) and AI-assisted technologies in the preparation of this manuscript. Specifically, ChatGPT (version GPT-4, OpenAI) was used to improve the readability and language of the article. The AI tool was not used for data analysis, interpretation of results, or drawing scientific conclusions. All content has been reviewed and verified by the authors to ensure accuracy and integrity.

Ethics Statement

The authors have nothing to report.

Consent

The authors consent to the publication of this manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

The necessary data used in the manuscript are already present in the manuscript.