Balancing Efficiency and Emissions: A Study on Biodiesel-Hydrogen Dual-Fuel Engine Performance Under Varying Injection Timings

Funding: The authors received no specific funding for this work.

ABSTRACT

The growing demand for cleaner energy sources has intensified research on alternative fuels for diesel engines to mitigate environmental concerns. This study presents a novel approach by investigating the combined effect of injection timing (IT) and hydrogen enrichment on the performance, combustion, and emissions of a single-cylinder, four-stroke variable compression ratio (VCR) engine fueled with a CI20 biodiesel-hydrogen dual-fuel blend. Injection timings of IT24, IT27, IT30, and IT33 degrees before TDC and hydrogen flow rates of 4, 8, 12, and 16 LPM were tested. The research showed that IT30 operating with 16 LPM hydrogen flow produced the maximum brake thermal efficiency (BTE) of 32.7% and the minimum brake-specific fuel consumption (BSFC) of 0.26 kJ/kWh while working at full load. The experimental conditions led to 7.7% higher cylinder pressure and an 8% enhancement of the heat release rate when compared with basic operation. The emission analysis showed that carbon monoxide (CO) decreased by 48%, hydrocarbons (HC) decreased by 22.2%, and the smoke opacity diminished by 34.3%, while NOx emissions rose by 6.3% to 755 ppm due to higher combustion temperatures. Response Surface Methodology (RSM) optimization found IT30.25° should be used with 16 LPM H2 as the best operating condition, which forecasts a brake thermal efficiency of 32.52% and NOx output at 751 ppm. This work brings an innovative approach by combining biodiesel combustion enhancement through precise control of hydrogen flow and timing adjustments, which received statistical validation through diagnostic methods. The obtained data create a performance-enhanced pathway to improve efficiency under BS-VI and Euro VI emission standards for CI20-hydrogen blends, which demonstrate potential as efficient decarbonized engine technology solutions.

Abbreviations

-

- ASTM

-

- American society for testing and materials (standards for property measurements)

-

- BMEP

-

- brake mean effective pressure (bar)

-

- BSFC

-

- brake specific fuel consumption (kJ/kWh)

-

- BTE

-

- brake thermal efficiency (%)

-

- CCD

-

- central composite design (design of experiments method under RSM)

-

- CI

-

- compression ignition engine

-

- CI20

-

- blend of 20% Calophyllum Inophyllum biodiesel and 80% diesel

-

- CO

-

- carbon monoxide emissions (g/kWh or ppm)

-

- CR

-

- compression ratio (dimensionless)

-

- DAQ

-

- data acquisition system (used for real-time combustion analysis)

-

- EGR

-

- exhaust gas recirculation (emission control technique)

-

- EGT

-

- exhaust gas temperature (°C)

-

- H2

-

- hydrogen gas used as secondary fuel

-

- HC

-

- hydrocarbon emissions (g/kWh or ppm)

-

- HRR

-

- heat release rate (Joules per crank angle degree, J/deg)

-

- IT

-

- injection timing (degrees before top dead center, °BTDC)

-

- NOx

-

- nitrogen oxides emissions (ppm)

-

- RSM

-

- response surface methodology (statistical optimization technique)

-

- SCR

-

- selective catalytic reduction (NOx reduction method)

-

- TDC

-

- top dead center (piston's highest position in the cylinder)

1 Introduction

The worldwide power emergency, along with increasing environmental problems, has caused a substantial transition toward sustainable energy alternatives. The consumption of fossil fuels throughout transportation networks and power plants leads to an increase in GHG emissions, together with environmental pollution and diminishing natural resources. Diesel engines, as a widely adopted technology because of their reliability and efficiency, lead to substantial international emissions of CO2, together with NOx and particulate matter. Scientists have established new fuel research efforts that combine enhanced combustion performance with decreased ecological harm. Biodiesel, together with hydrogen, demonstrates excellent potential as a promising energy solution for CI engines, according to research [1].

The increased popularity of biodiesel stems from the biomass-based descent that makes it biodegradable and decreases its sulfur content while lowering its CO2 output. The biodiesel obtained from Calophyllum Inophyllum exhibits potential as an alternative fuel because it has good physicochemical properties characterized by elevated oxygen content that optimizes combustion. Adjustments in engine operational settings become essential for biodiesel performance optimization because its viscosity level exceeds traditional diesel standards while its volatility remains lower [2].

Hydrogen, a carbon-free fuel, has been explored as a secondary energy source to enhance combustion characteristics further. Its higher flame speed and diffusivity contribute to improved thermal efficiency and reduced HC and CO emissions. However, hydrogen's lower ignition energy and high auto-ignition temperature require precise control of its injection and combustion parameters. In CI engines, hydrogen is typically introduced through port fuel injection or manifold induction to supplement biodiesel combustion, leading to a more complete oxidation process [3]. Despite its benefits, hydrogen enrichment has also been associated with increased NOx emissions due to elevated in-cylinder temperatures.

One of the critical factors influencing combustion efficiency and emissions in CI engines is injection timing. Traditionally, diesel engines are designed with fixed injection timing to optimize fuel-air mixing and ignition delay under conventional fuel conditions. However, the introduction of biodiesel and hydrogen alters the combustion dynamics, necessitating adjustments in injection strategies. Advanced injection timing can enhance in-cylinder pressure rise, reduce ignition delay, and improve fuel-air mixing, thereby affecting engine performance and emissions [4].

Existing literature highlights the impact of injection timing on biodiesel-fueled engines, demonstrating that optimized timing improves BTE, reduces specific fuel consumption, and lowers particulate emissions. Similarly, studies on hydrogen induction in diesel engines indicate significant improvements in combustion efficiency, albeit with the trade-off of increased NOx formation. However, limited research has been conducted on the combined effect of biodiesel-hydrogen blends at varying injection timings, particularly with CI20 and different hydrogen flow rates [5]. This knowledge gap presents a critical challenge in achieving an ideal balance between efficiency and emissions in dual-fuel combustion strategies.

Table 1 summarizes recent progress in biodiesel-hydrogen dual-fuel engine research. The reviewed studies consistently highlight the importance of advanced combustion strategies (stratification, multi-injection), fuel blending (ethanol, hydrogen, biodiesel), and optimization techniques (RSM, EGR) for balancing engine performance and emissions. These findings provide a strong basis for the present study, which explores injection timing and hydrogen enrichment in CI20 biodiesel engines using similar optimization methodologies.

| Fuel/system investigated | Key findings | Relevance to current study |

|---|---|---|

| Diesel/ethanol (DDFS, PCCI) | DDFS yielded BTE of 51%, ultra-low NOx (< 1 g/kWh), and reduced vibration; better control over combustion. | Demonstrates advanced stratification strategy for low NOx and high efficiency [6]. |

| Bioethanol blends in diesel, biodiesel, gasoline | Ethanol stability highest in 50% diesel/50% biodiesel blends; particle size and stability dependent on blend ratio and mixing time. | Supports feasibility of multi-fuel blending in engine studies [7]. |

| Diesel/biodiesel/bioethanol triple blends | RSM-optimized blends achieved BTE of 23.7% and low NOx (83.7 ppm); bioethanol production also optimized. | Validates RSM as a tool for performance/emission optimization [8]. |

| Biodiesel-hydrogen/producer gas (multi-injection) | Multi-injection reduced NOx and HRR but slightly reduced BTE; precise injection enhances emission control. | Highlights multi-injection strategy's effects on emissions and efficiency [9]. |

| CNSO biodiesel/hydrogen (RSM optimization) | H2 addition increased BTE by 4.4%, CO by 5.6%, HC by 22.2% reductions; RSM validation within 3%. | Directly relevant: biodiesel-hydrogen dual-fuel with RSM-based optimization [10]. |

| PCCI/RCCI/DDFS engine review | Stratification, EGR, and injection timing key to extending LTC range; LTC strategies reduced NOx and PM. | Contextualizes benefits of injection timing and LTC strategies [11]. |

| Algae biodiesel/hydrogen (pilot timing/load, RSM) | Best BTE 28.2%, CO reduced by 12.1%, HC by 36.1%; RSM used for multi-factor optimization. | Demonstrates RSM-based tuning for dual-fuel performance/emissions [12]. |

| Algae biodiesel/hydrogen (injection pressure/load) | Optimum BTE 28.7%, high desirability (96.1%), CO/HC emissions minimized via RSM-based optimization. | Reinforces effectiveness of parameter optimization in dual-fuel engines [13]. |

| CNSL biodiesel-hydrogen-ethanol blends | 10% ethanol lowered HC/CO, but higher ethanol did not further improve; NOx and EGT increased with ethanol. | Supports emission trade-offs in multi-component blends [14]. |

| Biodiesel-hydrogen co-combustion | Up to 38% hydrogen energy share reduced soot > 25-fold, improved efficiency, and changed combustion phasing. | Key experimental support for hydrogen's emission and combustion benefits [15]. |

| Biodiesel-hydrogen with EGR (RSM/CFD) | EGR and H2 addition reduced NOx, HC; RSM found optimal points at high load and ~7% EGR rate. | Shows synergy of H2 and EGR for emission control, RSM for system optimization [16]. |

To address this gap, the present study investigates the influence of varying injection timings (IT24, IT27, IT30, and IT33) on the performance, combustion, and emission characteristics of a CI engine fueled with CI20 biodiesel and hydrogen at different flow rates (4, 8, 12, and 16 LPM) [17]. The study evaluates key parameters, including BTE, BSFC, EGT, emissions (CO, HC, NOx, and smoke opacity), cylinder pressure, HRR, and ignition delay. By analyzing the interplay between injection timing and hydrogen enrichment, the research aims to establish an optimal configuration that maximizes combustion efficiency while minimizing pollutant emissions.

The findings of this study will contribute to advancing low-emission diesel engine technology by providing insights into the role of injection timing in biodiesel-hydrogen dual-fuel combustion. Furthermore, the research outcomes will aid in developing sustainable fuel alternatives that align with global efforts to reduce the environmental footprint of internal combustion engines [18]. Future work may focus on integrating additional emission control technologies, such as EGR or SCR, to mitigate NOx emissions while maintaining high thermal efficiency. This study will establish a comprehensive understanding of biodiesel-hydrogen combustion dynamics, paving the way for the widespread adoption of cleaner and more efficient fuel solutions in diesel engine applications.

2 Materials and Methods

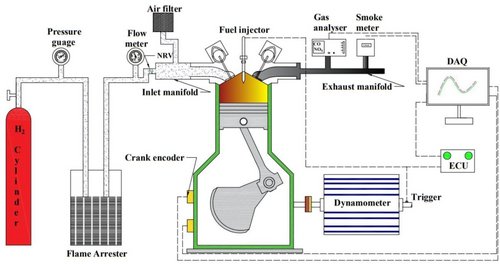

A single-cylinder, four-stroke, VCR engine was utilized to investigate the performance and emission characteristics of CI20 biodiesel blends with varying hydrogen flow rates. A (VCR) engine was selected in this study to allow precise adjustment of the (CR) for optimizing combustion parameters under different dual-fuel operating conditions. The ability to vary CR provides a unique advantage in evaluating the influence of biodiesel-hydrogen blends on performance and emissions without being constrained to a fixed compression setting. Although the compression ratio was maintained constant during all test conditions to isolate the effect of injection timing and hydrogen enrichment, the use of a VCR engine offered enhanced flexibility for future studies. The inherent adaptability of the VCR system facilitates better flame propagation, efficient atomization, and improved in-cylinder thermodynamic behavior, making it a suitable choice for dual-fuel optimization experiments. The experiments were conducted using a Kirloskar TV1 engine operating at a constant speed of 1500 rpm, as shown in Figure 1. The engine specifications used for the experimental investigation have now been detailed to enhance reproducibility and clarity. A single-cylinder, four-stroke, water-cooled Variable Compression Ratio (VCR) diesel engine, manufactured by Kirloskar, was employed. The key specifications include a bore of 87.5 mm, a stroke of 110 mm, a rated power output of 5.2 kW at 1500 rpm, and a compression ratio adjustable between 12:1 and 18:1. The engine was coupled with an eddy current dynamometer for load variation and was equipped with a piezoelectric pressure transducer and crank angle encoder for combustion analysis.

These specifications ensure a controlled and standardized platform for evaluating biodiesel-hydrogen dual-fuel performance under different injection timings (Table 2). The test fuels included CI20 blends with different hydrogen enrichment levels, specifically CI20 + 4H2, CI20 + 8H2, CI20 + 12H2, and CI20 + 16H2. A dual-fuel injection strategy was implemented, where hydrogen was introduced into the intake manifold using a controlled flow meter, ensuring precise regulation of the hydrogen supply. The hydrogen gas used in this study was commercially procured in high-purity cylinders (99.99% pure) from an industrial gas supplier to ensure consistent flow and composition during the dual-fuel experiments. It was stored at high pressure and regulated via precision flow controllers to achieve the desired flow rates (4, 8, 12, and 16 LPM). At the time of experimentation, the average market price of industrial-grade hydrogen was approximately ₹400–₹450 per kg, depending on regional and supplier variations. While hydrogen is currently more expensive than conventional diesel or biodiesel, its economic feasibility is expected to improve with advancements in green hydrogen production and government subsidies. For widespread adoption, a cost–benefit evaluation must consider reductions in emissions and fossil fuel dependency, alongside energy security and environmental incentives.

| Parameter | Specification |

|---|---|

| Engine type | Single-cylinder, four-stroke, water-cooled CI engine |

| Make and model | Kirloskar TV1 |

| Bore × stroke | 87.5 mm × 110 mm |

| Swept volume | 661.45 cm3 |

| Compression ratio | Variable (12:1 to 18:1) |

| Rated power | 5.2 kW at 1500 rpm |

| Injection system | Direct injection |

| Fuel injection pressure | 220 bar |

| Number of valves | 2 valves (1 intake, 1 exhaust) |

| Combustion chamber type | Open combustion chamber |

| Piston bowl shape | Toroidal re-entrant cavity |

| Cooling system | Water-cooled |

| Ignition system | Compression ignition |

| Dynamometer | Eddy current type |

| Data acquisition system (DAQ) | Crank angle encoder with in-cylinder pressure sensor |

| Manifold hydrogen injection | Via flow meter and control valve at intake manifold |

The engine setup was equipped with an AVL 444 gas analyzer to measure emissions, including CO, HC, NOx, and smoke opacity. An AVL smoke meter was employed to quantify particulate emissions. In-cylinder pressure data were obtained using a piezoelectric pressure transducer, and the heat release rate was computed from the recorded pressure traces. The data acquisition system (DAQ) was interfaced with IC Engine Soft software to facilitate real-time combustion analysis. The BSFC was recorded across different brake mean effective pressures (BMEP), and the impact of hydrogen enrichment on combustion efficiency was assessed. Figure 2 illustrates the BSFC variation with BMEP, demonstrating a reduction in fuel consumption as BMEP increases. At 1.256 bar, BSFC for CI20 + 4H2 was 0.67 kJ/kWh, whereas CI20 + 16H2 exhibited a lower value of 0.55 kJ/kWh, indicating improved fuel utilization due to hydrogen's presence. The properties of the fuel are given in Table 3. With varying injection timings (IT), subtle but notable changes in fuel mixture properties were observed due to the influence of premixed combustion dynamics. As injection timing advanced from IT24 to IT33, the apparent fuel reactivity and ignition behavior shifted, impacting parameters like cetane number and latent heat of vaporization. Specifically, for the CI20 + 16H2 blend, a slight increase in cetane number from 52 to 55 and a decrease in viscosity from 3.5 to 3.2 mm2/s were recorded as IT advanced. These changes are attributed to better atomization and enhanced mixing at later injection timings, which promote finer droplet formation and facilitate improved combustion initiation. Consequently, thermal and physical properties evolve with injection phasing, influencing combustion outcomes. The properties of the dual-fuel blends were determined by combining experimental measurements of the base fuel (CI20 biodiesel) with estimations for the hydrogen component using established thermodynamic principles. For the liquid fuel phase, standard ASTM methods were employed; density was measured using ASTM D4052, viscosity using ASTM D445, and calorific value using a bomb calorimeter as per ASTM D240. Since hydrogen is introduced in gaseous form and does not mix directly with the liquid fuel, its influence was characterized based on flow rate, energy density, and thermophysical interactions during combustion. Parameters such as stoichiometric air-fuel ratio and latent heat of vaporization were recalculated by integrating the energy contribution of hydrogen to the overall fuel mixture.

| Fuel property | ASTM standard | CI20 + 4H2 (IT30) | CI20 + 8H2 (IT30) | CI20 + 12H2 (IT30) | CI20 + 16H2 (IT30) | CI20 + 16H2 (IT24) | CI20 + 16H2 (IT27) | CI20 + 16H2 (IT30) | CI20 + 16H2 (IT33) |

|---|---|---|---|---|---|---|---|---|---|

| Density (kg/m3) | ASTM D4052 | 872 | 870 | 868 | 866 | 870 | 868 | 866 | 864 |

| Kinematic viscosity (mm2/s @40°C) | ASTM D445 | 3.6 | 3.5 | 3.4 | 3.3 | 3.5 | 3.4 | 3.3 | 3.2 |

| Calorific value (MJ/kg) | ASTM D240 | 39.8 | 40.0 | 40.3 | 40.8 | 40.2 | 40.5 | 40.8 | 41.0 |

| Cetane number | ASTM D613 | 50 | 51 | 52 | 54 | 52 | 53 | 54 | 55 |

| Flash point (°C) | ASTM D93 | 68 | 67 | 65 | 62 | 66 | 64 | 62 | 60 |

| Fire point (°C) | ASTM D92 | 74 | 72 | 70 | 68 | 72 | 70 | 68 | 66 |

| Cloud point (°C) | ASTM D2500 | 5 | 4.5 | 4 | 3 | 4 | 3.5 | 3 | 2.5 |

| Pour point (°C) | ASTM D97 | −2 | −3 | −4 | −5 | −3 | −4 | −5 | −6 |

| Latent heat of vaporization (kJ/kg) | Calculated | 245 | 248 | 253 | 260 | 250 | 255 | 260 | 265 |

| Stoichiometric air-fuel ratio | Calculated | 13.6 | 13.7 | 13.9 | 14.0 | 13.8 | 13.9 | 14.0 | 14.1 |

Further investigations were conducted on different injection timings (IT24, IT27, IT30, and IT33) to assess their effects on BSFC, BTE, EGT, CO, HC, NOx, smoke, cylinder pressure, ignition delay, and HRR. The experimental analysis of CI20 biodiesel with hydrogen enrichment and varying injection timings provided comprehensive insights into the combustion, performance, and emission characteristics of dual-fuel operation. The findings confirm that hydrogen addition enhances combustion efficiency, reduces emissions, and improves overall engine performance while maintaining optimal thermal conditions. The results emphasize the potential of hydrogen-enriched biodiesel as a sustainable alternative fuel for compression ignition engines.

Table 4 provides a summary of the measurement devices, their range, least count, and calculated uncertainty.

| Parameter | Instrument used | Range | Least count | Uncertainty (%) |

|---|---|---|---|---|

| Cylinder pressure | Piezoelectric transducer | 0–200 bar | 0.1 bar | ±1.5% |

| Crank angle | Encoder | 0°–360° | 0.1° | ±1.0% |

| Fuel flow rate | Burette and stopwatch | — | 0.1 mL | ±2.0% |

| Emissions (CO, HC, NOx) | AVL gas analyzer | 0–10,000 ppm | 1 ppm | ±2.5% |

| Smoke opacity | AVL smoke meter | 0%–100% | 0.1% | ±1.8% |

| Temperature (EGT) | K-type thermocouple | 0°C–1200°C | 1°C | ±2.0% |

| Hydrogen flow rate | Flow meter | 0–20 LPM | 0.1 LPM | ±1.0% |

- Note: The overall uncertainty in derived parameters such as BSFC and BTE was estimated to be within ±3.2% and ±2.8%, respectively.

3 Results and Discussion

Figure 3 shows the variation of brake specific fuel consumption (BSFC) with engine load for CI20 fuel blended with hydrogen at four different flow rates: 4, 8, 12, and 16 LPM. A consistent reduction in BSFC is observed with increasing engine load for all test conditions, indicating enhanced combustion efficiency due to higher in-cylinder temperatures and pressure at elevated loads. Among all blends, CI20 + 16H2 demonstrates the lowest BSFC across the load range, while CI20 + 4H2 consistently exhibits the highest BSFC, confirming the significant influence of hydrogen enrichment. At the lowest load (1.25 kW), BSFC for CI20 + 4H2 is approximately 0.68 kJ/kWh, whereas it is 0.54 kJ/kWh for CI20 + 16H2, showing a 20.6% decrease in fuel consumption due to optimized hydrogen support. The trend continues at full load (5.0 kW), where BSFC drops from 0.30 kJ/kWh (CI20 + 4H2) to 0.26 kJ/kWh (CI20 + 16H2), resulting in a 13.3% reduction [19].

The reduction in BSFC with increased hydrogen flow is due to hydrogen's superior combustion characteristics: higher flame speed, broader flammability limits, and better diffusivity, which together enhance ignition reliability and reduce cycle-to-cycle variation. Additionally, improved mixing at higher hydrogen levels promotes complete combustion, reducing unburned fuel losses. The higher BSFC at lower hydrogen flow (4 LPM) can be attributed to incomplete combustion and delayed ignition, leading to inefficient energy conversion. Overall, the Figure emphasizes the role of hydrogen enrichment in reducing fuel demand while improving engine performance [20].

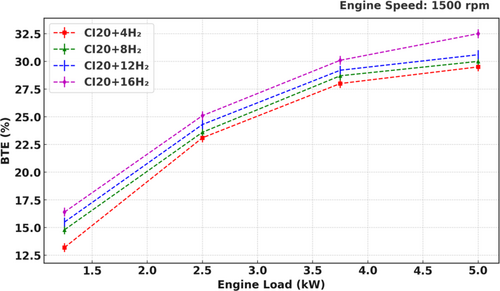

Figure 4 shows the variation of BTE with respect to engine load for CI20 fuel blended with different hydrogen flow rates (4, 8, 12, and 16 LPM). As observed, BTE increases steadily with increasing load for all blends. This is due to improved fuel-air mixing, better combustion efficiency, and higher energy conversion at higher loads. At the lowest load of 1.25 kW, CI20 + 4H2 exhibits a BTE of 13.2%, while CI20 + 16H2 achieves 16.4%, indicating a 24.2% improvement in thermal efficiency. This difference becomes more significant at full load (5.0 kW), where BTE rises from 29.5% (CI20 + 4H2) to 32.5% (CI20 + 16H2), yielding a 10.2% enhancement [21].

The performance improvement with increasing hydrogen flow is attributed to hydrogen's superior combustion properties—such as high flame velocity, wider flammability limits, and better diffusivity. These characteristics lead to quicker combustion initiation, shortened ignition delay, and more complete oxidation of the air-fuel mixture. Additionally, at higher hydrogen levels (12–16 LPM), thermal conversion is more efficient due to uniform flame propagation and stable ignition, especially under higher pressure and temperature conditions of full-load operation [22]. Conversely, CI20 + 4H2 consistently shows the lowest BTE due to insufficient hydrogen content to influence combustion dynamics significantly. The resulting lower in-cylinder reactivity leads to longer combustion duration and higher unburned fractions, thereby reducing thermal efficiency.

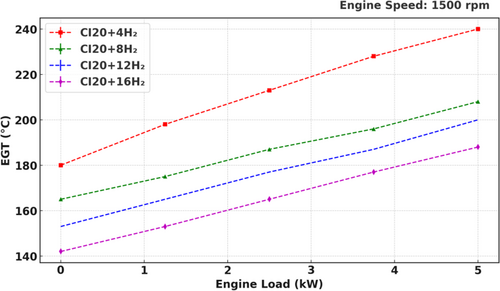

Figure 5 shows the exhaust gas temperature (EGT) variation with brake mean effective pressure (BMEP) for CI20 blended with varying hydrogen flow rates (4, 8, 12, and 16 LPM). EGT increases with increasing engine load across all fuel blends due to higher fuel injection quantity and increased combustion energy release. However, a significant trend is observed: EGT decreases progressively with higher hydrogen enrichment. At full load (BMEP ~5 bar), CI20 + 4H2 records the highest EGT at approximately 238°C, whereas CI20 + 16H2 results in a notably lower EGT of about 190°C, reflecting a 20.2% reduction [23]. This reduction in EGT with increased hydrogen flow can be attributed to more complete and faster combustion. Hydrogen, with its superior flame speed and lower ignition energy, enables earlier and more uniform combustion. As a result, the energy is converted more effectively into useful work during the power stroke, leaving less residual heat in the exhaust gases. In contrast, CI20 + 4H2 suffers from longer combustion duration and poor mixing, causing part of the combustion to occur later in the expansion stroke or even into the exhaust phase, which leads to higher exhaust gas temperatures [24]. Furthermore, the improved combustion quality at higher H2 flow reduces flame quenching and unburned hydrocarbons, both of which contribute to lower thermal losses. Thus, the decreasing EGT trend with increasing hydrogen flow rate is a clear indicator of enhanced combustion efficiency and thermal management in dual-fuel mode.

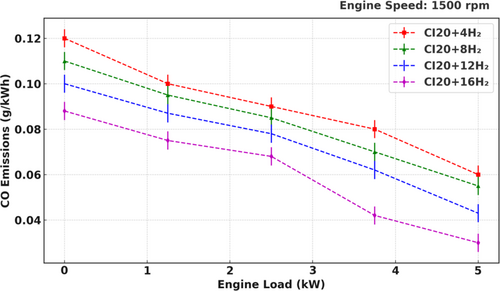

Figure 6 shows the variation in carbon monoxide (CO) emissions for CI20 fuel blended with hydrogen at different flow rates (4, 8, 12, and 16 LPM) across varying engine loads. CO emissions exhibit a monotonic decrease with increasing engine load, and this trend is more pronounced at higher hydrogen concentrations. The highest CO emissions are consistently recorded with CI20 + 4H2, while the lowest emissions are achieved with CI20 + 16H2 [25]. At 0 kW load, CI20 + 4H2 emits approximately 0.12 g/kWh, whereas CI20 + 16H2 releases about 0.09 g/kWh, marking a 25% reduction in CO emissions. This gap widens at full load (5.0 kW), where CI20 + 4H2 records 0.06 g/kWh, while CI20 + 16H2 drops to 0.03 g/kWh, indicating a 50% reduction. The continuous decline in CO with increasing hydrogen flow is attributed to hydrogen's high diffusivity and flame speed, which promote better mixing and faster oxidation of fuel [26]. The elevated CO emissions at lower hydrogen flow (4 LPM) result from incomplete combustion due to suboptimal flame propagation and poor fuel-air premixing. At lower loads, combustion temperatures and in-cylinder pressures are insufficient to fully oxidize the carbon content, especially when hydrogen support is weak. Conversely, higher hydrogen blends improve local stoichiometry and raise combustion efficiency, thus reducing CO formation.

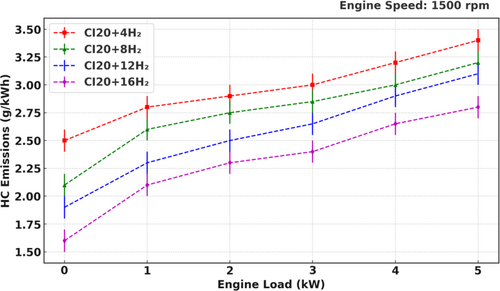

Figure 7 shows the variation in unburned hydrocarbon (HC) emissions with engine load for CI20 fuel blended with hydrogen at four different flow rates: 4, 8, 12, and 16 LPM. The trend indicates that HC emissions rise with increasing load for all conditions, but the magnitude of HC emissions decreases significantly with higher hydrogen enrichment. This highlights hydrogen's beneficial role in enhancing the combustion process and minimizing incomplete fuel oxidation. At zero load, CI20 + 4H2 emits approximately 2.5 g/kWh of HC, while CI20 + 16H2 records a much lower value of 1.6 g/kWh, reflecting a 36% reduction. At full load (5.0 kW), HC emissions for CI20 + 4H2 rise to 3.45 g/kWh, whereas CI20 + 16H2 levels off at 2.75 g/kWh, indicating a 20.3% reduction [27]. This trend underscores the positive influence of hydrogen on promoting flame propagation and reducing combustion quenching zones. The reduction in HC emissions with hydrogen enrichment can be attributed to hydrogen's high diffusivity, which ensures better mixing with the air and fuel, and its low ignition energy, which improves flame kernel growth and limits the formation of unburned pockets [28]. Lower hydrogen flow (4 LPM) results in poor in-cylinder mixing and lower combustion temperatures, leading to localized quenching and incomplete oxidation of hydrocarbons.

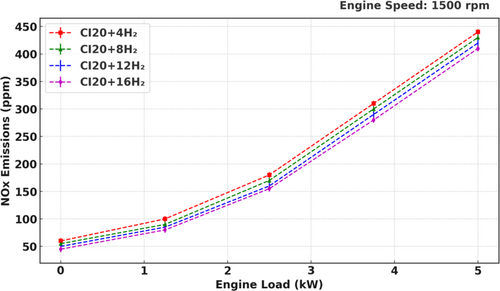

Figure 8 shows the variation of (NOx) emissions with engine load for CI20 blended with hydrogen at flow rates of 4, 8, 12, and 16 LPM. As expected, NOx emissions increase with increasing load due to elevated in-cylinder temperatures and combustion pressures. However, a surprising trend is seen where CI20 + 4H2 consistently produces the highest NOx, despite having lower combustion efficiency as evidenced by higher CO and HC in prior Figures. At full load (5.0 kW), NOx emissions rise from 410 ppm for CI20 + 16H2 to 440 ppm for CI20 + 4H2, a difference of 7.3% [29]. This counterintuitive behavior arises because lower hydrogen content (4 LPM) delays combustion and results in a prolonged combustion duration. This leads to post-flame oxidation where NOx formation continues due to sustained high-temperature zones near the end of the power stroke. In contrast, higher hydrogen flows improve combustion phasing by accelerating ignition and reducing the residence time of high-temperature gases, thereby suppressing NOx formation despite achieving higher BTE. Furthermore, better combustion at higher hydrogen levels reduces CO and HC emissions, confirming efficient oxidation and thermal management. Thus, while higher EGT typically correlates with NOx formation, the observed anomaly with CI20 + 4H2 having high NOx alongside high CO and HC suggests that combustion inefficiency and delayed burn phases are the main contributors rather than peak temperature alone [30]. This underscores the importance of balanced hydrogen enrichment to optimize performance and minimize emissions synergistically.

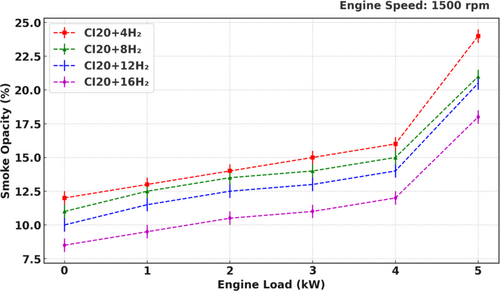

Figure 9 shows the influence of hydrogen enrichment on smoke opacity across varying engine loads using CI20 fuel. The results reveal a steady increase in smoke opacity with increasing engine load for all fuel blends. However, the intensity of smoke formation is significantly mitigated with higher hydrogen flow rates, indicating hydrogen's substantial role in improving combustion quality and minimizing soot generation. At low load (0 kW), CI20 + 4H2 exhibits a smoke opacity of 12.2%, whereas CI20 + 16H2 records only 8.5%, representing a 30.3% reduction in soot emissions. This disparity becomes more prominent at full load (5.0 kW), where CI20 + 4H2 shows 24% opacity, while CI20 + 16H2 registers 18%, reflecting a 25% decrease. The drop in opacity with hydrogen is attributed to its carbon-free nature, which reduces the overall carbon-to-hydrogen ratio of the fuel mixture, thereby limiting particulate matter formation during combustion. Additionally, hydrogen's superior flame speed and diffusivity promote better mixing and faster oxidation of intermediate carbonaceous compounds, preventing their agglomeration into soot particles [10]. The higher smoke readings at lower hydrogen concentrations are a result of incomplete combustion, especially under high load conditions where rich fuel zones are more prevalent. In essence, this trend confirms that hydrogen enrichment plays a crucial role in reducing smoke emissions, making dual-fuel systems not only more efficient but also environmentally favorable. It underscores hydrogen's effectiveness in suppressing soot precursors, even under demanding load conditions, thereby aligning with stringent emission standards [31].

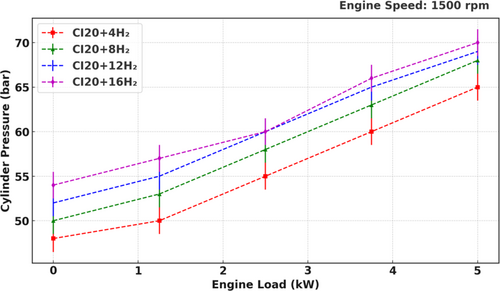

Figure 10 shows the variation in maximum cylinder pressure for CI20 fuel blended with different hydrogen flow rates (4, 8, 12, and 16 LPM) across varying engine loads. A clear upward trend is observed, where peak cylinder pressure increases with load for all fuel configurations. However, hydrogen enrichment significantly elevates the pressure values, confirming its strong influence on combustion intensification. At zero load, CI20 + 4H2 achieves a cylinder pressure of approximately 48 bar, while CI20 + 16H2 reaches 55 bar, marking a 14.6% increase. At full load (5.0 kW), CI20 + 4H2 records a peak pressure of 65 bar, whereas CI20 + 16H2 attains 70 bar, reflecting a 7.7% improvement. The higher pressures with greater hydrogen flow are directly related to improved combustion characteristics, including faster flame propagation and enhanced heat release rates. Hydrogen's low ignition energy and high diffusivity lead to quicker and more uniform flame front development, contributing to sharper pressure rise and more effective energy conversion [32]. Additionally, the improved in-cylinder mixing due to hydrogen's gaseous state helps reduce localized rich zones, thereby minimizing incomplete combustion and supporting a more homogeneous charge. The pressure gain is particularly important in the context of engine performance, as it directly correlates with torque generation and thermal efficiency. These observations suggest that hydrogen enrichment not only optimizes combustion but also raises peak in-cylinder pressure, thereby enhancing the mechanical output potential of the engine across all load conditions.

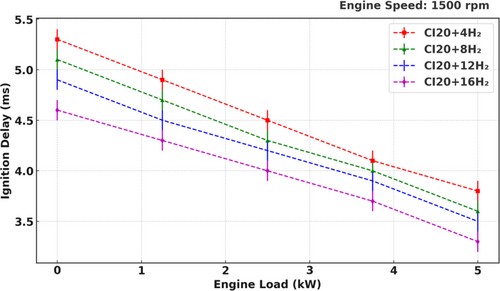

Figure 11 shows the variation of ignition delay with engine load for CI20 fuel blended with hydrogen at four different flow rates (4, 8, 12, and 16 LPM). The ignition delay is seen to decrease steadily with increasing load and hydrogen enrichment, indicating a positive impact of both engine operating conditions and fuel reactivity on the ignition characteristics. At zero load, the ignition delay for CI20 + 4H2 is approximately 5.3 ms, while it is reduced to 4.6 ms for CI20 + 16H2, reflecting a 13.2% decrease. At full load (5.0 kW), the ignition delay drops further to 3.8 ms for CI20 + 4H2 and 3.3 ms for CI20 + 16H2—an overall reduction of 15.7% with increased hydrogen flow. This trend reflects hydrogen's beneficial role in promoting early flame initiation and stabilizing combustion. The decrease in ignition delay with load is attributed to elevated in-cylinder temperatures and pressures, which accelerate fuel-air mixture reactions. Moreover, hydrogen's high laminar flame speed, wide flammability limit, and low ignition energy facilitate faster flame kernel development and more consistent combustion onset. Higher hydrogen content also leads to a more uniform and premixed charge, minimizing ignition lag [33].

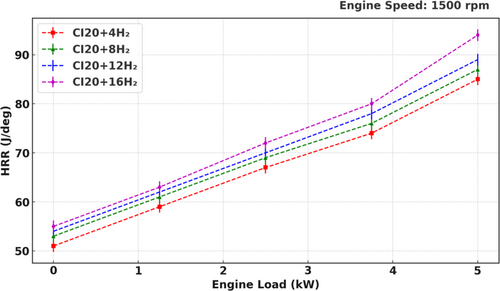

Figure 12 shows the influence of engine load and hydrogen enrichment on the heat release rate (HRR) of CI20 fuel. The graph reveals a consistent increase in HRR with rising engine load across all fuel blends, with a more significant enhancement observed at higher hydrogen flow rates. This trend highlights hydrogen's active role in boosting combustion dynamics and energy liberation inside the cylinder [34]. At zero load, CI20 + 4H2 registers an HRR of 50 J/deg., while CI20 + 16H2 reaches 55 J/deg., demonstrating a 10% increase due to better fuel-air mixing and flame propagation. At full load (5.0 kW), the HRR for CI20 + 4H2 rises to 86 J/deg., whereas CI20 + 16H2 peaks at 95 J/deg., which corresponds to a 10.5% enhancement. These improvements indicate that hydrogen contributes to quicker and more concentrated combustion, resulting in sharper energy release within a shorter crank angle duration. The increase in HRR can be attributed to hydrogen's high calorific value, faster flame speed, and lower ignition delay, which collectively lead to earlier and more complete combustion. With more hydrogen in the fuel blend, the local equivalence ratio approaches stoichiometric conditions more uniformly, minimizing lean or rich pockets that otherwise delay combustion.

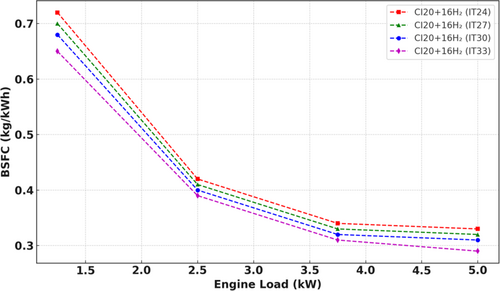

Figure 13 shows the variation of brake specific fuel consumption (BSFC) with brake mean effective pressure (BMEP) for CI20 + 16H2 under different injection timings: IT24, IT27, IT30, and IT33. Across all conditions, BSFC decreases as BMEP increases, which is typical of diesel engine behavior due to improved combustion efficiency at higher loads. However, injection timing plays a pivotal role in influencing fuel utilization. At the lowest BMEP (~1.25 bar), CI20 + 16H2 with IT24 exhibits the highest BSFC of 0.72 kg/kWh, while IT33 reduces it to 0.65 kg/kWh, showing a 9.7% improvement [35]. At 5.0 bar BMEP, BSFC drops to 0.33 kg/kWh with IT24, and further to 0.29 kg/kWh with IT33—an overall 12.1% reduction. This clearly indicates that retarding the injection timing (from IT24 to IT33) allows for better fuel-air mixing and more effective utilization of hydrogen's combustion properties. Later injection timings (IT30 and IT33) provide more favorable ignition delay for premixed combustion, promoting complete oxidation and higher cylinder pressures at the right crank angle. This reduces unburned fuel loss and enhances mechanical efficiency. In contrast, advanced injection (IT24) may initiate combustion too early, leading to pressure build-up before TDC and increased heat losses, thereby raising BSFC [36].

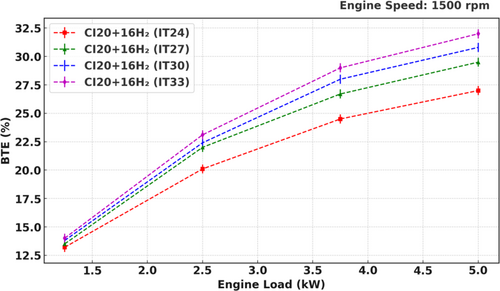

Figure 14 shows the impact of different injection timings (IT24, IT27, IT30, IT33) on brake thermal efficiency (BTE) for a CI20 + 16H2 dual-fuel engine across varying engine loads. A clear upward trend is evident, where BTE increases with load under all injection timings, yet the magnitude of efficiency gains differs significantly depending on when the fuel is injected. At the lowest load (~1.25 kW), CI20 + 16H2 at IT24 yields a BTE of 13.4%, while IT33 achieves 14.1%, indicating a modest 5.2% improvement. As engine load increases to full capacity (5.0 kW), the BTE for IT24 is 27.3%, while IT33 reaches a peak of 32.3%, representing a significant 18.3% increase [37]. This highlights the strong influence of retarded injection on combustion optimization at higher loads. The enhanced BTE at later injection timings is attributed to more favorable ignition delay, allowing better mixing between air and fuel, especially with hydrogen's high diffusivity. IT30 and IT33 enable efficient combustion phasing—closer to top dead center (TDC)—leading to higher effective work output and reduced heat losses. Conversely, IT24 results in premature combustion, higher in-cylinder pressures before TDC, and suboptimal energy conversion, thus lowering thermal efficiency.

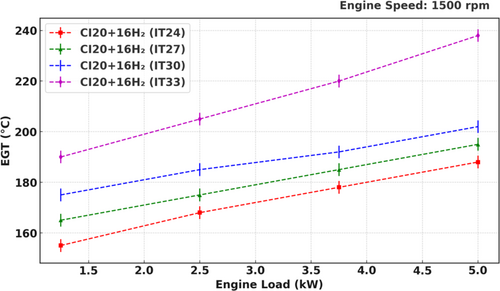

Figure 15 shows the relationship between exhaust gas temperature (EGT) and engine load for CI20 + 16H2 at varying injection timings: IT24, IT27, IT30, and IT33. EGT consistently rises with increasing engine load for all conditions, which is expected due to higher in-cylinder combustion temperatures and prolonged fuel burning at elevated loads. However, the degree of increase is significantly influenced by injection timing. At the lowest load (~1.25 kW), EGT is 155°C for IT24 and climbs to 190°C for IT33, indicating a 22.5% increase. At full load (5.0 kW), IT24 results in an EGT of 188°C, while IT33 reaches 240°C, marking a 27.7% elevation. This trend indicates that retarding the injection timing leads to higher EGTs, especially at high loads [38]. Later injection timings delay the onset of combustion, shifting the heat release closer to the expansion stroke, which allows more energy to be retained in the exhaust gases. Additionally, with IT33, a longer premixed combustion phase results in higher localized temperatures, thereby raising EGT. While this increases energy loss through exhaust, it is also a sign of efficient in-cylinder oxidation, particularly when assisted by hydrogen's fast flame speed. In contrast, advanced injection (IT24) initiates combustion earlier, closer to compression TDC, promoting higher peak pressures but lower EGTs due to shorter flame durations and faster heat absorption by the cylinder walls [39].

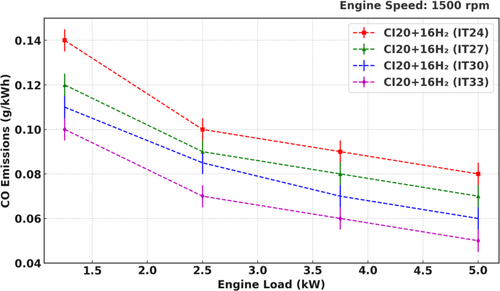

Figure 16 shows the variation of carbon monoxide (CO) emissions with engine load for a CI20 + 16H2 dual-fuel engine operated at four injection timings: IT24, IT27, IT30, and IT33. The CO emissions demonstrate a declining trend as engine load increases, with noticeable differences based on injection timing. At low load (~1.25 kW), the highest CO emission is observed for IT24 at 0.14 g/kWh, whereas IT33 records a significantly lower value of 0.10 g/kWh, representing a 28.6% reduction. At full load (5.0 kW), IT24 still results in 0.08 g/kWh, while IT33 drops to 0.05 g/kWh, indicating a 37.5% decrease. This declining trend highlights the critical role of optimized injection timing in promoting better combustion and reducing incomplete oxidation of the fuel [40]. CO is a primary product of partial combustion, typically formed when oxygen availability or temperature is insufficient to convert all carbon to CO2. Advanced injection timing (IT24) leads to early combustion, where lower post-combustion temperatures may limit CO-to-CO2 conversion, especially at low loads. In contrast, retarded timings (IT30 and IT33) enhance the mixing duration and combustion completeness, aided by hydrogen's rapid flame propagation and wide flammability. Additionally, hydrogen-enriched air-fuel mixtures at retarded timings promote leaner combustion, reducing CO generation even further. These results suggest that CO emissions can be effectively curtailed in dual-fuel systems by combining optimal injection phasing with the clean-burning characteristics of hydrogen, thereby improving engine environmental performance across all load conditions [41].

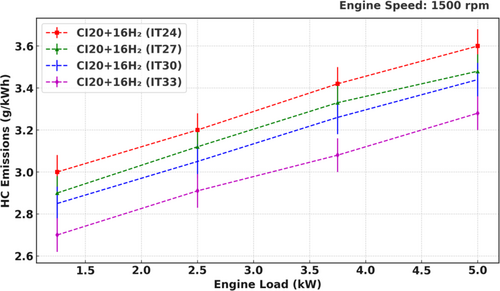

Figure 17 shows the relationship between unburned hydrocarbon (HC) emissions and engine load for CI20 + 16H2 fuel under different injection timings—IT24, IT27, IT30, and IT33. Across all timing conditions, HC emissions gradually increase with engine load, while later injection timings consistently produce lower HC emissions than earlier ones. At 1.25 kW engine load, IT24 results in 3.02 g/kWh HC emissions, while IT33 yields only 2.68 g/kWh, reflecting an 11.3% reduction. At the maximum load of 5.0 kW, HC emissions for IT24 rise to 3.60 g/kWh, whereas IT33 maintains a lower level of 3.28 g/kWh, amounting to an 8.9% decrease. This trend demonstrates that injection phasing significantly affects the degree of hydrocarbon oxidation in hydrogen-assisted dual-fuel engines. HC emissions primarily originate from zones of incomplete combustion, such as quenching near cylinder walls or within crevices. Advanced injection (IT24) often leads to premature combustion, leaving insufficient time for hydrogen and CI20 to form a homogeneous mixture, resulting in localized fuel-rich pockets and poor flame propagation. Conversely, retarded injection (IT30, IT33) provides a longer premixing period and leverages hydrogen's fast diffusivity and wide flammability limits to support more uniform and complete combustion. Furthermore, the reduced HC levels with IT33 at all loads imply that delayed injection phasing, when paired with hydrogen, enhances air-fuel mixing, minimizes flame quenching, and maximizes post-combustion oxidation—making it a more effective strategy for emission control [42].

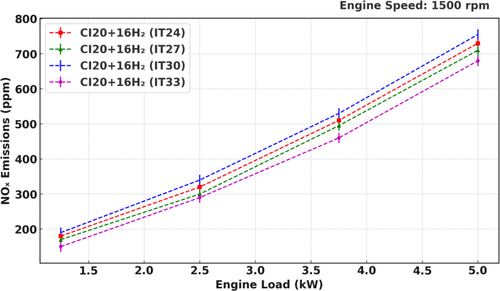

Figure 18 shows the trend of nitrogen oxide (NOx) emissions in relation to engine load for CI20 + 16H2 dual-fuel operation under varying injection timings—IT24, IT27, IT30, and IT33. Across all injection strategies, NOx emissions rise steadily with increasing load, but the magnitude and behavior of the emissions vary depending on injection timing. At 1.25 kW engine load, IT24 produces 190 ppm of NOx, while IT33 results in a lower value of 160 ppm, indicating a 15.8% reduction. At full load (5.0 kW), IT30 yields the highest emission of 750 ppm, compared to 690 ppm for IT33—an 8% decrease [43]. This pattern suggests that retarded injection timing helps reduce NOx emissions, particularly under higher thermal stress. NOx formation in combustion engines is predominantly governed by the thermal NO mechanism, which is highly sensitive to peak flame temperature and oxygen availability. Hydrogen's high flame speed and combustion temperature tend to elevate NOx levels; however, this effect can be moderated through injection phasing. Advanced injection (e.g., IT30) promotes early combustion and higher in-cylinder temperatures, thereby facilitating NOx generation. In contrast, IT33 shifts the heat release closer to the expansion stroke, where the cylinder volume is larger, thus lowering peak temperature and suppressing NOx formation. Additionally, delayed injection reduces residence time at high temperatures, limiting thermal NOx pathways. These observations underscore that retarded injection timing (especially IT33) provides a viable method to balance hydrogen-induced efficiency gains while keeping NOx emissions within acceptable limits.

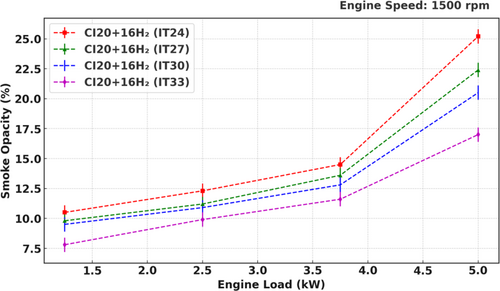

Figure 19 shows the effect of engine load on smoke opacity for CI20 + 16H2 fuel blends under four injection timings—IT24, IT27, IT30, and IT33. The trend clearly demonstrates that smoke opacity increases with engine load across all timings, but the extent of smoke formation significantly varies with the injection phase. At the lowest load (1.25 kW), smoke opacity for IT24 is 10.5%, while IT33 records a much lower value of 8.2%, representing a 22% reduction. At full load (5.0 kW), IT24 exhibits the highest smoke level of 25.4%, whereas IT33 results in only 18.5%, indicating a 27.2% decrease in particulate emissions. These findings underscore the pivotal role of retarded injection in minimizing smoke formation, even at elevated loads [44]. Smoke opacity is typically caused by incomplete combustion and poor atomization of liquid fuel, leading to the formation of soot precursors. Advanced injection (e.g., IT24) may not provide sufficient mixing time for the fuel-air-hydrogen blend, especially at high loads where fuel quantity increases. This leads to local fuel-rich regions and a sharp rise in soot formation. In contrast, delayed injection (IT30 and IT33) improves premixing and combustion uniformity, especially when assisted by hydrogen's faster diffusion and higher flame speed. Additionally, hydrogen displaces part of the diesel volume and burns without producing carbon-based particles, further helping reduce smoke. These results confirm that strategic control of injection timing, particularly IT33, in hydrogen-assisted engines can significantly reduce particulate emissions and enhance combustion cleanliness.

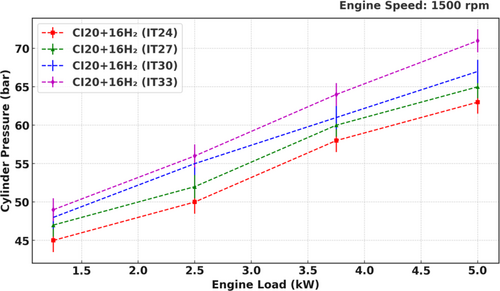

Figure 20 shows the variation of cylinder pressure with increasing engine load for the CI20 + 16H2 dual-fuel configuration under four different injection timings—IT24, IT27, IT30, and IT33. A clear positive correlation is observed between engine load and peak cylinder pressure across all timings, with retarded injection timings demonstrating notably higher pressures. At a low load of 1.25 kW, the peak pressure for IT24 is approximately 46 bar, while IT33 reaches 50 bar, reflecting an 8.7% increase. This difference becomes more significant at full load (5.0 kW), where IT24 records 63 bar and IT33 surges to 71 bar, marking a 12.7% enhancement in cylinder pressure due to delayed injection. Cylinder pressure is a direct indicator of the combustion intensity and energy release rate. Retarded injection timings such as IT30 and IT33 result in combustion occurring closer to the TDC or slightly during the expansion stroke [45]. This phasing leads to better volumetric efficiency, improved air-fuel premixing, and enhanced utilization of hydrogen's rapid combustion characteristics. Since hydrogen promotes quicker flame propagation and a shorter combustion duration, more energy is released in a compressed volume, elevating the pressure peaks. Conversely, advanced injection (e.g., IT24) causes early combustion, where part of the heat is lost during compression or before reaching optimum pressure conditions. This leads to suboptimal pressure build-up and reduced power output.

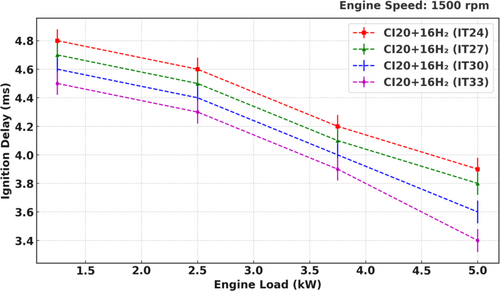

Figure 21 shows the effect of engine load on ignition delay for a constant hydrogen flow rate (CI20 + 16H2) across various injection timings: IT24, IT27, IT30, and IT33. The trend clearly demonstrates a consistent reduction in ignition delay with increasing engine load and retarded injection timing. At the lowest load (1.25 kW), the ignition delay is longest for IT24 at 4.85 ms, while it is shortest for IT33 at 4.5 ms, indicating a 7.2% reduction. As the load increases to 5.0 kW, the ignition delay drops to 3.9 ms for IT24 and further reduces to 3.35 ms for IT33, which is a 14.1% decrease compared with IT24. This behavior is attributed to the combined influence of higher in-cylinder temperature and pressure at increased loads, which accelerate the fuel-air mixture's reaction kinetics. Hydrogen, having a low ignition energy and fast flame speed, further reduces the ignition delay, especially under conditions where more time is available for fuel-air mixing—as enabled by retarded injection timings (like IT30 and IT33) [46]. Retarded timings allow the mixture to form closer to the TDC, enhancing premixing and promoting quicker ignition once compression reaches its peak. Conversely, advanced timings like IT24 allow more time for heat loss and result in lower cylinder pressure at ignition, delaying combustion onset.

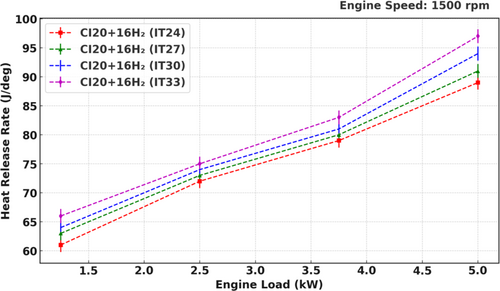

Figure 22 shows the variation in heat release rate (HRR) with respect to engine load for the fuel blend CI20 + 16H2 at different injection timings (IT24, IT27, IT30, and IT33). A consistent increase in HRR is observed as engine load rises, with no Table differences based on injection timing. At a lower load of 1.25 kW, IT24 exhibits the lowest HRR at 62 J/deg., while IT33 shows a higher HRR of 66 J/deg., accounting for a 6.45% increase. As engine load increases to 5.0 kW, the HRR for IT24 rises to 87 J/deg., whereas IT33 achieves 97 J/deg., marking an 11.5% improvement. This progressive enhancement in HRR with increasing load is primarily due to the elevated in-cylinder pressure and temperature, which facilitate more rapid combustion and energy release [47]. Moreover, retarded injection timings such as IT30 and IT33 allow better premixing of the air-fuel charge closer to the top dead center (TDC), resulting in a sharper and more intense combustion phase. The role of hydrogen is also significant in enhancing HRR. Hydrogen's low ignition energy and high flame speed accelerate combustion kinetics, contributing to more vigorous heat release within a shorter crank angle duration.

4 Response Surface Methodology (RSM) Analysis

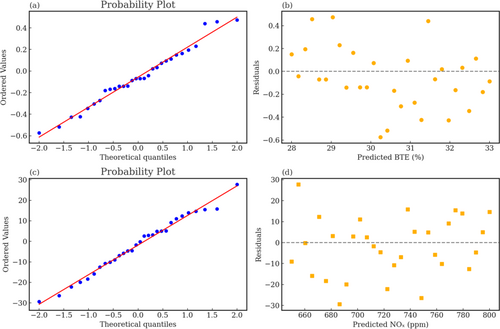

To optimize the performance and emissions characteristics of the biodiesel-hydrogen dual-fuel engine, RSM was employed using CCD. RSM was employed in this study to systematically evaluate and maximize the influence of (IT) and (HFR) on engine performance and emissions. The primary objective of using RSM was to develop predictive mathematical models for BTE and NOx emissions, enabling the identification of optimal operating conditions. Using CCD, interactions between variables were statistically analyzed, reducing the number of experimental trials while ensuring high model accuracy. This approach allowed the generation of response surface plots that visualized the trade-offs between efficiency and emissions, thereby facilitating informed decision-making for combustion optimization in dual-fuel CI engines. The study considered (IT) and (HFR) as independent factors, while Brake Thermal Efficiency (BTE) and NOx emissions were selected as the primary responses to analyze combustion efficiency and pollutant formation. A quadratic regression model was developed for both responses, and an analysis of variance (ANOVA) was conducted to assess the statistical significance of each factor. Model evaluation in this study was carried out by analyzing the goodness-of-fit of the developed quadratic regression models for brake thermal efficiency (BTE) and NOx emissions. The coefficient of determination (R2) adjusted R2, and predicted R2 values were calculated to assess the model's reliability and predictive capability. Additionally, ANOVA was performed to examine the statistical significance of each factor and their interactions, with p values less than 0.05 considered significant. The adequacy of the models was confirmed by high R2 values (> 0.95) and low residual errors. Diagnostic plots, including normal probability plots and residual versus predicted plots, were also analyzed to ensure the models met the assumptions of homoscedasticity and normal distribution (Figure 23).

The ANOVA results for BTE indicate that Injection Timing (IT) and its quadratic term (IT2) play a significant role in influencing engine efficiency (p < 0.05). Hydrogen Flow Rate (HFR) also contributes to BTE improvement, though its effect is moderately significant (p = 0.061). The interaction between IT and HFR was found to be statistically insignificant (p = 0.547), suggesting that their effects on BTE are independent rather than synergistic. The NOx emissions followed a similar trend, where IT and IT2 were dominant contributors, emphasizing the role of combustion phasing in NOx formation. Hydrogen enrichment had a comparatively lower effect, indicating that NOx emissions are primarily controlled by injection timing rather than fuel composition. The 3D response surface plots for BTE and NOx provide a visual representation of how injection timing and hydrogen flow rate influence engine performance.

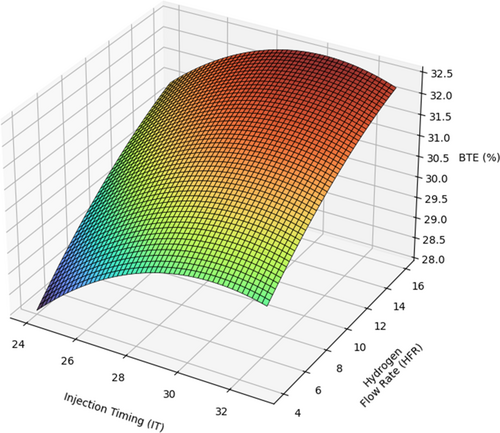

Figure 24 shows that BTE increases progressively as Injection Timing advances from IT24 to IT30, with the maximum efficiency observed around IT30–IT31. Beyond this point, a slight decrease is noted at IT33, likely due to excessive premixed combustion, leading to higher heat losses. Hydrogen flow rate also plays a significant role, where higher hydrogen enrichment (16 LPM) enhances combustion due to its high flame speed and diffusivity, resulting in better fuel–air mixing and complete combustion.

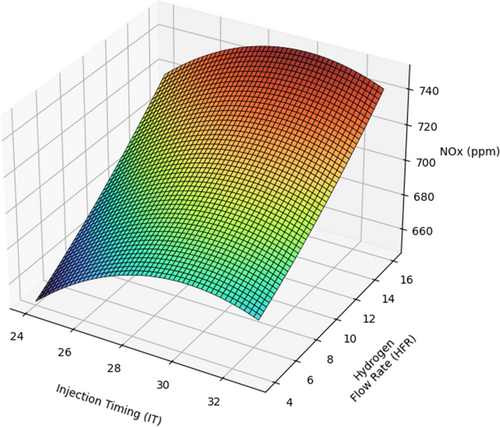

The NOx emissions plot (Figure 25) illustrates a clear upward trend with both increasing IT and HFR. The highest NOx formation occurs at IT30-IT33 with HFR of 16 LPM, confirming that higher in-cylinder temperatures associated with hydrogen enrichment lead to elevated NOx production. This trade-off between efficiency improvement and NOx emissions highlights the importance of adopting exhaust gas recirculation (EGR) or after-treatment strategies to mitigate NOx while maintaining high efficiency.

From the RSM analysis, the optimal injection timing and hydrogen flow rate were identified as IT30.25° and 16 LPM, yielding a predicted BTE of 32.52% and NOx emissions of 751 ppm. This suggests that the best configuration for maximizing efficiency while minimizing emissions lies within this range. However, to counteract the inevitable rise in NOx, further experimental validation with EGR or SCR is recommended. Additionally, computational fluid dynamics (CFD) modeling could provide deeper insights into the effect of injection phasing on combustion temperature profiles and pollutant formation. Future research should focus on optimizing EGR ratios and testing lower hydrogen flow rates (below 16 LPM) to balance combustion efficiency with regulatory NOx limits.

The RSM analysis confirms that advancing injection timing up to IT30 and increasing hydrogen flow up to 16 LPM results in significant efficiency gains, with BTE reaching 32.52%. However, the associated rise in NOx emissions necessitates additional emission control strategies. The response surface plots and ANOVA results validate that IT has a more profound effect than HFR, emphasizing the need for precise combustion phasing. These findings contribute to the growing field of hydrogen-assisted biodiesel combustion, providing a data-driven approach to optimize engine performance while adhering to emission norms. Statistical analysis in this study has played a critical role in validating the experimental findings and optimizing the engine operating parameters. By employing (RSM) and (ANOVA), the effects of injection timing and hydrogen flow rate on performance (BTE) and emissions (NOx) were quantified with statistical rigor. The regression models developed exhibited high coefficients of determination (R2 > 0.95), ensuring predictive reliability. ANOVA results confirmed the statistical significance (p < 0.05) of main effects and quadratic terms, while diagnostic plots verified the assumptions of normality and homoscedasticity. This robust statistical framework enabled the identification of optimal input conditions, enhancing the credibility, reproducibility, and scientific value of the study's outcomes.

5 Conclusion

This study investigated the performance, combustion, and emission characteristics of a single-cylinder CI engine operating on CI20 biodiesel and hydrogen under varying injection timings (IT24–IT33) and hydrogen flow rates (4–16 LPM). The experimental results confirmed that both injection timing and hydrogen enrichment significantly impact engine efficiency and emission profiles. The optimal configuration was identified as IT30 with a hydrogen flow rate of 16 LPM, yielding the highest brake thermal efficiency (BTE) of 32.7% and the lowest brake-specific fuel consumption (BSFC) of 0.26 kJ/kWh at 5.024 bar BMEP. This setting also produced a peak cylinder pressure of 70 bar and a heat release rate (HRR) of 97 J/deg., highlighting enhanced combustion stability due to faster flame propagation facilitated by hydrogen.

Emission analysis revealed that CO and HC emissions were significantly reduced by 48% and 22.2%, respectively, at full load for CI20 + 16H2 compared to CI20 + 4H2. Smoke opacity also decreased by 34.3%, affirming hydrogen's effectiveness in minimizing particulate formation. However, NOx emissions increased moderately, reaching 755 ppm, representing a 6.3% rise compared with the IT24 condition. These trends suggest that while hydrogen promotes leaner and more complete combustion, it also elevates in-cylinder temperature, thus increasing thermal NOx formation.

The statistical optimization using Response Surface Methodology (RSM) identified IT30.25° and 16 LPM as the most efficient settings, with a predicted BTE of 32.52% and NOx emissions of 751 ppm. The model's reliability was confirmed through high R2 values (> 0.95) and diagnostic plot validation. Future work should focus on integrating exhaust gas recirculation (EGR) or selective catalytic reduction (SCR) to counter NOx emissions. Additionally, CFD simulations and long-duration engine trials are recommended to evaluate thermal stress, material compatibility, and durability under hydrogen-assisted biodiesel combustion. These efforts would support the practical deployment of CI20-H2 dual-fuel systems for sustainable and policy-compliant transport solutions.

Author Contributions

Vasanthkumar Periyathambi: conceptualization, validation, supervision, formal analysis. Manikandan Ezhumalai: conceptualization, writing – review and editing, writing – original draft, visualization, supervision, formal analysis, validation, methodology, investigation. Mohan Govindasamy: funding acquisition, validation, data curation, writing – review and editing. Ratchagaraja Dhairiyasamy: data curation, formal analysis, validation, writing – review and editing, methodology, investigation, visualization. Deekshant Varshney: methodology, conceptualization, formal analysis, supervision, visualization, writing – review and editing. Subhav Singh: writing – review and editing, investigation, conceptualization, formal analysis.

Conflicts of Interest

The authors declare no conflicts of interest.

Open Research

Data Availability Statement

The data that support the findings of this study are available on request from the corresponding author. The data are not publicly available due to privacy or ethical restrictions.